Patents

Literature

32results about How to "Does not affect luminosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photoluminescent colour glass and its production method

InactiveCN1405106ALong bright timeDoes not affect luminosityGlass furnace apparatusLuminescent compositionsPhotoluminescenceLuminescent material

The invention discloses a colour photoluminescence glass and its production method, which comprises 85-92% of glass material and 8-15% of compound luminescent material, and the composition of compound luminescent material includes: (1). one or several kinds of SiO2, Al2O3, B2O3; (2) one or several kinds of Na2O, LiO, K2O and SrCO; (3). one or two kinds of P2O5 and NH2; (4) one or several kinds of Tb2O3, Eu2O3, Y2O3, Er2O3 and Ce2O3; and (5) one or several kinds of TiCl, Nd2O3, Dy2O3 and La2O3. According to the luminescent colour the said materials can have different combinations and mixing ratio, and its luminescent colour can have various colours of red, orange, yellow, blue and purple, etc. After the natural light can be absorbed by said glass for 10-15 min., it can emit colour light for 6-8 hr.

Owner:刘家贵

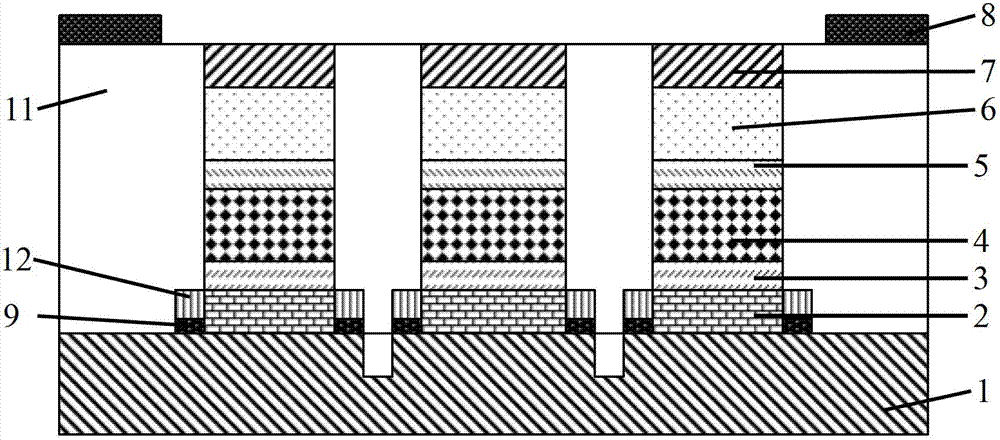

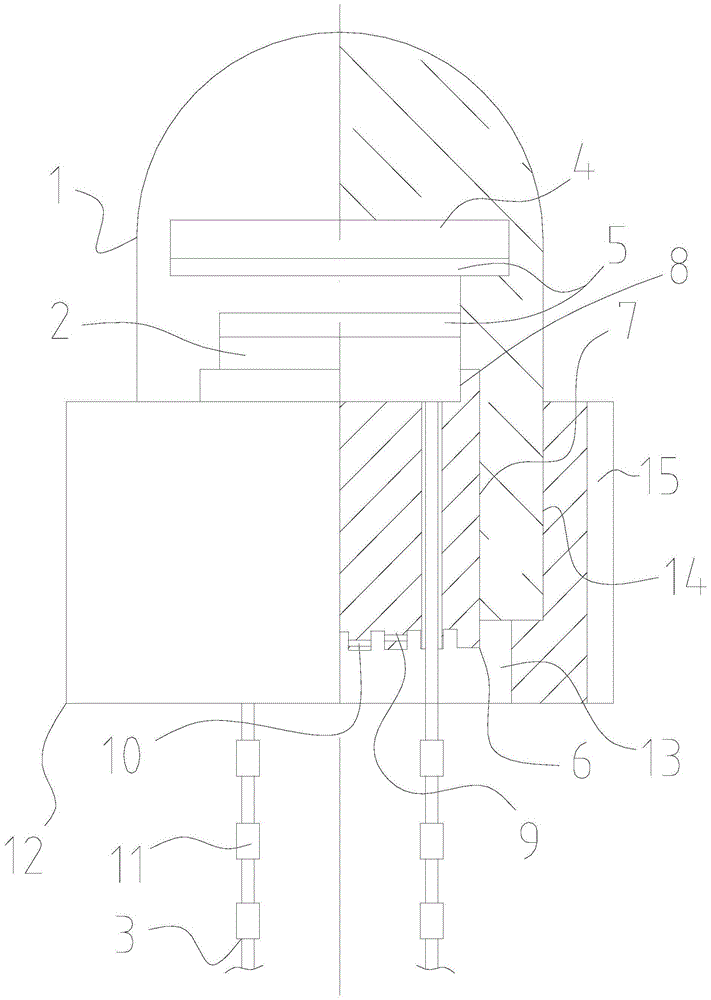

Method for manufacturing AlGaInP-LED (Light Emitting Diode) integrated micro display component with single-side electrode structure

ActiveCN102790144AAdvantages of production methodSimple structureSolid-state devicesSemiconductor devicesPlanar electrodeLed array

The invention discloses a method for manufacturing an AlGaInP-LED (Light Emitting Diode) integrated micro display component with a single-side electrode structure, wherein the steps comprises: etching multiple first grooves which are mutually intersected on a device body; growing a lower electrode metal layer on the bottom part of each groove to form the lower electrode metal layer; growing an insulating medium layer above a lower electrode; corroding an area of the lower electrode metal layer outside a lower electrode diagram downward till reaching a certain depth in an N-shaped substrate layer in order to form multiple second grooves; filling opaque diaphragms into the second grooves and the upper part of a protection medium of the lower electrode; manufacturing an upper electrode above a light emitting unit; and electroforming upper and lower electrode leads. With the adoption of the method for manufacturing the LED array micro display device with the planar electrode structure disclosed by the invention, the process difficulty resulting from the manufacturing of the electrodes on the front face and the back face respectively can be prevented; since the manufactured micro display device is provided with the double bar type upper and lower electrodes of which the different faces are perpendicular to each other, the more even current distribution can be obtained; and therefore, the micro display device available for even luminance is obtained.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

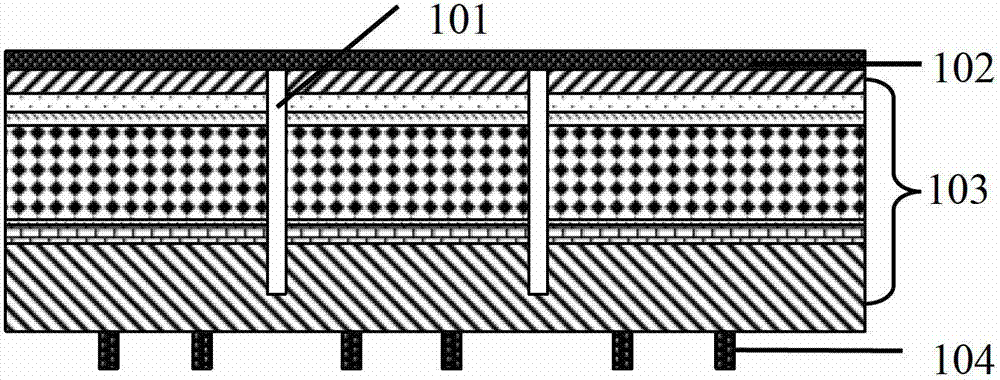

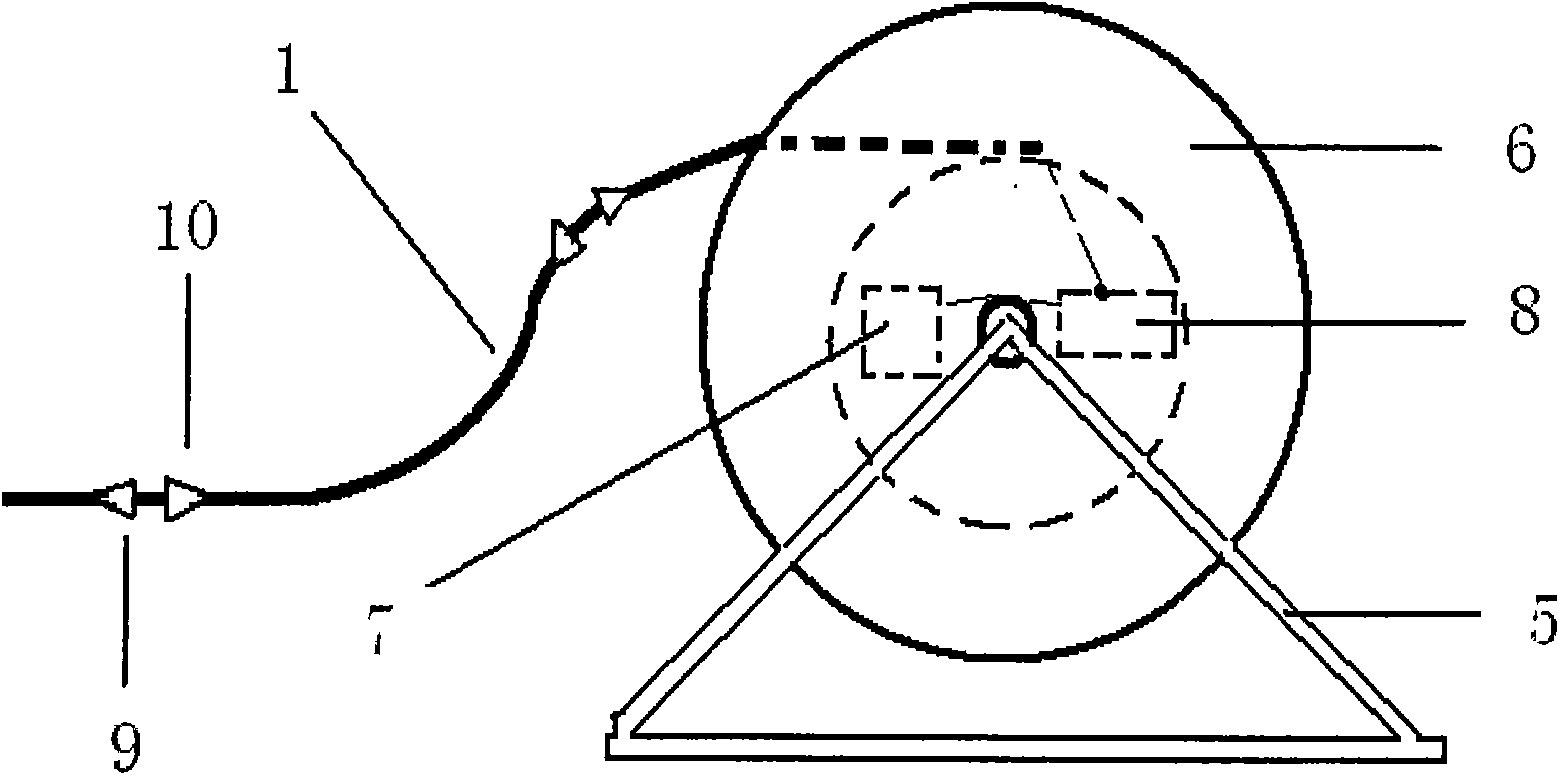

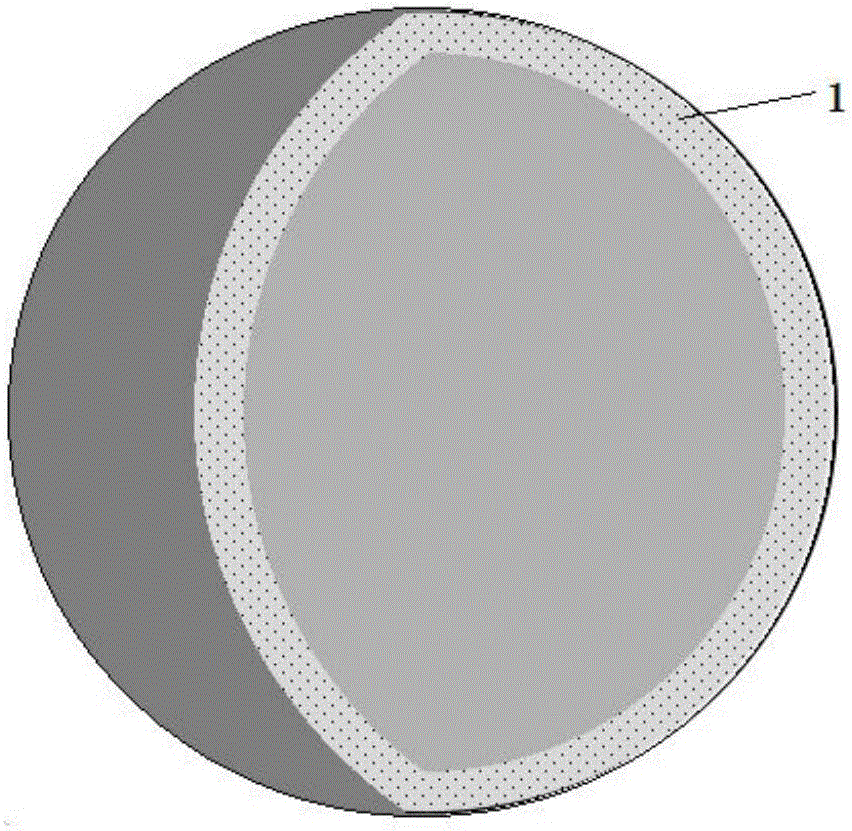

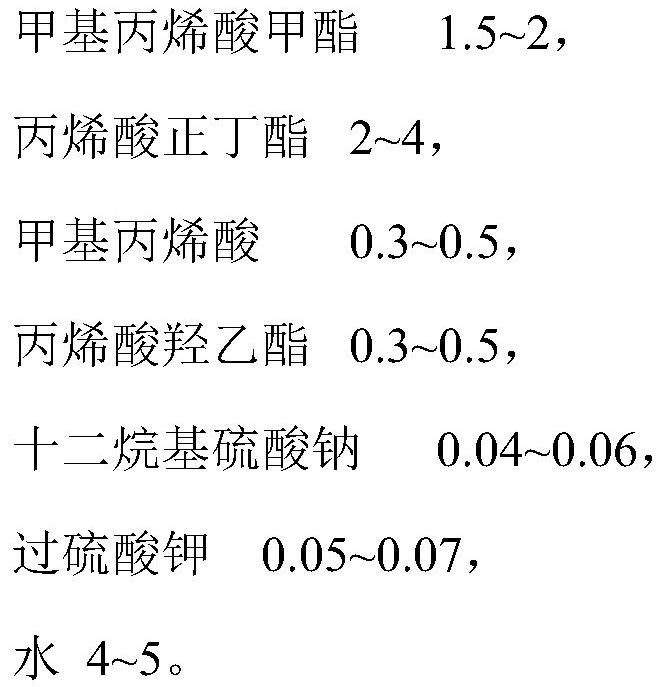

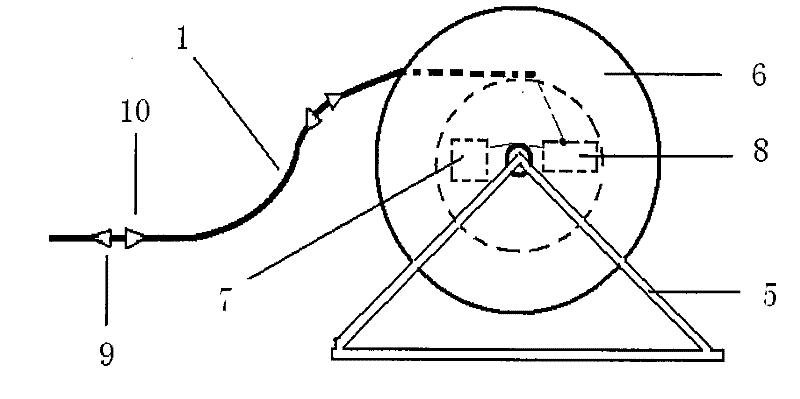

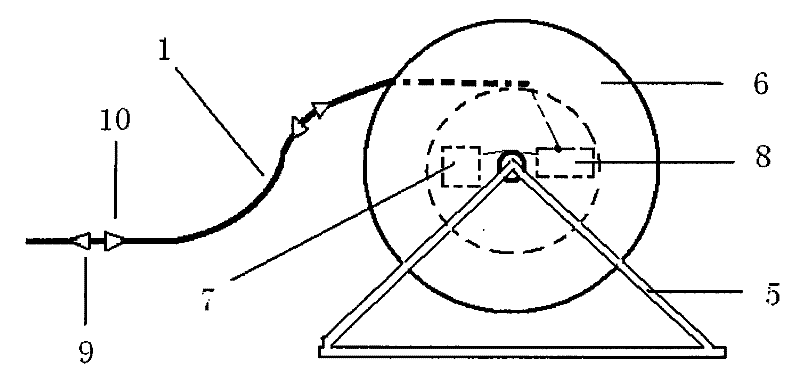

Firefighting guide illumination line

InactiveCN101640955AEasy to useSuitable for night visual observationElectrical apparatusElectroluminescent light sourcesCoalElectroluminescent wire

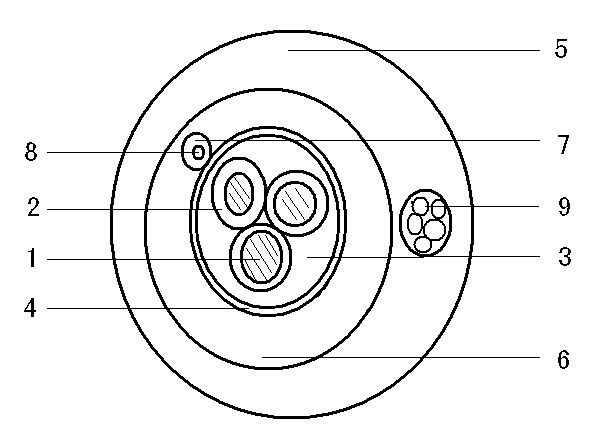

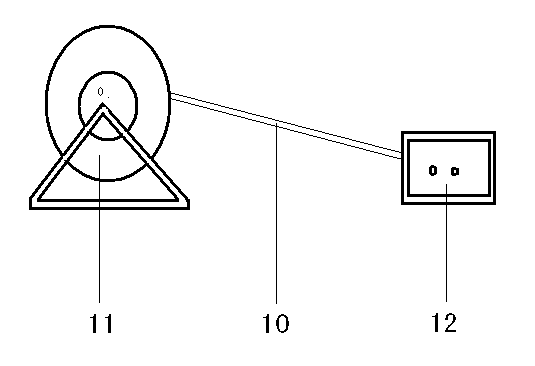

The invention relates to a firefighting guide illumination line comprising a continuously luminous strong electroluminescence line (1), a PVC transparent plastic layer (2), an electroluminescence line(3) and a flexible wire cable (4) parallel to the electroluminescence line (3), wherein the PVC transparent plastic layer (2) is arranged outside the strong electroluminescence line (1); the electroluminescence line (3) and the flexible wire cable (4) are arranged in the strong electroluminescence line (1) which is wound on a rotatable wire coil wheel (6) with a stand (5); the center of the wirecoil wheel (6) is provided with charging batteries (7) and a driving controller (8) and is connected in series with one end of the strong electroluminescence line (1); the power-on strong electroluminescence line (1) can continuously illuminate when being electrified, and the wire coil wheel (6) is used to randomly withdraw and release the strong electroluminescence line (1). The firefighting guide illumination line is mainly applied to underground places, such as markets, subways, coal mine, and the like for rescue and guides refugees to evacuate towards a destination direction.

Owner:SHANGHAI KEYAN PHOSPHOR TECH

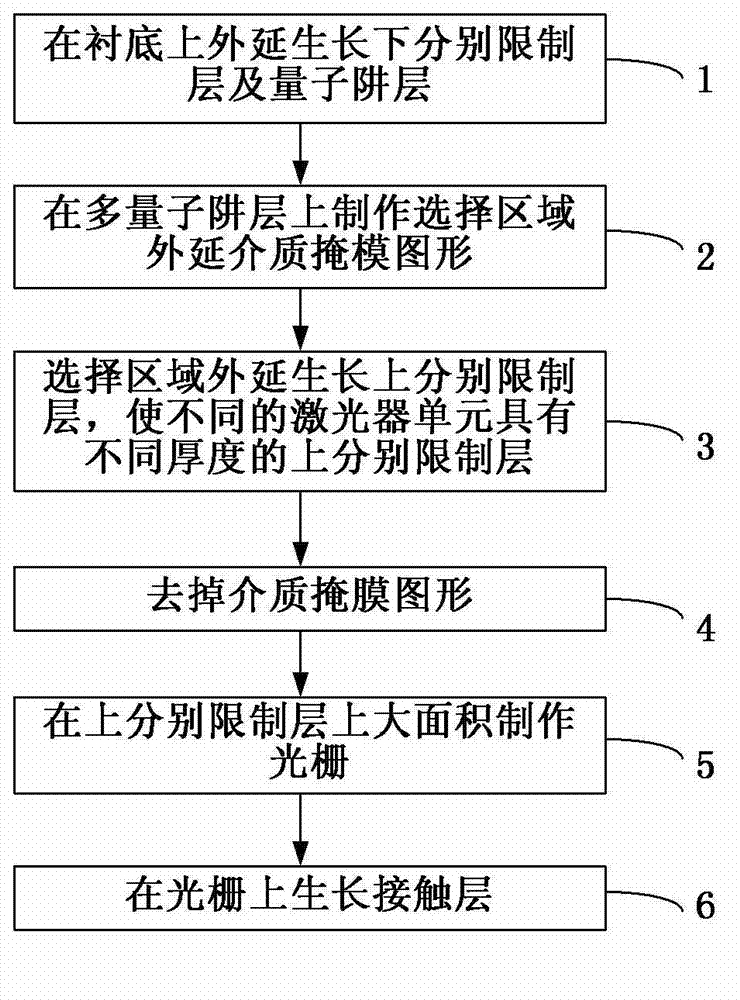

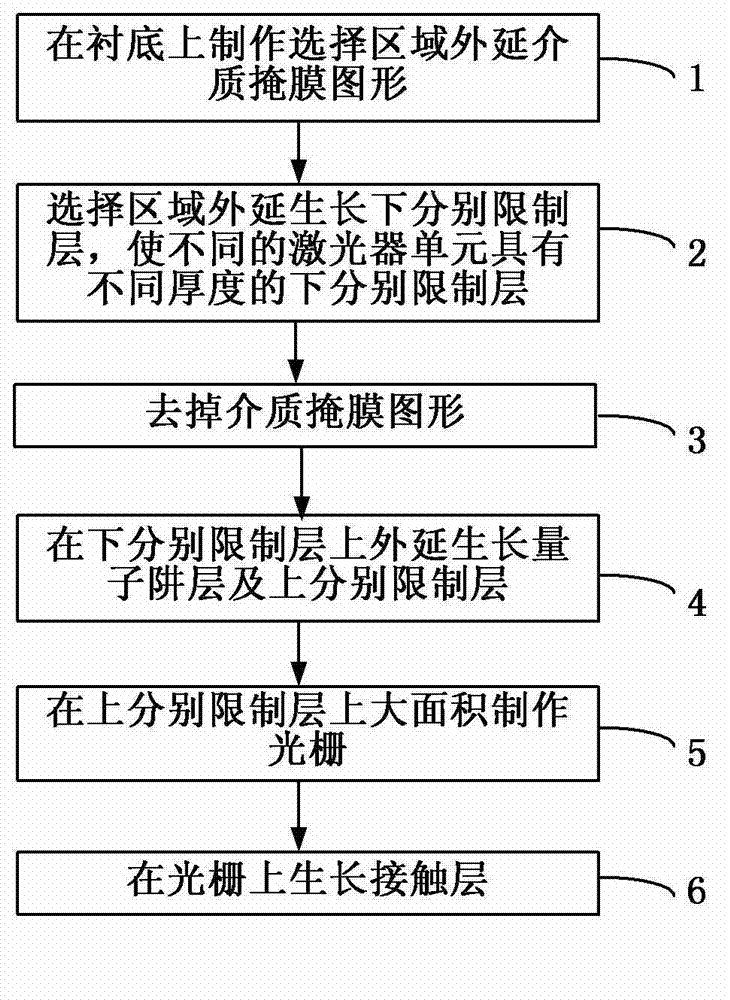

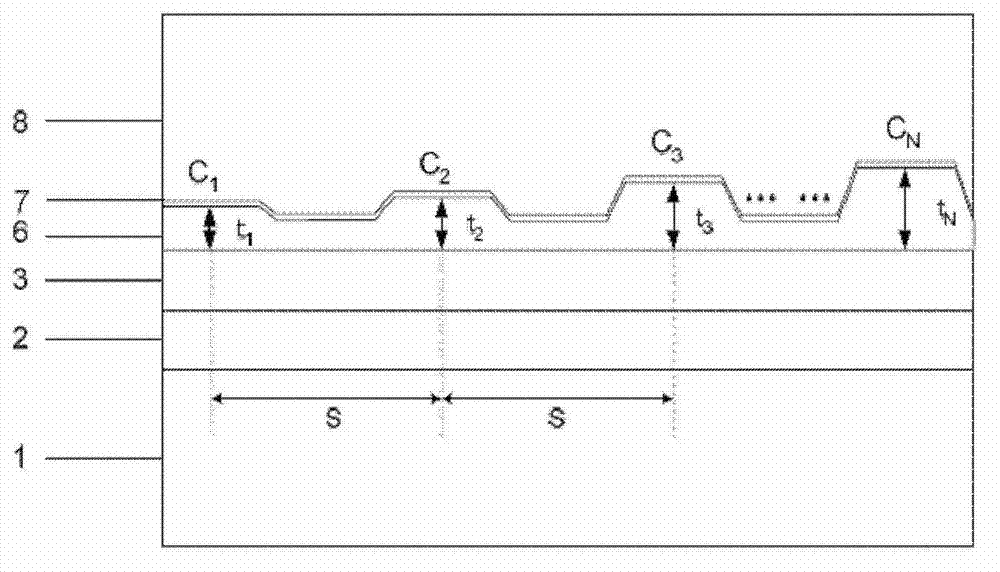

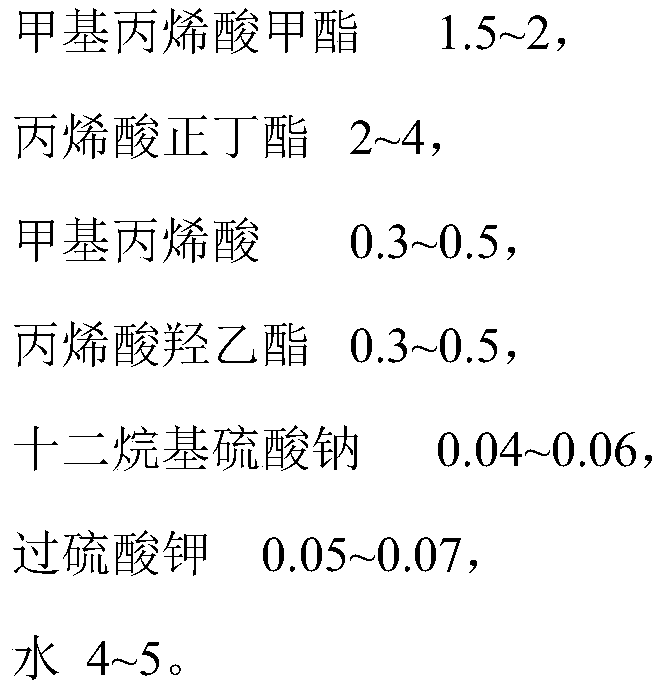

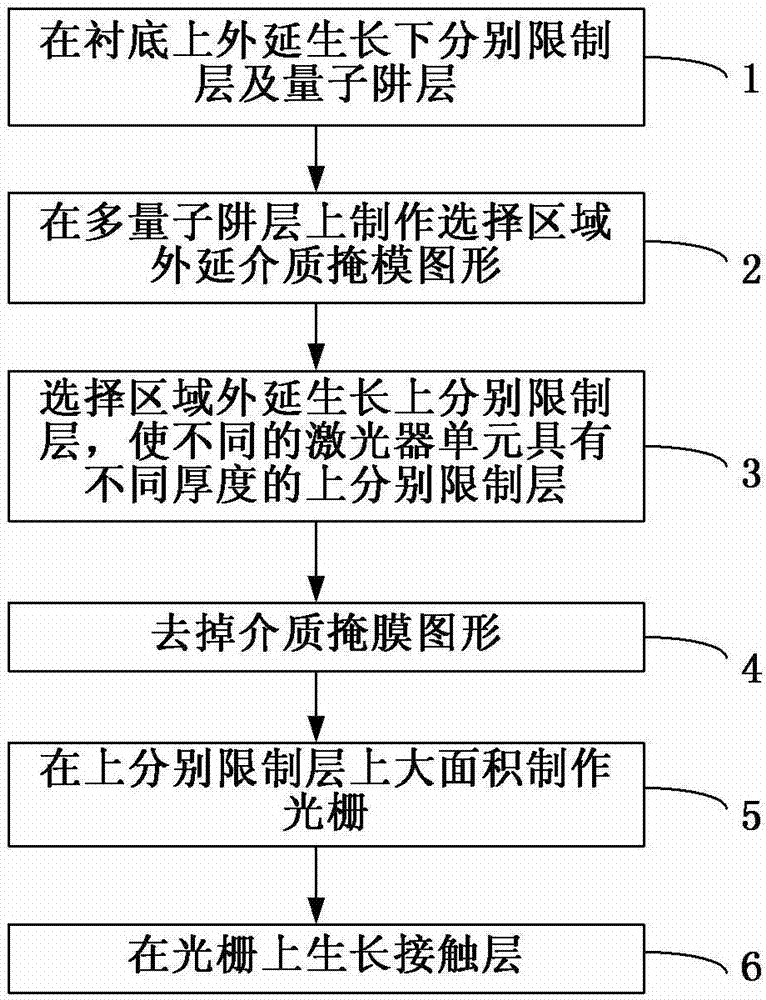

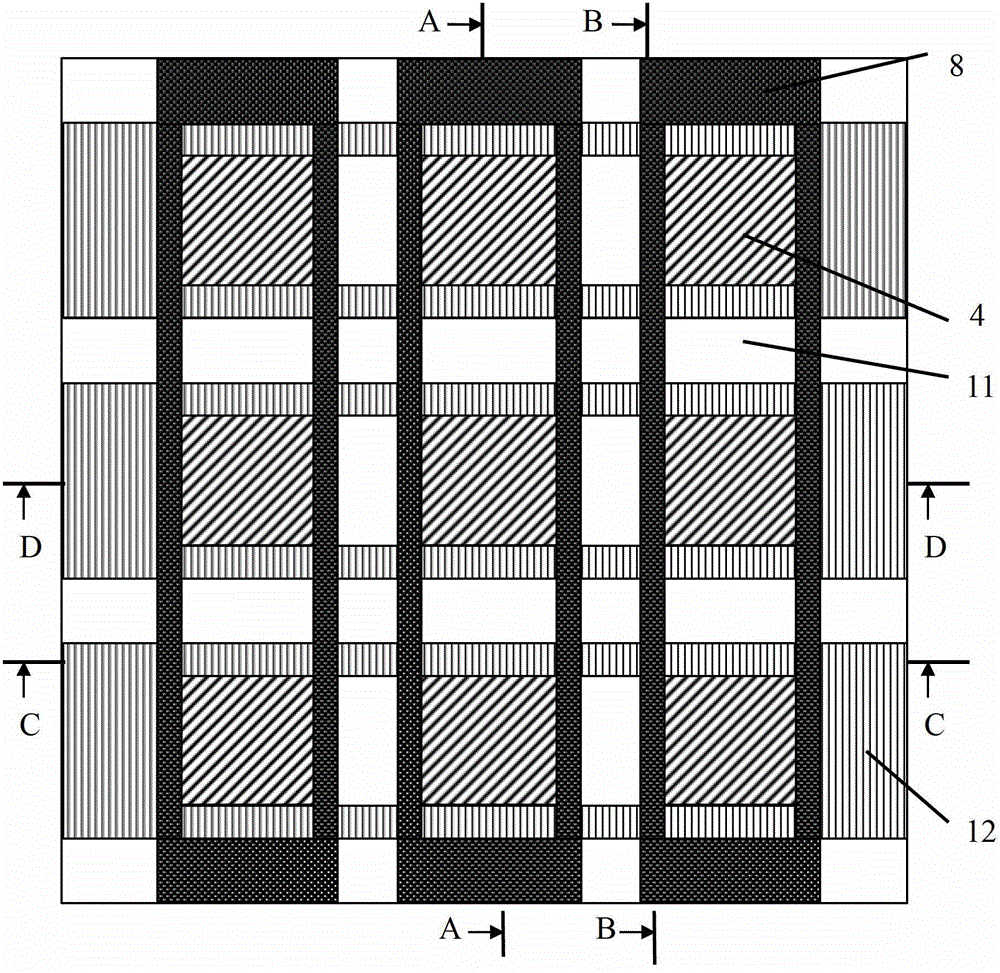

Method for manufacturing distributed feedback laser device array by virtue of selection region epitaxy technology

ActiveCN102820616ADoes not affect luminosityEasy to manufactureLaser optical resonator constructionSemiconductor laser arrangementsDistributed feedback laserGrating

The invention provides a method for manufacturing a distributed feedback laser device array by virtue of a selection region epitaxy technology. The method comprises the following steps of: respectively growing a lower respective limiting layer and a quantum well layer on a substrate by epitaxy growth; manufacturing selection region epitaxy medium mask patterns on the quantum well layer; growing an upper respective limiting layer on a selection region by epitaxy growth to ensure that different laser device units are provided with the upper respective limiting layer parts with different thicknesses; removing the medium mask pattern; manufacturing an optical grating on the upper respective limiting layer in large area; and growing a contact layer on the optical grating 7 to finish the preparation of the laser device array. The method disclosed by the invention can be used for obtaining different light-emitting wavelengths of different array units while the light-emitting performance of a quantum well material is not influenced.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Dynamic indication guiding illuminating line

ActiveCN103024962ATo achieve the purpose of indicating directionEasy to useElectrical apparatusElectroluminescent light sourcesFirefightingEngineering physics

A dynamic indication guiding illuminating line comprises a multi-core electroluminescent line, a multi-output electroluminescent line drive and a power source. The dynamic indication guiding illuminating line is characterized in that dielectric layers are coated on the surfaces of three continuous metal wires which are spirally wound to form a multi-core electrode, an electroluminescent layer is coated on the surface of the multi-core electrode for one time, a transparent conducting layer which is in continuous contact with an outer flexible electrode is coated outside the electroluminescent layer, and transparent plastic is used for sealing to form the multi-core electroluminescent line. When the dynamic indication guiding illuminating line is used, the multi-core electroluminescent line, the multi-output electroluminescent line drive and the power source are in series connection to form directional flowing luminescence. The guiding illuminating line for firefighting is mainly applied to rescuing at places such as markets, subways, coal mines and fields to guide trapped people to evacuate according to target directions.

Owner:SHANGHAI KERUN PHOSPHOR TECH

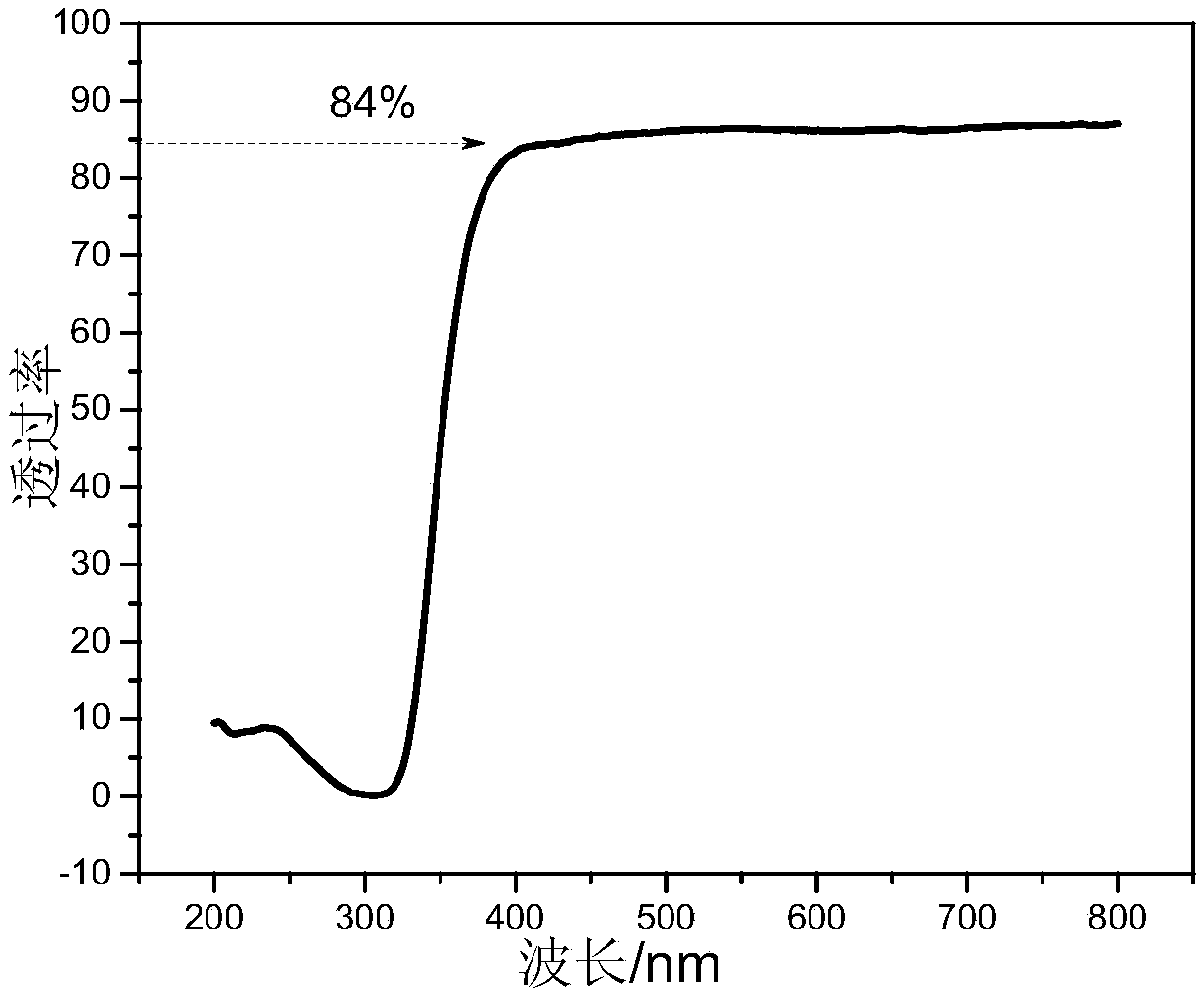

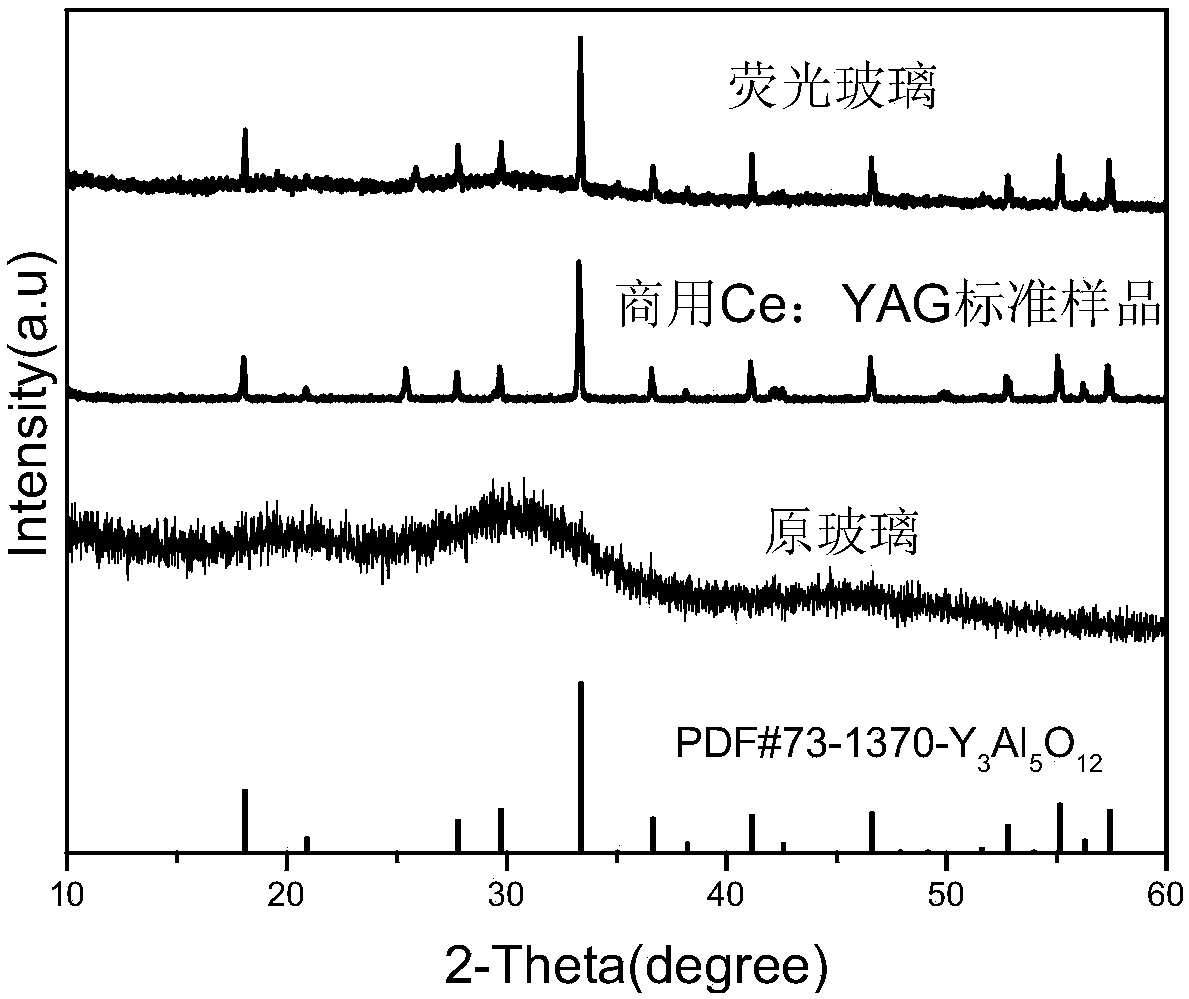

Preparation method of low-melting-point fluorescent glass

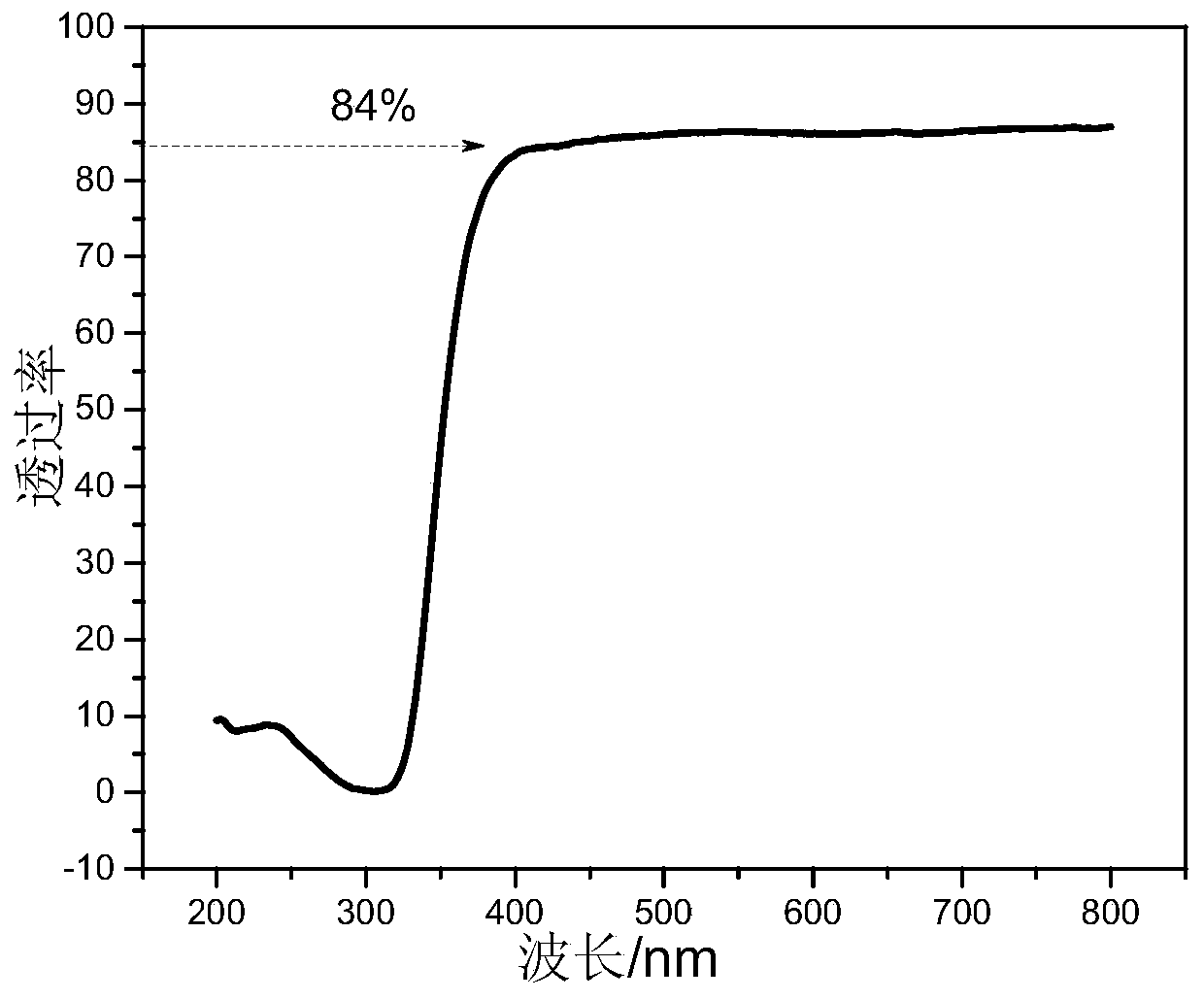

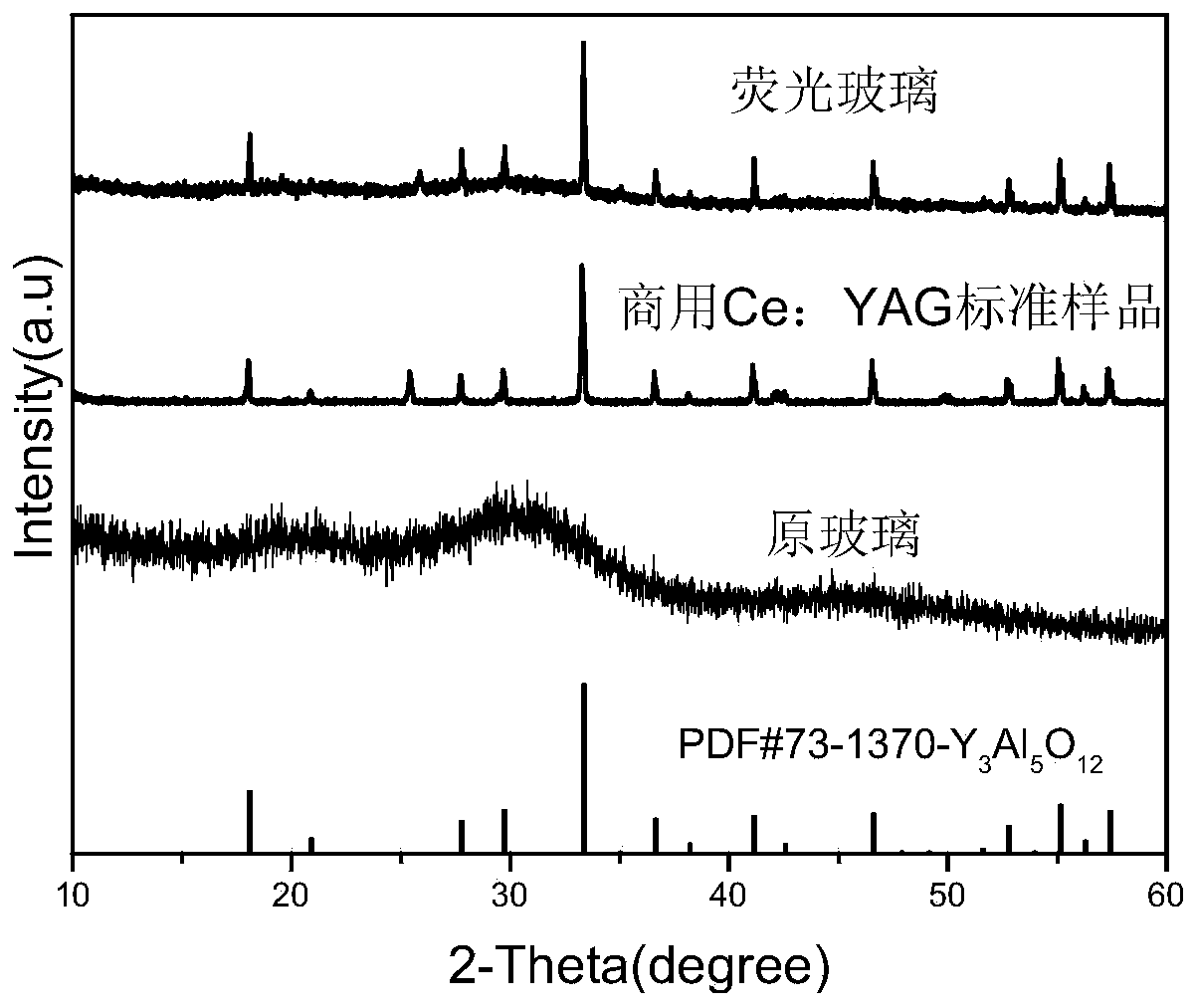

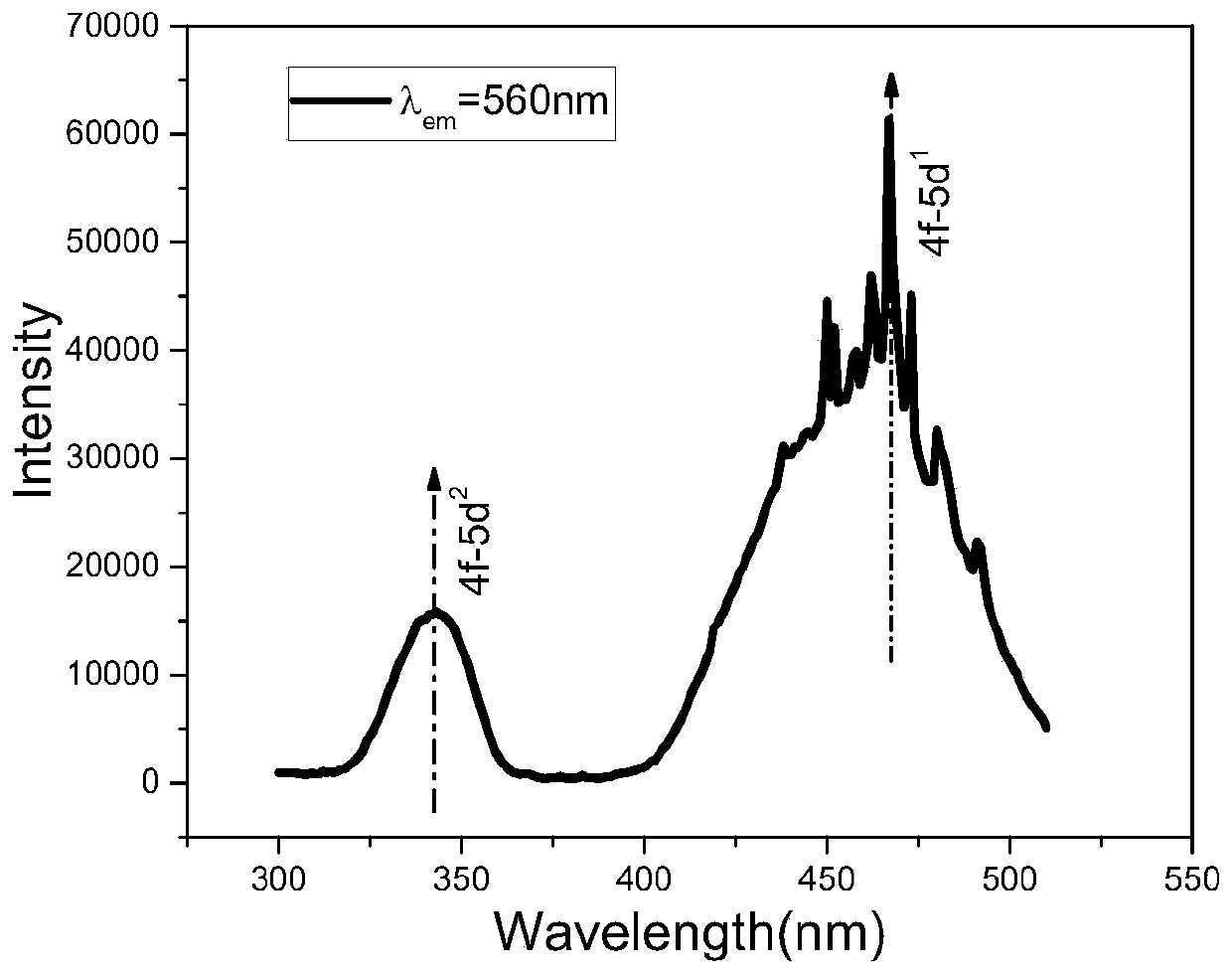

ActiveCN107686243AIntegrity guaranteedGuaranteed chemical stabilityChemical stabilityMaterials science

The invention discloses a preparation method of low-melting-point fluorescent glass and belongs to the field of preparation of glass materials. The preparation method is characterized in that the (NaPO3)6-NaF-CaO-B2O3-Sb2O3-Li2O-ZnO low-melting-point fluorescent glass is provided through the optimized design of the glass components, and the specific preparation steps are provided as follows: (1) firstly preparing the low-melting-point bare glass; (2) then mixing a commercial yttrium aluminium garnet structure yellow fluorescent powder and the low-melting-point glass powder in an alumina crucible, and firing and forming. The cost of the provided components for preparing the fluorescent glass is low, the operation process is simple and effective, the heat resisting property and the machiningproperty are excellent, the energy consumption in the production is low, the chemical stability is excellent, a solution is provided for solving the problems of a high-power LED device like light attenuation and color temperature drifting, and the limitations of the traditional fluorescent powder are expected to be broken.

Owner:UNIV OF SCI & TECH BEIJING

Full-depth flexible luminous pavement and preparation method thereof

InactiveCN108625246ADoes not affect luminosityImprove comfortIn situ pavingsRoad surfaceMaterials science

The invention discloses a full-depth flexible luminous pavement which comprises the following components in percentage by weight: 88.0-96.0% of white stone material, 1.0-2.5% of white stone powder, 1.5-4.5% of a transparent binding material and 1.5-5.0% of luminous powder. The invention further provides a preparation method of the full-depth flexible luminous pavement. The pavement comfort can begreatly improved, and the pavement has the obvious advantages in aspects such as water permeability, skid resistance, afterglow time and the like. Meanwhile, even if the pavement surface is polluted,due to a special pavement structure, luminous property of the afterglow time can be still kept below the pavement surface.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

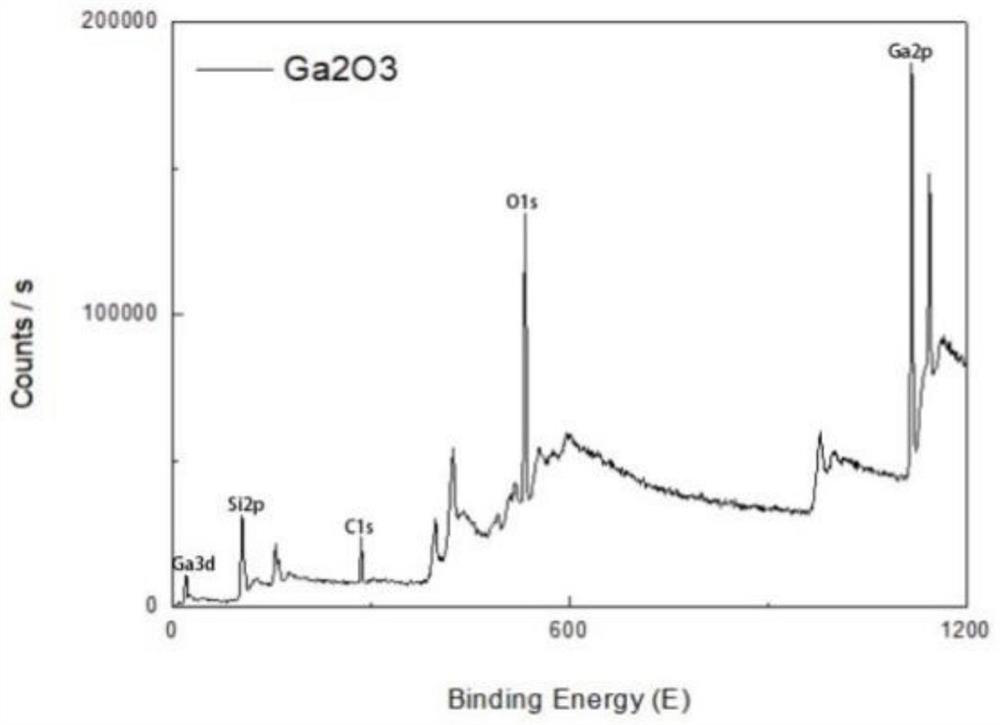

Two-dimensional gallium nitride film confinement template preparation method and prepared two-dimensional gallium nitride film

ActiveCN113549898AStable structureSmall sizeFinal product manufactureSolid state diffusion coatingSemiconductor materialsPhysical chemistry

The invention discloses a two-dimensional gallium nitride film confinement template preparation method, and relates to the technical field of semiconductor material preparation. The method comprises the following steps of transferring liquid metal gallium to the surface of a substrate to form a metal gallium film; performing film oxidation on metal gallium to obtain a gallium oxide film on the surface of the substrate; preparing a two-dimensional boron nitride film by adopting a chemical vapor deposition method; transferring the two-dimensional boron nitride film to the top surface of the gallium oxide film, so that the gallium oxide film is coated by the two-dimensional boron nitride film to obtain a silicon wafer-gallium oxide film-two-dimensional boron nitride film compound; and putting the silicon wafer-gallium oxide film-two-dimensional boron nitride film compound into an environment containing a nitrogen source for nitriding treatment, and cooling to obtain the gallium nitride film. The method has the beneficial effects that based on the stability, the insulativity and the promotion effect on the exciton luminescence performance of boron nitride, the two-dimensional boron nitride and the substrate are taken as templates, gallium nitride is grown between the two-dimensional boron nitride and the substrate in a confinement manner, the high-energy surface of gallium nitride is passivated, and a stable two-dimensional gallium nitride structure is formed.

Owner:ANHUI ZEZHONG SAFETY TECH

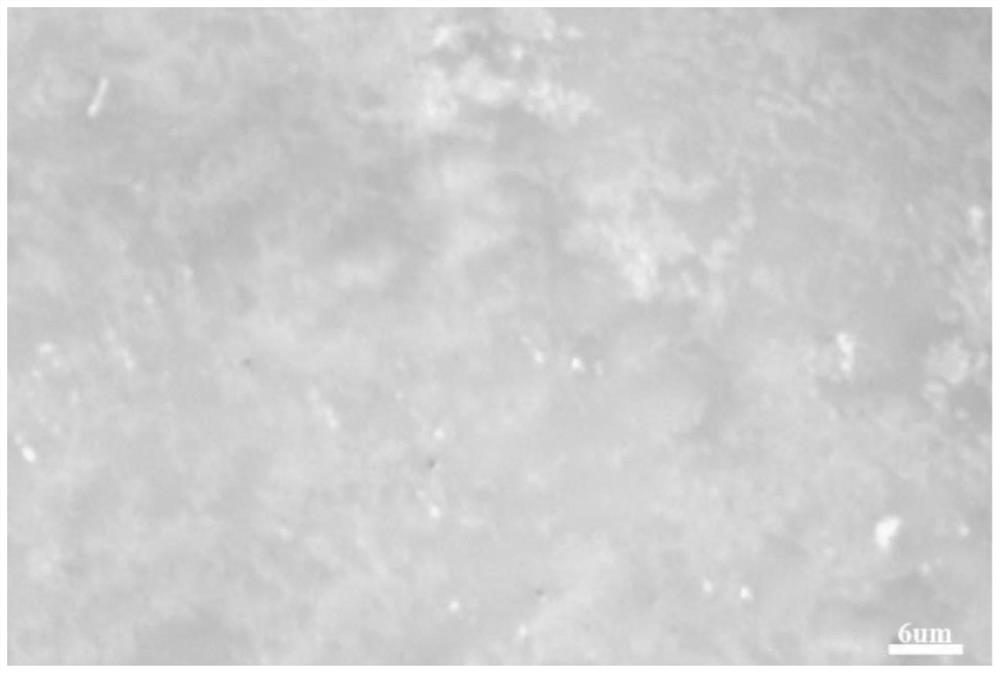

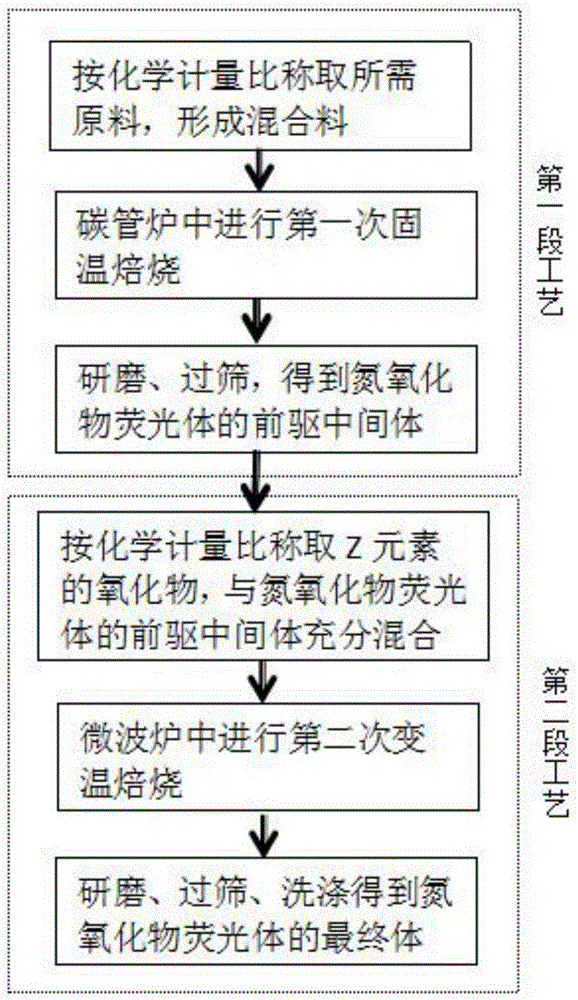

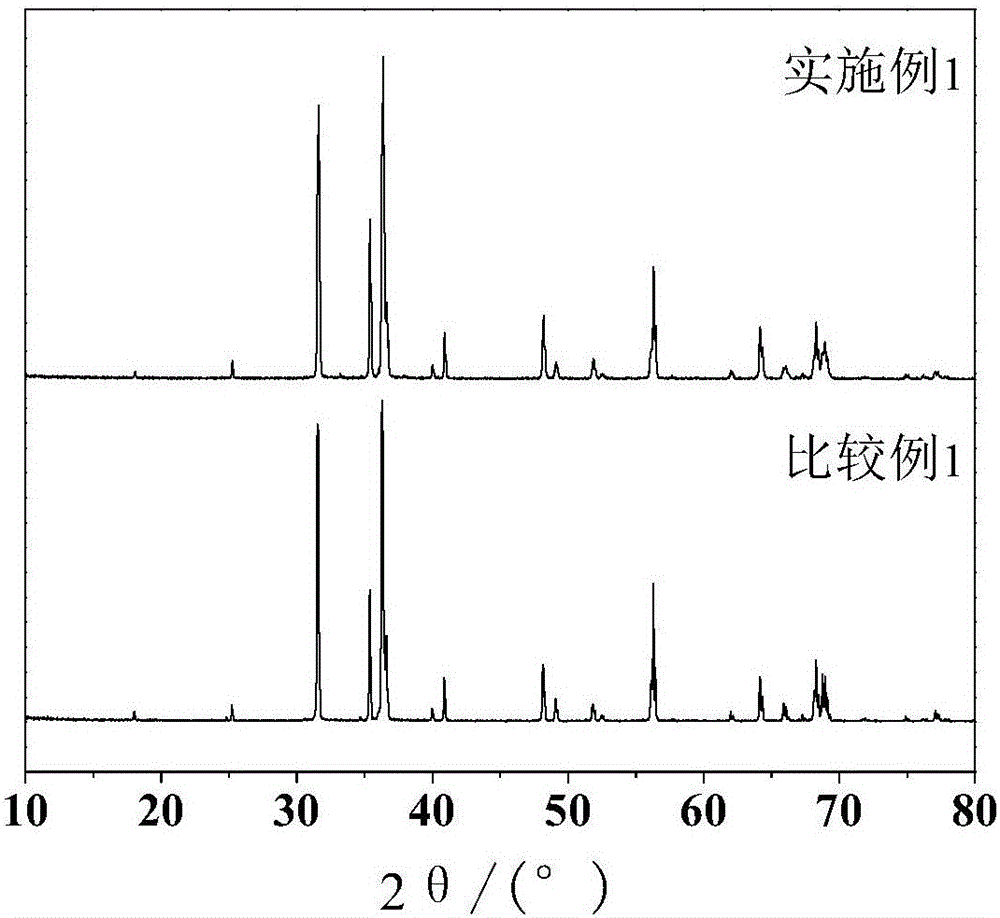

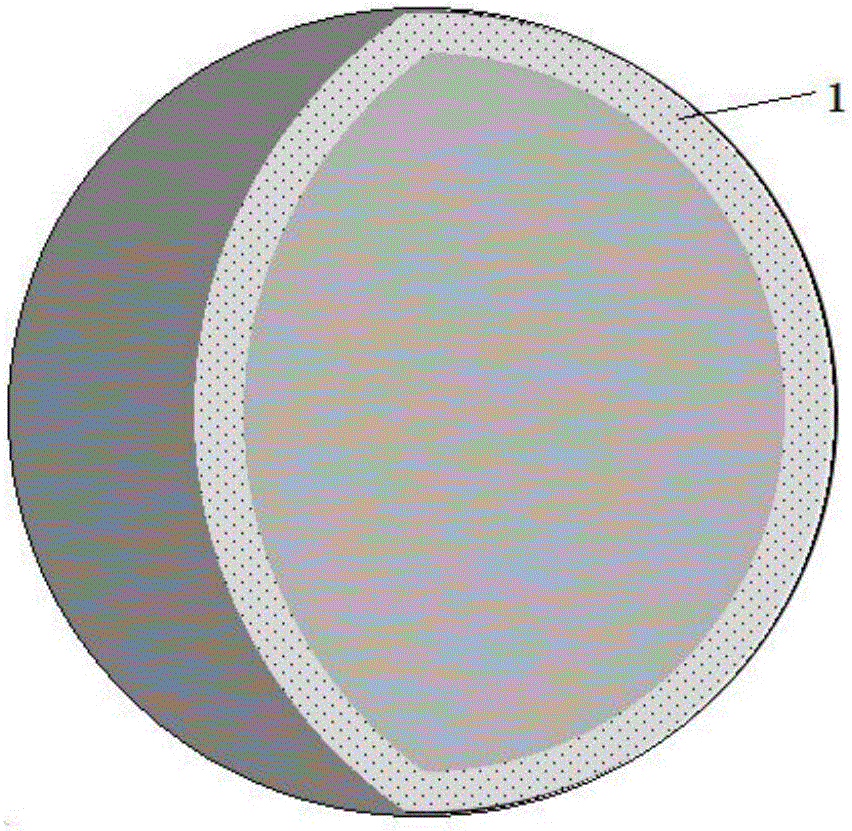

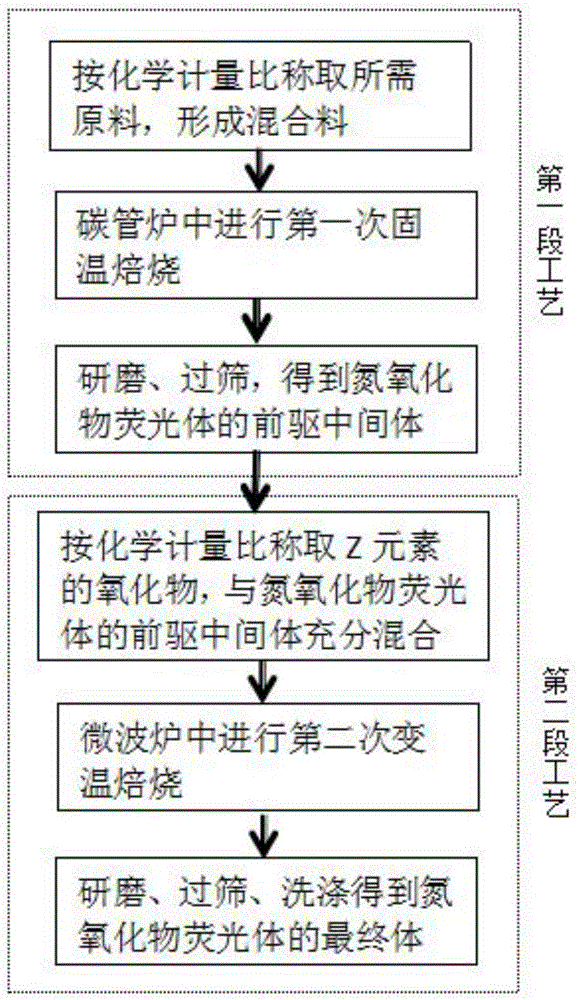

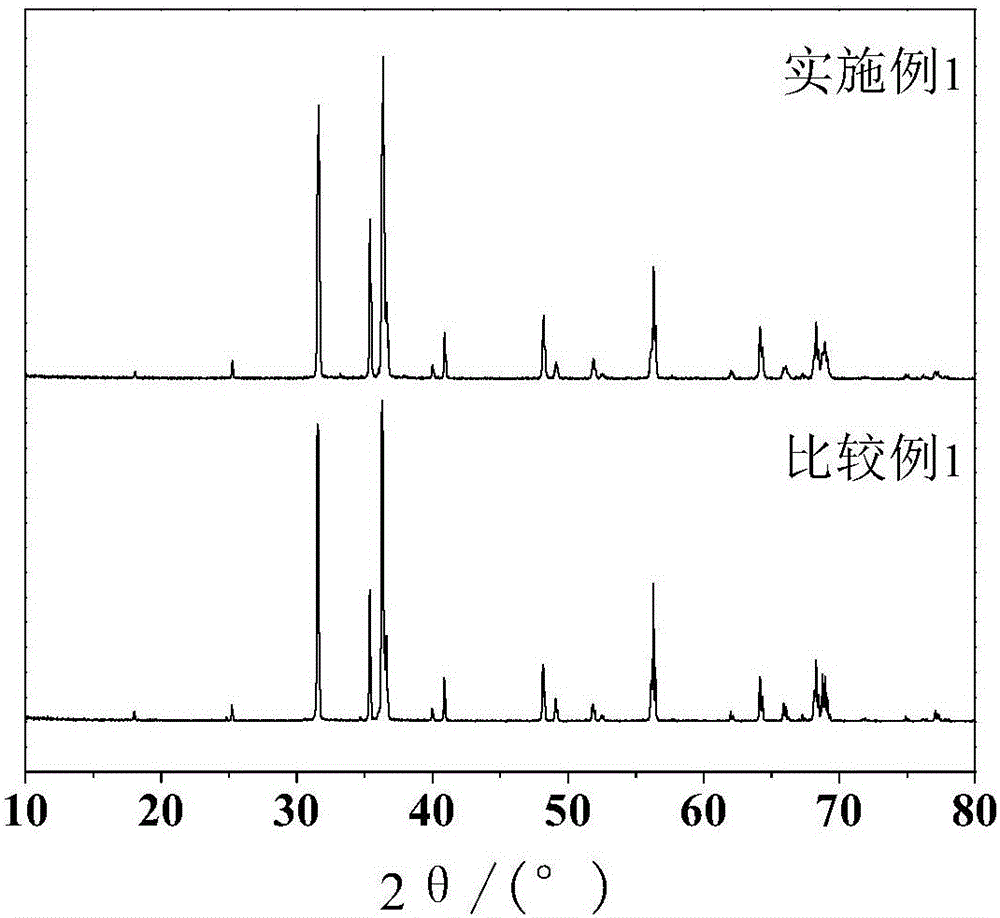

Nitrogen oxide fluorophor with anti-static function, preparation method and light-emitting device thereof

ActiveCN105969356AImprove anti-static effectImproved anti-static propertiesLuminescent compositionsSemiconductor devicesInorganic compoundNitrogen oxide

The invention relates to a nitrogen oxide fluorophor with the anti-static function. The nitrogen oxide fluorophor is characterized by comprising an inorganic compound with the anti-static function, wherein the inorganic compound comprises an anti-static material, a matrix material and a light-emitting material, elements of the matrix material and elements of the light-emitting material are subjected to solid solution to form a precursor midbody of the nitrogen oxide fluorophor, and the surface of the precursor midbody of the Nitrogen oxide fluorophor and the elements of the anti-static material are subjected to solid solution to form the final nitrogen oxide fluorophor. The nitrogen oxide fluorophor has the high anti-static effect, is good in chemical stability and applicable to various light-emitting devices. The preparation method adopts dual technologies and a two-stage method, and is simple, reliable and applicable to industrial batch production and manufacturing.

Owner:JIANGSU BREE OPTRONICS CO LTD

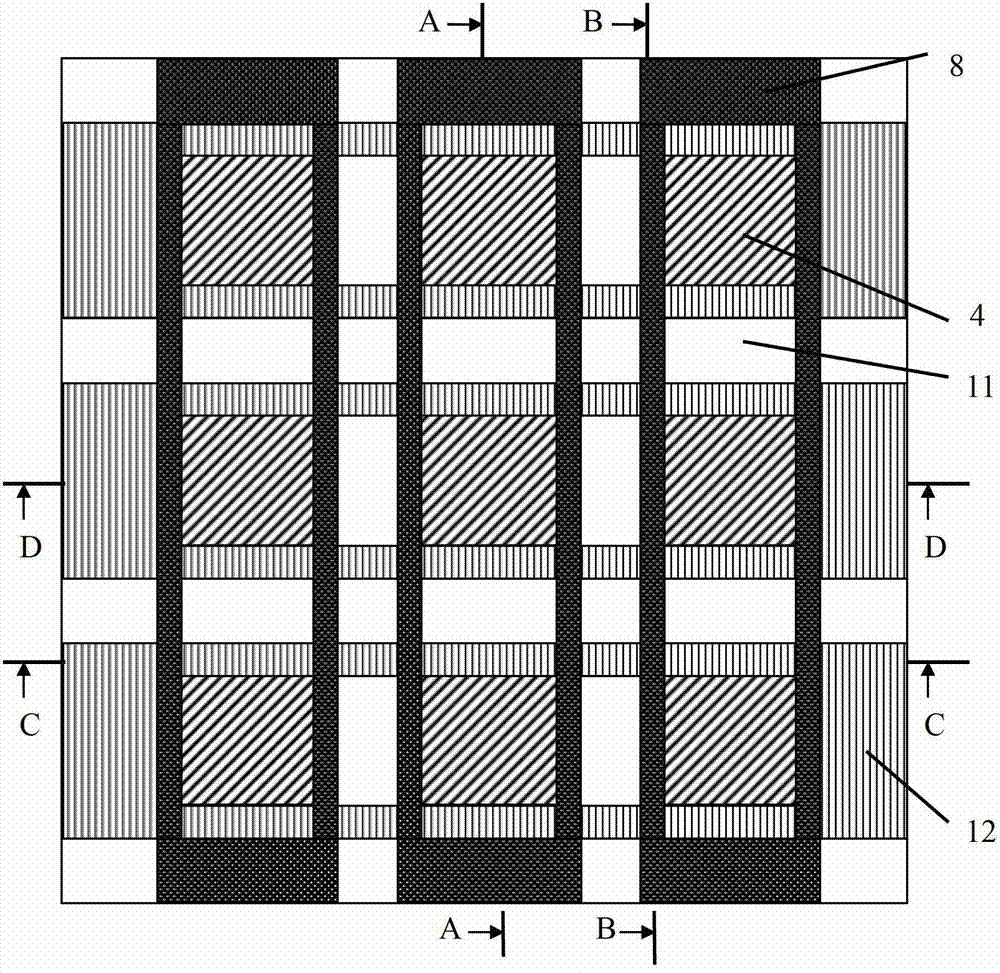

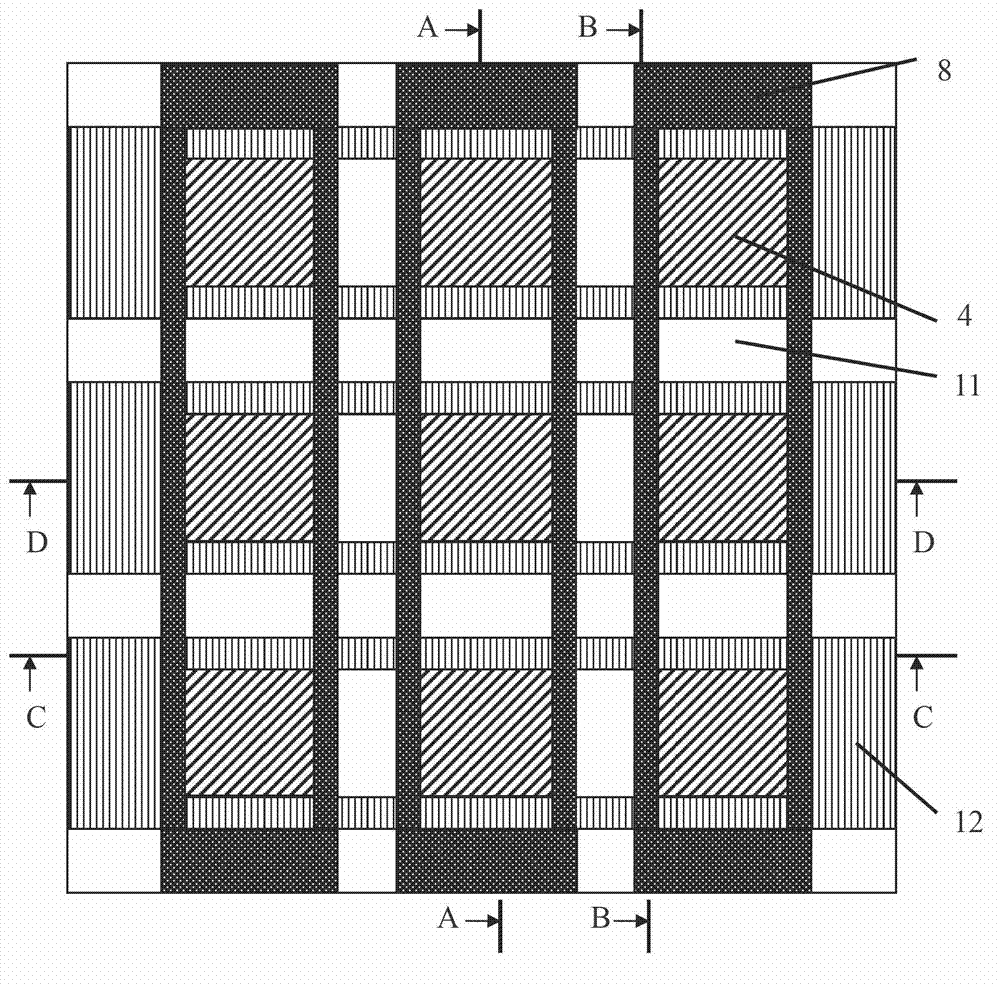

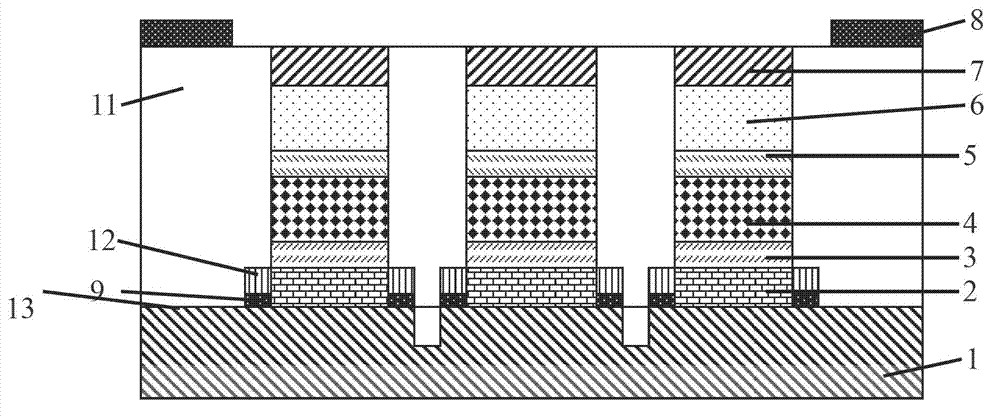

AlGaInP-LED (Light Emitting Diode) integrated micro-display device with single-face electrode structure

ActiveCN102790071ASimple structureStable structureSolid-state devicesSemiconductor devicesPower flowCurrent distribution

The invention discloses an AlGaInP-LED (Light Emitting Diode) integrated micro-display device with a single-face electrode structure, comprising an N-type substrate layer and multiple light emitting units, wherein the N-type substrate layer is used for supporting the micro-display device; the multiple light emitting units are arranged above the N-type substrate layer and are separated by multiple mutually-intersected channels; opaque diaphragms are filled in the channels; and a lower electrode is arranged on the lower stage top of each light emitting unit, and an upper electrode is arranged on top of each light emitting unit. According to the AlGaInP-LED integrated micro-display device with the single-face electrode structure, the difficulty in the process of manufacturing electrodes on the front side and the back side is avoided, the double strip-shaped upper electrode and lower electrode perpendicular in a non-coplanar manner are adopted, and more uniform current distribution can be obtained.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

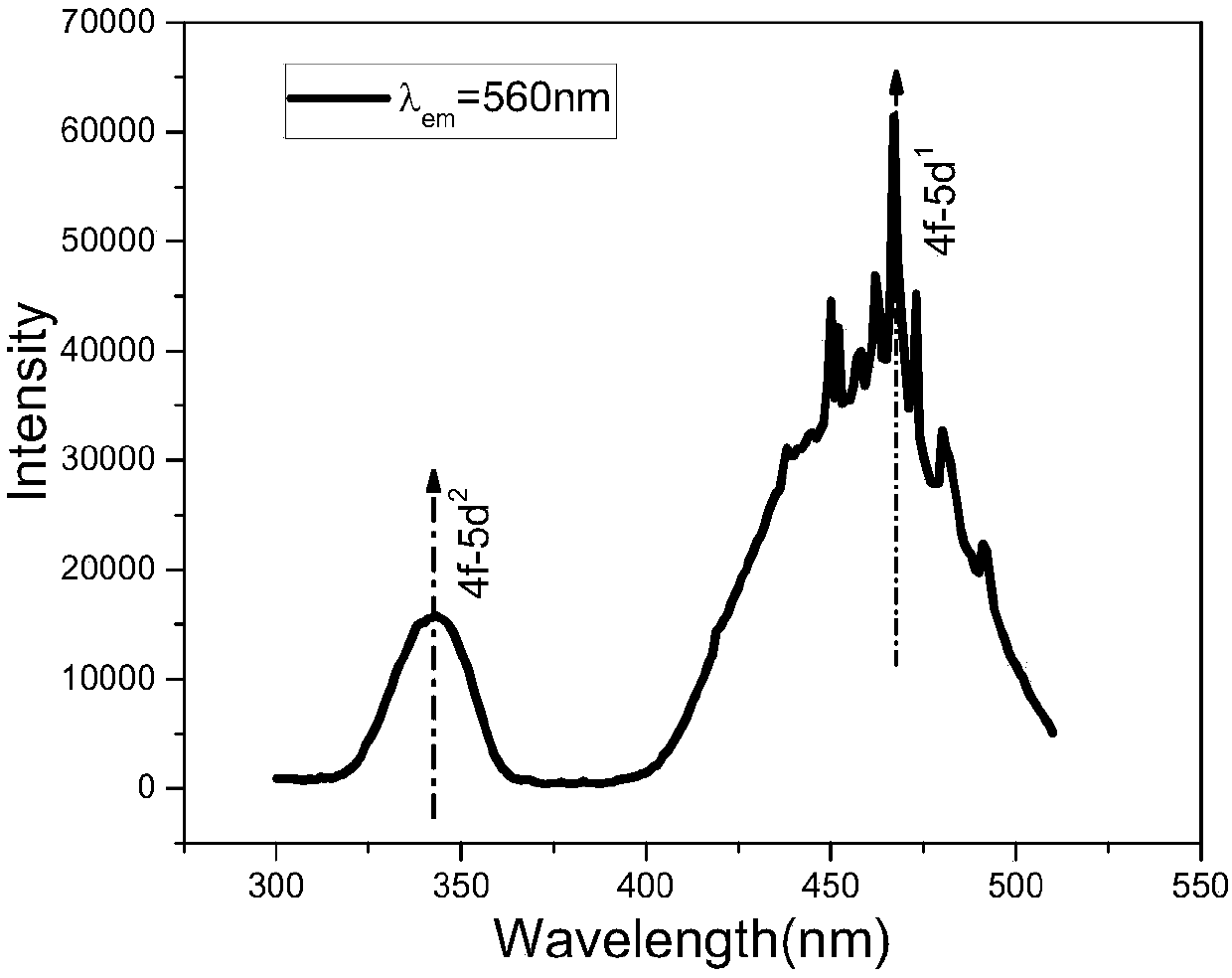

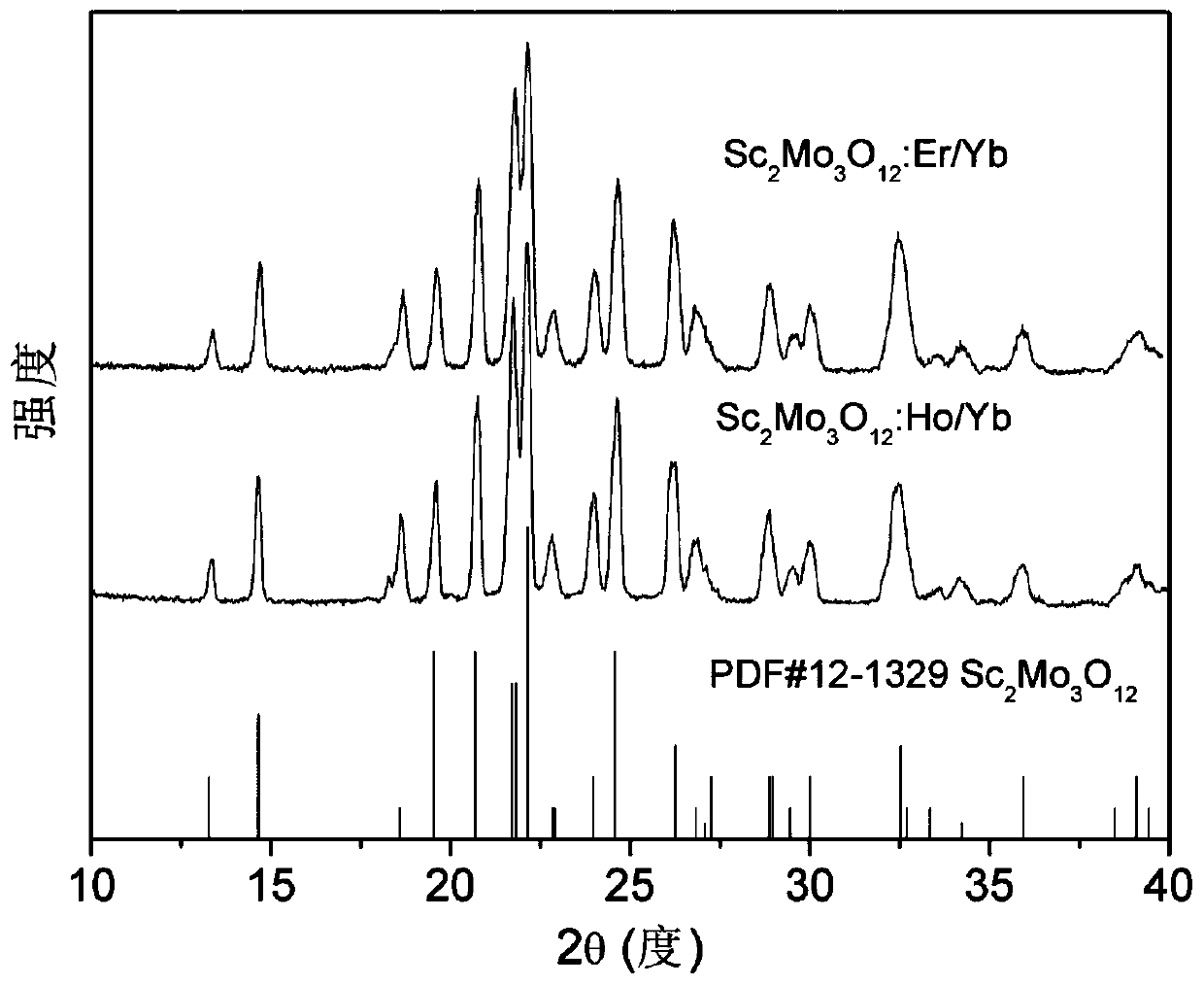

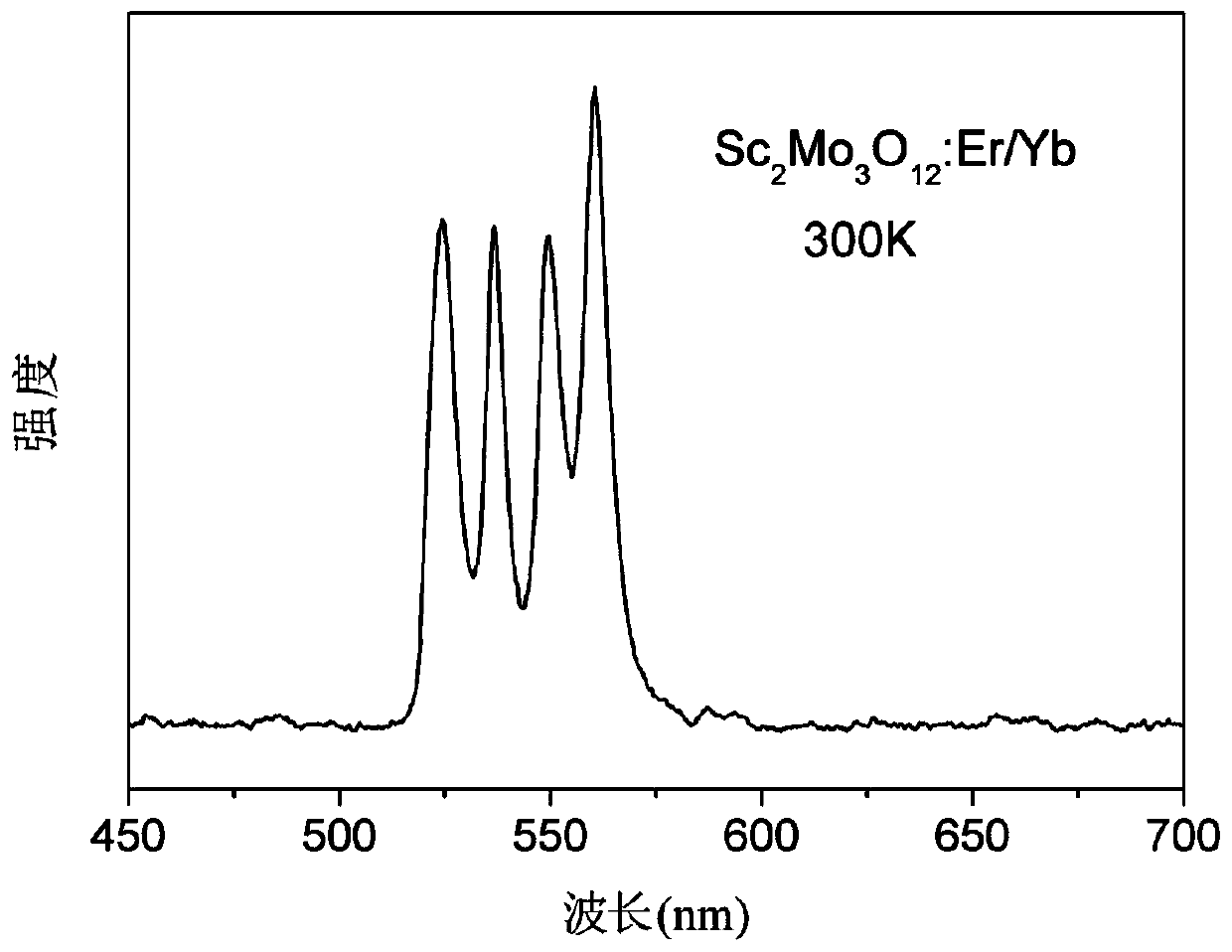

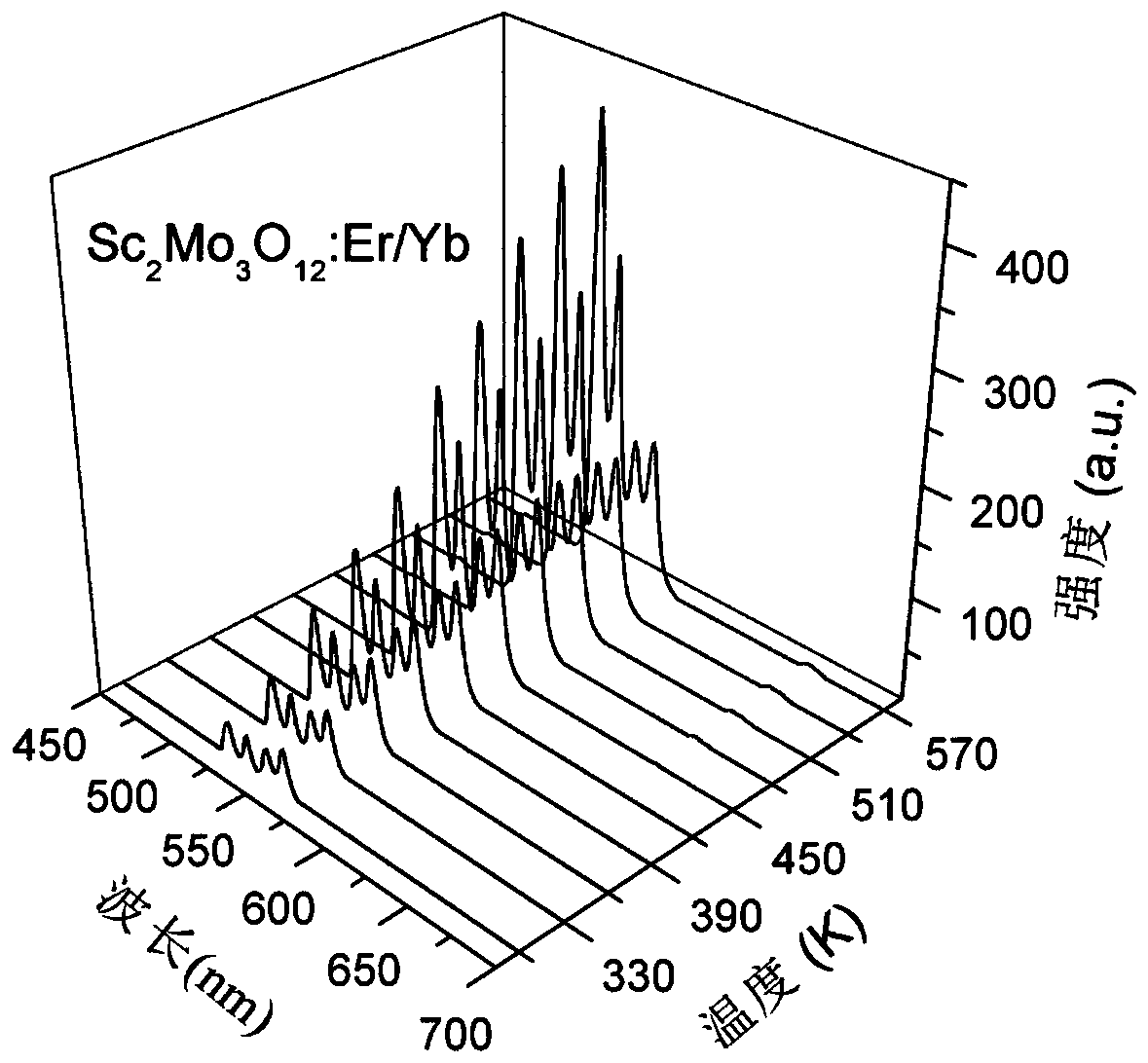

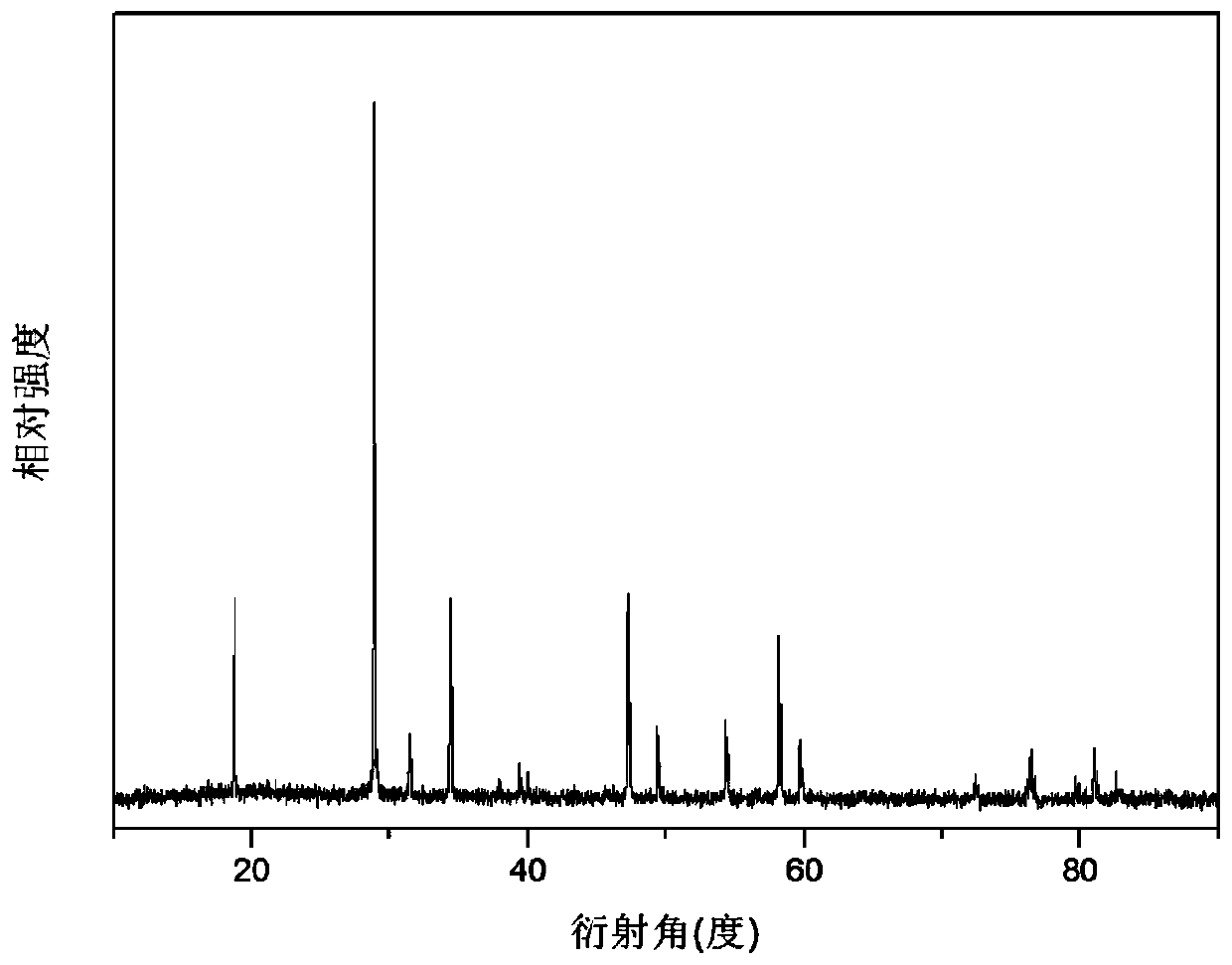

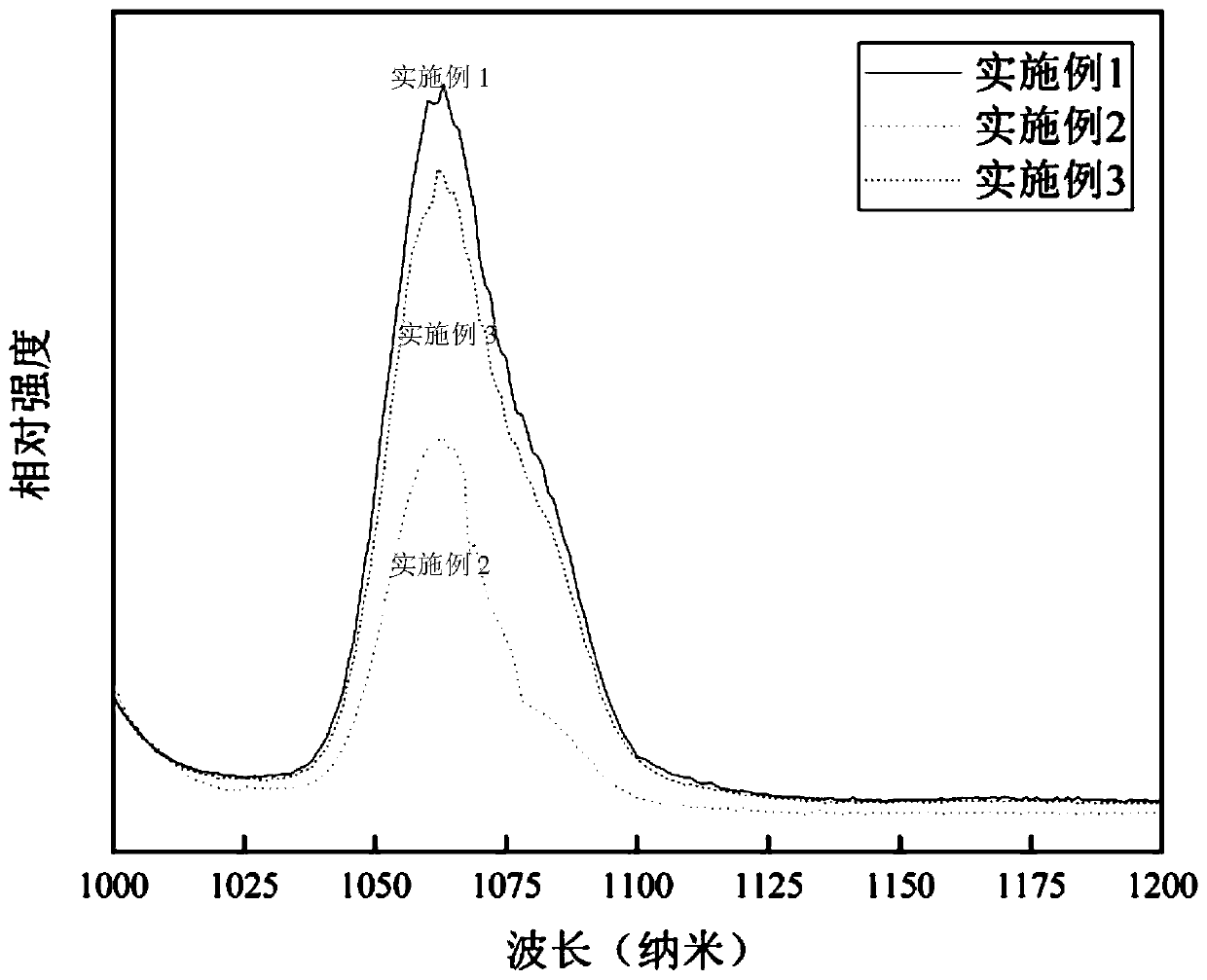

Rare earth doped up-conversion luminescent material with excellent damp-proof property and preparation method thereof

InactiveCN110846033AGood chemical stabilityHigh quenching concentrationLuminescent compositionsUpconversion luminescenceThermal dilatation

The invention belongs to the technical field of up-conversion luminescent materials, and specifically relates to a rare earth doped up-conversion luminescent material with an excellent damp-proof property and a preparation method thereof. The chemical formula of the up-conversion luminescent material is Sc<2-2x>Ln<2x>M<3>O<12>, Ln represents one or more of Er, Ho, Tm, Yb, Gd, and Dy, M representsMo or W, and 0<x<=0.40. The prepared up-conversion luminescent material has a negative thermal expansion performance and has different properties compared with a conventional material; as the temperature rises, the emitted light is enhanced; and a possible material and research idea are provided for modulating the light emitting strength at will through temperature adjustment.

Owner:JIANGSU UNIV OF TECH

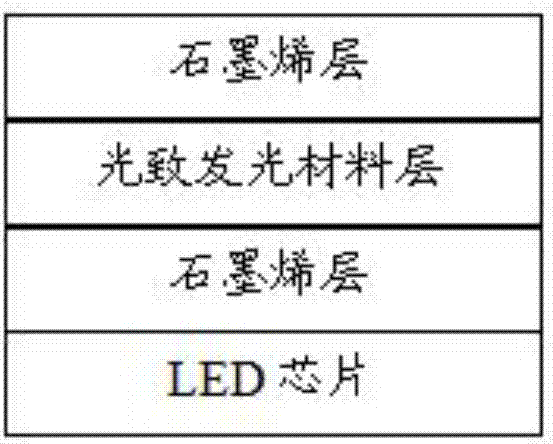

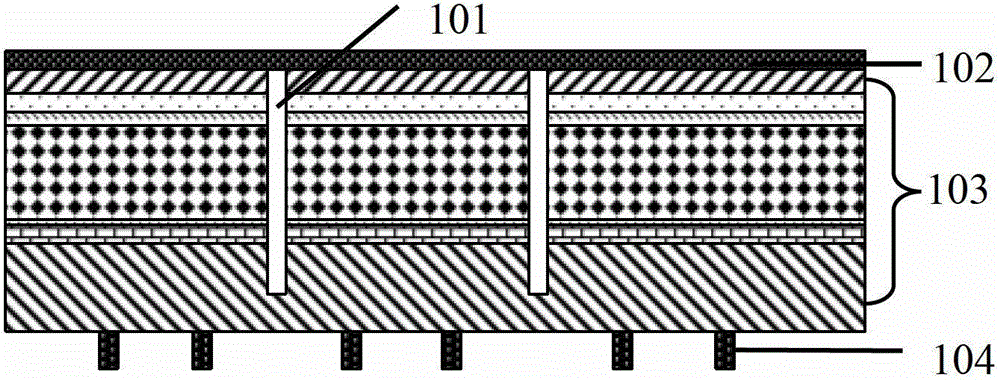

Graphene photoluminescent substrate and preparation method and application thereof

PendingCN106920867ALow absorption rateEfficient conductionLuminescent compositionsSemiconductor devicesSurface layerManufacturing technology

The invention provides a graphene photoluminescent substrate having a sandwich structure. The core layer of the sandwich structure is a photoluminescent material layer, and the surface layer of the sandwich structure is a graphene layer. At the same time, the invention provides a preparation method and application of the graphene photoluminescent substrate. Graphene is adopted as a protective layer of a photoluminescent substrate, so that a photoluminescent material sensitive to heat is effectively prevented from being affected by high temperature generated when an LED chip works, and erosion of the photoluminescent material by micromolecules such as oxygen and water can also be avoided, thereby maintaining relatively high luminescent performance; and graphene itself has a low absorptivity of light, and does not have obvious influence on luminescent performance of a solid luminescent device. Thus, by adoption of the graphene photoluminescent substrate provided by the invention, the application range of the photoluminescent material sensitive to heat can be greatly expanded without substantially transforming an existing solid luminescent device manufacturing technology on the basis of an LED chip.

Owner:滁州市量子光电有限公司

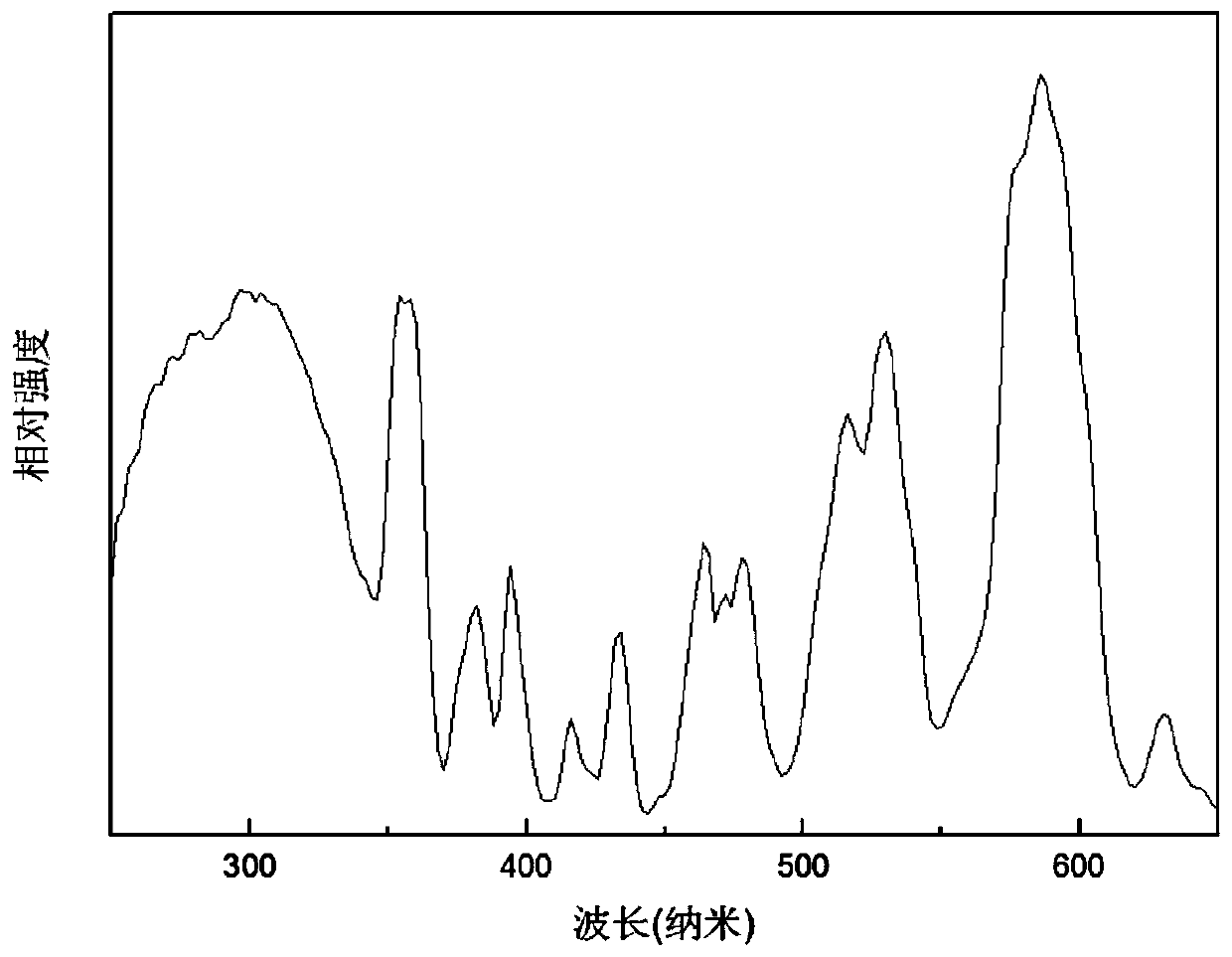

Fluorescent film containing near-infrared fluorescent powder and application thereof

InactiveCN109749741AHigh luminous intensityStable in natureLuminescent compositionsPhotovoltaic energy generationFluorescenceLength wave

The invention discloses a fluorescent film containing near-infrared fluorescent powder and an application thereof. The fluorescent film is prepared by the following steps: weighing and mixing raw materials evenly according to metering ratios of elements in a chemical formula, calcining the raw materials in a muffle furnace, carrying out cooling, crushing and grinding, and carrying out grinding andsieving after an annealing process to prepare LiEu(MoO4)2:Nd<3+> near-infrared fluorescent powder; and mixing the near-infrared fluorescent powder with glass powder uniformly, adding an organic glue,stirring the mixture into a gel shape, carrying out heating curing, and then calcining the mixture in a muffle furnace to obtain the fluorescent film. The fluorescent film can be excited by ultraviolet and visible light, and the luminous range is 1656-1166nm. The near-infrared fluorescent film prepared by the method has excellent luminous performance, can be used for preparing solar cells, can convert solar spectra which cannot be utilized by some solar cells into near-infrared light with a wavelength within 1166nm to be applied by the solar cells, thereby improving the conversion efficiencyof the solar cells.

Owner:CHINA JILIANG UNIV

Water-based acrylic fluorescent coating and preparation method thereof

ActiveCN110655841ADoes not affect luminosityChange film formationAntifouling/underwater paintsLuminescent paintsEmulsionNano sio2

The invention provides a water-based acrylic fluorescent coating and a preparation method thereof. The preparation method comprises the following steps: preparing silicon dioxide coated modified fluorescent powder; adding the obtained silicon dioxide coated modified fluorescent powder into a water-based solvent and stirring to obtain modified fluorescent powder suspension; adding the modified fluorescent powder suspension into an emulsion containing an acrylate monomer, adding an initiator, carrying out a reaction, and adjusting the pH value to 6.5-7.5 to obtain a stable nano SiO2 / acrylate composite emulsion, wherein the component of the emulsion B comprises methyl methacrylate, and the component of the emulsion C comprises n-butyl acrylate; and uniformly mixing the obtained nano SiO2 / acrylate composite emulsion with a curing agent and an auxiliary agent to obtain the water-based acrylic fluorescent coating. The silicon dioxide is adopted to coat and modify fluorescent powder, the modified fluorescent powder is used as a core, and the acrylate copolymer is used as a shell, so that the luminescence property of the fluorescent powder is enhanced, and the stability of the emulsion isimproved.

Owner:广西经正科技开发有限责任公司

Method for manufacturing distributed feedback laser device array by virtue of selection region epitaxy technology

ActiveCN102820616BDoes not affect luminosityEasy to manufactureLaser optical resonator constructionSemiconductor laser arrangementsDistributed feedback laserDielectric

A method for manufacturing a distributed feedback laser array includes: forming a bottom separate confinement layer on a substrate; forming a quantum-well layer on the bottom separate confinement layer; forming a selective-area epitaxial dielectric mask pattern on the quantum-well layer; forming a top separate confinement layer on the quantum-well layer through selective-area epitaxial growth using the selective-area epitaxial dielectric mask pattern, the top separate confinement layer having different thicknesses for different laser units; removing the selective-area epitaxial dielectric mask pattern; forming an optical grating on the top separate confinement layer; and growing a contact layer on the optical grating. The present disclosure achieves different emission wavelengths for different laser units without significantly affect emission performance of the quantum-well material.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

UV led lamp beads

ActiveCN104864284BDoes not affect luminosityPrevent agingLighting heating/cooling arrangementsLight fasteningsUltravioletEngineering

The invention provides an ultraviolet LED lamp bead which adopts the structure that a transparent silicone pad is arranged at a position right above a chip in a lamp body; fluorescent powder is arranged between the silicone pad and the chip; a heat dissipation column is also arranged on the lamp body; the chip is in contact with the heat dissipation column. Through the arrangement of the silicone pad and the fluorescent powder, the problems of ageing and yellowing of the lamp body can be effectively avoided, the illumination performance of the lamp body can be optimized, and the service life of the lamp body can be greatly prolonged on the premise that the luminescence performance of the lamp body is not impacted; through the arrangement of the heat dissipation column, the heat dissipation speed of the chip can be greatly improved, and thus the lamp body can be protected from ageing and yellowing, and the service life of the lamp body can be further prolonged.

Owner:牧歌电子(浙江)有限公司

Method for manufacturing AlGaInP-LED (Light Emitting Diode) integrated micro display component with single-side electrode structure

ActiveCN102790144BSimple structureStable structureSolid-state devicesSemiconductor devicesPlanar electrodeLed array

The invention discloses a method for manufacturing an AlGaInP-LED (Light Emitting Diode) integrated micro display component with a single-side electrode structure, wherein the steps comprises: etching multiple first grooves which are mutually intersected on a device body; growing a lower electrode metal layer on the bottom part of each groove to form the lower electrode metal layer; growing an insulating medium layer above a lower electrode; corroding an area of the lower electrode metal layer outside a lower electrode diagram downward till reaching a certain depth in an N-shaped substrate layer in order to form multiple second grooves; filling opaque diaphragms into the second grooves and the upper part of a protection medium of the lower electrode; manufacturing an upper electrode above a light emitting unit; and electroforming upper and lower electrode leads. With the adoption of the method for manufacturing the LED array micro display device with the planar electrode structure disclosed by the invention, the process difficulty resulting from the manufacturing of the electrodes on the front face and the back face respectively can be prevented; since the manufactured micro display device is provided with the double bar type upper and lower electrodes of which the different faces are perpendicular to each other, the more even current distribution can be obtained; and therefore, the micro display device available for even luminance is obtained.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

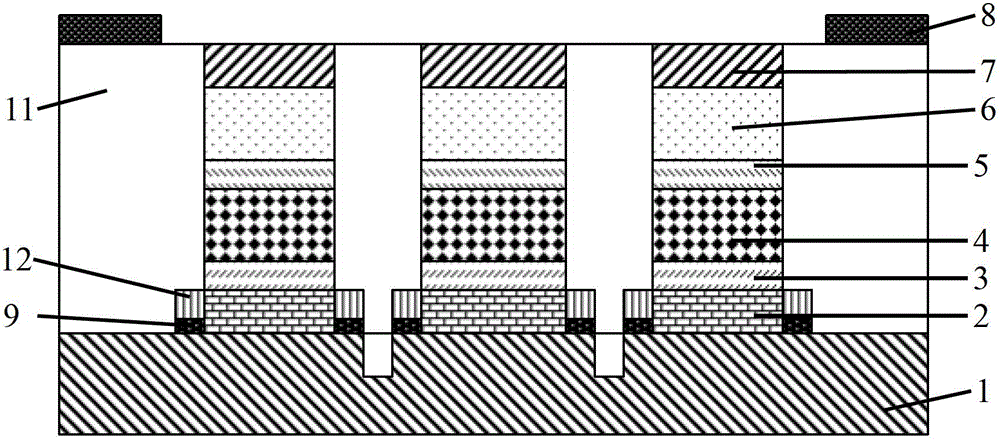

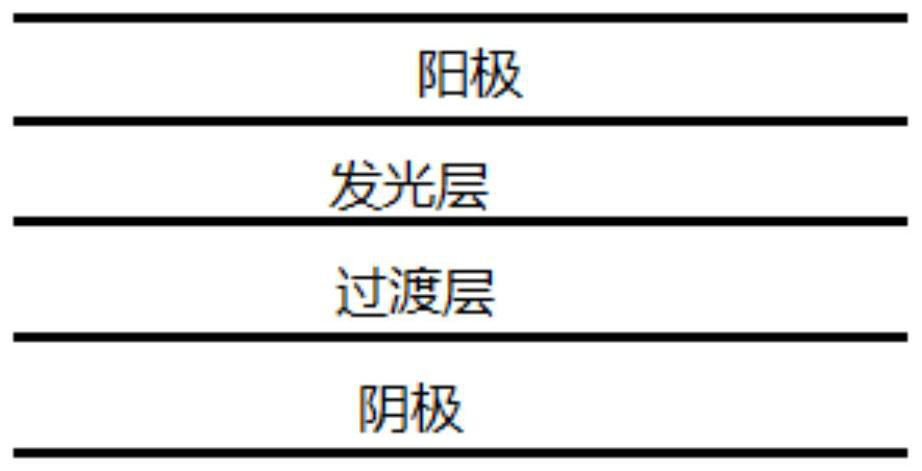

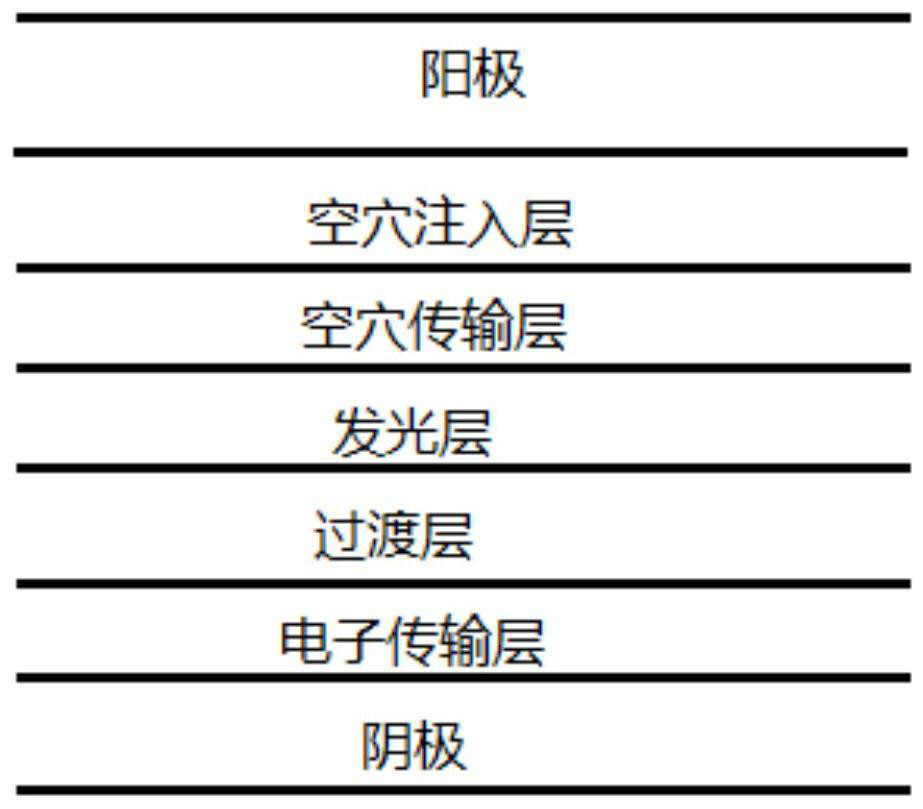

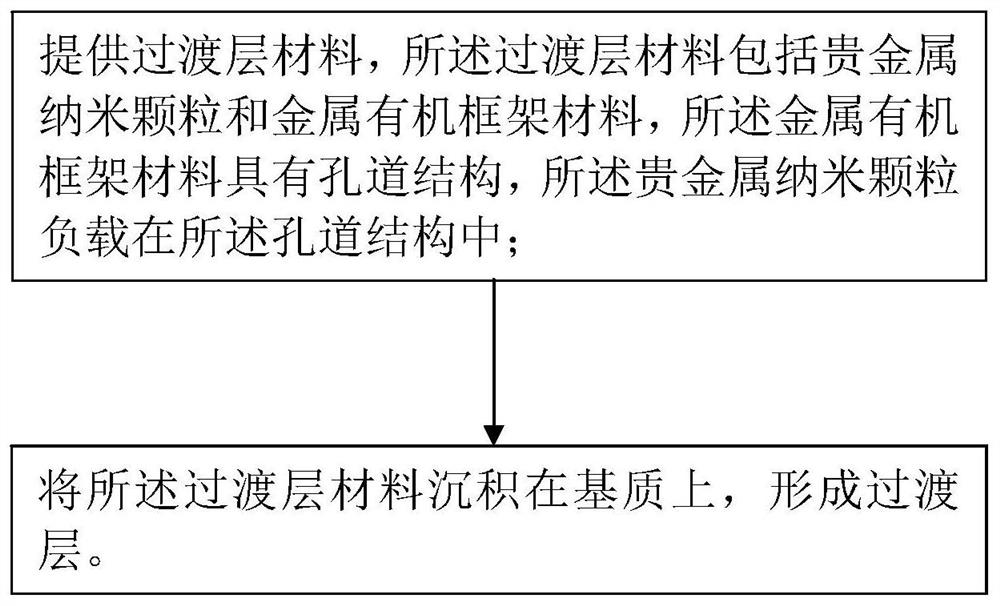

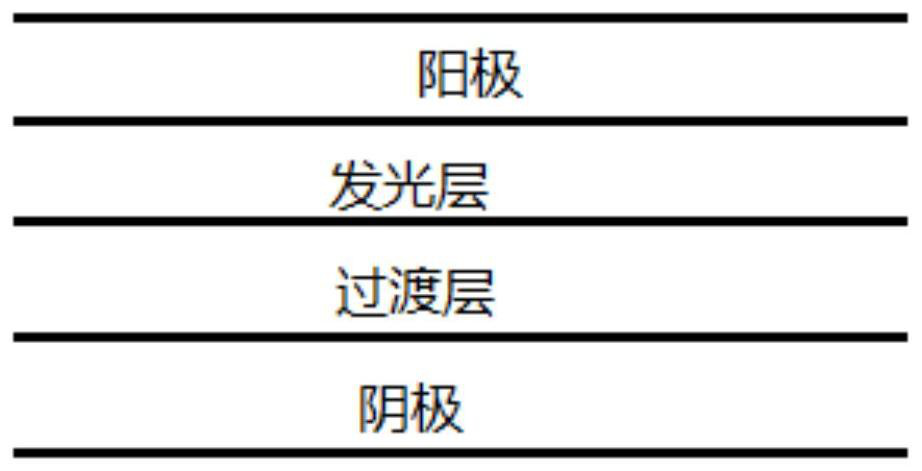

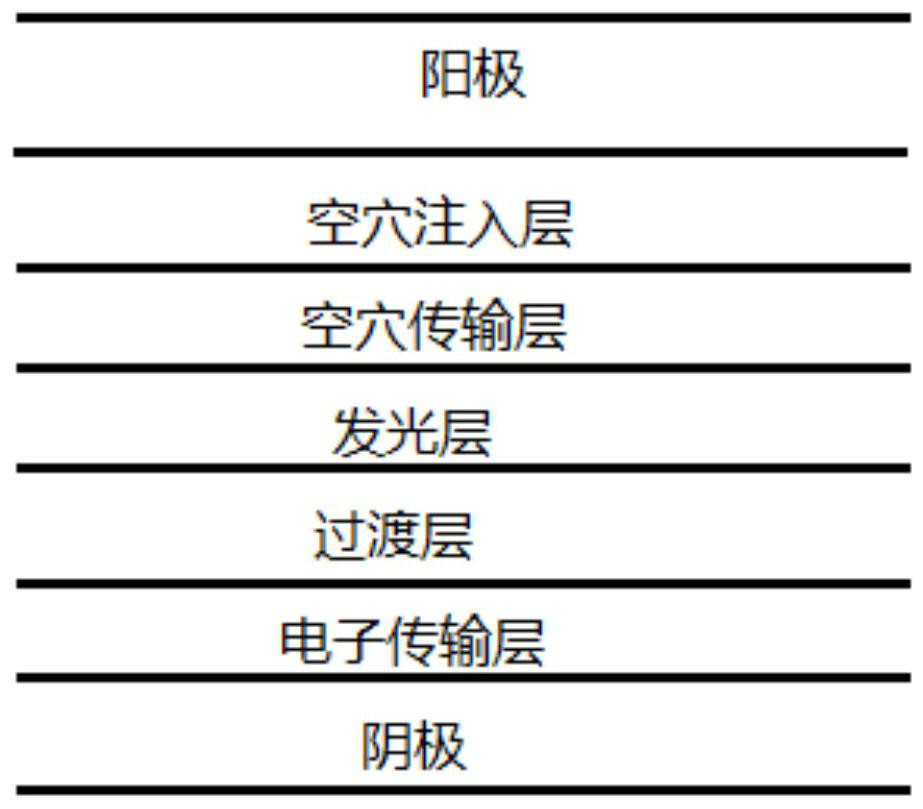

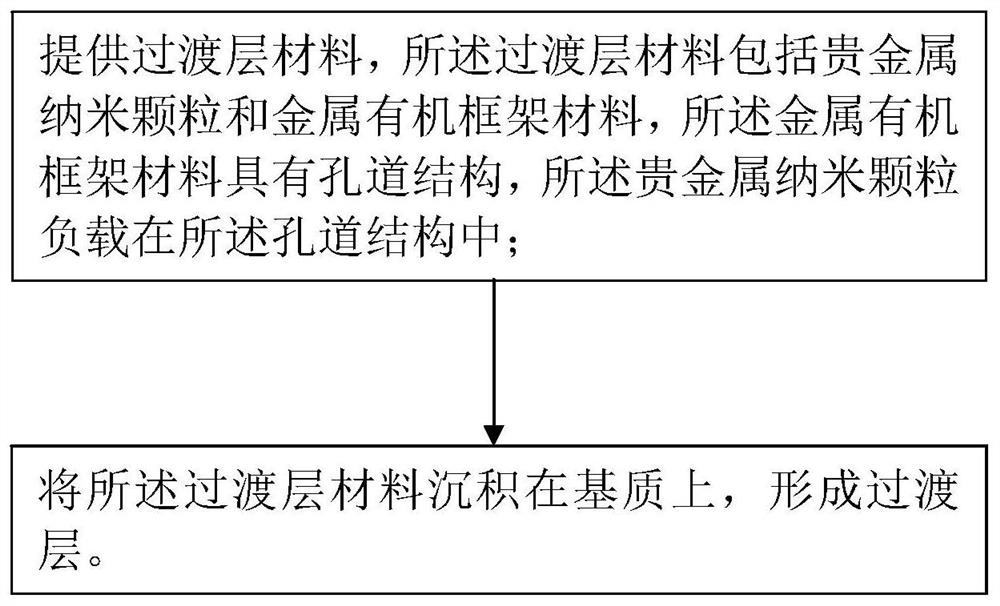

Light-emitting diode and its preparation method

ActiveCN113130783BImprove luminous performanceWith plasmon resonance effectSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeNanoparticle

The invention belongs to the field of display technology, in particular to a light emitting diode and a preparation method thereof. The light-emitting diode provided by the present invention includes: an anode, a cathode, a light-emitting layer arranged between the anode and the cathode, a transition layer arranged between the cathode and the light-emitting layer, and the materials of the transition layer include: noble metal nanoparticles and metal organic framework materials, Metal-organic framework materials have a pore structure, and noble metal nanoparticles are loaded in the pore structure. The problem of unbalanced electron transport rate and hole transport rate existing in the existing light-emitting diode is solved, and the light-emitting performance of the light-emitting diode is improved.

Owner:TCL CORPORATION

A kind of preparation method of low melting point fluorescent glass

The invention discloses a preparation method of low-melting-point fluorescent glass and belongs to the field of preparation of glass materials. The preparation method is characterized in that the (NaPO3)6-NaF-CaO-B2O3-Sb2O3-Li2O-ZnO low-melting-point fluorescent glass is provided through the optimized design of the glass components, and the specific preparation steps are provided as follows: (1) firstly preparing the low-melting-point bare glass; (2) then mixing a commercial yttrium aluminium garnet structure yellow fluorescent powder and the low-melting-point glass powder in an alumina crucible, and firing and forming. The cost of the provided components for preparing the fluorescent glass is low, the operation process is simple and effective, the heat resisting property and the machiningproperty are excellent, the energy consumption in the production is low, the chemical stability is excellent, a solution is provided for solving the problems of a high-power LED device like light attenuation and color temperature drifting, and the limitations of the traditional fluorescent powder are expected to be broken.

Owner:UNIV OF SCI & TECH BEIJING

A kind of waterborne acrylic fluorescent paint and preparation method thereof

ActiveCN110655841BDoes not affect luminosityChange film formationAntifouling/underwater paintsLuminescent paintsEmulsionFluorescence

Owner:广西经正科技开发有限责任公司

Firefighting guide illumination line

InactiveCN101640955BEasy to useSuitable for night visual observationElectrical apparatusElectroluminescent light sourcesEngineering physicsElectroluminescent wire

Owner:SHANGHAI KEYAN PHOSPHOR TECH

A kind of fluorescent powder quantum dot composite particle and its preparation method and application

ActiveCN111334280BEnsure Optical ConsistencySolve the problem of subsidence and stratificationMaterial nanotechnologyNanoopticsQuantum dotSilicon oxide

Owner:HUAZHONG UNIV OF SCI & TECH

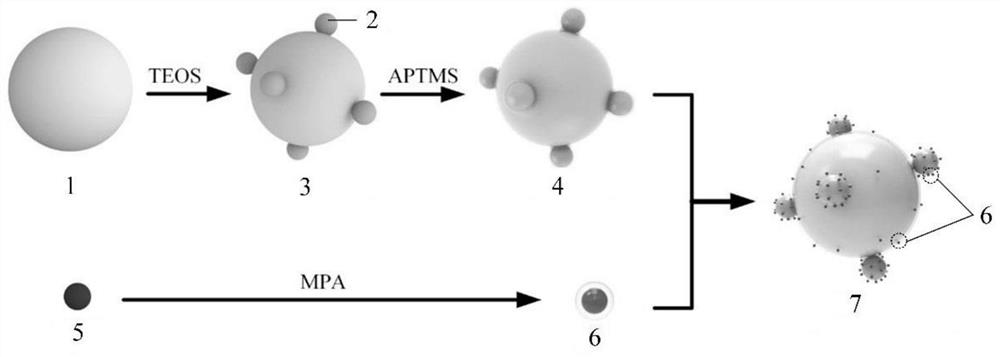

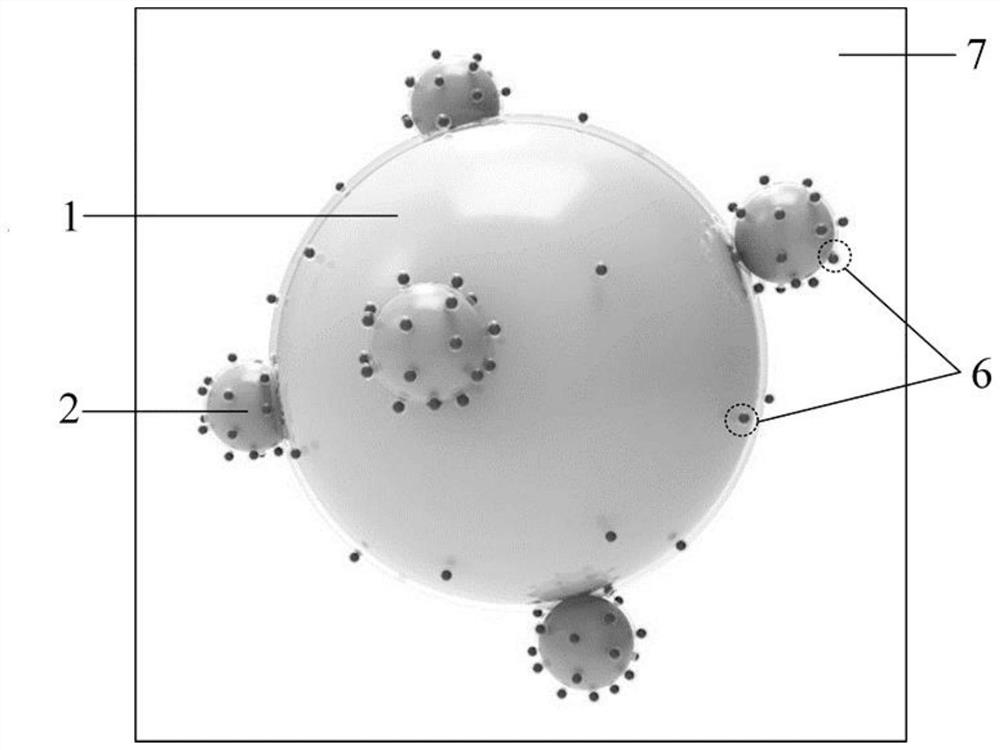

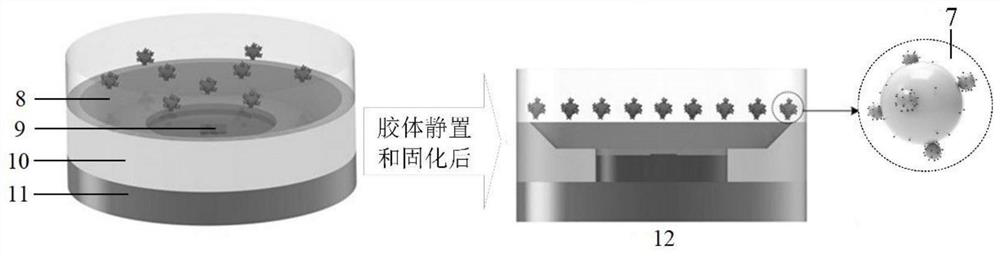

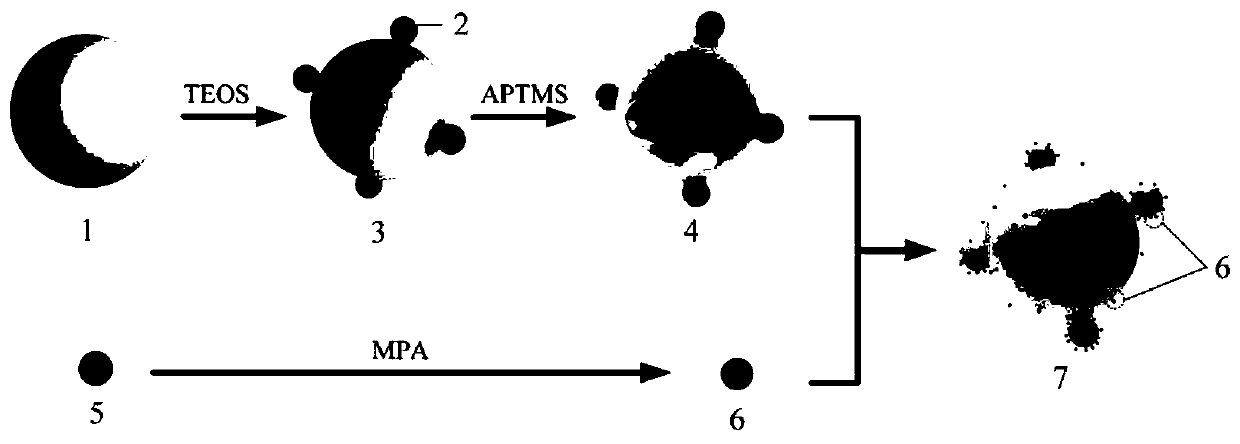

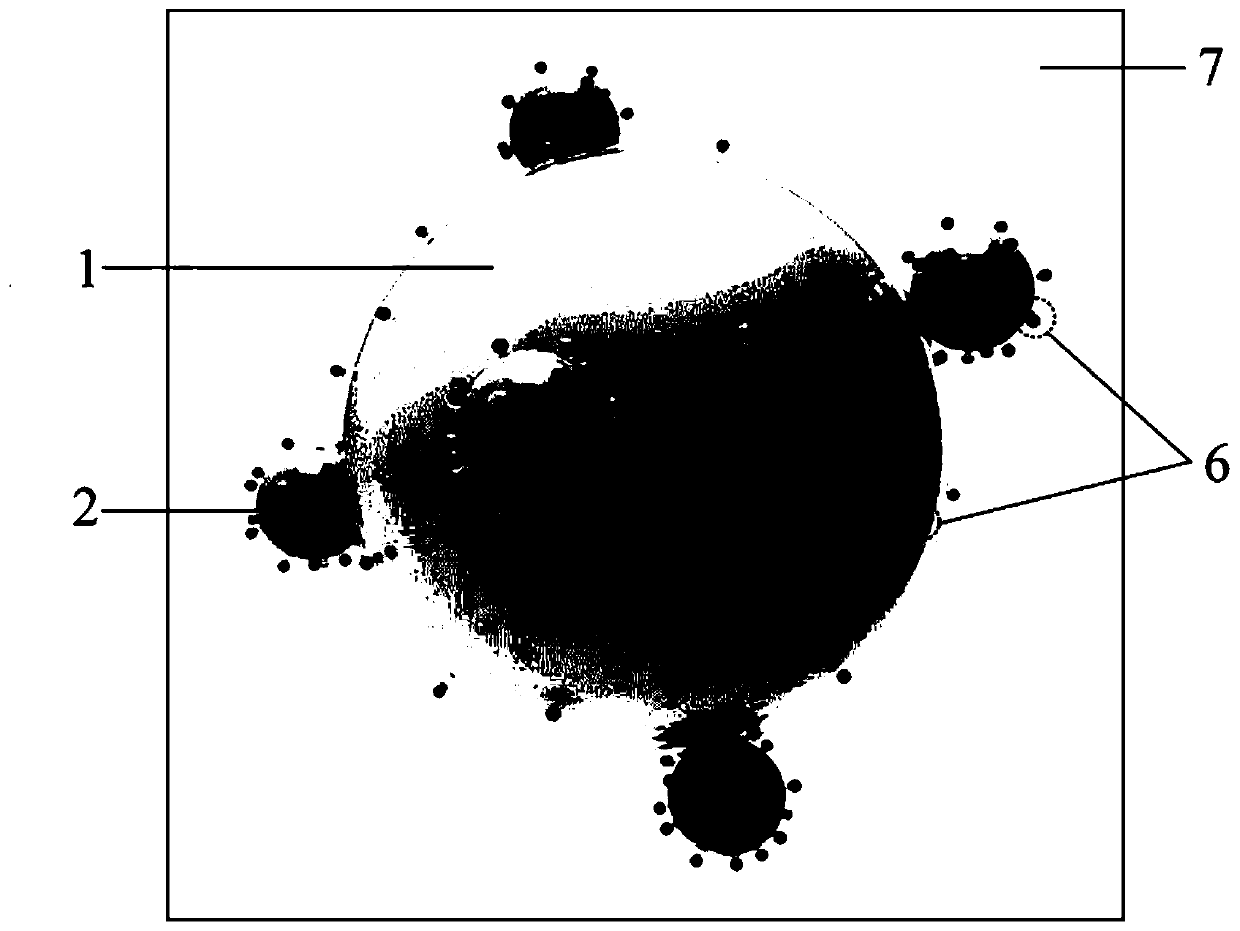

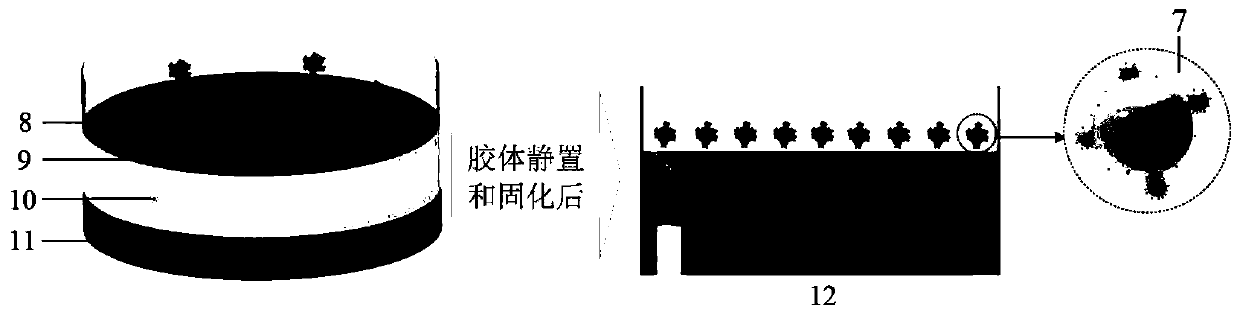

Fluorescent powder quantum dot composite particles as well as preparation method and application thereof

ActiveCN111334280AEnsure Optical ConsistencySolve the problem of subsidence and stratificationMaterial nanotechnologyNanoopticsPhysical chemistryQuantum dot

The invention belongs to the field of white light LEDs, and particularly discloses fluorescent powder quantum dot composite particles and a preparation method and application thereof. The method comprises the following steps: preparing silicon dioxide on the surface of fluorescent powder so as to form a fluorescent powder-silicon dioxide composite structure; carrying out surface positive electricity modification on the fluorescent powder-silicon dioxide to obtain positively charged fluorescent powder-silicon dioxide; carrying out surface electronegative modification on the quantum dots to obtain electronegative quantum dots; adsorbing the negatively charged quantum dots on the surface of the positively charged fluorescent powder-silicon dioxide through an electrostatic adsorption effect, so as to prepare the fluorescent powder quantum dot composite particles. The fluorescent powder quantum dot composite particles prepared by the method provided by the invention keep the fluorescent powder and the quantum dots relatively static in the packaging process, ensure the optical consistency of the quantum dot white light LED, and solve the problem of sedimentation layering caused by greatdifference between the particle sizes of the fluorescent powder and the quantum dots.

Owner:HUAZHONG UNIV OF SCI & TECH

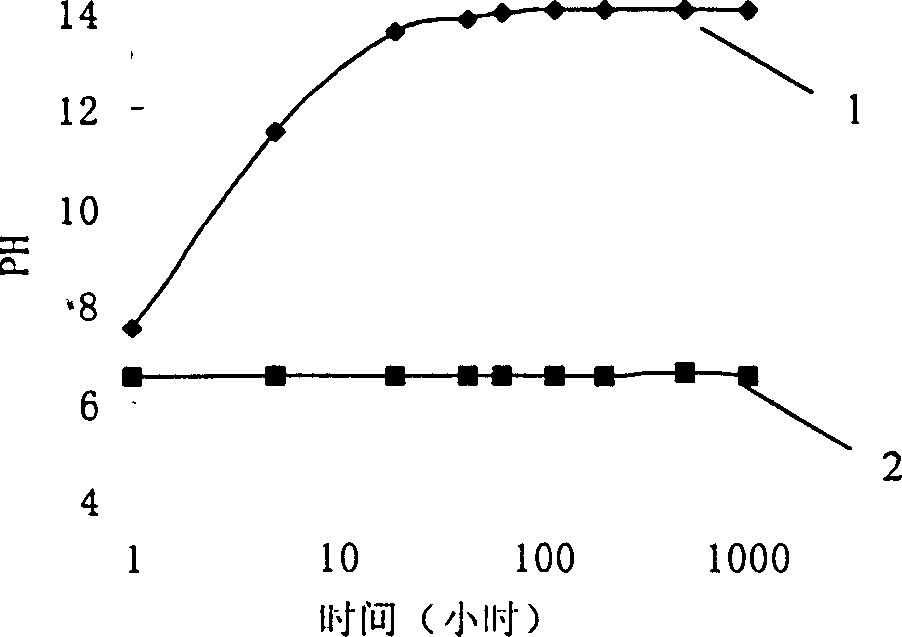

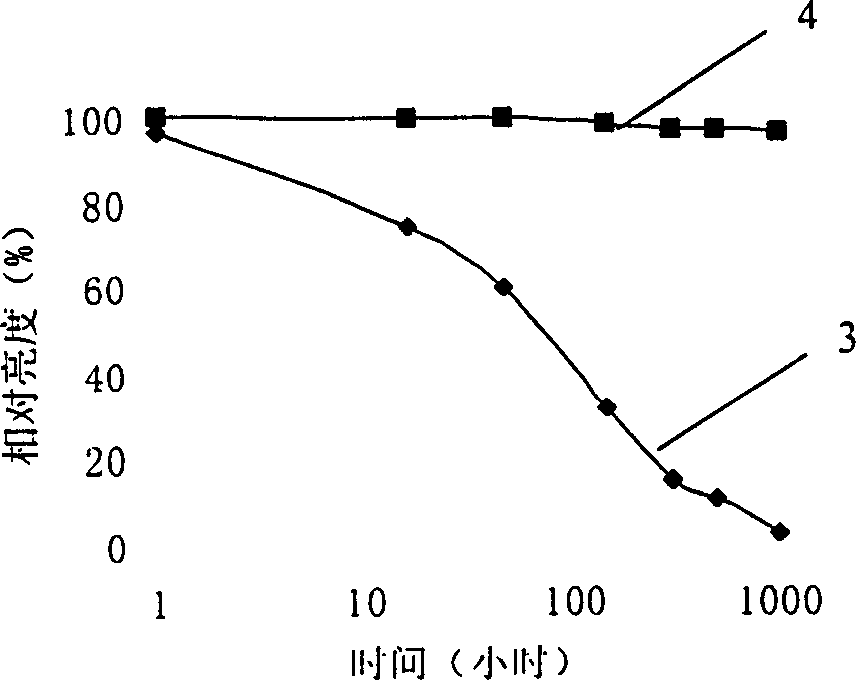

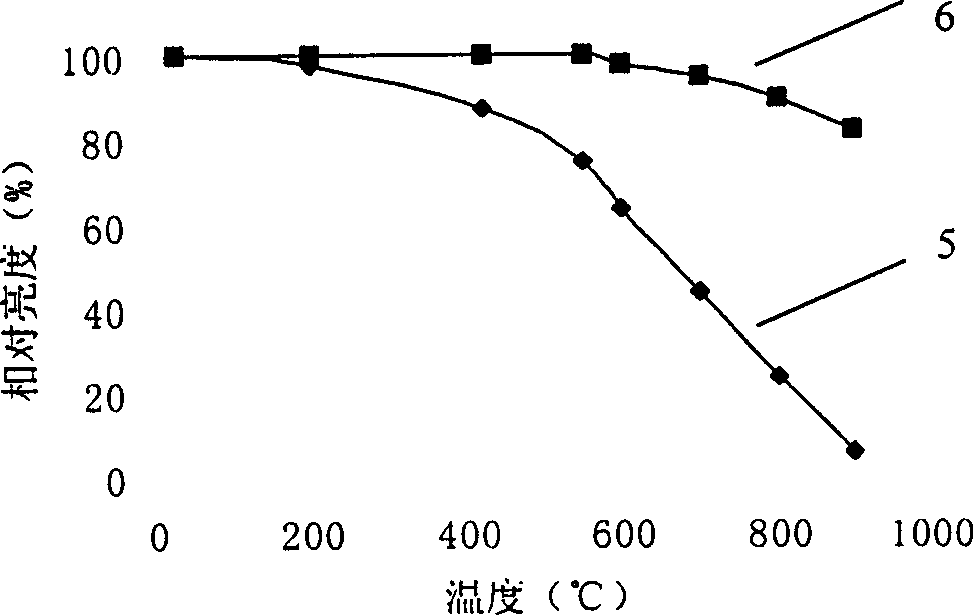

Long persistence phosphor of alkali earth aluminate for SiO2 glass painting and its prepn. method thereof

InactiveCN1159408CImprove water resistanceImprove heat resistanceLuminescent compositionsAluminatePhosphor

The present invention discloses an alkaline earth aluminate long-afterglow phosphor powder with SiO2 glass coating layer and its preparation method. This invented preparation method includes the following steps: hydrolyzing silicate in an aqueous solution containing cosolvent and catalyst to obtain an uniform transparent solution, mixing the above-mentioned alkaline earth aluminate long-afterglow phosphor powder and the above-mentioned obtained solutino according to a certain proportion, filtering, drying and heating so as to obtain the invented alkaline earth aluminate long-afterglow phosphor powder with SiO2 glass coating layer. It not only can raise water-proofing and heat-resisting properties, but also does not affect its luminous performance, and its preparation process is simple and easy to implement industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH +1

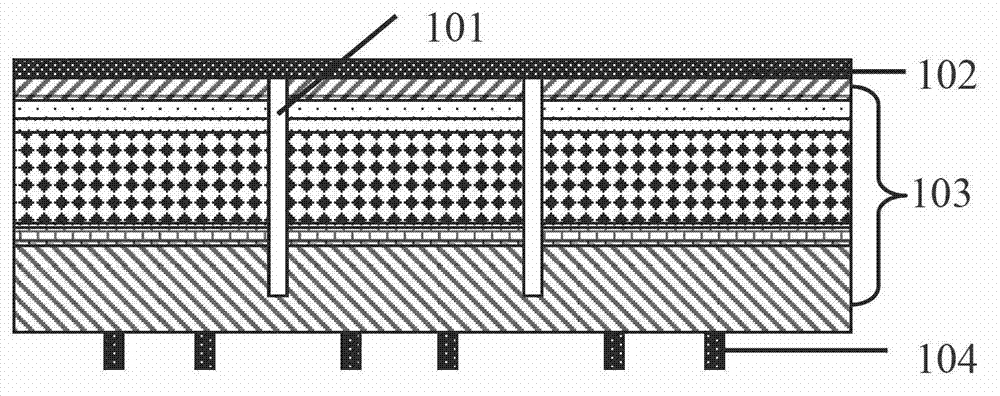

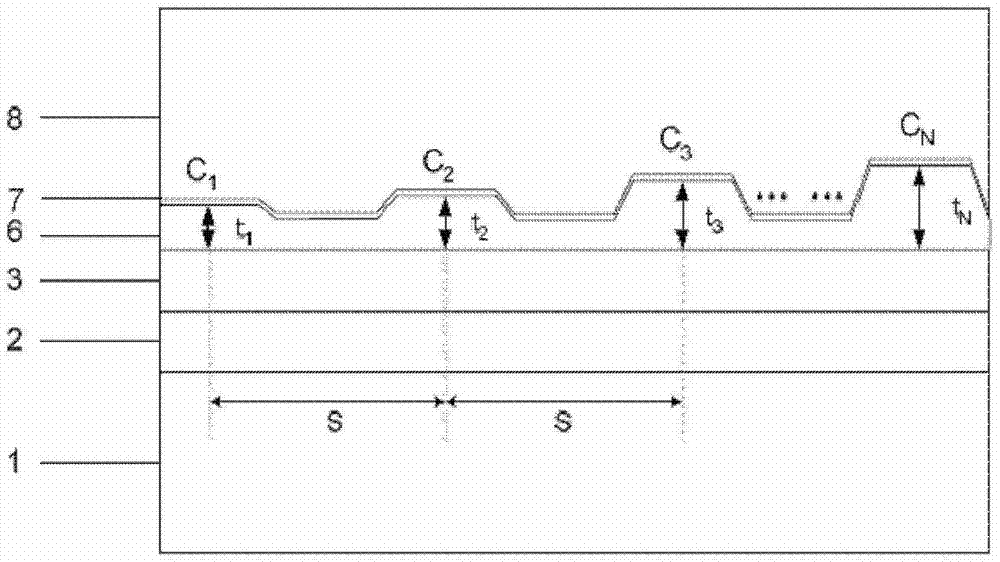

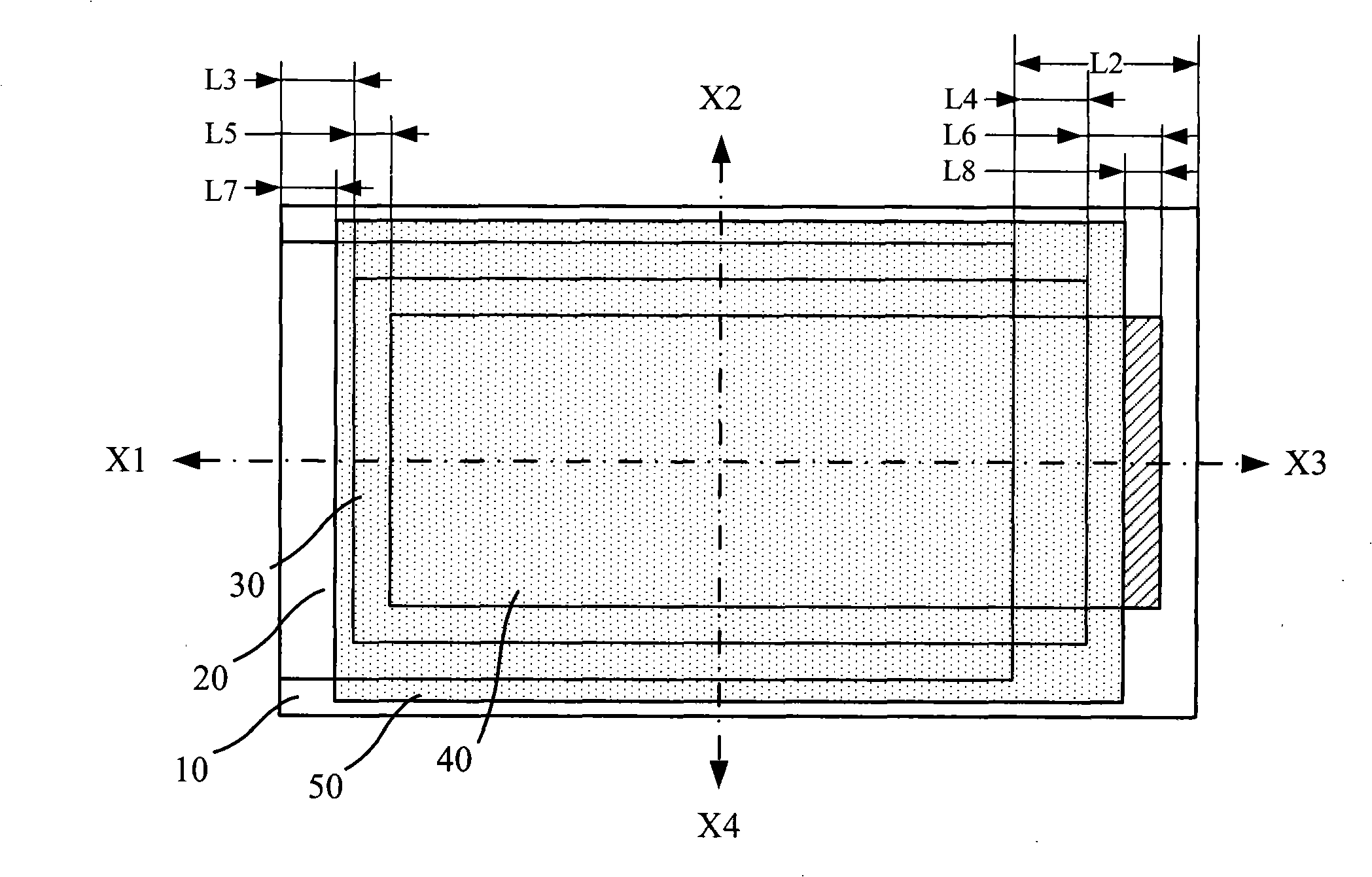

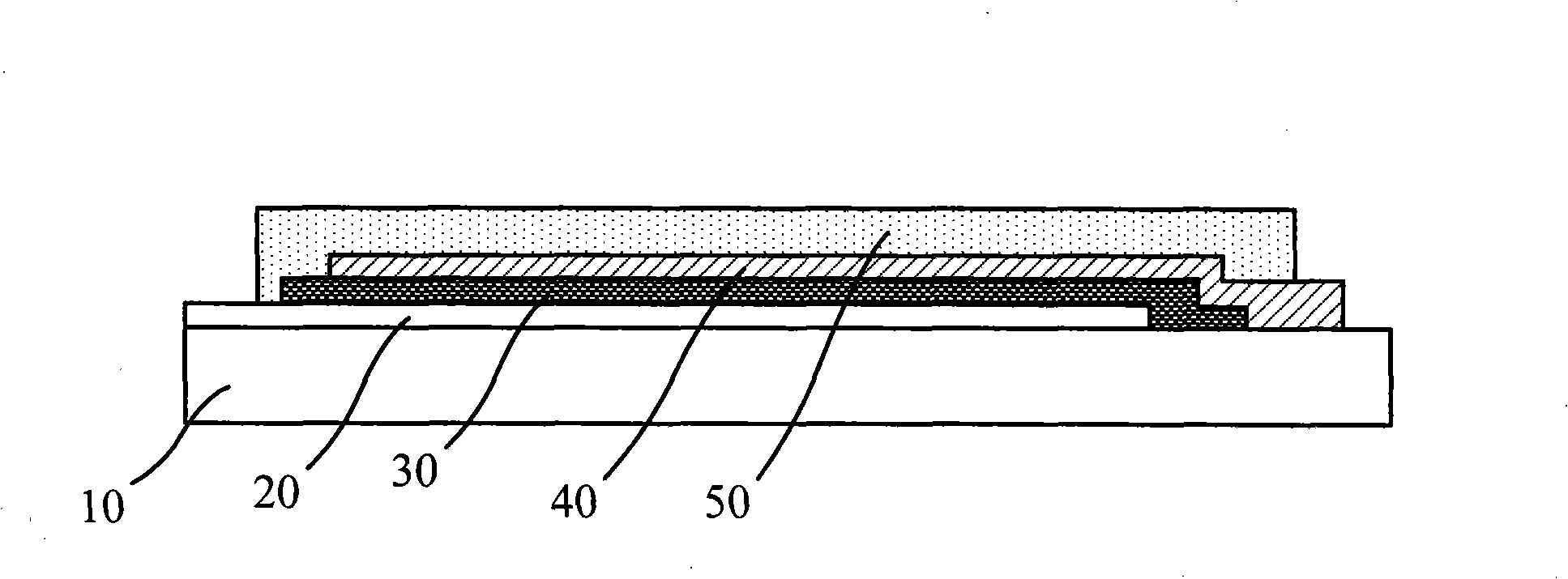

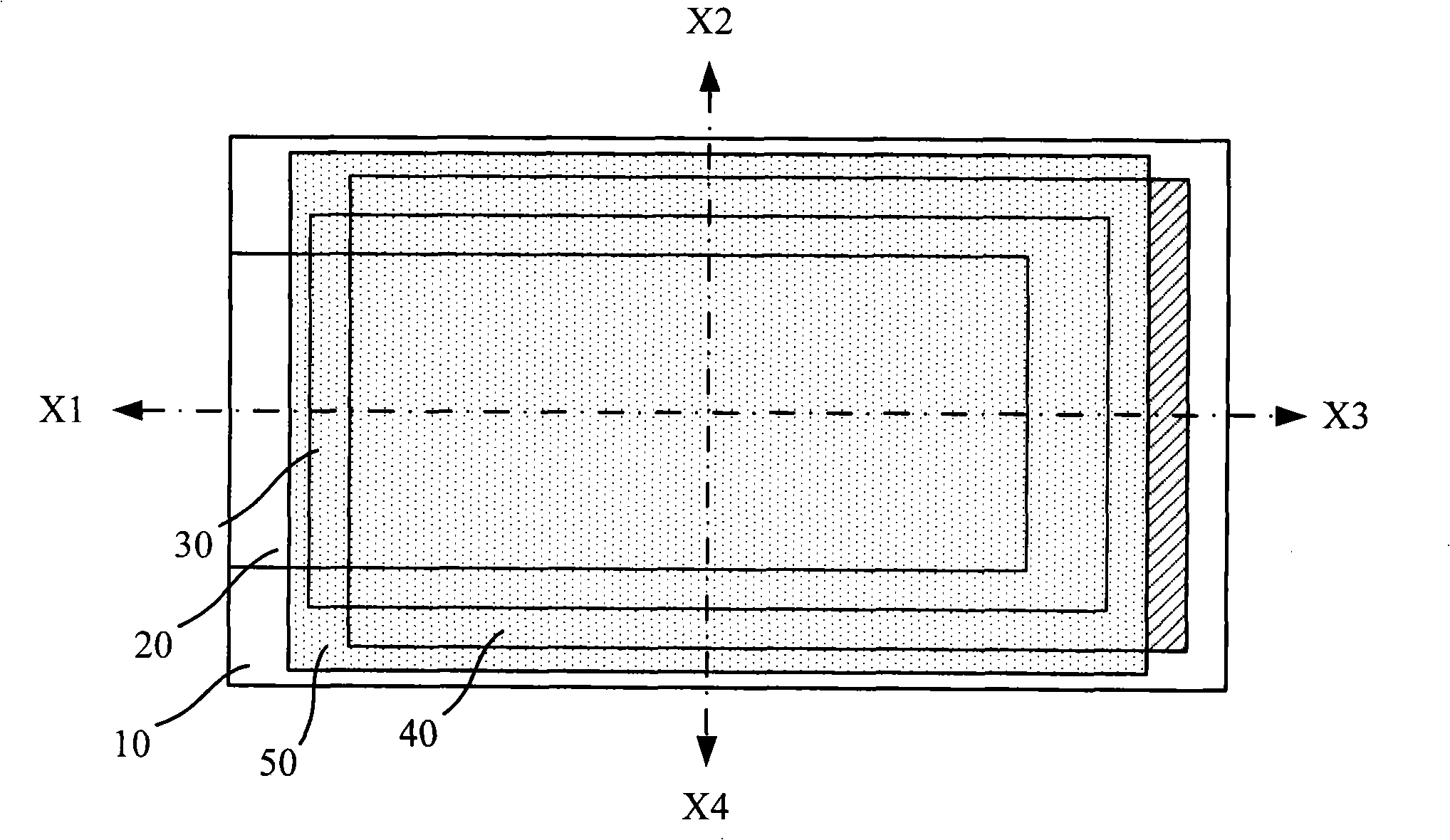

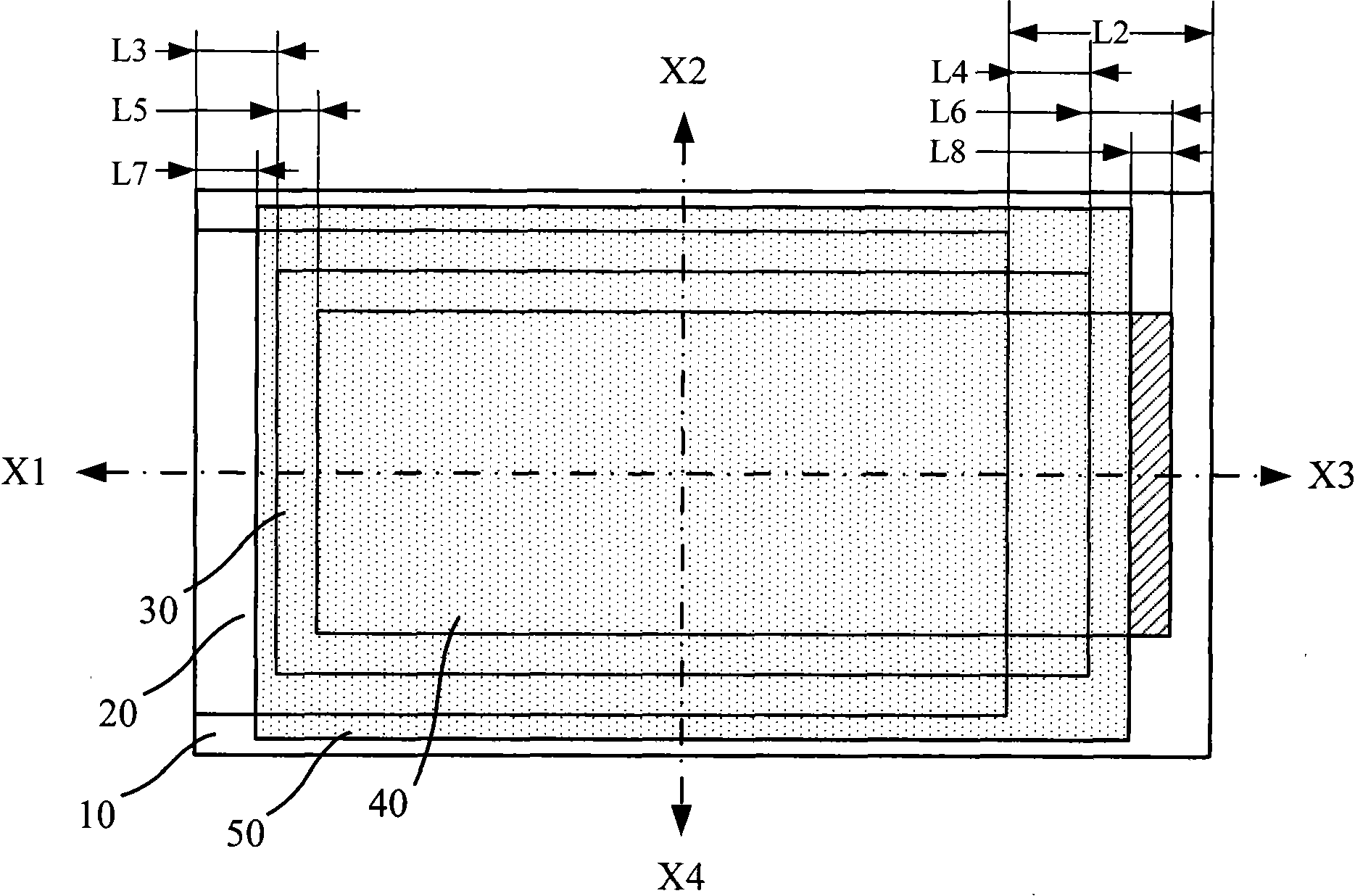

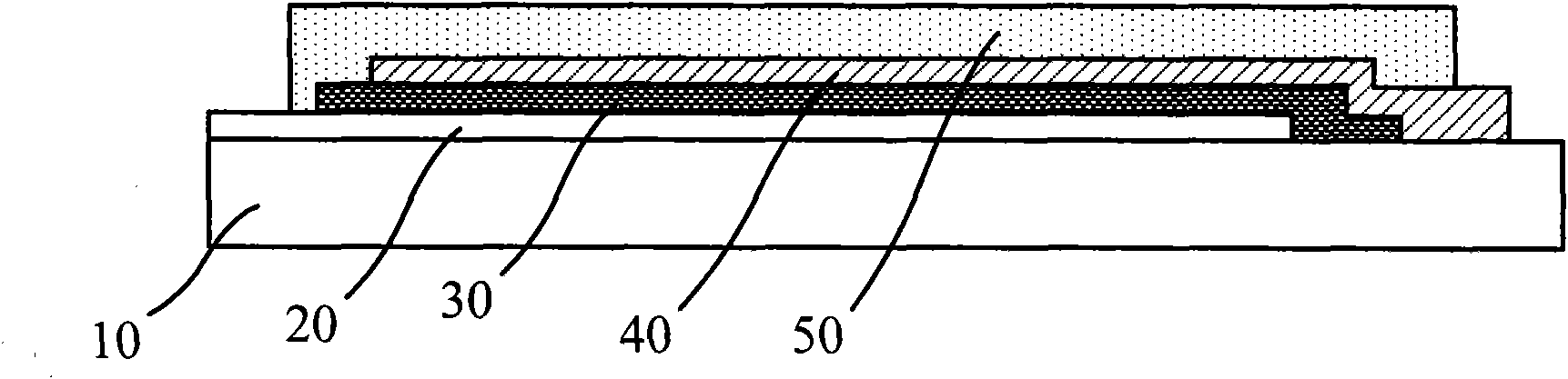

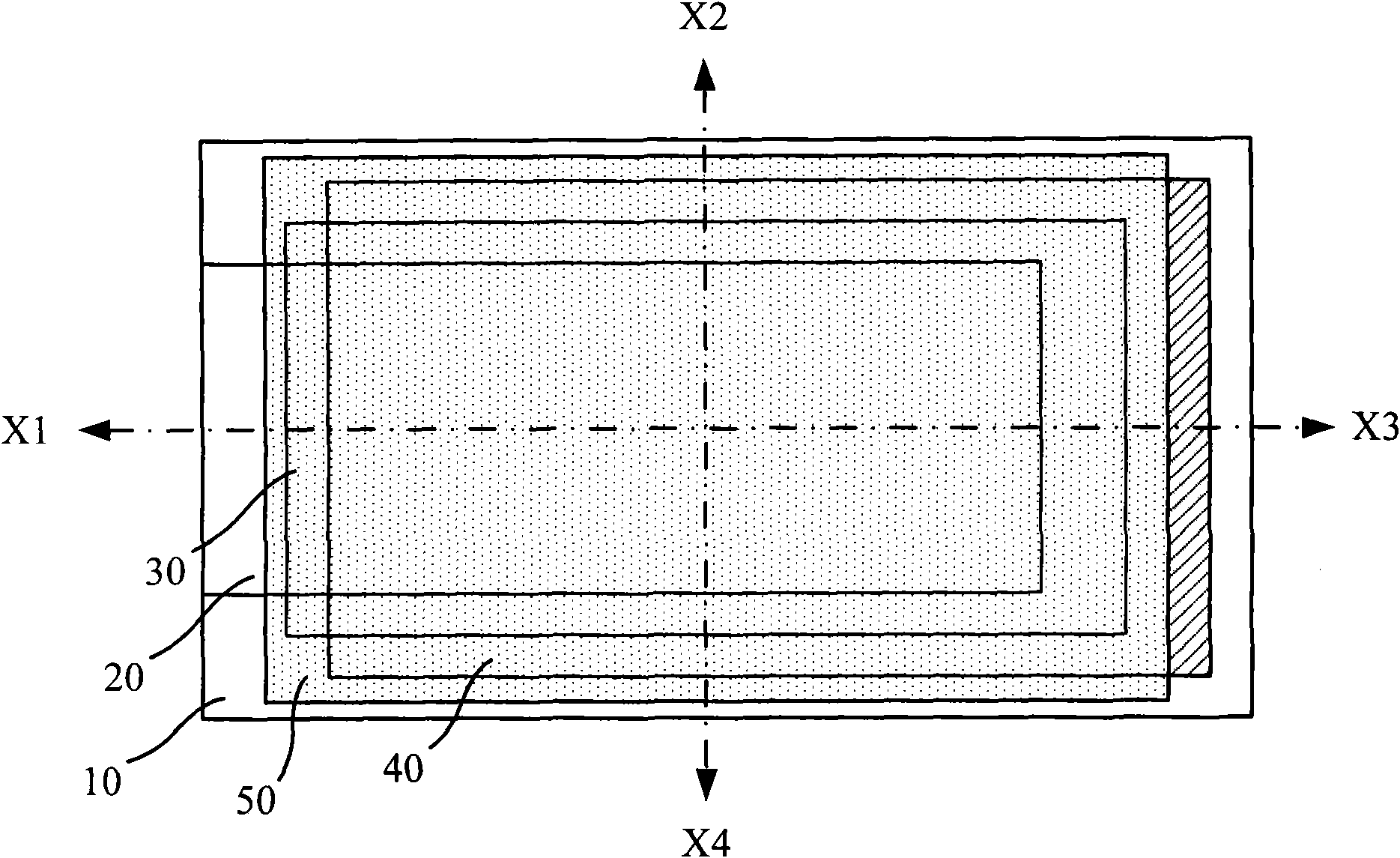

Organic electroluminescence panel and manufacturing method thereof

ActiveCN101771133BOvercoming the technical problem of high structural alignment accuracy requirementsDoes not affect luminositySolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerEngineering

The invention relates to an organic electroluminescence panel and a manufacturing method thereof. The organic electroluminescence panel comprises a base plate, a bottom electrode, an organic layer, a top electrode and a sealing layer, wherein the bottom electrode, the organic layer, the top electrode and the sealing layer are formed on the base plate from bottom to top; the distance between the edges of the bottom electrode, the organic layer and the top electrode in at least one direction and the edge of the base plate is increased progressively, and the distance between the edges of the bottom electrode, the organic layer and the top electrode in at least the other direction and the edge of the base plate is decreased progressively; the part of the top electrode overlapped above the bottom electrode is formed in the range of the organic layer; the sealing layer is covered on the bottom electrode, the organic layer and the top electrode, and at least part of the bottom electrode is exposed out in the distance-increased direction; and at least part of the top electrode is exposed out in the distance-decreased direction. The invention adopts a technical means that each layer structure on the organic electroluminescence panel relatively offsets for a certain distance, and can reduce the requirement of alignment accuracy. Accordingly, the invention can simplify equipment and process, can reduce cost, and can increase manufacturing speed and yield.

Owner:BOE TECH GRP CO LTD

A kind of nitrogen oxide phosphor with antistatic function and its preparation method and light-emitting device

ActiveCN105969356BImprove anti-static effectImproved anti-static propertiesLuminescent compositionsSemiconductor devicesPhosphorNitrogen oxide

The invention relates to a nitrogen oxide fluorophor with the anti-static function. The nitrogen oxide fluorophor is characterized by comprising an inorganic compound with the anti-static function, wherein the inorganic compound comprises an anti-static material, a matrix material and a light-emitting material, elements of the matrix material and elements of the light-emitting material are subjected to solid solution to form a precursor midbody of the nitrogen oxide fluorophor, and the surface of the precursor midbody of the Nitrogen oxide fluorophor and the elements of the anti-static material are subjected to solid solution to form the final nitrogen oxide fluorophor. The nitrogen oxide fluorophor has the high anti-static effect, is good in chemical stability and applicable to various light-emitting devices. The preparation method adopts dual technologies and a two-stage method, and is simple, reliable and applicable to industrial batch production and manufacturing.

Owner:JIANGSU BREE OPTRONICS CO LTD

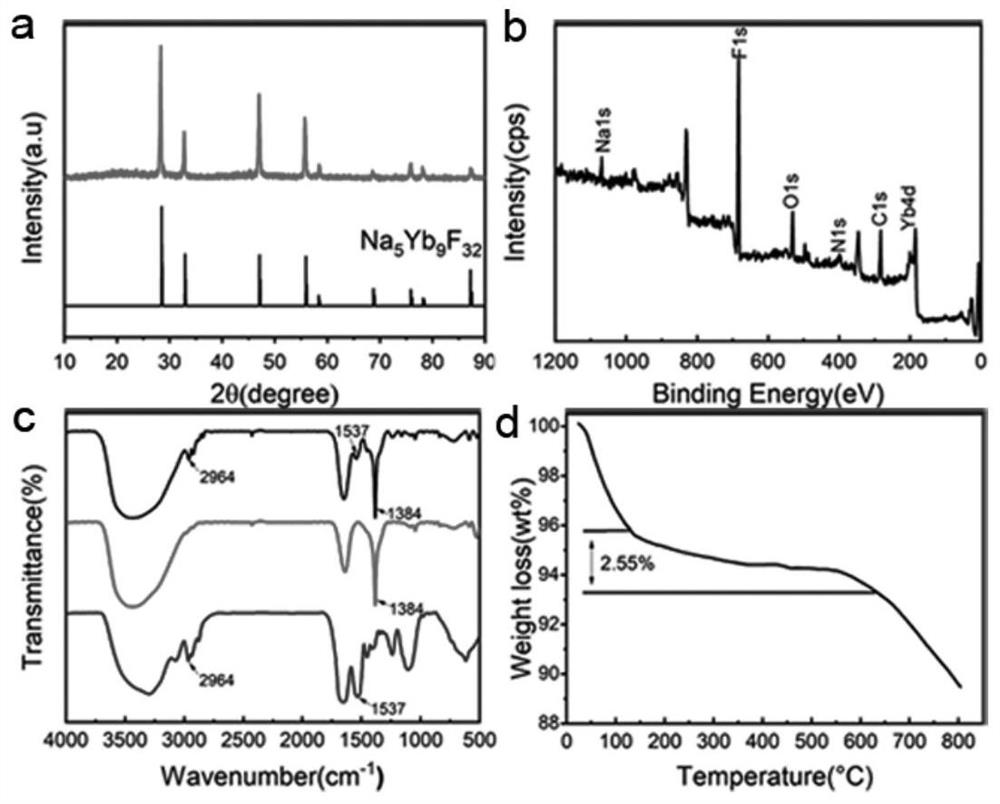

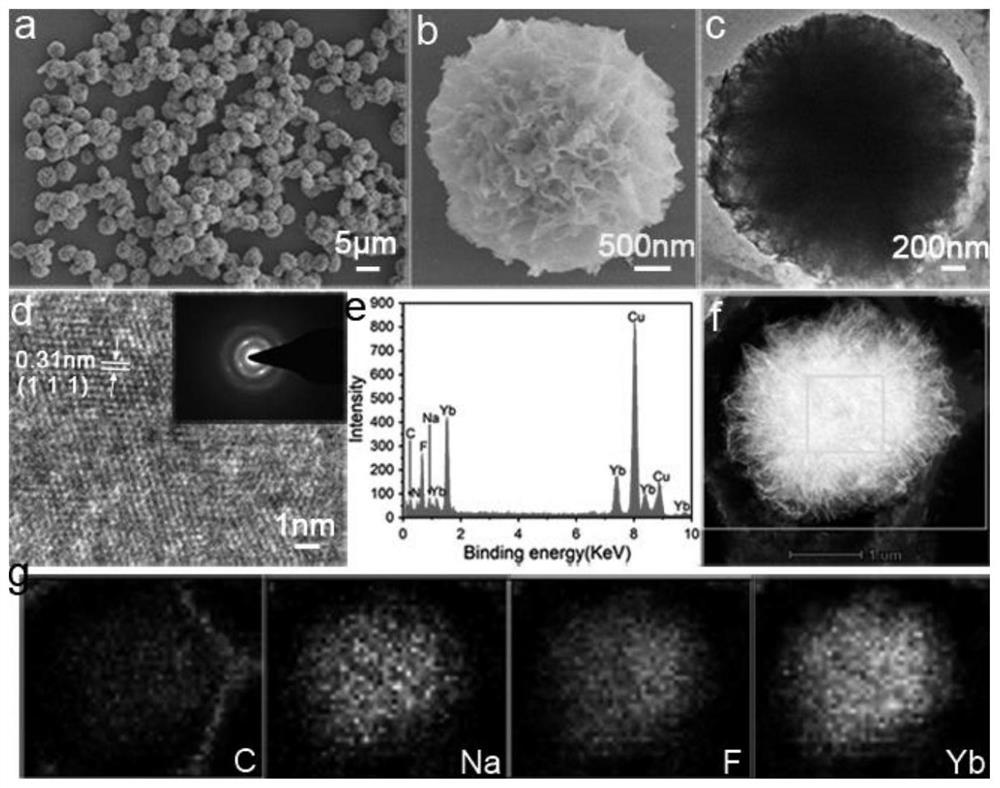

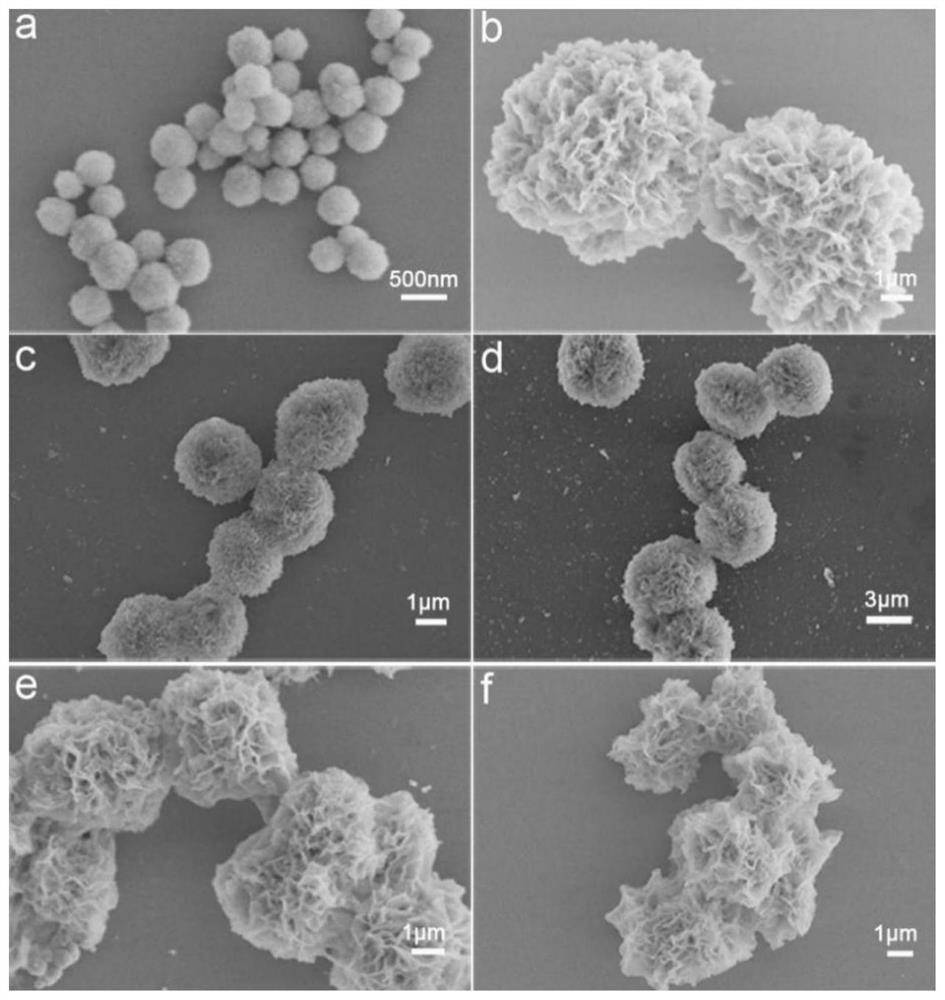

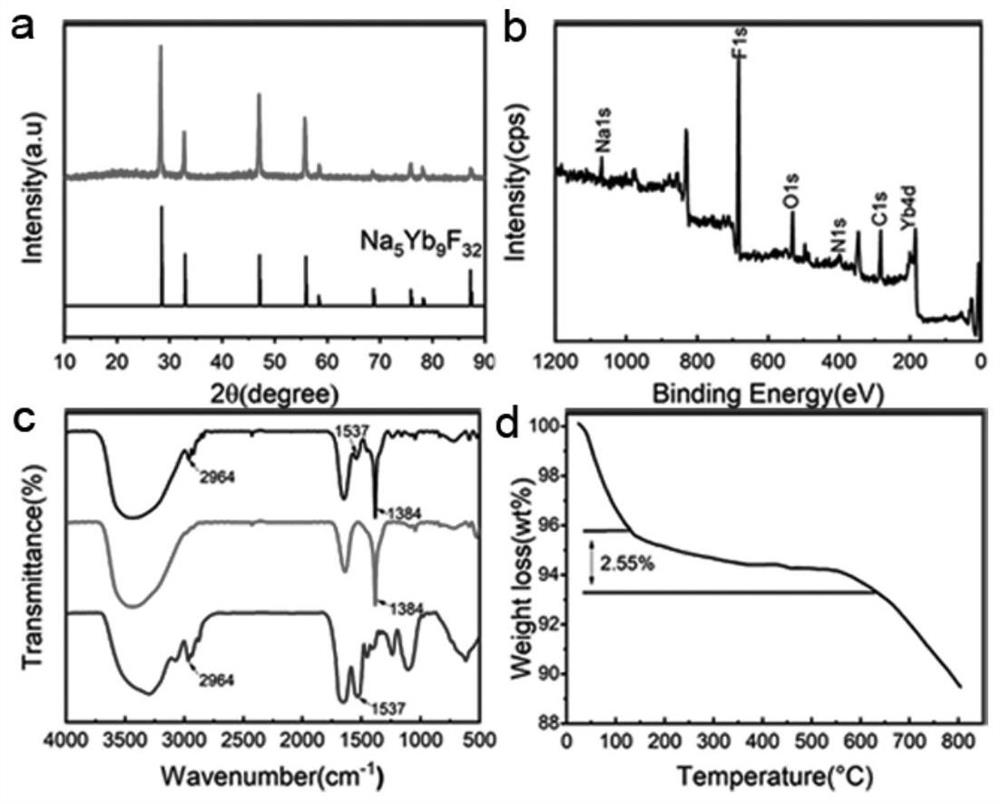

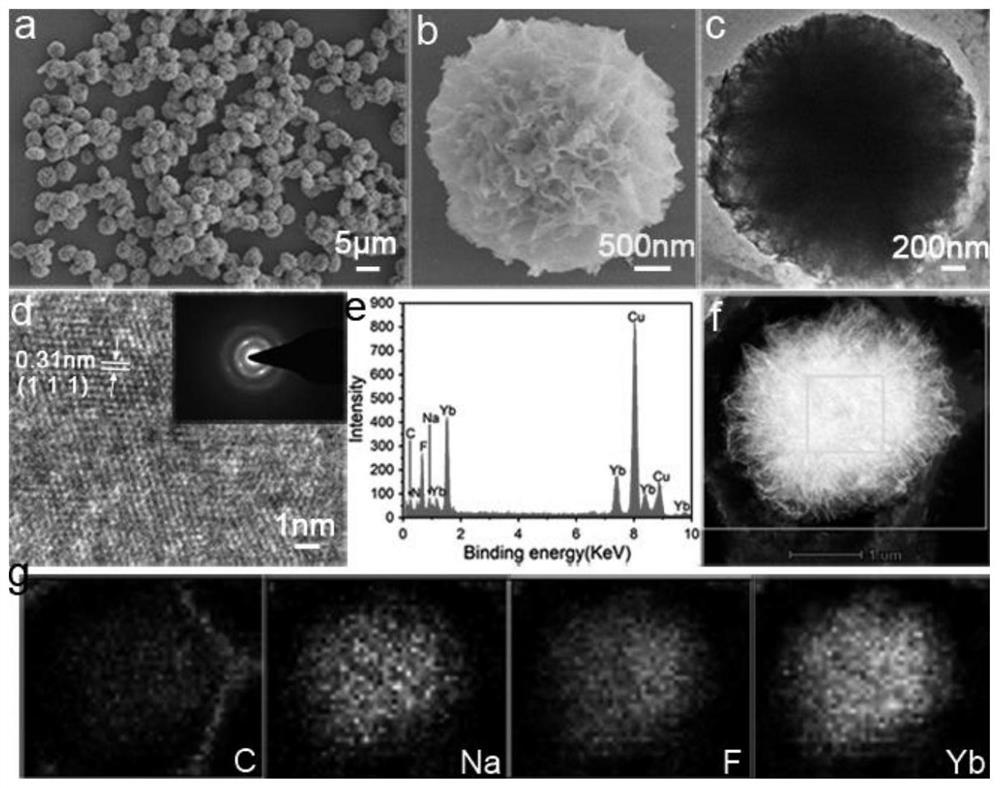

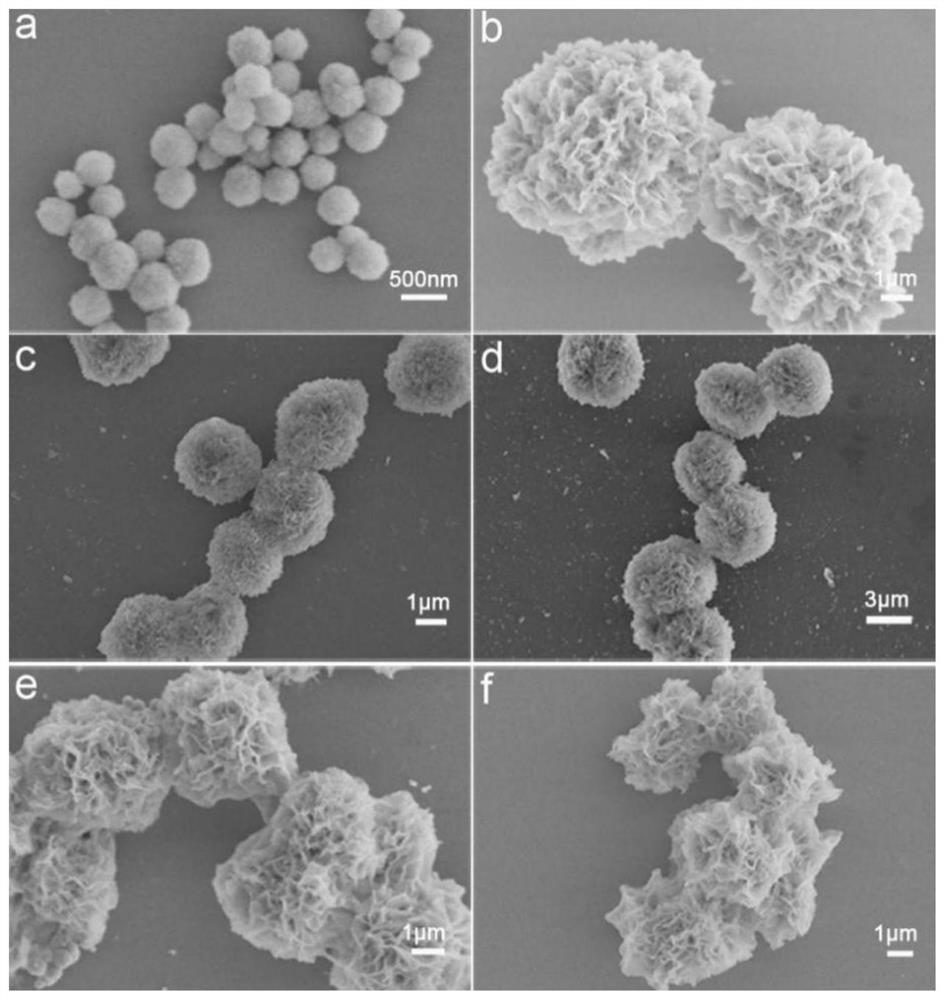

Rare earth fluoride hybrid nanoflower and preparation method thereof

ActiveCN112552914AEasy to prepareMild conditionsCarrier-bound/immobilised peptidesOn/in organic carrierLanthanidePhysical chemistry

The invention belongs to the technical field of nano materials, and particularly relates to a rare earth fluoride hybrid nanoflower and a preparation method thereof. According to the method, protein is used as a mineralization template, and rare earth fluoride is used as an inorganic component. Compared with the prior art, synthesis of the protein-rare earth fluoride hybrid nanoflower can be achieved under the low-temperature condition, and the method is mild in reaction condition, environmentally friendly and low in energy consumption; the prepared hybrid nanoflower has a high specific surface area, and on the basis that the stability and activity of protein are guaranteed to the maximum extent, the unique luminescence characteristic of lanthanide series metal is added; the method has a good protein immobilization effect, and the luminescence property of the original lanthanide series metal is not influenced; and the prepared nanoflower is doped with different types of lanthanide ions, and has a huge application potential in the aspects of biosensing, biocatalysis and medical diagnosis and treatment.

Owner:LANZHOU UNIVERSITY

A rare earth fluoride hybrid nanoflower and its preparation method

ActiveCN112552914BEasy to prepareMild conditionsCarrier-bound/immobilised peptidesOn/in organic carrierMedicineLanthanide

The invention belongs to the technical field of nanometer materials, and in particular relates to a rare earth fluoride hybrid nanoflower and a preparation method thereof. The present invention uses protein as a mineralization template and rare earth fluoride as an inorganic component. Compared with the prior art, the synthesis of protein-rare earth fluoride hybrid nanoflowers can be realized under low temperature conditions. The method has mild reaction conditions and is green. Environmental protection, low energy consumption; the prepared hybrid nanoflowers have a high specific surface area, and on the basis of ensuring the stability and activity of the protein to the greatest extent, the unique luminescence characteristics of lanthanide metals are added; the immobilization effect of this method on the protein It is good and will not affect the luminescent properties of the original lanthanide metals; the prepared nanoflowers are doped with different kinds of lanthanide ions, and have great application potential in biosensing, biocatalysis, and medical diagnosis and treatment.

Owner:LANZHOU UNIVERSITY

Organic electroluminescence panel and manufacturing method thereof

ActiveCN101771133AOvercoming the technical problem of high structural alignment accuracy requirementsDoes not affect luminositySolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerEngineering

The invention relates to an organic electroluminescence panel and a manufacturing method thereof. The organic electroluminescence panel comprises a base plate, a bottom electrode, an organic layer, a top electrode and a sealing layer, wherein the bottom electrode, the organic layer, the top electrode and the sealing layer are formed on the base plate from bottom to top; the distance between the edges of the bottom electrode, the organic layer and the top electrode in at least one direction and the edge of the base plate is increased progressively, and the distance between the edges of the bottom electrode, the organic layer and the top electrode in at least the other direction and the edge of the base plate is decreased progressively; the part of the top electrode overlapped above the bottom electrode is formed in the range of the organic layer; the sealing layer is covered on the bottom electrode, the organic layer and the top electrode, and at least part of the bottom electrode is exposed out in the distance-increased direction; and at least part of the top electrode is exposed out in the distance-decreased direction. The invention adopts a technical means that each layer structure on the organic electroluminescence panel relatively offsets for a certain distance, and can reduce the requirement of alignment accuracy. Accordingly, the invention can simplify equipment and process, can reduce cost, and can increase manufacturing speed and yield.

Owner:BOE TECH GRP CO LTD

Light emitting diode and preparation method thereof

ActiveCN113130783AImprove luminous performanceWith plasmon resonance effectSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeNanoparticle

The invention belongs to the technical field of display, and particularly relates to a light-emitting diode and a preparation method thereof. The light-emitting diode provided by the invention comprises an anode, a cathode, a light-emitting layer arranged between the anode and the cathode, and a transition layer arranged between the cathode and the light-emitting layer, wherein the transition layer is made of noble metal nanoparticles and a metal organic framework material, the metal organic framework material has a pore channel structure, and the noble metal nanoparticles are loaded in the pore channel structure. According to the invention, the problem that the electron transmission rate and the hole transmission rate of an existing light-emitting diode are unbalanced is solved, and the light-emitting performance of the light-emitting diode is improved.

Owner:TCL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com