Organic electroluminescence panel and manufacturing method thereof

A technology for electroluminescent panels and electroluminescent devices, which is applied in the manufacture of semiconductor/solid-state devices, circuits, electrical components, etc., can solve the problems of slow production speed, high process requirements, high production costs, etc. Overcome the effect of high requirements on alignment accuracy and simplify equipment and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

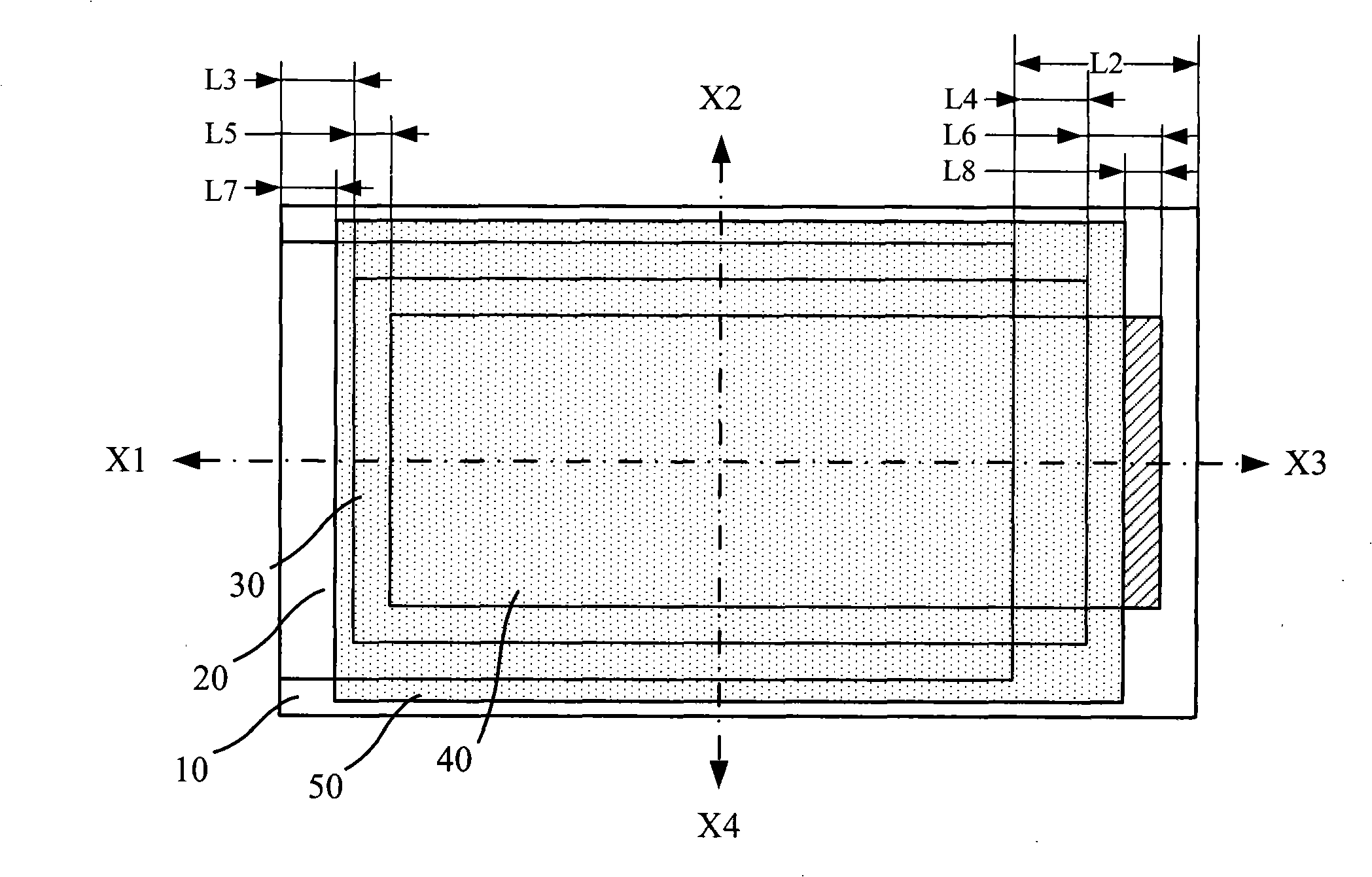

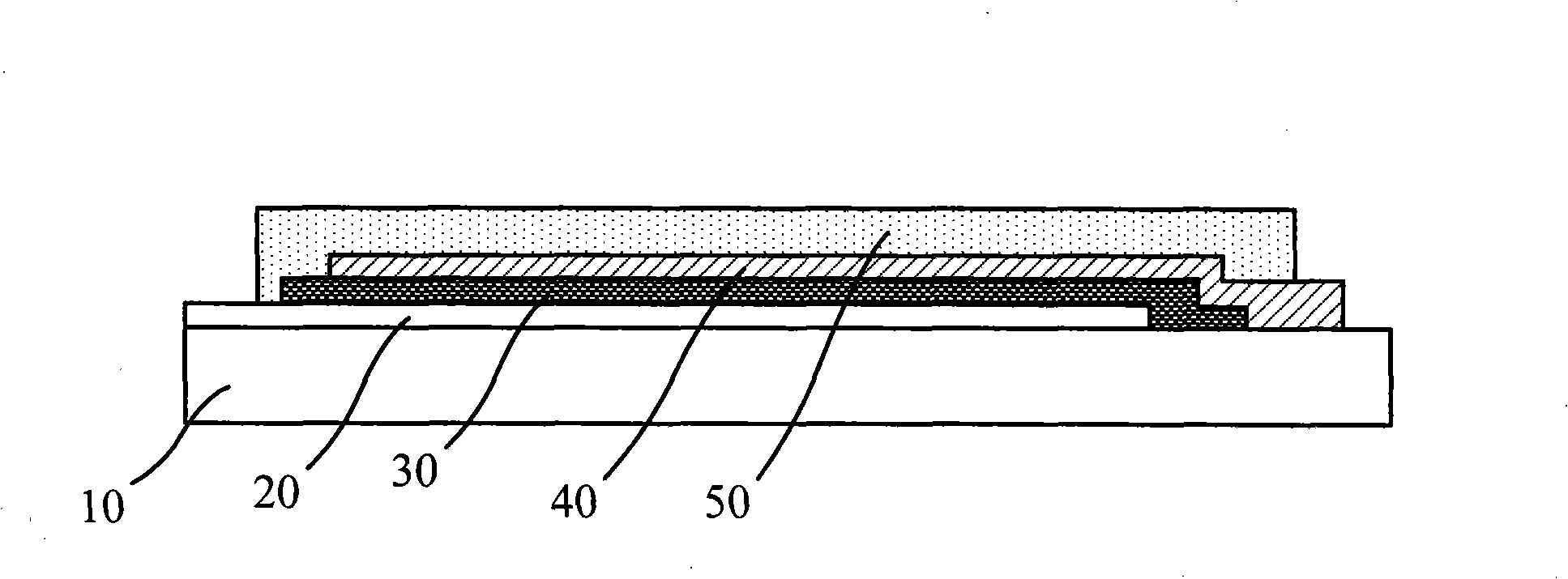

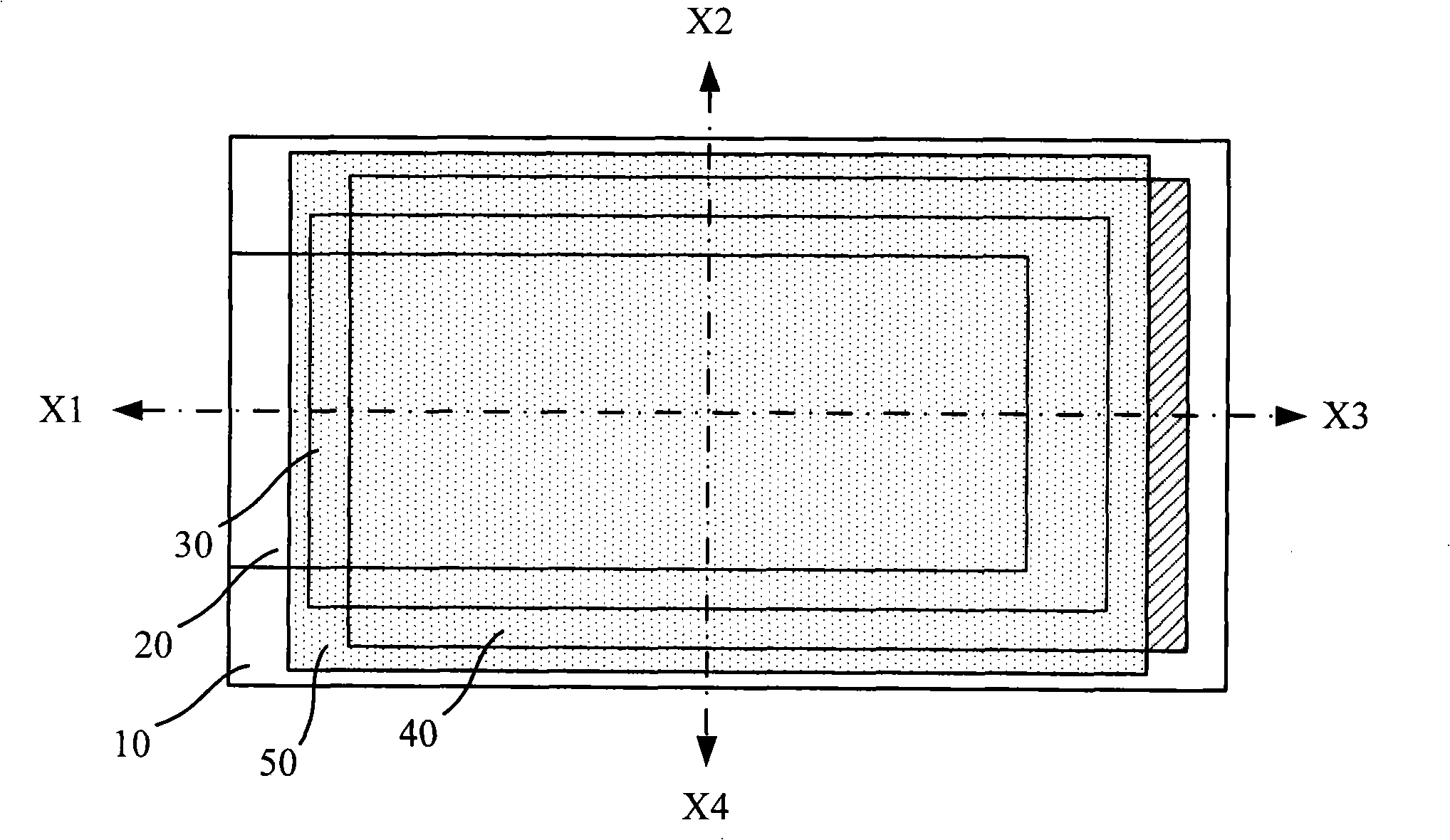

[0036] figure 1 It is a schematic top view structure diagram of the first embodiment of the organic electroluminescent panel of the present invention, figure 2 It is a side-view structure diagram of the first embodiment of the organic electroluminescence panel of the present invention. Such as figure 1 As shown, the organic electroluminescence panel mainly includes a substrate 10 , and a bottom electrode 20 , an organic layer 30 , a top electrode 40 and a sealing layer 50 are sequentially formed on the substrate 10 from bottom to top. For the sake of clarity of description, in the plane where the substrate 10 is located, it is considered that there are four directions respectively facing both ends of the horizontal axis and the vertical axis, that is, the first direction X1, the second direction X2, the third direction X3 and the fourth direction X4. In the example, the first direction X1 and the third direction X3 are respectively towards the two ends of the horizontal a...

no. 4 example

[0058] Figure 5 It is a top view structure schematic diagram of the fourth embodiment of the organic electroluminescence panel of the present invention. In this embodiment, the bottom electrode 20, the organic layer 30, the top electrode 40 and the sealing layer 50 stacked on the substrate 10 can be used as an organic electroluminescent device unit, and the substrate 10 corresponding to each organic electroluminescent device unit can be seen As a unit on the whole substrate 10, the setting of its edge is set according to the alignment requirements, then a plurality of organic electroluminescent device units can be formed in parallel on the whole substrate 10, such as Figure 5 shown.

[0059] It is also possible to form organic electroluminescent device units in series alone, or in combination of series and parallel. This embodiment is especially suitable for continuous production of organic electroluminescent panels in batches using a roll-to-roll manufacturing process, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com