Two-dimensional gallium nitride film confinement template preparation method and prepared two-dimensional gallium nitride film

A technology of gallium nitride film and boron nitride film, which is applied in the direction of gaseous chemical plating, coating, metal material coating process, etc., can solve the problem that gallium nitride is not a two-dimensional material, and achieve the reduction of spectral broadening and optimization Electrical and optical intrinsic properties, the effect of lowering the energy barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a confined template of a two-dimensional gallium nitride film, specifically comprising the following steps:

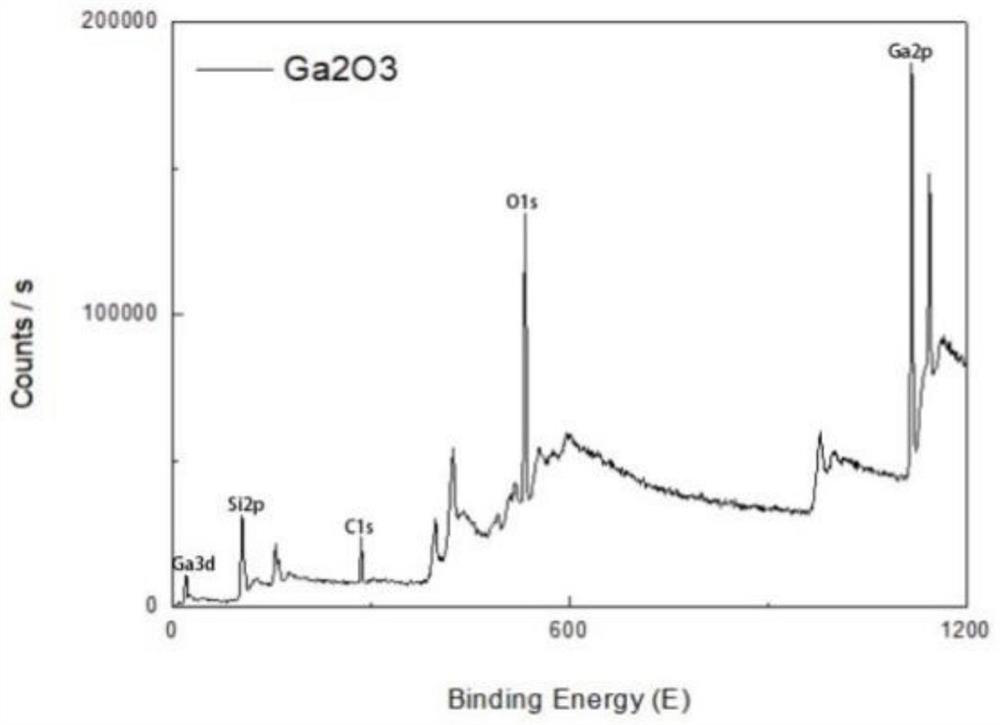

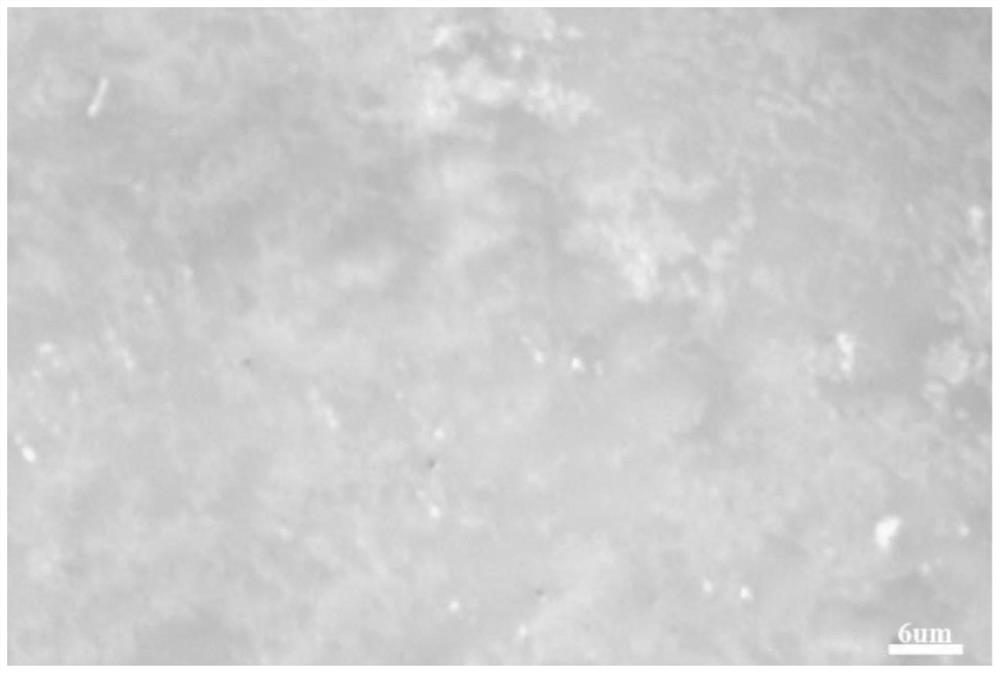

[0043] Heating to 40°C to melt gallium metal to obtain liquid gallium metal, using the heat release film to absorb liquid gallium metal, pressing the liquid metal gallium on the silicon wafer to obtain a gallium metal film, putting the gallium metal film into a quartz tube and heating to 450°C, The gallium oxide film is obtained by accelerating the reaction process of gallium. At room temperature, liquid metal gallium and air form a self-limiting oxide layer, but since peeling off the self-limiting oxide layer directly will cause defects such as wrinkles, which will further affect the properties of gallium nitride, so the choice of adsorbing gallium liquid to prepare metal gallium thin films is Gallium reacts slowly with air, so it can be heated appropriately to accelerate the reaction, so that the metal gallium film can be quickly oxidize...

Embodiment 2

[0047] A method for preparing a confined template of a two-dimensional gallium nitride film, specifically comprising the following steps:

[0048] Heating to 40°C to melt gallium metal to obtain liquid gallium metal, use heat release film to absorb liquid gallium metal, press liquid gallium metal on the quartz plate to obtain gallium metal film, put the gallium metal film into the quartz tube and heat to 500°C, accelerate The gallium reaction process results in a gallium oxide film. At room temperature, liquid metal gallium and air form a self-limiting oxide layer, but since peeling off the self-limiting oxide layer directly will cause defects such as wrinkles, which will further affect the properties of gallium nitride, so the choice of adsorbing gallium liquid to prepare metal gallium thin films is Gallium reacts slowly with air, so it can be heated appropriately to accelerate the reaction, so that the metal gallium film can be quickly oxidized into a gallium oxide film.

...

Embodiment 3

[0052] A method for preparing a confined template of a two-dimensional gallium nitride film, specifically comprising the following steps:

[0053] Heating to 40°C to melt metal gallium to obtain liquid metal gallium, use heat release film to absorb liquid metal gallium, press liquid metal gallium on the mica substrate to obtain metal gallium film, put the metal gallium film into a quartz tube and heat to 550 ℃, accelerate the reaction process of gallium to obtain gallium oxide film. At room temperature, liquid metal gallium and air form a self-limiting oxide layer, but since peeling off the self-limiting oxide layer directly will cause defects such as wrinkles, which will further affect the properties of gallium nitride, so the choice of adsorbing gallium liquid to prepare metal gallium thin films is Gallium reacts slowly with air, so it can be heated appropriately to accelerate the reaction, so that the metal gallium film can be quickly oxidized into a gallium oxide film.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com