Preparation method of low-melting-point fluorescent glass

A technology of low-melting point glass and fluorescent glass, which is applied in the field of preparation of low-melting point fluorescent glass, can solve the problems of difficult commercialization, high firing temperature, and high cost, and achieve low raw material prices, low production energy consumption, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of low melting point raw glass:

[0022] Weigh the low melting point glass component 14% (NaPO 3 ) 6 -44%NaF-3%CaO-35%B 2 o 3 -2%Sb 2 o 3 -2%Li 2 O (both are mole fractions), and then put the weighed components into a mortar and grind them evenly for 30 minutes. After grinding, put them into a cleaned alumina crucible and place Sintering in the furnace, the sintering process is from room temperature to 200°C, the heating time is 30min, at 200°C for 20min, then 130min to 750°C and holding for 30min, finally take it out at 750°C and pour it into the mold for rapid cooling to form the original Glass block, you can get low melting point glass.

[0023] (2) Preparation of fluorescent glass:

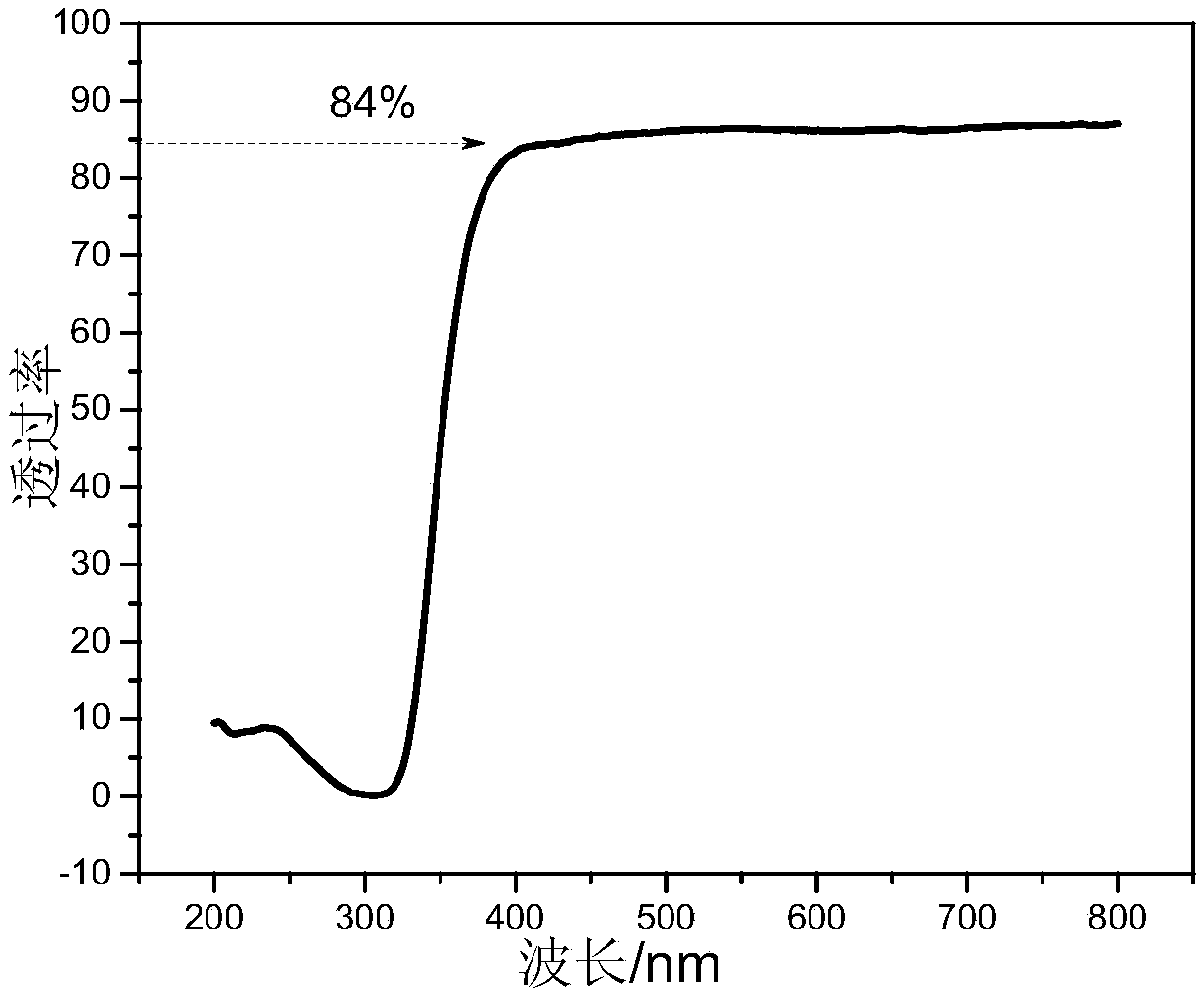

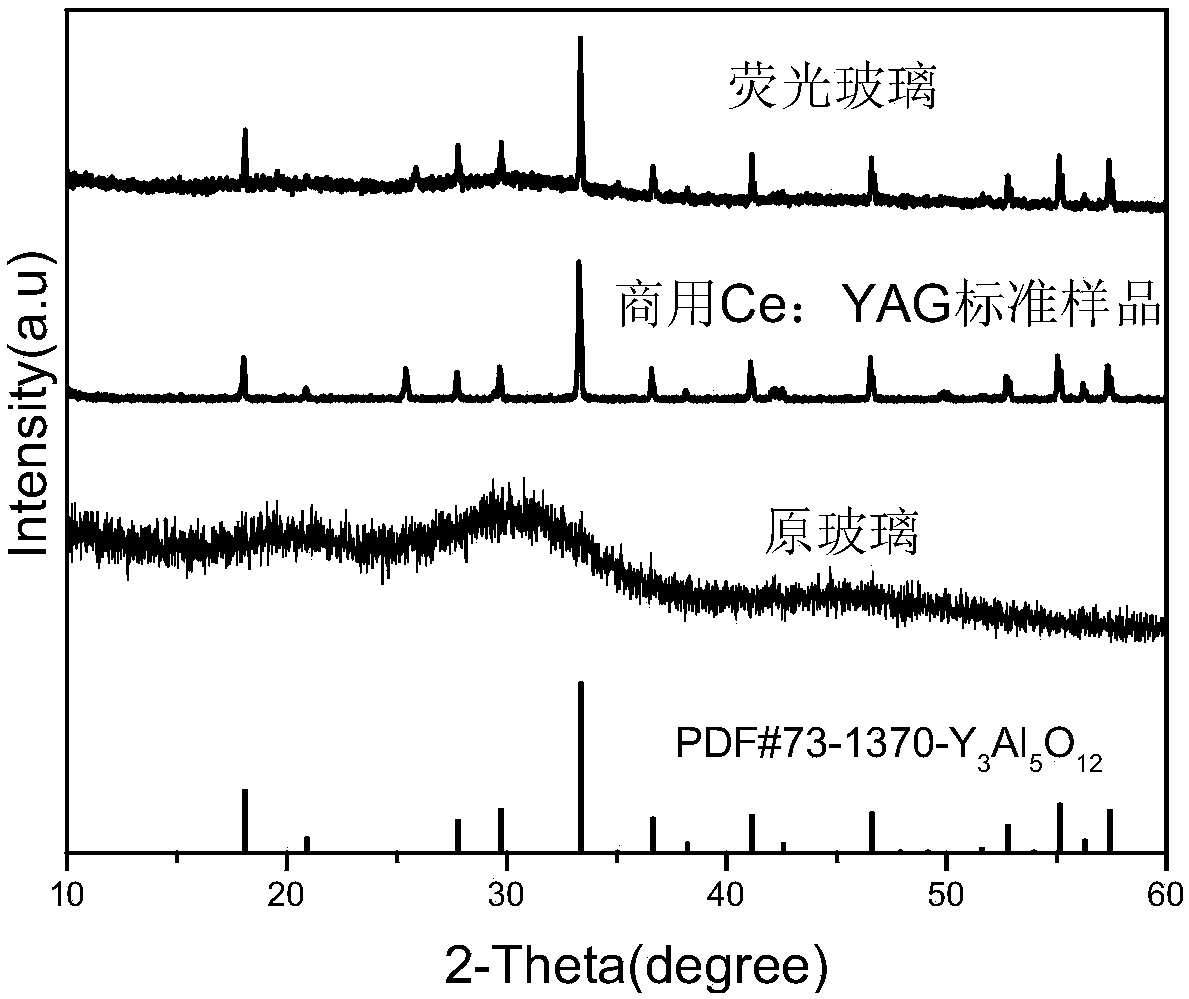

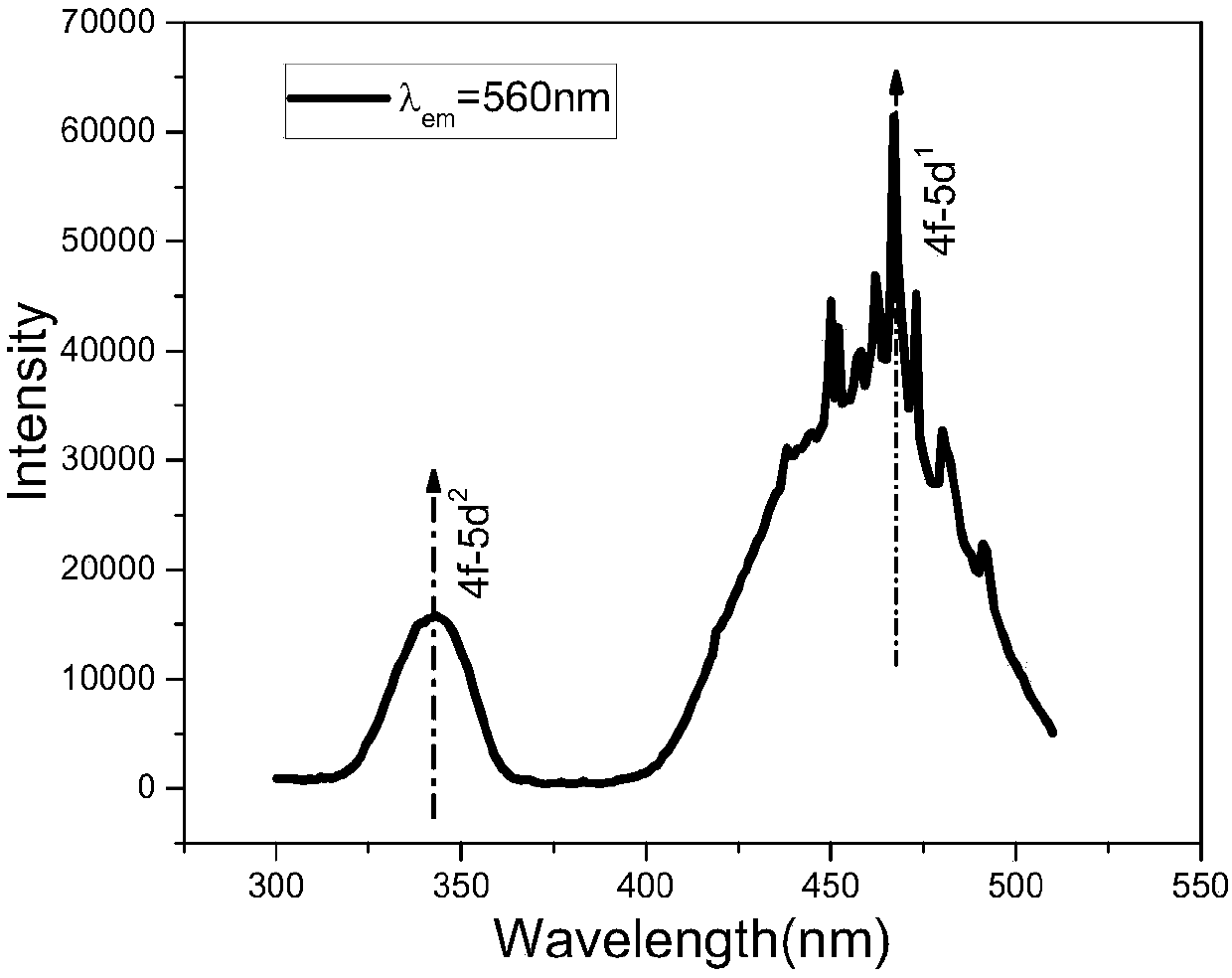

[0024] Crush the fired low-melting-point raw glass into the required glass powder, and grind it with 0.4g of commercial yttrium-aluminum-garnet-structured yellow phosphor (Ce:YAG) through a mortar, and dry it after grinding for 30 minutes spare. Take the mixed ...

Embodiment 2

[0026] (1) Preparation of low melting point raw glass:

[0027] Weigh the low melting point glass component 11% (NaPO 3 ) 6 -35%NaF-6%CaO-37%B 2 o 3 -3%Sb 2 o 3 -2%Li 2 O-6%ZnO (both are mole fractions), put the weighed components into the mortar and grind them evenly for 40 minutes, put them into a cleaned alumina crucible after grinding, and Put it in a muffle furnace for sintering. The sintering process takes 30 minutes from room temperature to 200°C, heats it at 200°C for 10 minutes, then takes 120 minutes to reach 750°C and holds it for 30 minutes, and finally takes it out at 750°C and pours it into the mold. The low melting point glass can be obtained by rapid cooling to form the original glass block.

[0028] (2) Preparation of fluorescent glass:

[0029]The fired low-melting raw glass is broken into the required glass powder, and 0.3g of commercial yttrium aluminum garnet structure yellow phosphor (Ce: YAG) is ground uniformly by a mortar, and the grinding time...

Embodiment 3

[0031] (1) Preparation of low melting point raw glass:

[0032] Weigh the low melting point glass component 15% (NaPO 3 ) 6 -38%NaF-4%CaO-35%B 2 O 3 -3%Sb 2 O 3 -2%Li 2 O-3% ZnO (both mole fractions), and then put the weighed components into a mortar and grind them evenly. The grinding time is 35min. Sintering in a muffle furnace, the sintering process is from room temperature to 200 °C with a heating time of 35 minutes, holding at 200 °C for 15 minutes, then reaching 750 °C for 140 minutes and holding for 20 minutes, and finally taking it out at a high temperature of 750 °C and pouring it into the mold Quick cooling to form the original glass block, the low melting point glass can be obtained.

[0033] (2) Preparation of fluorescent glass:

[0034] The fired low-melting raw glass is broken into the required glass powder, and 0.2g of commercial yttrium aluminum garnet structure yellow phosphor (Ce: YAG) is ground uniformly through a mortar, and the grinding time is 35m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com