A kind of nitrogen oxide phosphor with antistatic function and its preparation method and light-emitting device

A nitrogen oxide and anti-static technology, applied in the field of nitrogen oxide phosphors and their preparation, can solve problems such as defects and reduce luminous performance, and achieve the effects of improved anti-static performance, high luminous efficiency, and high-efficiency luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

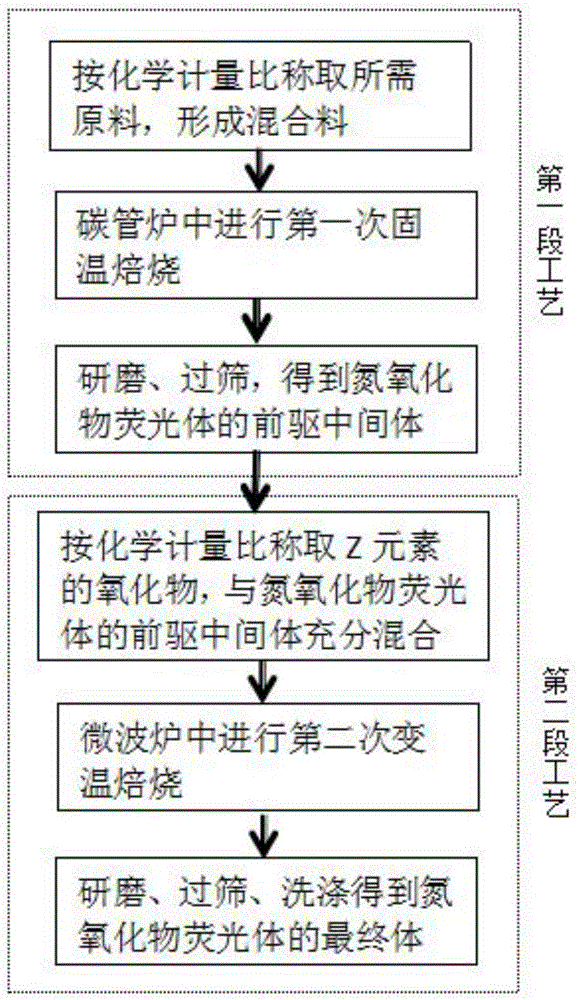

Method used

Image

Examples

Embodiment 1

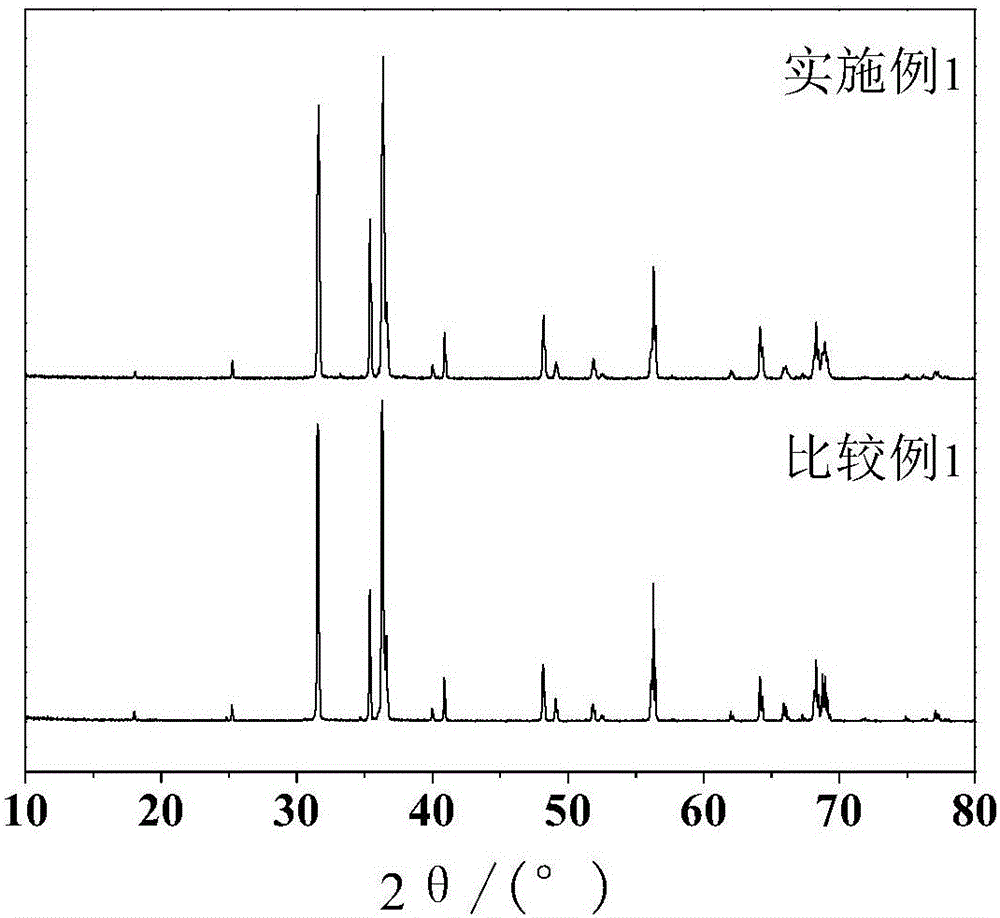

[0038] Weigh 49.37g of Ca 3 N 2 , 40.98g of AlN, 46.76g of Si 3 N 4 , 0.176g of Eu 2 o 3 , the above raw materials were fully mixed in a nitrogen atmosphere for 3 hours, put into a molybdenum crucible, and then quickly moved into a carbon tube furnace, and then gradually heated up to 1780°C under the protection of a nitrogen atmosphere, kept for 12 hours, and then naturally cooled to room temperature. Grinding and sieving to obtain the precursor intermediate of the nitrogen oxide phosphor. Weigh 0.004g of SeO 2 Fully mixed with the precursor intermediate of the above-mentioned phosphor, and then placed in a nitrogen-filled microwave oven for the second temperature-variable roasting, wherein: the first-stage roasting temperature is 1300 ° C, and the roasting time is 1 hour; the second-stage roasting temperature is 1450 ° C, roasting After 3 hours, the temperature was naturally lowered to room temperature, and then crushed, washed, dried, and sieved to obtain the final bod...

Embodiment 2

[0044] Weigh 39.53g of Ca 3 N 2 , 9.46g of Sr 3 N 2 , 32.79g of AlN, 55.65g of Si 3 N 4 , 17.59g of Eu 2 o 3 , the above raw materials were fully mixed in a nitrogen atmosphere for 3 hours, put into a molybdenum crucible, and then quickly moved into a carbon tube furnace, and then gradually heated up to 1700°C under the protection of a nitrogen atmosphere, kept for 24 hours, and then naturally cooled to room temperature. Grinding and sieving to obtain the precursor intermediate of the nitrogen oxide phosphor. Weigh 1.11g of SeO 2 Fully mixed with the precursor intermediate of the above-mentioned phosphor, and then placed in a nitrogen-filled microwave oven for the second variable-temperature roasting, wherein: the first-stage roasting temperature is 1300°C, and the roasting time is 0.5 hours; the second-stage roasting temperature is 1500°C, and the roasting time is The time is 0.5 hours, and then the temperature is lowered to room temperature, and the final body of nit...

Embodiment 3

[0050] Weigh 4.94g of Ca 3 N 2 , 75.7g of Sr 3 N 2 , 7.33g of Ba 3 N 2 , 49.18g of AlN, 36.47g of Si 3 N 4 , 8.8g of Eu 2 o 3 , the above raw materials were fully mixed in a nitrogen atmosphere for 3 hours, put into a molybdenum crucible, and then quickly moved into a carbon tube furnace, and then gradually heated up to 1900 °C under the protection of a nitrogen atmosphere, kept for 1 hour, and then naturally cooled to room temperature. Grinding and sieving to obtain the precursor intermediate of the nitrogen oxide phosphor. Weigh 2.22g of SeO 2 Fully mixed with the precursor intermediate of the above-mentioned phosphor, and then placed in a nitrogen-filled microwave oven for the second variable-temperature roasting, wherein: the first-stage roasting temperature is 1200°C, and the roasting time is 5 hours; the second-stage roasting temperature is 1400°C, and the roasting time is After 3 hours, the temperature was lowered to room temperature, crushed, washed, dried, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com