Method for manufacturing distributed feedback laser device array by virtue of selection region epitaxy technology

A technology of selective area epitaxy and laser array, applied in the direction of lasers, laser devices, semiconductor lasers, etc., can solve the problems of thickness material quality degradation, effective refractive index change, deviation from gain peak, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

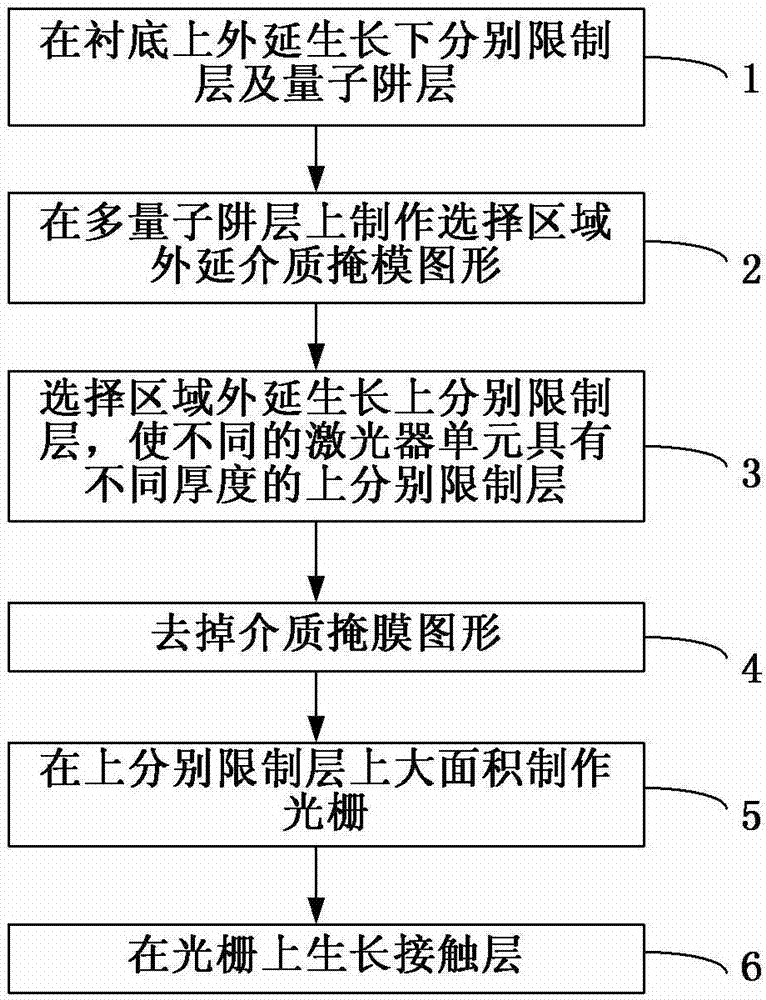

[0031] see figure 1 , image 3 , Figure 5 and Image 6 As shown, the present invention provides a method (first embodiment) for making a distributed feedback laser array using the selective area epitaxy technique, comprising the following steps:

[0032] Step 1: Epitaxially grow the confinement layer 2 and the quantum well layer 3 respectively on the substrate 1. The substrate 1 is a GaAs substrate, InP substrate, GaN substrate, SiC substrate, Si substrate, or other III-V , II-VI group material substrate;

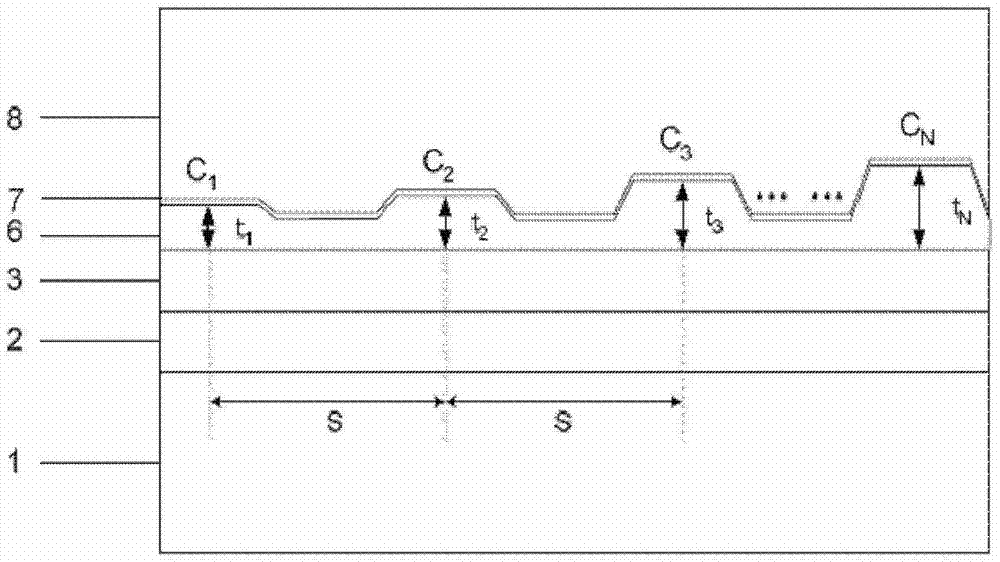

[0033] Step 2: making a selective area epitaxial dielectric mask pattern 4 on the quantum well layer 3 ( Figure 5 ) or 5( Image 6 ). The period of the dielectric mask pair in mask pattern 4 or 5 and the period of the array unit ( image 3 ) are the same, both are S. mask pattern 4 ( Figure 5 ) The distance between the mask pairs remains unchanged, and the mask width gradually increases, that is, the mask M 1 , M 2 , M 3 to M N The width satisfies W 1 2 3 N...

no. 2 example

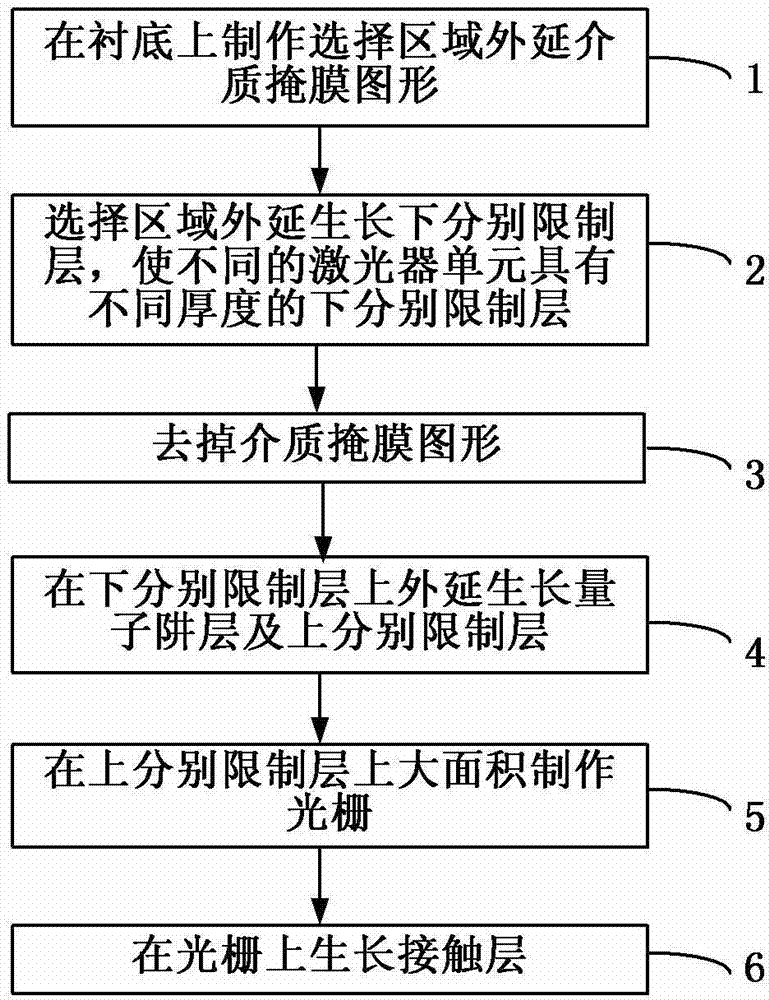

[0038] see again figure 2 , Figure 4 , Figure 5 and Image 6 As shown, the present invention also provides a method (second embodiment) for making a distributed feedback laser array using the selective area epitaxy technique, comprising the following steps:

[0039] Step 1: making a selective area epitaxial dielectric mask pattern 4 on the substrate 1 ( Figure 5 ) or 5( Image 6 ). The substrate 1 is a GaAs substrate, an InP substrate, a GaN substrate, a SiC substrate, a Si substrate, or other III-V, II-VI group material substrates. The period of the dielectric mask pair in mask pattern 4 or 5 and the period of the array unit ( Figure 4 ) are the same, both are S. mask pattern 4 ( Figure 5 ) The distance between the mask pairs remains unchanged, and the mask width gradually increases, that is, the mask M 1 , M 2 , M 3 to M N The width satisfies W 1 2 3 N . mask pattern 5( Image 6 ) in which the mask width remains constant and the mask pair spacing gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com