Pipe piece flexible production line

A flexible production line and segment technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of ineffective layout of the production line, large footprint of the production line and supporting facilities, and insufficient smooth transfer of segment molds, etc., to achieve Save transshipment time, shorten transportation distance, and improve the effect of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

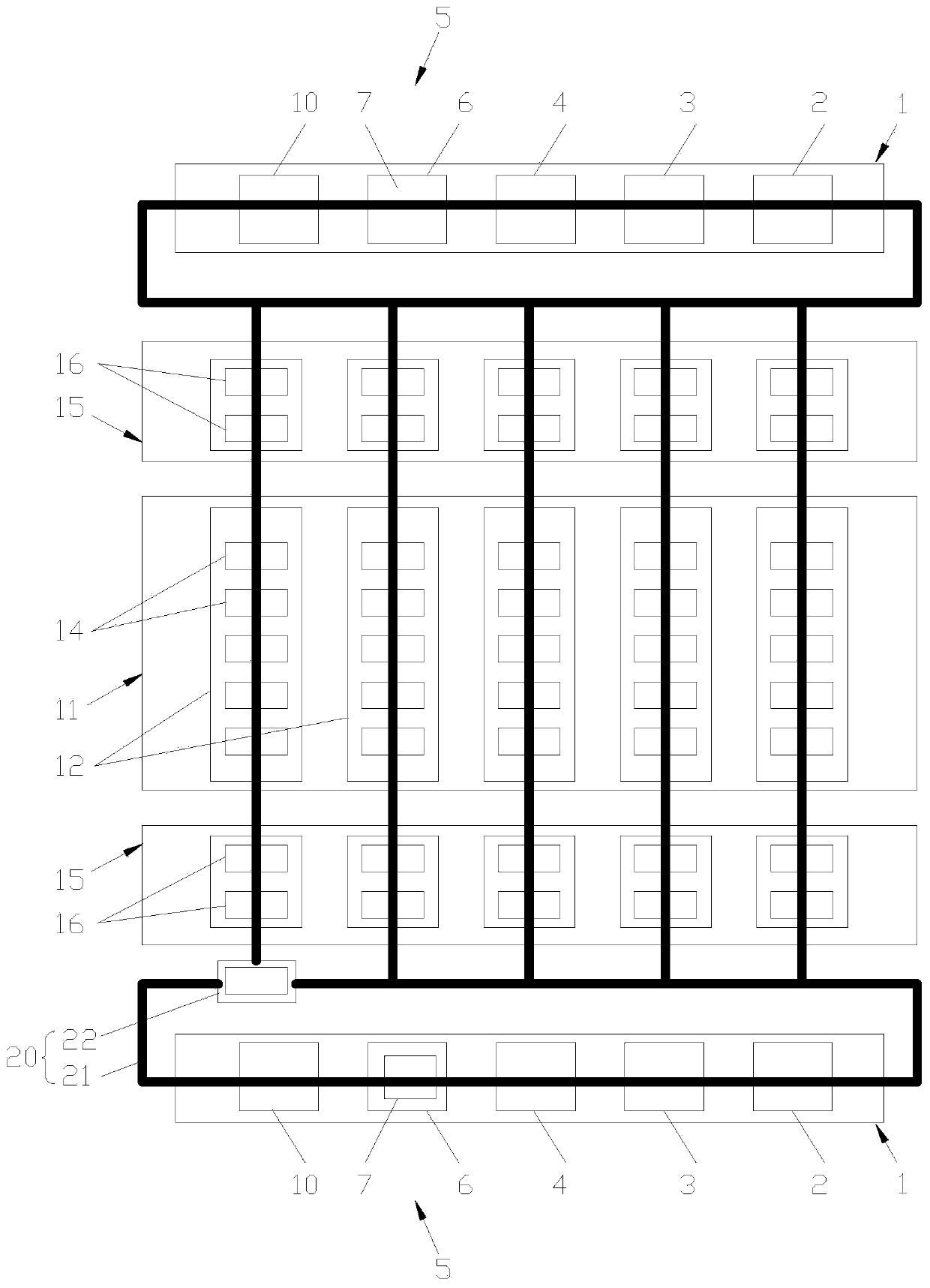

[0029] Embodiment 1 of the present invention: a segment flexible production line, constituted as Figure 1 to Figure 3 As shown, a segment flexible production line includes a production pouring line 1, a steam curing area 11, a static stop area 15, a mold walking device 20 and a steel cage processing area 17, and both sides of the steam curing area 11 are respectively composed of nearly Far away is provided with a static stop area 15 and a production pouring line 1. The mold walking device 20 includes a track 21 and a transport trolley 22. The track 21 is connected to the production pouring line 1, the steam curing area 11 and the static stop area 15. Carrying trolley 22 is arranged on track 21, and above described steam curing area 11 and the static stop area 15 on both sides are integrally provided with reinforcement cage processing area 17, and described reinforcement cage processing area 17 can not only process and manufacture reinforcement cage, also is provided with usefu...

Embodiment 2

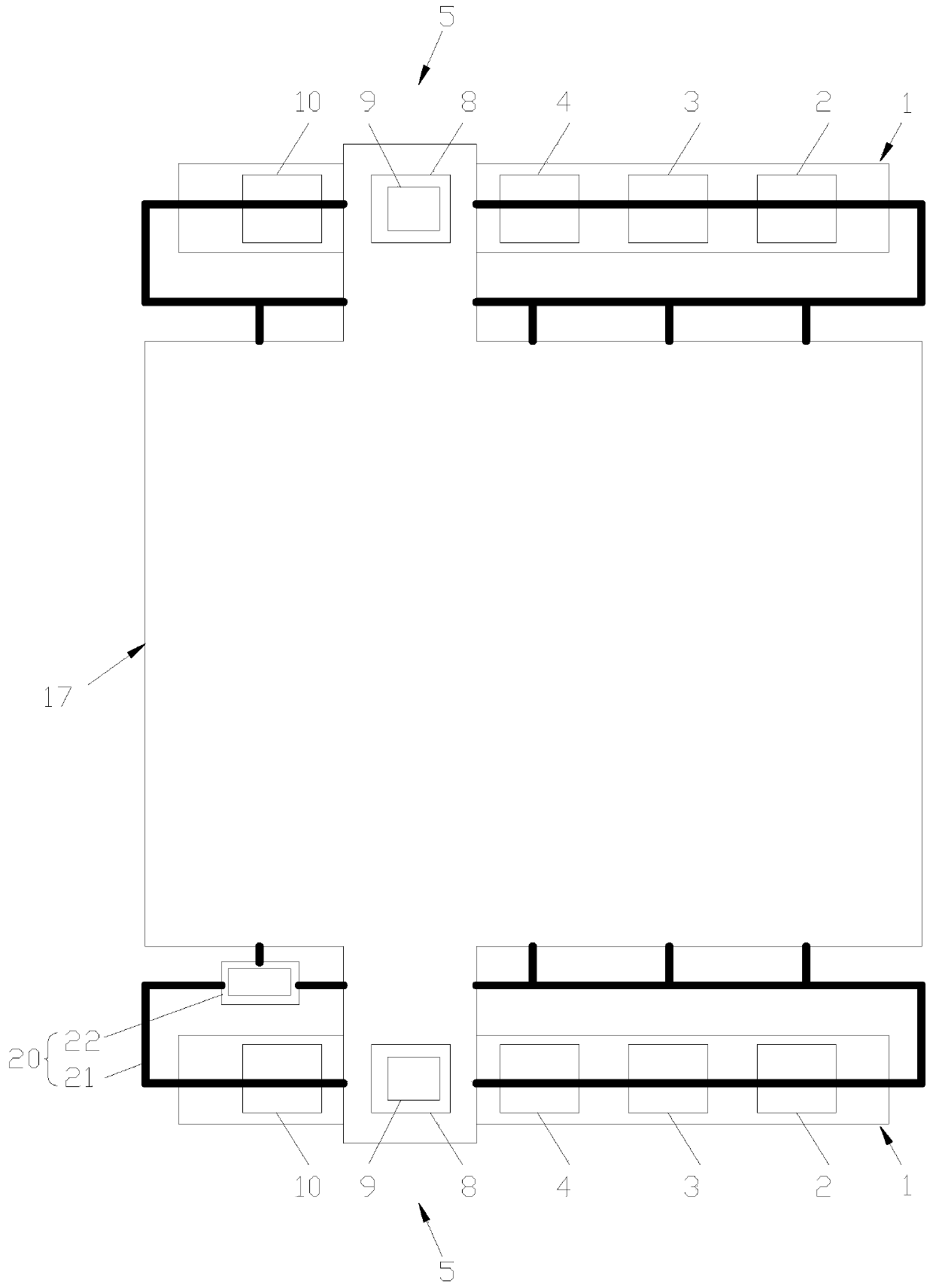

[0038] Embodiment 2: a flexible production line for segments, constituted as Figure 2 to Figure 4 As shown, a segment flexible production line includes a production pouring line 1, a steam curing area 11, a static stop area 15, a mold walking device 20 and a steel cage processing area 17, and both sides of the steam curing area 11 are respectively composed of nearly Far away is provided with a static stop area 15 and a production pouring line 1. The mold walking device 20 includes a track 21 and a transport trolley 22. The track 21 is connected to the production pouring line 1, the steam curing area 11 and the static stop area 15. Carrying trolley 22 is arranged on track 21, and above described steam curing area 11 and the static stop area 15 on both sides are integrally provided with reinforcement cage processing area 17, and described reinforcement cage processing area 17 can not only process and manufacture reinforcement cage, also is provided with useful The hoisting tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com