Rare earth doped up-conversion luminescent material with excellent damp-proof property and preparation method thereof

A moisture-proof performance, rare earth doping technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problem of disappearance of negative thermal expansion performance, and achieve the effect of high quenching concentration and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

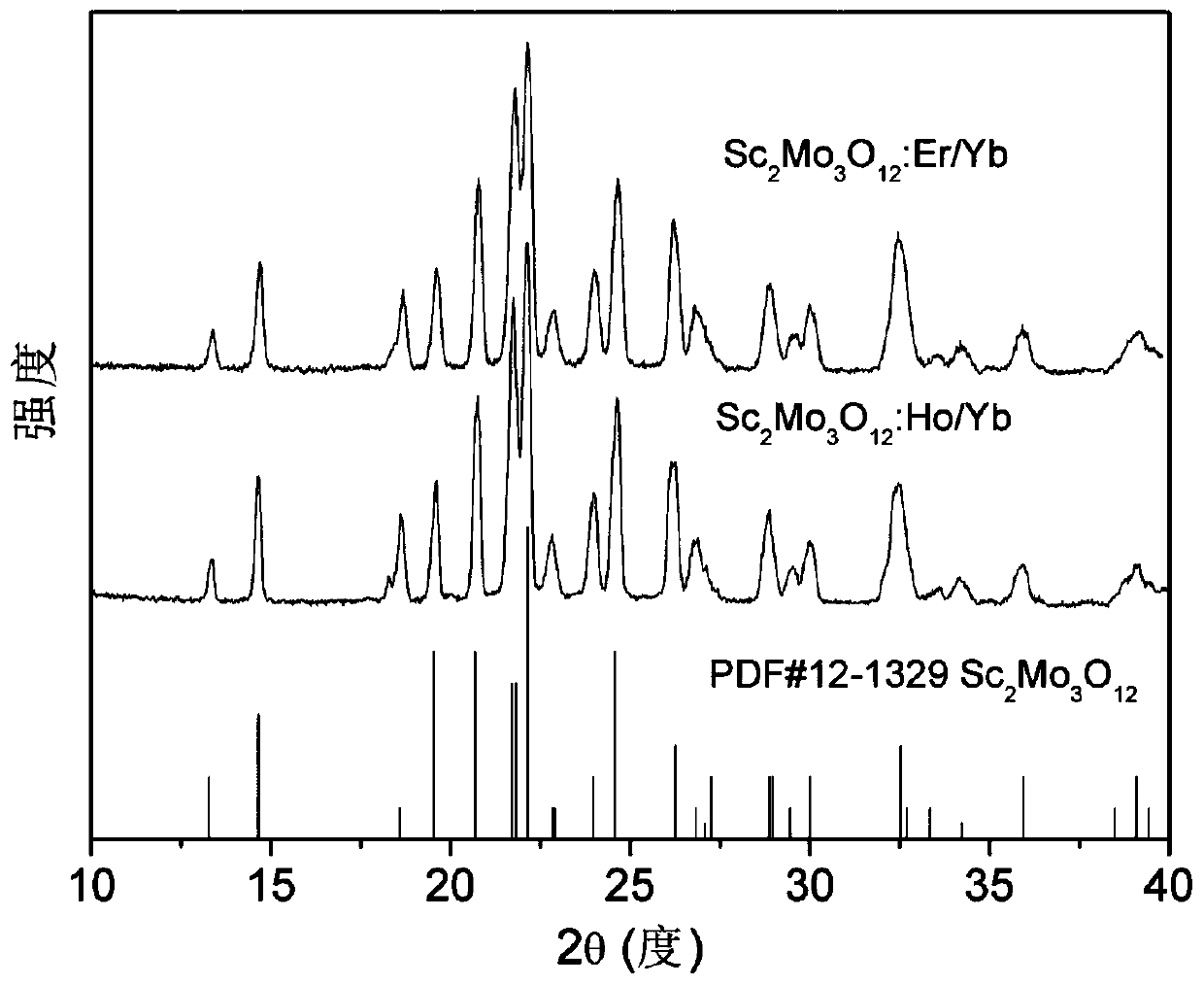

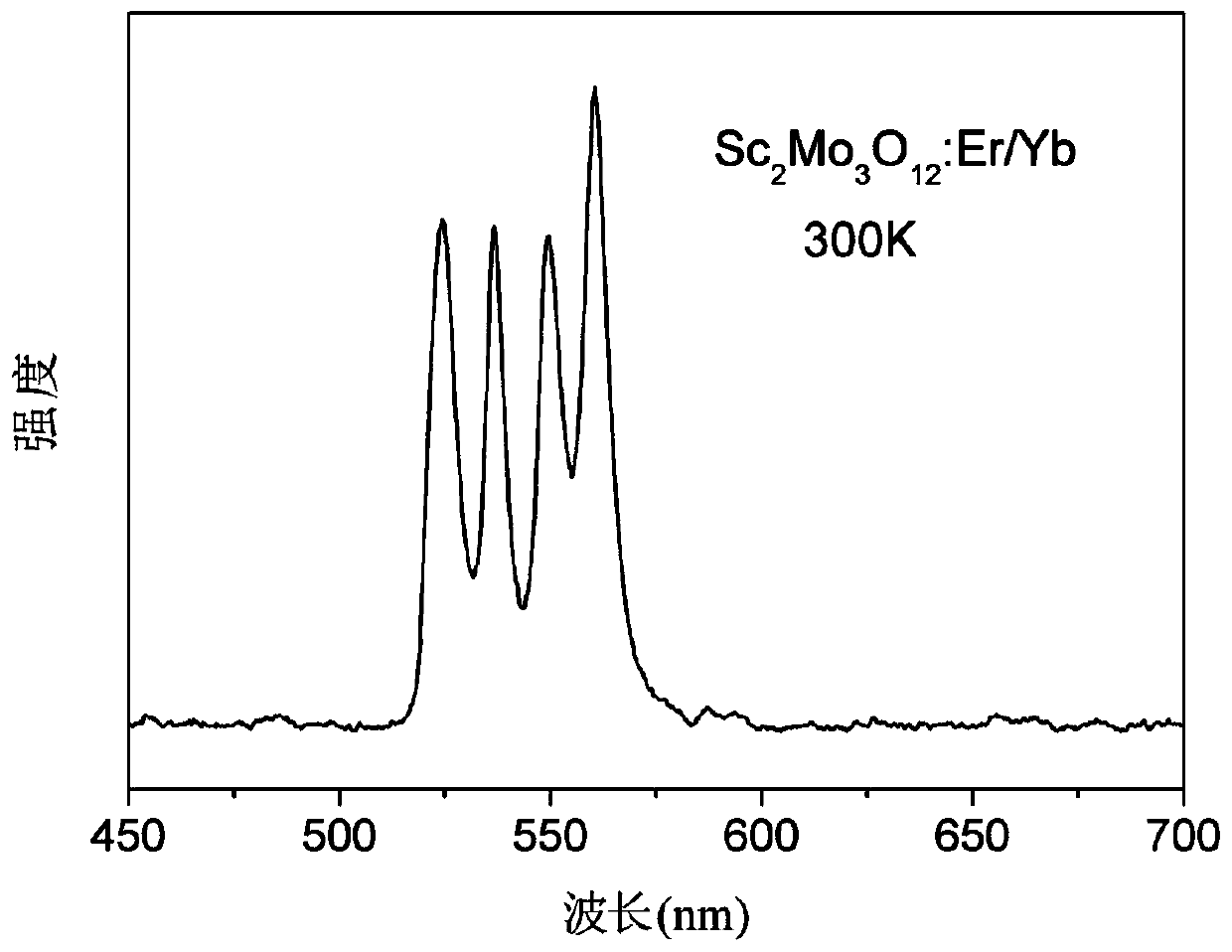

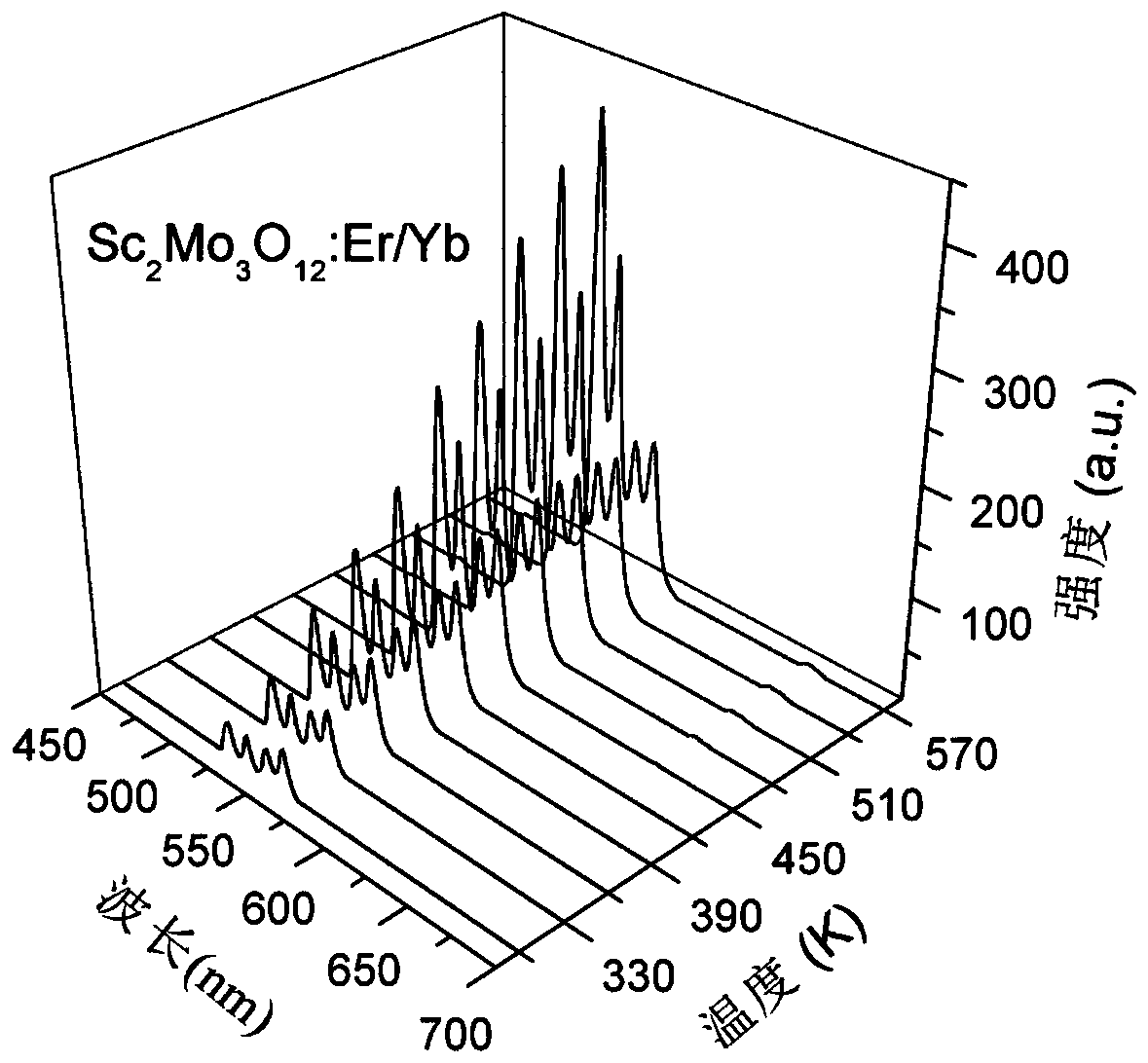

[0032] Sc prepared in this example 1.6 Er 0.04 Yb 0.36 Mo 3 O 12 The material process is as follows:

[0033] 1) Follow Sc 1.6 Er 0.04 Yb 0.36 Mo 3 O 12 Mol ratio, weighed Sc 2 O 3 , Yb 2 O 3 , MoO 3 , Er 2 O 3 For each suitable quality, grind 2-3 times with absolute ethanol to make it evenly mixed;

[0034] 2) After grinding, the sample is placed in an oven at 80 degrees Celsius for two hours to dry, and then the powder is placed in the corundum boat, and then the corundum boat with medicines is placed in a high-temperature furnace, kept at 500 degrees Celsius in an air atmosphere for 6 hours, and then cooled naturally To room temperature

[0035] 3) Take out the sample from the high-temperature furnace, grind it with alcohol 2-3 times, and then dry it;

[0036] 4) Finally, put the dried sample into a corundum boat, put it in a high-temperature furnace, slowly raise the temperature to 900 degrees Celsius in an air atmosphere, keep it for 6 hours, then cool it naturally, and take it...

Embodiment 2

[0038] Sc prepared in this example 1.6 Ho 0.04 Yb 0.36 Mo 3 O 12 The material process is as follows:

[0039] 1) Follow Sc 1.6 Ho 0.04 Yb 0.36 Mo 3 O 12 Mol ratio, weighed Sc 2 O 3 , Yb 2 O 3 , MoO 3 , Ho 2 O 3 For each suitable quality, grind 2-3 times with absolute ethanol to make it evenly mixed;

[0040] 2) After grinding, the sample is placed in an oven at 80 degrees Celsius for two hours to dry, and then the powder is placed in a corundum boat. Put the corundum boat with medicines into a high-temperature furnace, keep it at 500 degrees Celsius in an air atmosphere for 6 hours, and then naturally cool to room temperature;

[0041] 3) Take out the sample from the high-temperature furnace, grind it with alcohol 2-3 times, and dry it;

[0042] 4) Finally, put the dried sample in a corundum boat, put it in a high-temperature furnace, slowly raise the temperature to 900 degrees Celsius in an air atmosphere, keep it for 6 hours, then cool it naturally, and take it out for use.

Embodiment 3

[0044] Sc prepared in this example 1.6 Tm 0.04 Yb 0.36 Mo 3 O 12 The material process is as follows:

[0045] 1) Follow Sc 1.6 Tm 0.04 Yb 0.36 Mo 3 O 12 Mol ratio, weighed Sc 2 O 3 , Yb 2 O 3 , MoO 3 , Tm 2 O 3 For each suitable quality, grind 2-3 times with absolute ethanol to make it evenly mixed;

[0046] 2) After grinding, the sample is placed in an oven at 80 degrees Celsius for two hours to dry, and then the powder is placed in a corundum boat. Put the corundum boat with medicines into a high-temperature furnace, keep it at 500 degrees Celsius in an air atmosphere for 6 hours, and then naturally cool to room temperature;

[0047] 3) Take out the sample from the high-temperature furnace, grind it with alcohol 2-3 times, and dry it;

[0048] 4) Finally, put the dried sample in a corundum boat, put it in a high-temperature furnace, slowly raise the temperature to 900 degrees Celsius in an air atmosphere, keep it for 6 hours, then cool it naturally, and take it out for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com