Fluorescent film containing near-infrared fluorescent powder and application thereof

A phosphor and near-infrared technology, applied in the field of optical materials, can solve the problems of accelerated solar cell aging, low solar cell efficiency, and inability to be utilized, and achieves improved solar light utilization, excellent solar spectrum adjustment function, and preparation efficiency. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

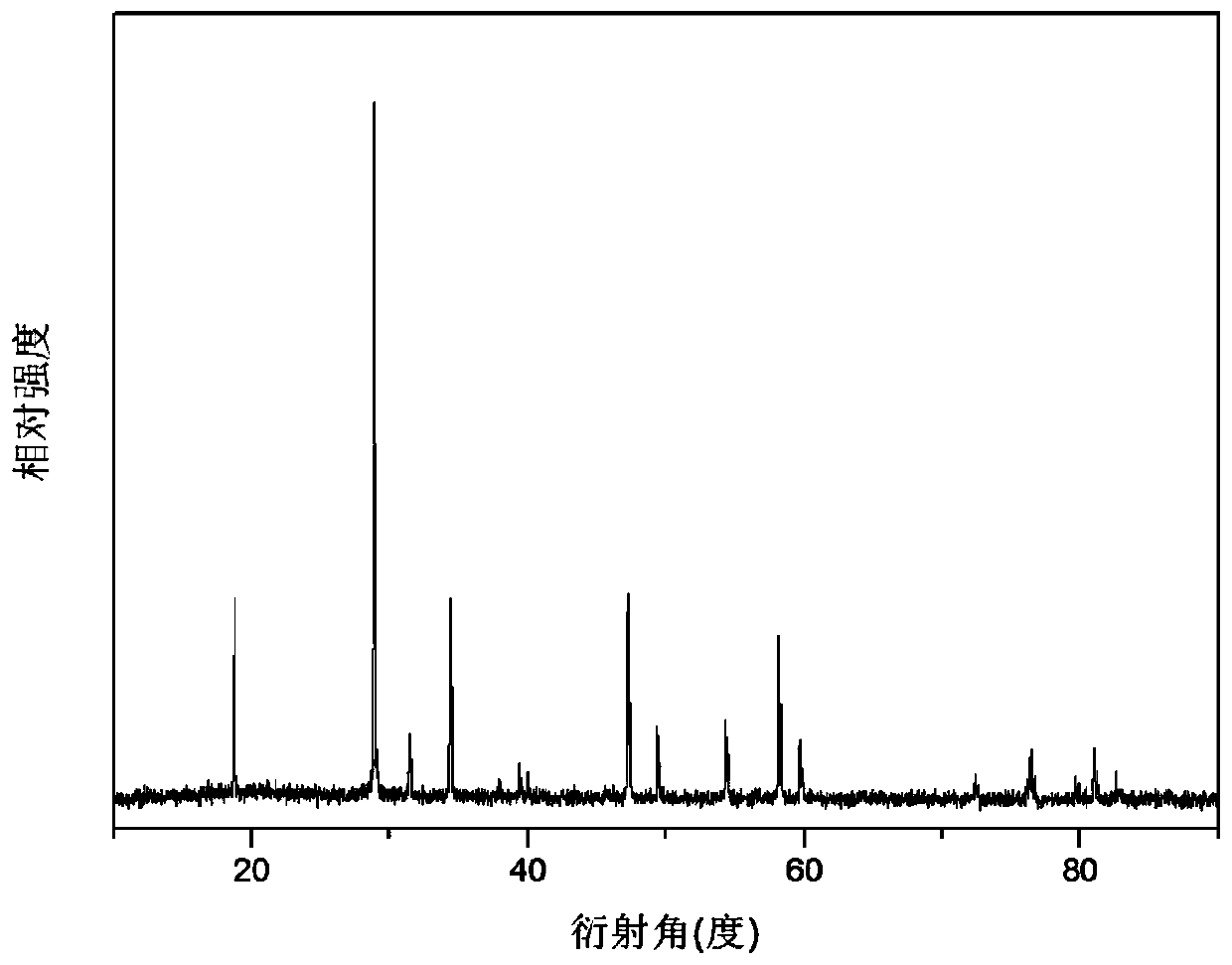

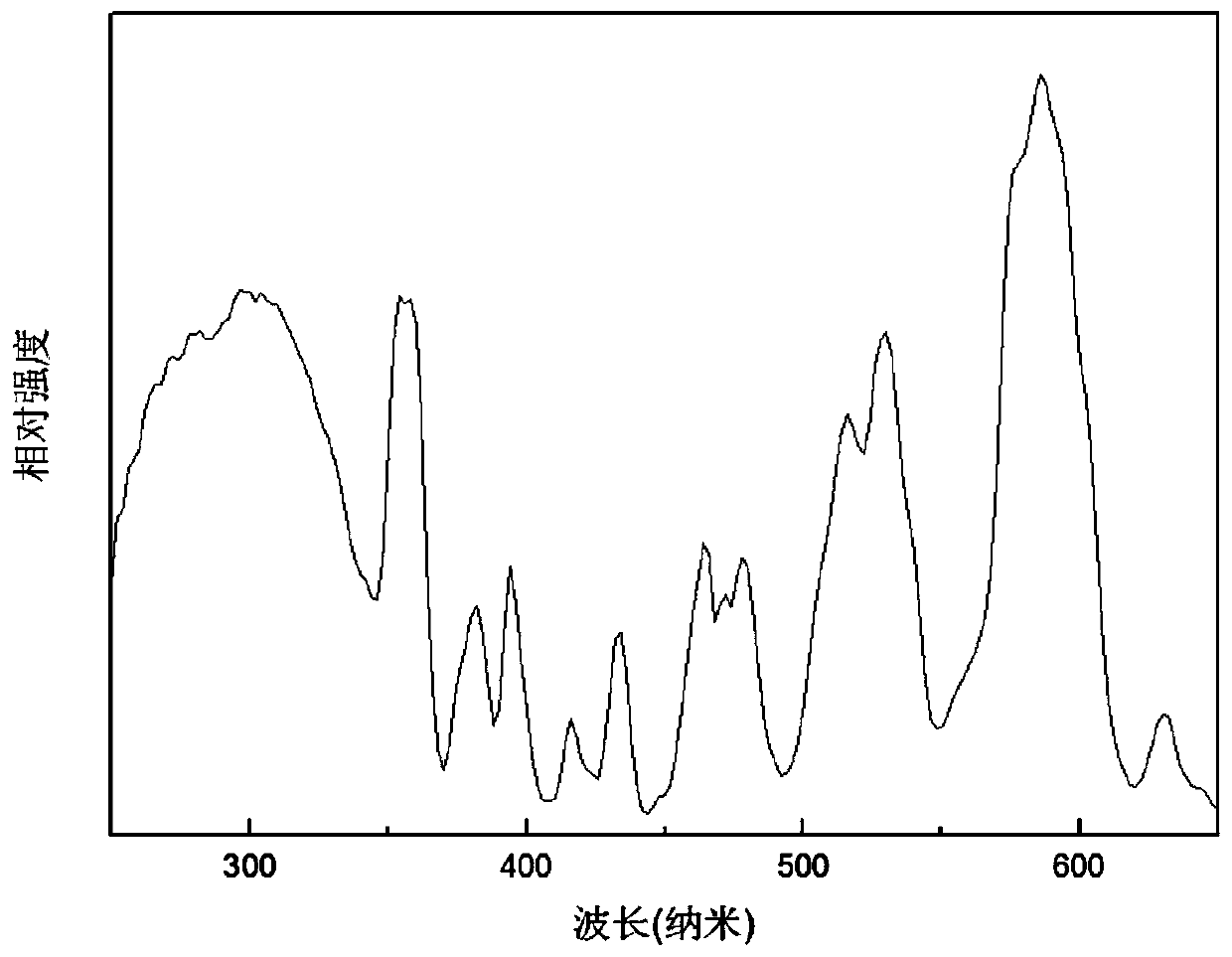

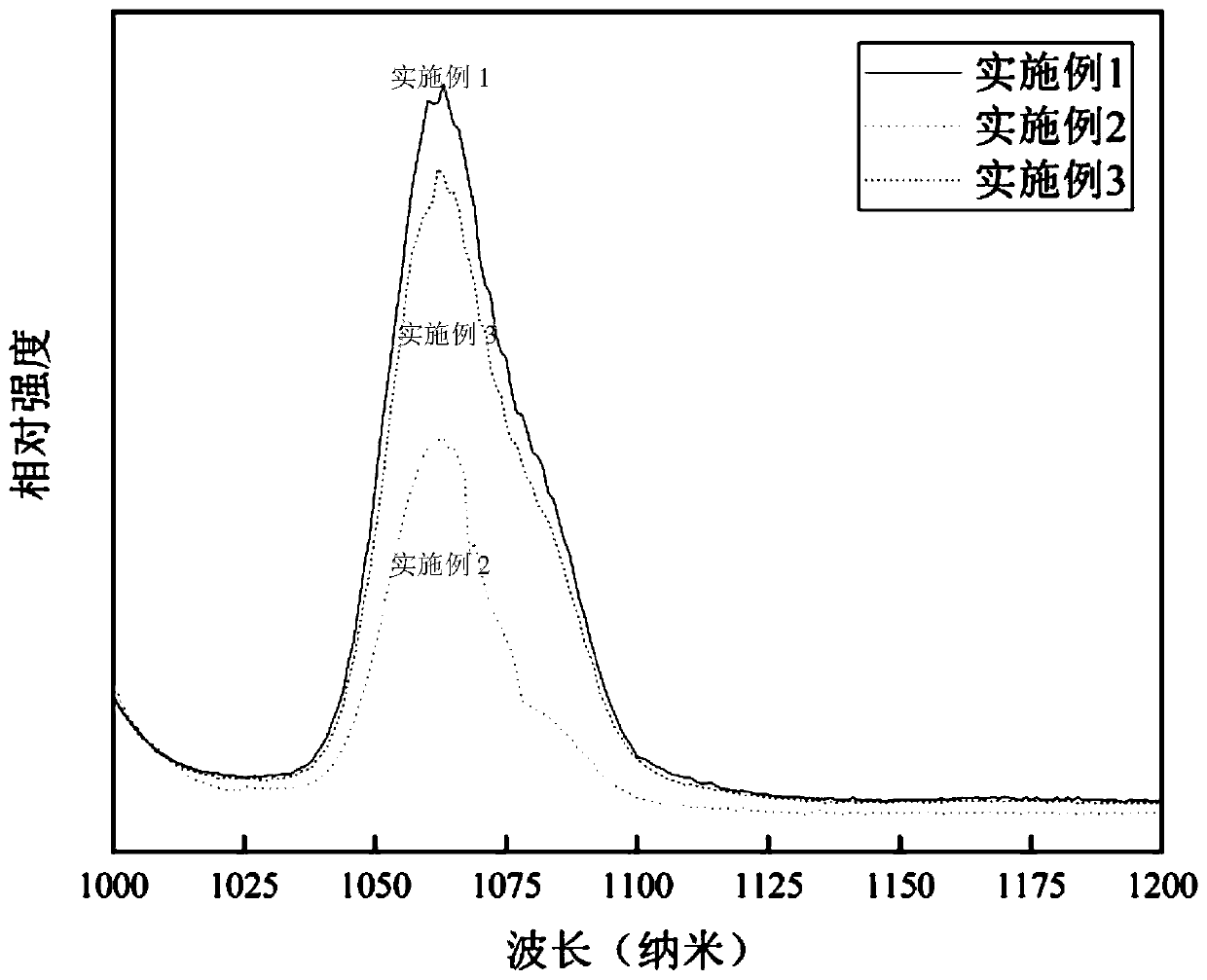

[0029] Embodiment 1: a kind of fluorescent film, by the commercial K of 56wt% 2 O-Na 2 O-Al 2 o 3 -SiO 2 Glass powder with 56wt% LiEu 6.3 (MoO 4 ) 2 :Nd 3+ 6.7 Near-infrared phosphor composition

[0030] The first step is to accurately weigh 6.4683g of lithium carbonate, 1.3382g of europium oxide, 3.6488g of molybdenum trioxide and 6.8536g of neodymium oxide according to the stoichiometric ratio, and grind them in an agate mortar to make them uniform. / min heating rate to 866°C and calcined at 866°C for 5h, cooled to room temperature 25°C, crushed and ground the sample, then raised the temperature to 666°C at a heating rate of 5°C / min in the muffle furnace and heated at 666°C Calcined at low temperature for 3h, cooled naturally to room temperature 25°C, and then fully ground to obtain the final product LiEu 6.3 (MoO 4 ) 2 :Nd 3+ 6.7 .

[0031] In the second step, the LiEu obtained in the first step is 6.3 (MoO 4 ) 2 :Nd 3+ 6.7 Near-infrared phosphors and co...

Embodiment 2

[0035] Embodiment 2: a kind of fluorescent film, by the commercial K of 56wt% 2 O-Na 2 O-Al 2 o 3 -SiO 2 Glass powder with 56wt% LiEu 6.2 (MoO 4 ) 2 :Nd 3+ 6.8 Near-infrared phosphor composition

[0036] The first step is to accurately weigh 6.4666g of lithium carbonate, 1.3464g of europium oxide, 3.6548g of molybdenum trioxide and 6.8544g of neodymium oxide according to the stoichiometric ratio, and grind them in an agate mortar to make them uniform. The heating rate was raised to 866°C and calcined at 866°C for 5 hours. After cooling to room temperature at 25°C, the sample was crushed and ground, and then heated to 666°C at a heating rate of 5°C / min in the muffle furnace and heated at 666°C. Calcined at low temperature for 3h, cooled naturally to room temperature 25°C, and then fully ground to obtain the final product LiEu 6.3 (MoO 4 ) 2 :Nd 3+ 6.8 .

[0037] In the second step, the LiEu obtained in the first step is 6.2 (MoO 4 ) 2 :Nd 3+ 6.8 Near-infrare...

Embodiment 3

[0038] Embodiment 3: a kind of fluorescent film, by the commercial K of 56wt% 2 O-Na 2 O-Al 2 o 3 -SiO 2 Glass powder with 56wt% LiEu 6.4 (MoO 4 ) 2 :Nd 3+ 6.6 Near-infrared phosphor composition

[0039] The first step is to accurately weigh 6.4675g of lithium carbonate, 1.3366g of europium oxide, 3.6426g of molybdenum trioxide and 6.8516g of neodymium oxide according to the stoichiometric ratio, and grind them in an agate mortar to make them uniform. The heating rate was raised to 866°C and calcined at 866°C for 5 hours. After cooling to room temperature at 25°C, the sample was crushed and ground, and then heated to 666°C at a heating rate of 5°C / min in the muffle furnace and heated at 666°C. Calcined at low temperature for 3h, cooled naturally to room temperature 25°C, and then fully ground to obtain the final product LiEu 6.4 (MoO 4 ) 2 :Nd 3+ 6.6 .

[0040] In the second step, the LiEu obtained in the first step is 6.4 (MoO 4 ) 2 :Nd 3+ 6.6 Near-infrare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com