Aqueous heat-insulating anticorrosive paint

An anti-corrosion coating, water-based technology, applied in anti-corrosion coatings, reflective/signal coatings, coatings, etc., can solve the problem of low adhesion between thermal insulation layer and anti-corrosion layer, reduced life of metal structure buildings, and inability to distribute quartz powder evenly, etc. problem, to achieve the effect of good anti-rust and anti-corrosion performance, excellent anti-corrosion and adhesion, and excellent barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

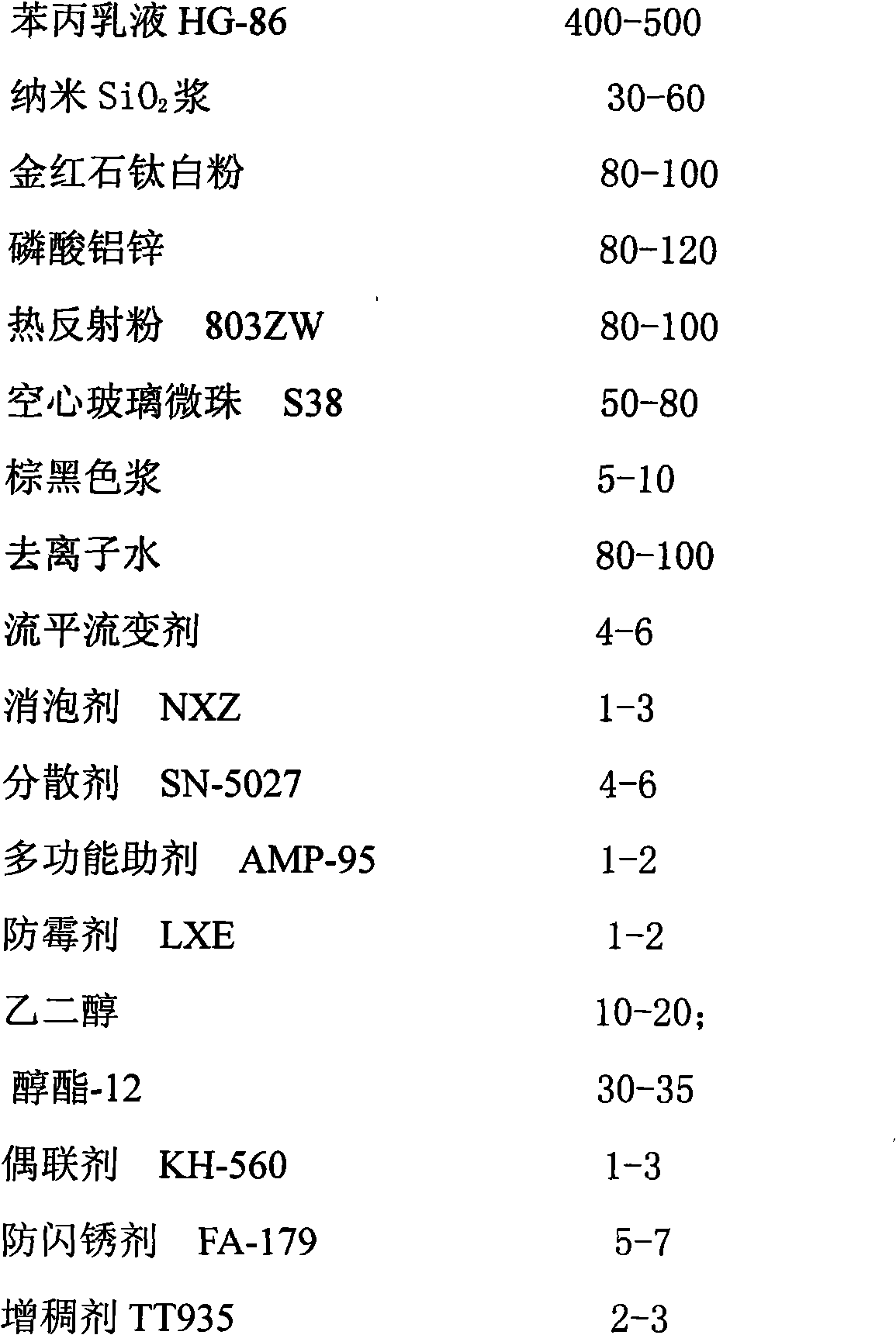

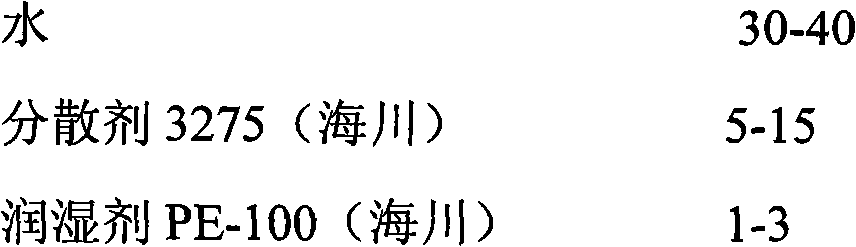

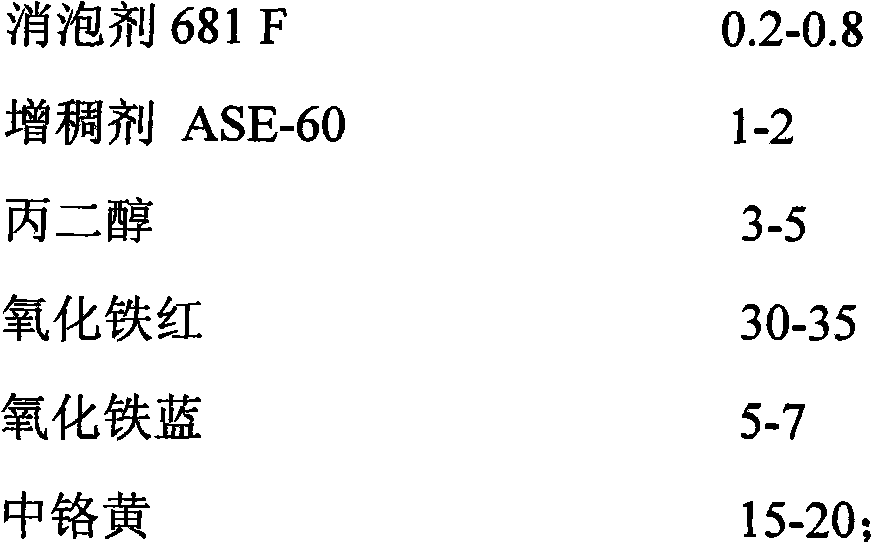

[0020] Embodiment: A kind of water-based thermal insulation anticorrosion coating: adopt styrene-acrylic emulsion, nano-SiO 2 Pulp is the main film-forming substance. With the cooperation of various functional pigments and fillers, various additives and brown-black paste, a one-component off-white water-based heat-insulating and anti-corrosion coating is made. The components in the formula are as follows:

[0021]

[0022] The preparation process steps of water-based heat-insulating and anti-corrosion coating are as follows:

[0023] a. Add deionized water into the dispersing tank, add dispersant, 1 / 2 defoamer, multifunctional additive, antifungal agent, ethylene glycol, alcohol ester-12, coupling agent under medium speed stirring, and disperse and mix After uniformity, add rutile titanium dioxide, heat reflective powder, and aluminum zinc phosphate, disperse at high speed for 40 minutes, and then grind to a fineness of less than 20 μm to form a pigment slurry.

[0024] b....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com