Graphene photoluminescent substrate and preparation method and application thereof

A technology of photoluminescence and photoluminescent materials, which is applied in the field of graphene photoluminescent substrates and its preparation, can solve problems such as the decline of luminescent performance of photoluminescent materials, the overall design complexity of light-emitting devices, and the overheating of photoluminescent materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention provides the preparation method of graphene photoluminescence substrate described in above-mentioned technical scheme, comprises the following steps:

[0043] The photoluminescent material is mixed with the dispersant, and the obtained photoluminescent material dispersion is coated inside the interlayer formed by the graphene layer to form a photoluminescent material layer to obtain a graphene photoluminescent substrate.

[0044] In the present invention, the preparation method of the graphene photoluminescent substrate comprises the following steps: mixing the photoluminescent material with a dispersant, and coating the obtained photoluminescent material dispersion inside the interlayer formed by the graphene layer , forming a photoluminescent material layer to obtain a graphene photoluminescent substrate. In the present invention, there is no special limitation on the type of the dispersant, and a compound known to those skilled in the art that c...

Embodiment 1

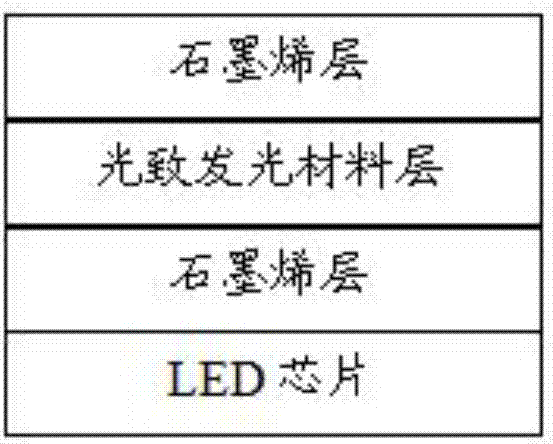

[0067] The preparation structure is successively graphene photoluminescence substrate of graphene layer, photoluminescence material layer, graphene layer, comprises the following steps:

[0068]Polyphenylene vinylene was mixed with chlorobenzene, and stirred at 500rpm for 15min to obtain a polyphenylene vinylene dispersion with a concentration of 1%. The polyphenylene vinylene dispersion was coated on one side of the graphene layer, and then another A graphene layer is covered on the liquid surface of the polyphenylene vinylene dispersion liquid, dried naturally, and a photoluminescent material layer is formed inside the interlayer formed by the graphene layer, and the obtained structure is successively a graphene layer, a photoluminescent material layer, Graphene photoluminescence substrate of graphene layer; Wherein, the thickness of each layer in the graphene photoluminescence substrate is 10nm.

Embodiment 2

[0070] The preparation structure is successively graphene photoluminescence substrate of graphene layer, photoluminescence material layer, graphene layer, comprises the following steps:

[0071] The carbon photoluminescent material is mixed with polyethylene terephthalate (PET), stirred at 300rpm for 25min to obtain a carbon photoluminescent material dispersion with a concentration of 10%, and the single side of the graphene layer is coated with the carbon photoluminescent material dispersion, and then another layer of graphene layer is covered on the liquid surface of the carbon photoluminescent material dispersion, vacuum-dried, and a photoluminescent material layer is formed inside the interlayer formed by the graphene layer to obtain The structure is a graphene layer, a photoluminescent material layer, and a graphene photoluminescent substrate of a graphene layer in sequence; wherein, the thickness of each layer in the graphene photoluminescent substrate is 1000nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com