Water-based acrylic fluorescent coating and preparation method thereof

A technology of water-based acrylic and fluorescent coatings, applied in the field of coatings, can solve problems such as complex synthesis process, environmental pollution, uneven luminescence, etc., and achieve the effects of good optical transparency, convenient process adjustment, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A water-based acrylic fluorescent paint, which is prepared by the following steps:

[0052] 1. Modified phosphor powder coated with silica.

[0053] Weigh one part of tetraethyl orthosilicate, dissolve it in 1.5 parts of ethanol and 3 parts of water, adjust the pH value to 3~4 with hydrochloric acid, heat and stir at 40°C for 30 minutes to form a transparent sol, mix 2 parts of fluorescent powder Immerse in the sol, stir at 50°C for 60 minutes, adjust the pH value to 6-7 with ammonia water, wait for complete gelation, place in an oven at 100°C for drying, calcinate at 400°C for 4 hours, cool and grind.

[0054] 2. Preparation of aqueous acrylic fluorescent emulsion.

[0055] Mix 10 parts of absolute ethanol and 60 parts of water, add 6 parts of modified phosphor powder while stirring, and stir for 30 minutes for later use; add 1 / 2 phosphor powder suspension To the turbid liquid, add 0.5-1 part of NaHCO3 and 0.4-0.5 part of sodium lauryl sulfate, stir mechanically for ...

Embodiment 2

[0061] A water-based acrylic fluorescent paint, which is prepared by the following steps:

[0062] 1. Modified phosphor powder coated with silica.

[0063] With embodiment 1.

[0064] 2. Preparation of aqueous acrylic fluorescent emulsion.

[0065] In the steps of Example 1, the phosphor suspension was added all at once at the beginning, instead of being divided into two parts.

[0066] 3. Preparation of fluorescent paint.

[0067] With embodiment 1.

[0068] In this embodiment, the fluorescent powder suspension in step 2 is added in one step.

Embodiment 3

[0070] A kind of acrylic fluorescent paint, it adopts the following steps to prepare:

[0071] 1. Modified phosphor powder coated with silica.

[0072] Weigh one part of tetraethyl orthosilicate, dissolve it in 1.5 parts of ethanol and 3 parts of water, adjust the pH value to 3~4 with hydrochloric acid, heat and stir at 40°C for 30 minutes to form a transparent sol, mix 2 parts of fluorescent powder Immerse in the sol, stir at 50°C for 60 minutes, adjust the pH value to 6-7 with ammonia water, wait for complete gelation, place in an oven at 100°C for drying, calcinate at 400°C for 4 hours, cool and grind.

[0073] 2. Preparation of aqueous acrylic fluorescent emulsion.

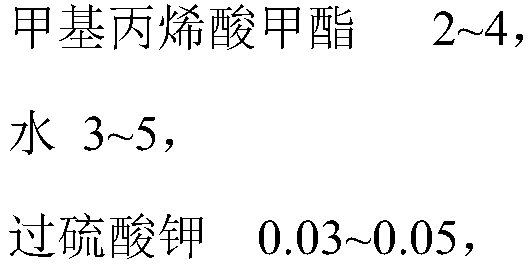

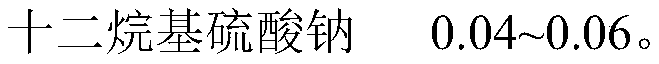

[0074] Add pre-emulsified emulsion A (3 parts of methyl methacrylate, 4 parts of water, 0.04 part of potassium persulfate, 0.05 part of sodium lauryl sulfate) in a three-necked flask equipped with stirring, condensing reflux tube and thermometer, After reacting for half an hour, the temperature was raised to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com