An automatic vibrating feeding tray for metal short tubes

A technology of vibrating feeding and short tube, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of fast processing speed and slow feeding speed of metal short tube, and achieve the speed of supplying and feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

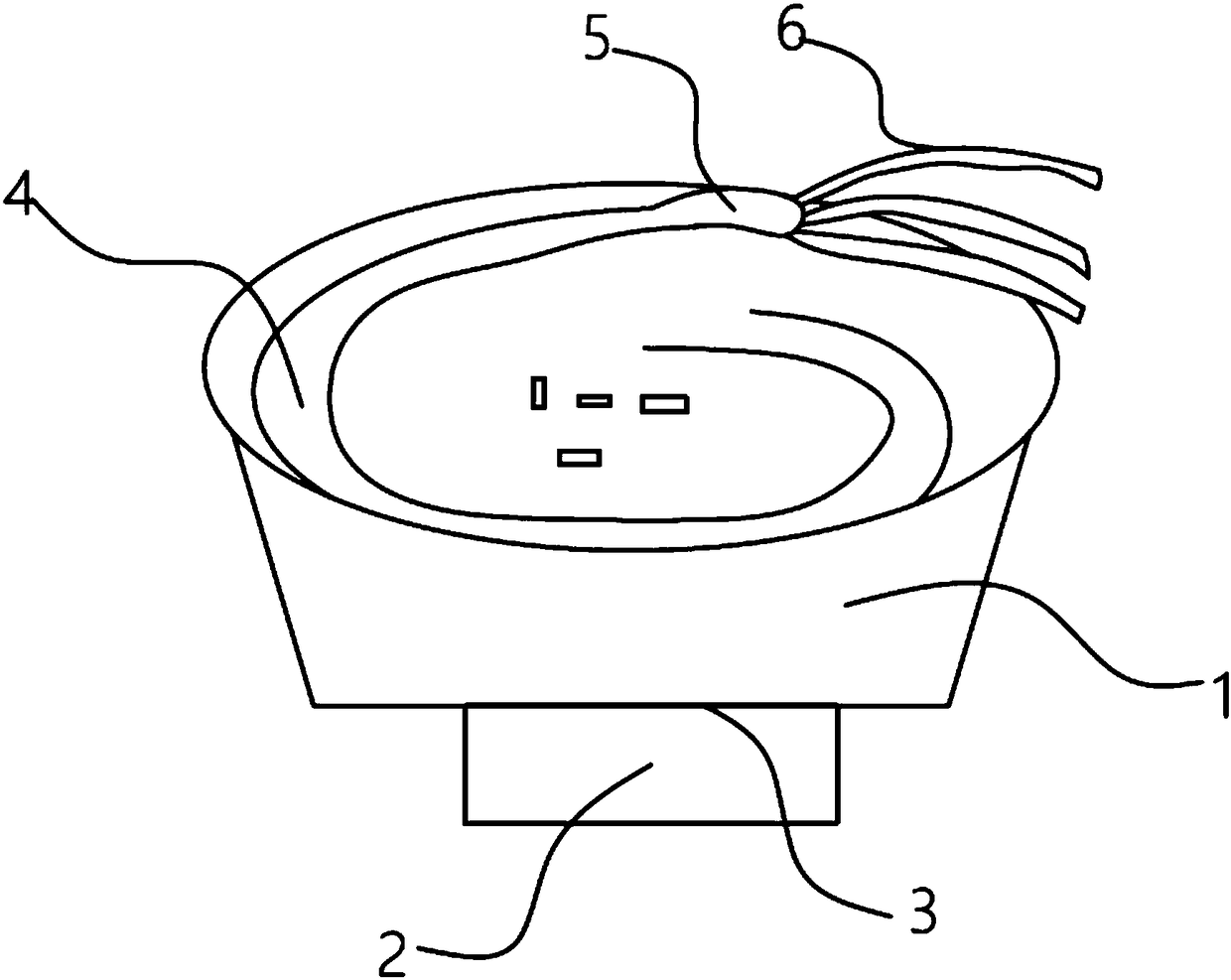

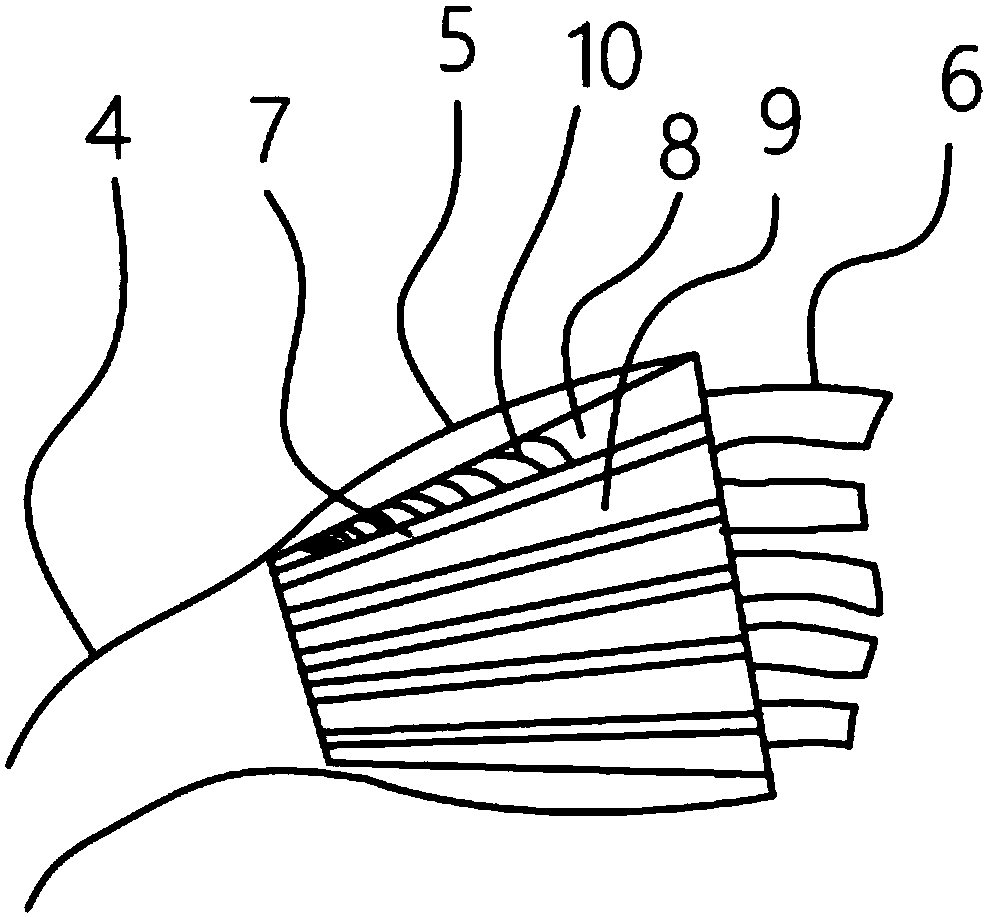

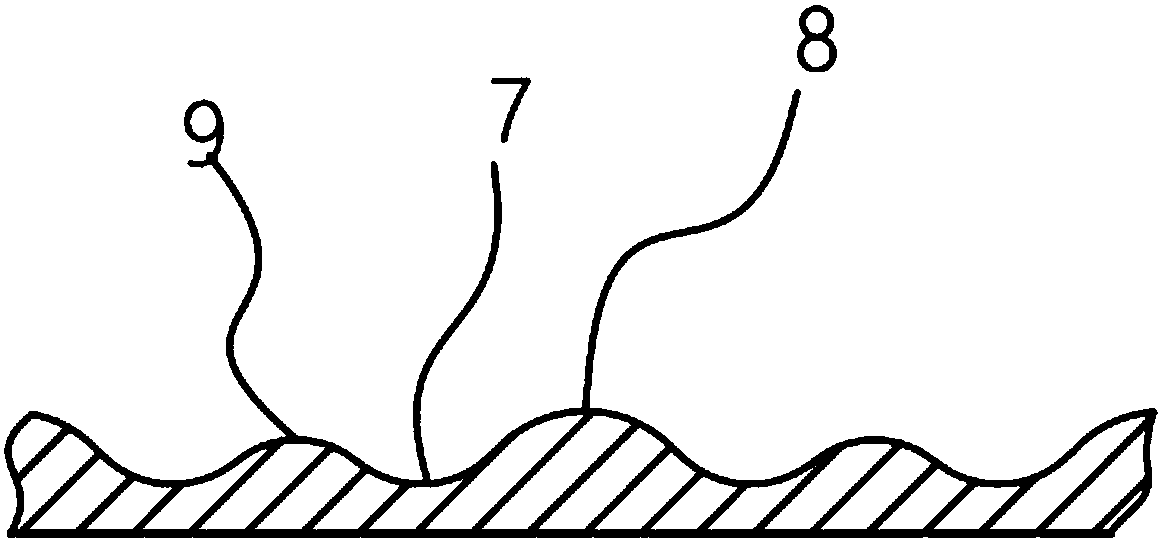

[0022] A metal short tube automatic vibrating feeding tray, such as figure 1 and figure 2 As shown, the feeding tray includes a base 1 with a vibrator 2, and a feeding hopper 3 for loading short metal pipes is arranged above the base 1. The inner wall of the feeding hopper 3 is provided with a spirally rising feeding channel 4, which is characterized in that the feeding channel 4 The upper part is provided with a directional disk 5 for directional arrangement of short metal pipes, and several feeding branch channels 6 are arranged behind the directional disk 5, and several directional channels 7 are arranged on the directional disk 5, and the feeding branch channels 6 One-to-one correspondence with the directional road 7, the bottom of the directional road 7 is an arc surface, and the two sides of the directional road 7 are respectively provided with a high directional surface 8 and a low directional surface 9 with different heights, and the high directional surface 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com