Process for producing Ti and apparatus therefor

A manufacturing method and technology for manufacturing devices, which are applied in the electrolysis process, cells, electrolysis components, etc., can solve problems such as high price, and achieve the effects of suppressing changes, increasing supply speed, and stabilizing operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

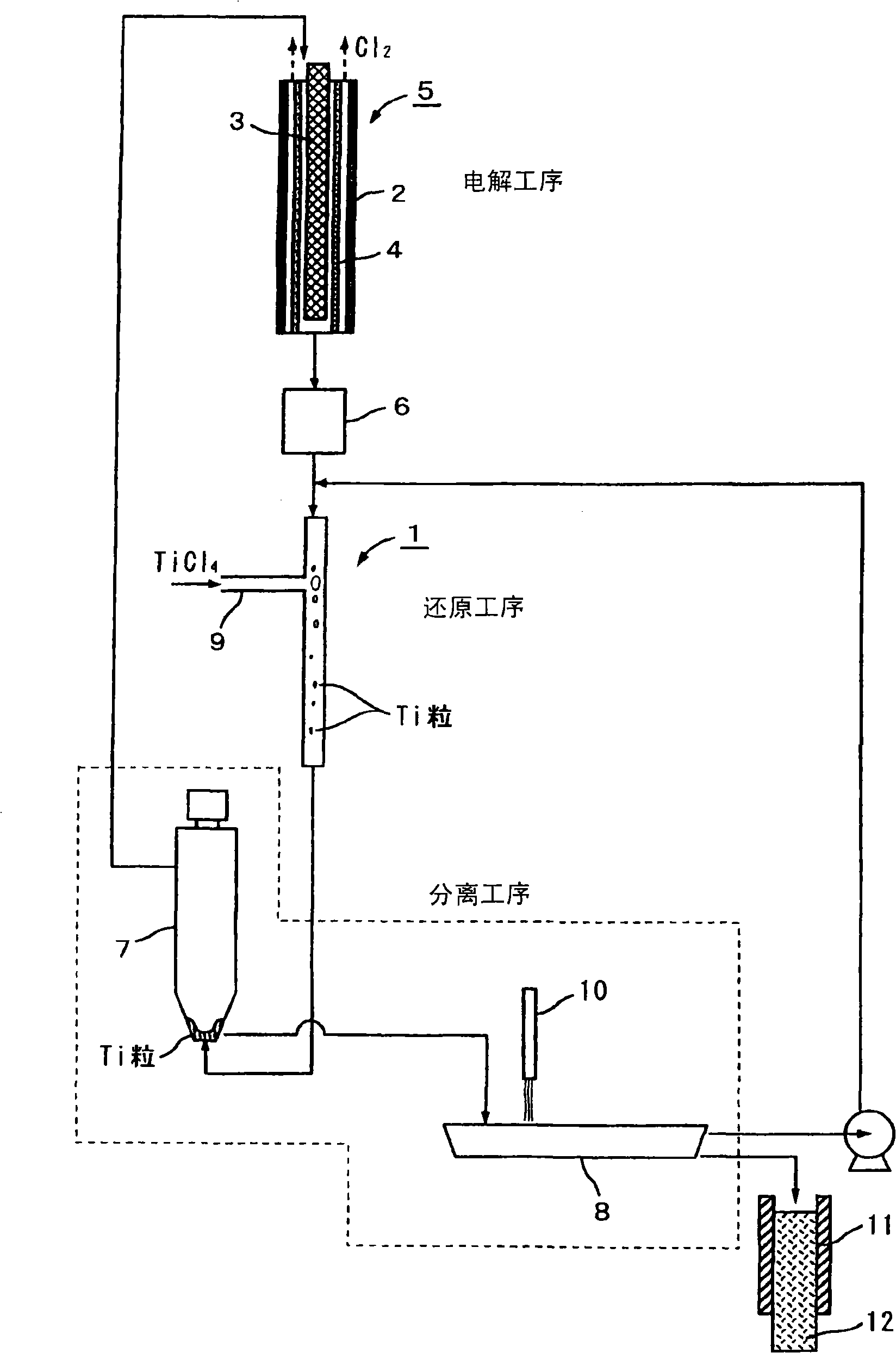

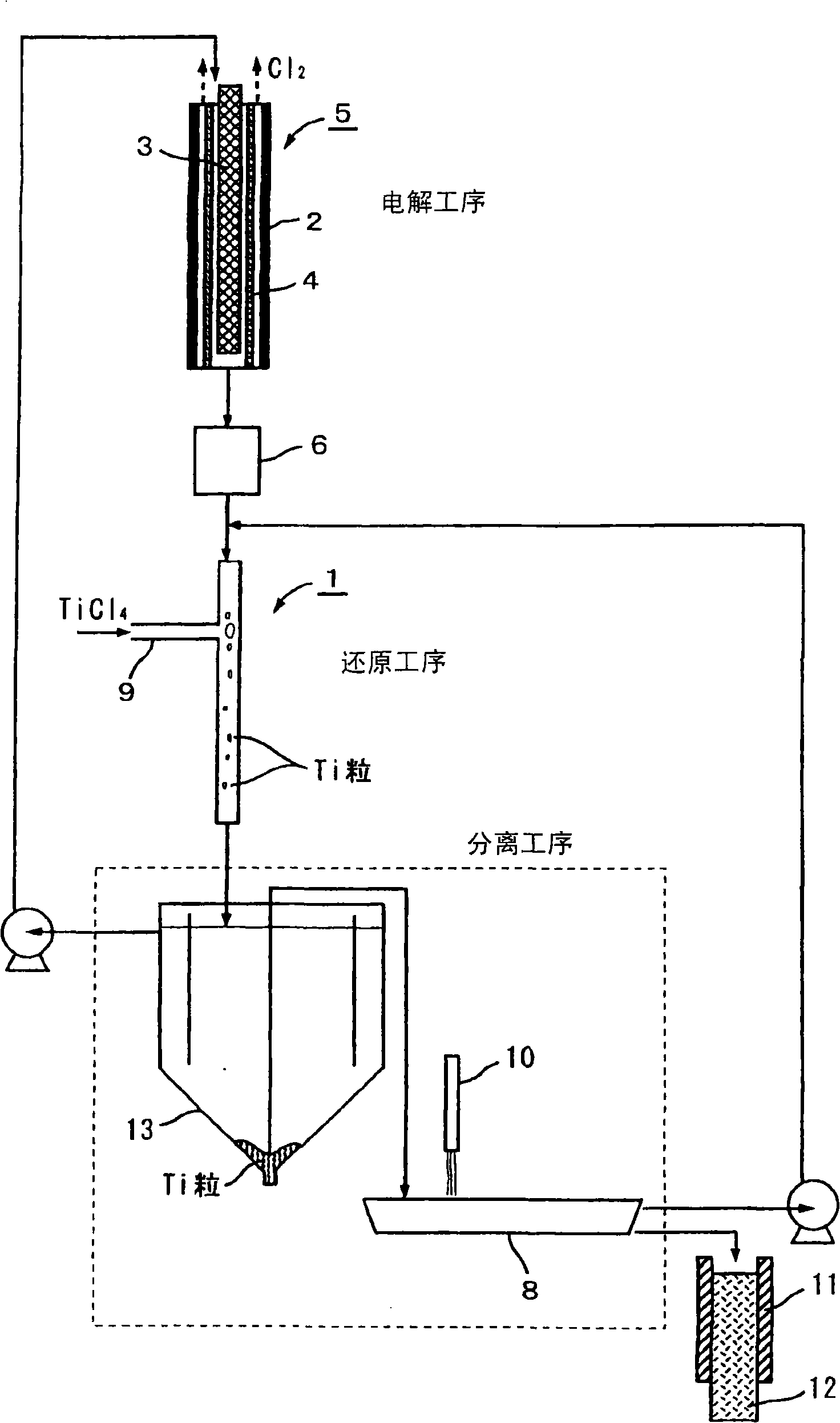

[0039] Hereinafter, the manufacturing method and manufacturing apparatus of this invention are demonstrated concretely with reference to drawings.

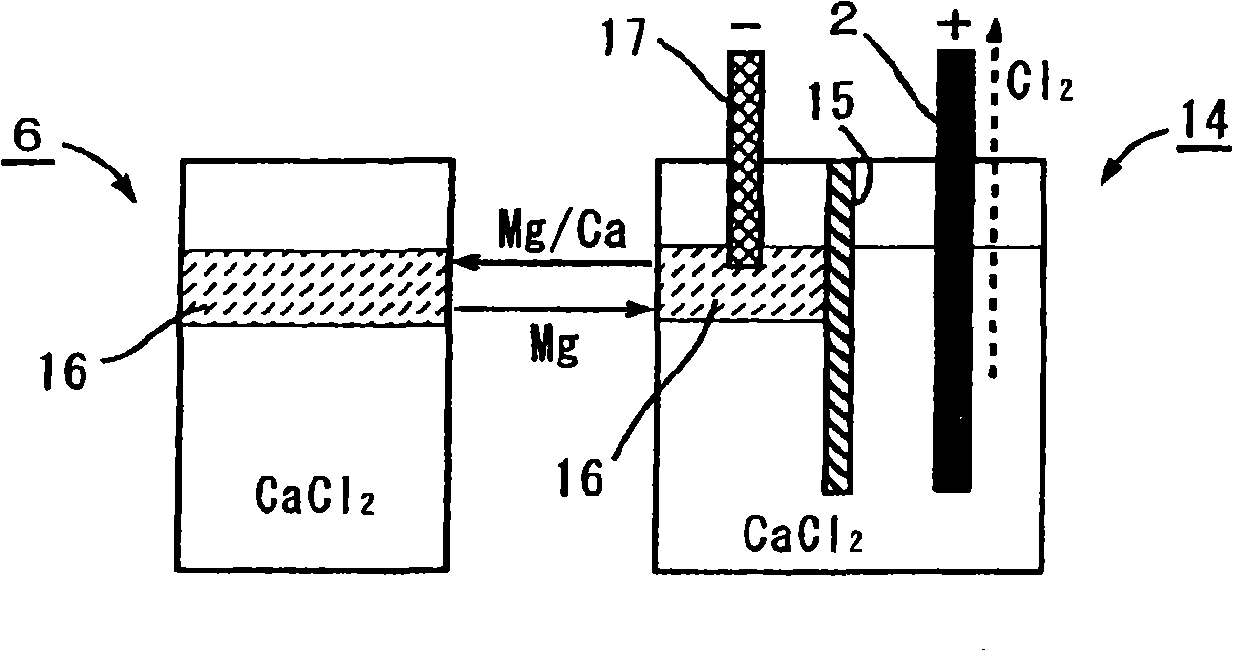

[0040] figure 1 It is a figure which shows the schematic structure example of the manufacturing apparatus of Ti of this invention. Such as figure 1 shown, the device has: maintain a CaCl-containing 2 And the molten salt with Ca dissolved is used to make the TiCl4 supplied to the molten salt react with the Ca to generate the Ti particle reduction tank 1; it is used to separate the Ti generated in the molten salt from the molten salt Particle separation mechanism; keep the molten salt separated from the Ti particles, have an anode 2 and a cathode 3, and use the main electrolytic tank 5 for electrolysis of the molten salt to generate Ca on the cathode side; provide a Ca supply source, and introduce The molten salt in the main electrolytic tank 5 is used in the adjustment tank 6 for feeding the molten salt into the reduction tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com