Firefighting guide illumination line

A lighting line and fire-fighting technology, applied to lighting devices, light sources, electrical components, etc., can solve problems such as high power consumption, inability to be operated independently by a single person, and easy heating during work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

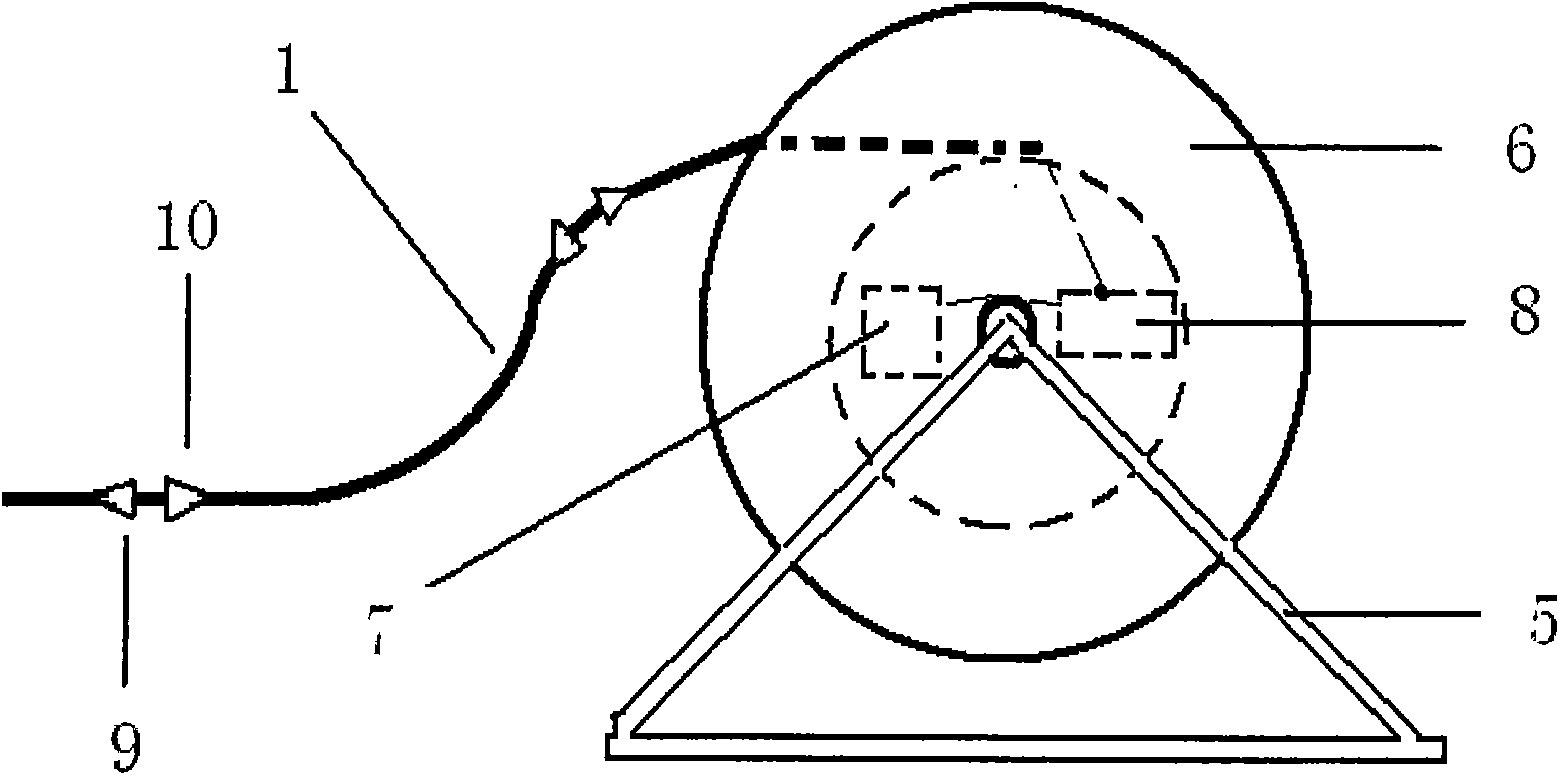

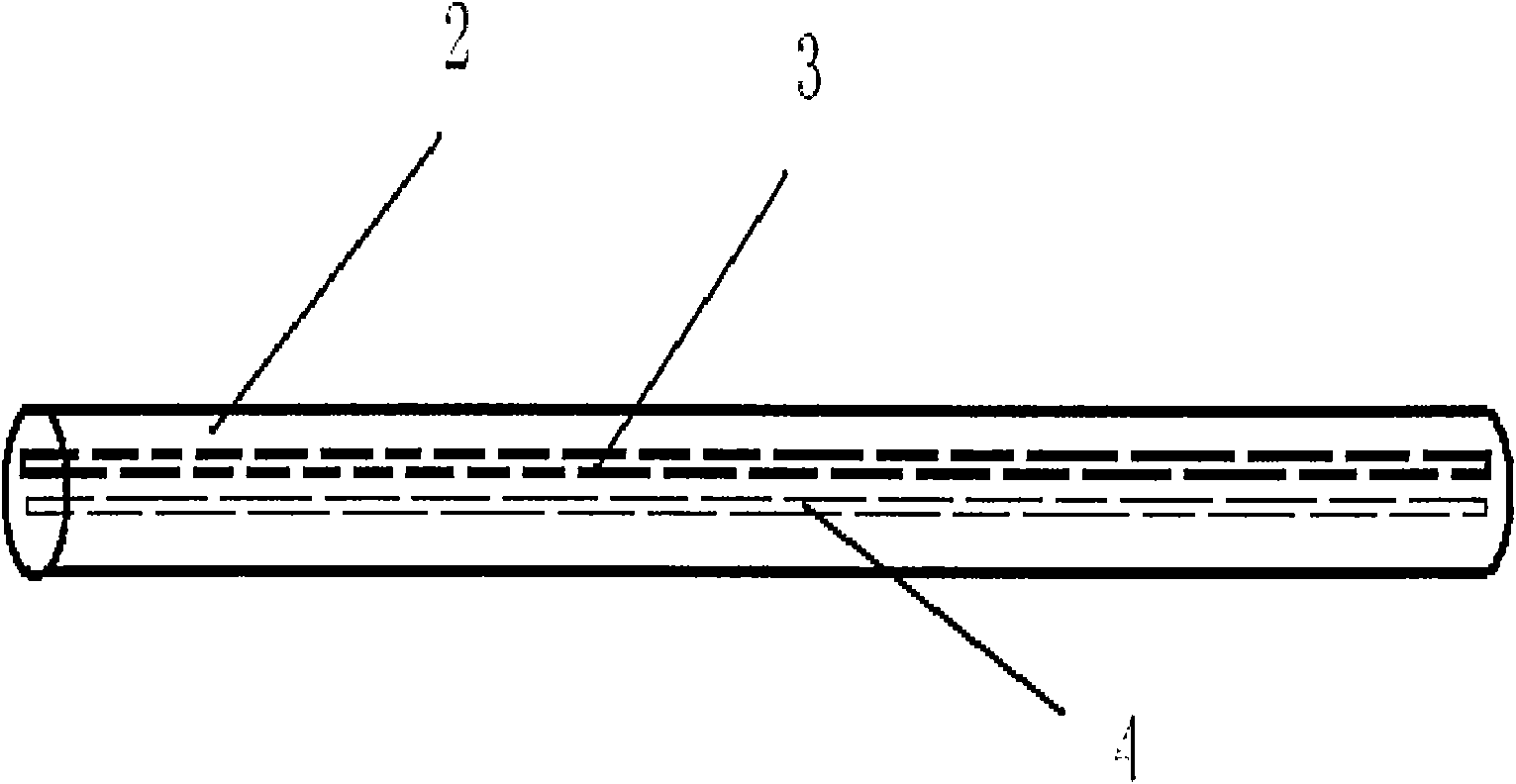

[0028] A powerful electroluminescent wire (1) with a length of 100 meters that continuously emits light. The outside of the powerful electroluminescent wire is a PVC colorless transparent plastic layer (2), and the inside of the powerful electroluminescent wire is an electroluminescent wire that emits blue-green light The core (3) and the flexible long afterglow luminous steel wire rope (4) parallel to it; the strong electroluminescent wire is made by using a wire extruder. The powerful electroluminescent wire is wound on a rotatable iron wire reel (6) with an iron bracket (5). The rechargeable battery (7) and drive controller (8) are arranged in the center of the wire reel, and are connected with the electroluminescent wire One end of the core is connected in series, the light-emitting line can emit light continuously when the power is turned on, and the light-emitting line can be retracted and released at will by using the wire reel wheel.

[0029] The surface of the PVC tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com