System and method for manufacturing cell stack of secondary battery

A battery cell, secondary battery technology, applied in secondary battery manufacturing, secondary batteries, large flat batteries/batteries, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiments described in this specification and the structures shown in the drawings are merely preferred examples of disclosed inventions, and there may be various alternatives to the embodiments of this specification and the drawings at the time of filing this application. Variations.

[0047] The system and method for manufacturing a battery cell stack for a secondary battery according to the present invention will be specifically described below with reference to the accompanying drawings, based on the embodiments described later.

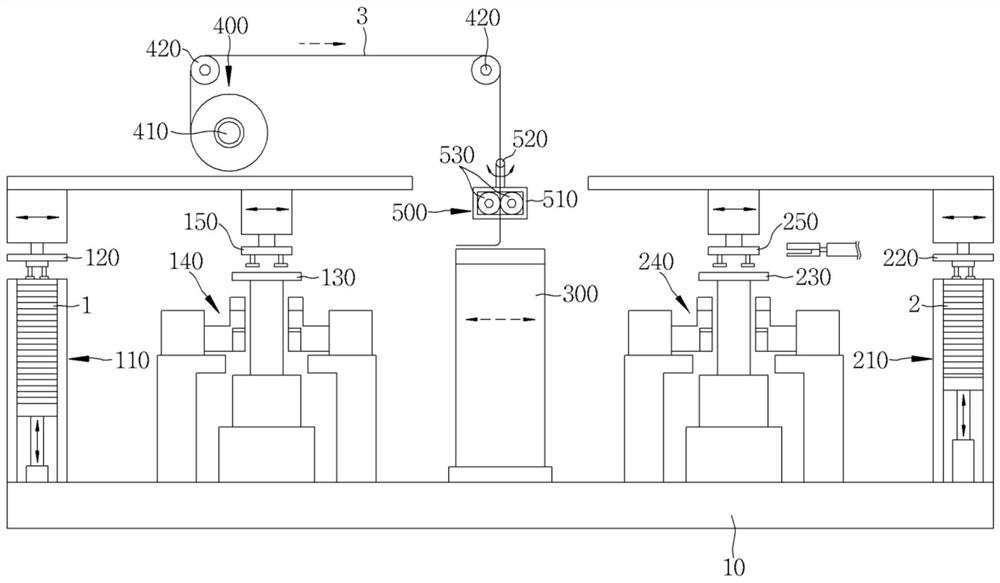

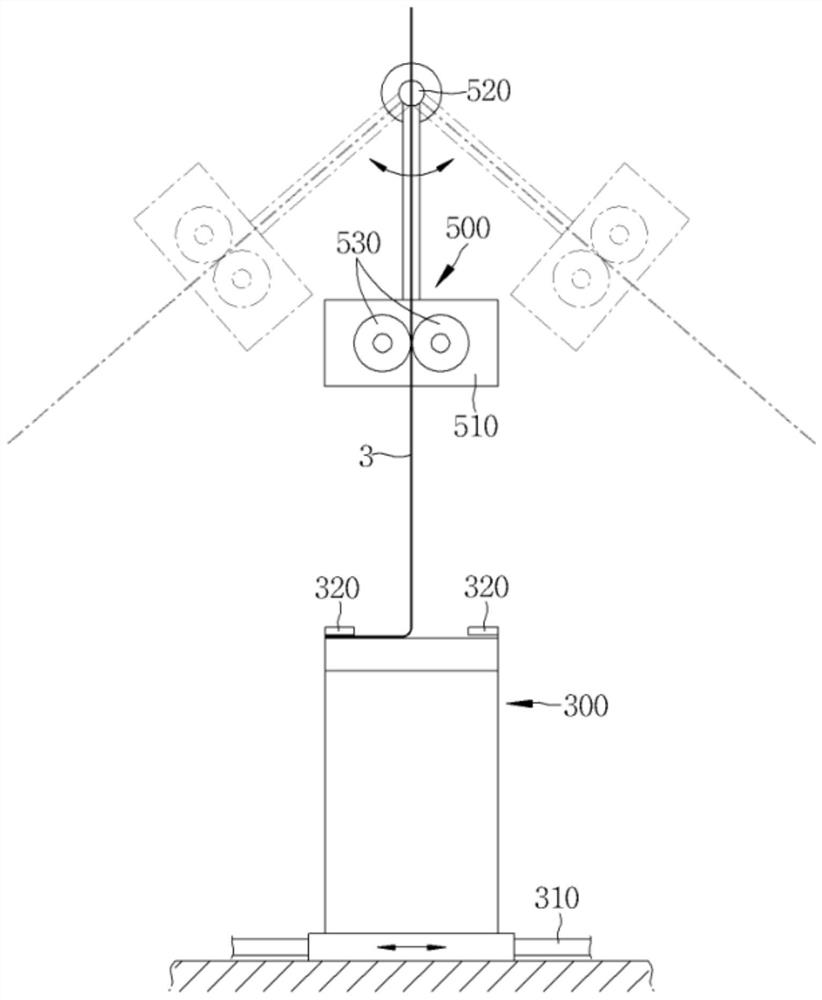

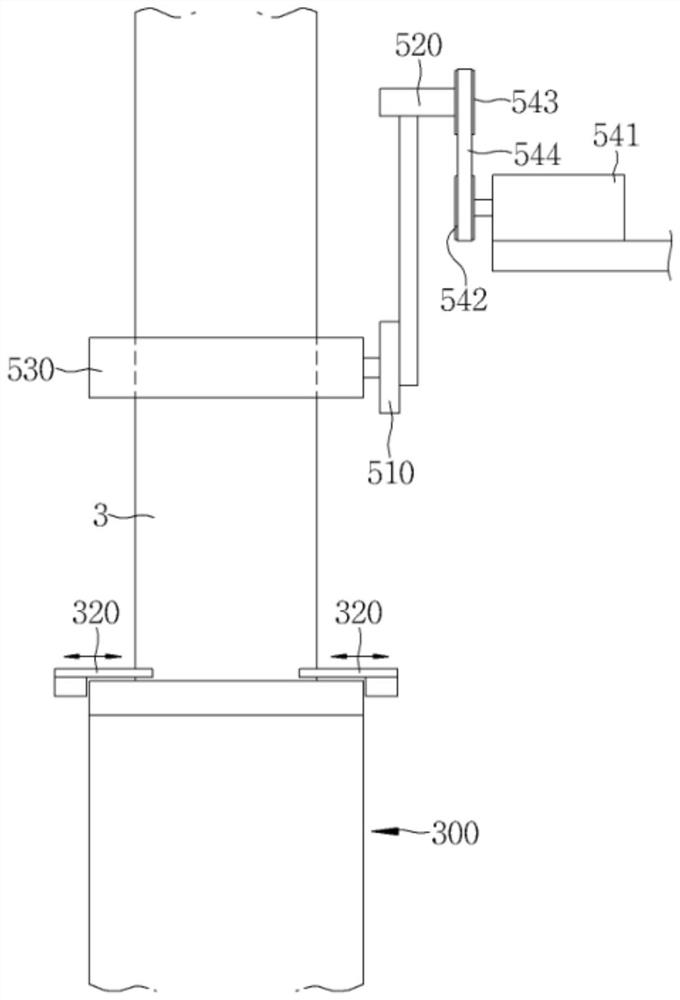

[0048] Figure 1 to Figure 4 is a diagram showing a battery cell stack manufacturing system for a secondary battery according to an embodiment of the present invention.

[0049] First if refer to figure 1, the battery cell stack manufacturing system of the present invention includes: a stacking platform 300 installed to reciprocate horizontally left and right by means of a linear motion device; a separation membrane supply part 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com