Heating furnace

A heating furnace and heating tube technology, applied in the field of poultry breeding, can solve the problems of unstable temperature in the poultry house, gas poisoning, and easy temperature loss in the poultry house, so as to avoid excessive heat loss, reduce labor consumption, and avoid partial The effect of temperature aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

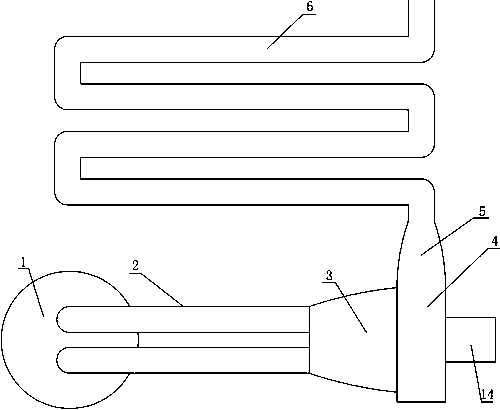

[0031] Such as Figure 1~4 As shown, the heating furnace includes a furnace body 1, a heat supply pipe 2, a blower 4, a motor 14 and a heating pipe 6; a gas furnace 7 is provided at the bottom of the furnace body 1, and a gas pipe 8 is connected to one side of the gas furnace 7, The top of the furnace body 1 is provided with a number of heat supply pipes 2, the heat supply pipes 2 double-layer structure, the heat supply pipes 2 are connected to one side of the blower 4 through the heating cover 3, the blower 4 is provided with a pressurized cover 5, and a heating pipe 6 It is connected with the pressure cover 5, and the motor 14 is connected with the blower 4. When the heating furnace was in operation, the gas furnace 7 burned natural gas from the gas pipe 8 to generate heat. Under the negative pressure generated by the blower 4, the hot gas in the furnace body 1 enters the heating hood 3 through a plurality of heat supply pipes, passes through the pressurized cover 5 on the ...

Embodiment 2

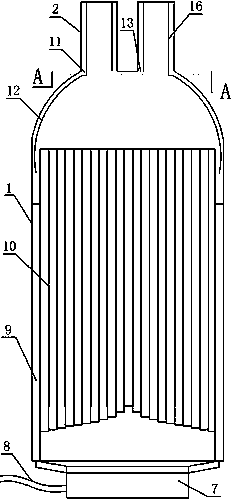

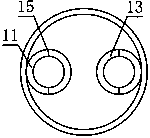

[0037] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the heat supply pipe 2 has a single-layer structure. The furnace body 1 includes air inlet pipes 9 and heat pipes 10 , the air inlet pipes 9 are evenly distributed on the inner wall of the furnace body 1 , and the heat pipes 10 are evenly distributed in the inner cavity of the furnace body 1 .

[0038] In this case, the furnace body 1 can also be put into the poultry house, and the heat dissipation of the heat supply pipe 2 can also be fully utilized in the temperature rise of the poultry house.

Embodiment 3

[0040] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the heat taken out by the air blower 4 does not pass through the heating pipe 6, but is directly blown into the poultry house.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com