Long persistence phosphor of alkali earth aluminate for SiO2 glass painting and its prepn. method thereof

A long afterglow phosphor, alkaline earth aluminate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

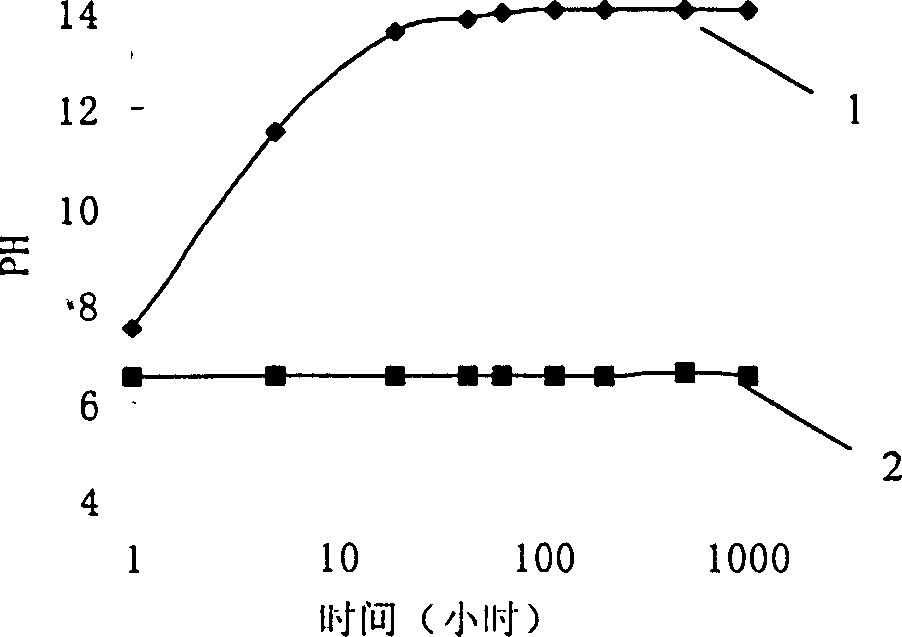

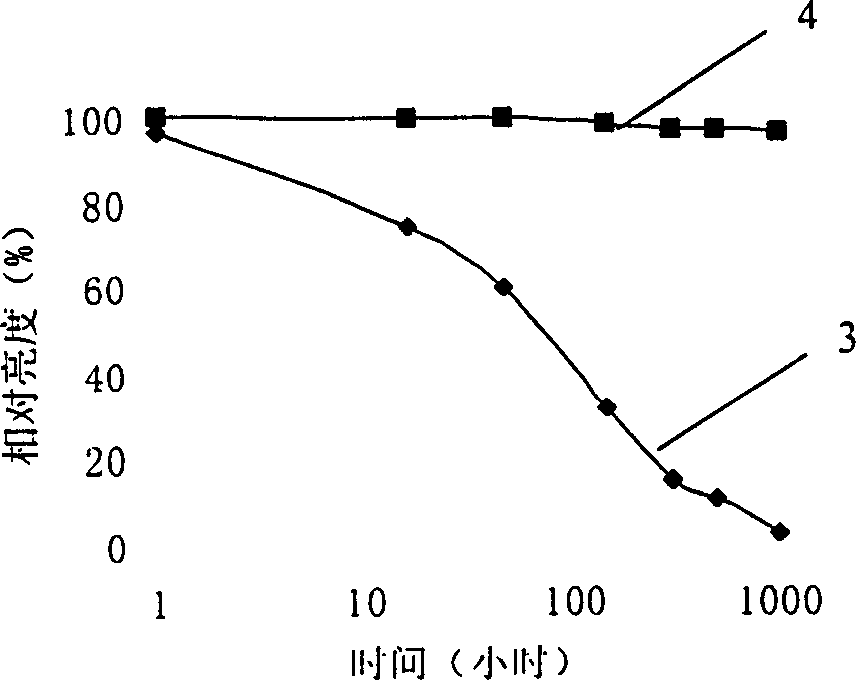

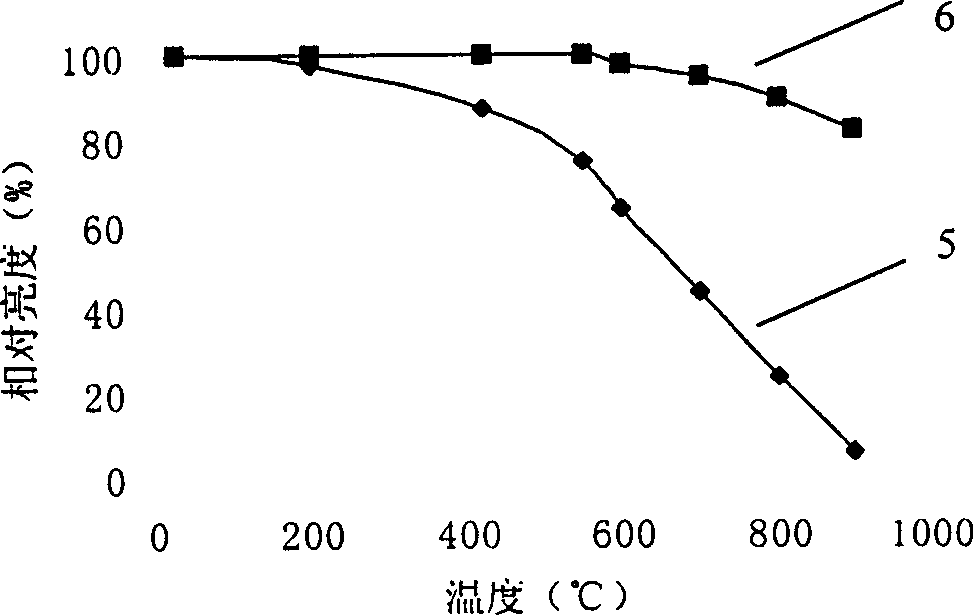

[0060] 10g ethyl orthosilicate, 5gH 2 O, 76gC 2 h 5 OH and 0.2g HCl were mixed, and ethyl orthosilicate was added under the condition of stirring, and the stirring was continued for 15 minutes to become a uniform transparent solution, which was aged at 40°C for 72 hours. Take 46g strontium aluminate long afterglow phosphor (emission main peak 520nm, particle size d 50 35 μ) was mixed with the above transparent solution and stirred for 15 minutes, filtered and dried naturally. Then heat treatment at 350°C for 30 minutes to obtain SiO 2 5% coating with SiO 2 Glass coated alkaline earth strontium aluminate long persistence phosphor. They were then soaked in water and heated at 500°C-900°C for 30 minutes to observe their pH and relative brightness. Such as figure 1 , figure 2 and image 3 As shown, the results show that the pH is 6.5 after soaking in the aqueous solution for more than 1000 hours, and the relative luminous brightness is 100%. The relative luminance after...

Embodiment 2

[0062] 10g ethyl orthosilicate, 7gH 2 O, 76g C 2 h 5 OH, 0.1gCH 3 COOH was mixed, and ethyl orthosilicate was added under the condition of stirring, and the stirring was continued for 15 minutes to become a uniform transparent solution, which was aged at 50° C. for 48 hours. Take 30g of commercial calcium aluminate long afterglow phosphor (emission main peak 420nm, particle size d 50 40μ) mixed with the above transparent solution for 15 minutes, filtered, dried naturally, and then heat-treated at 320°C for 30 minutes to obtain SiO 2 10% coating with SiO 2 Glass coated alkaline earth calcium aluminate long persistence phosphor. They were then soaked in water and heated at 500°C-900°C for 30 minutes to observe their pH and relative brightness. Such as Figure 4 , Figure 5 and Figure 6As shown, the results are shown as follows: the pH is 7.0 after soaking in the aqueous solution for more than 1000 hours, and the relative luminous brightness is 100%. The relative lumin...

Embodiment 3

[0064] Using the same method as in Example 1, and with 0.1g H 2 SO 4 Instead of HCl, the results are as follows: the pH is 6.5 after soaking in the aqueous solution for more than 1000 hours, and the relative luminance is 100%. The relative luminance after heat treatment at 900°C is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com