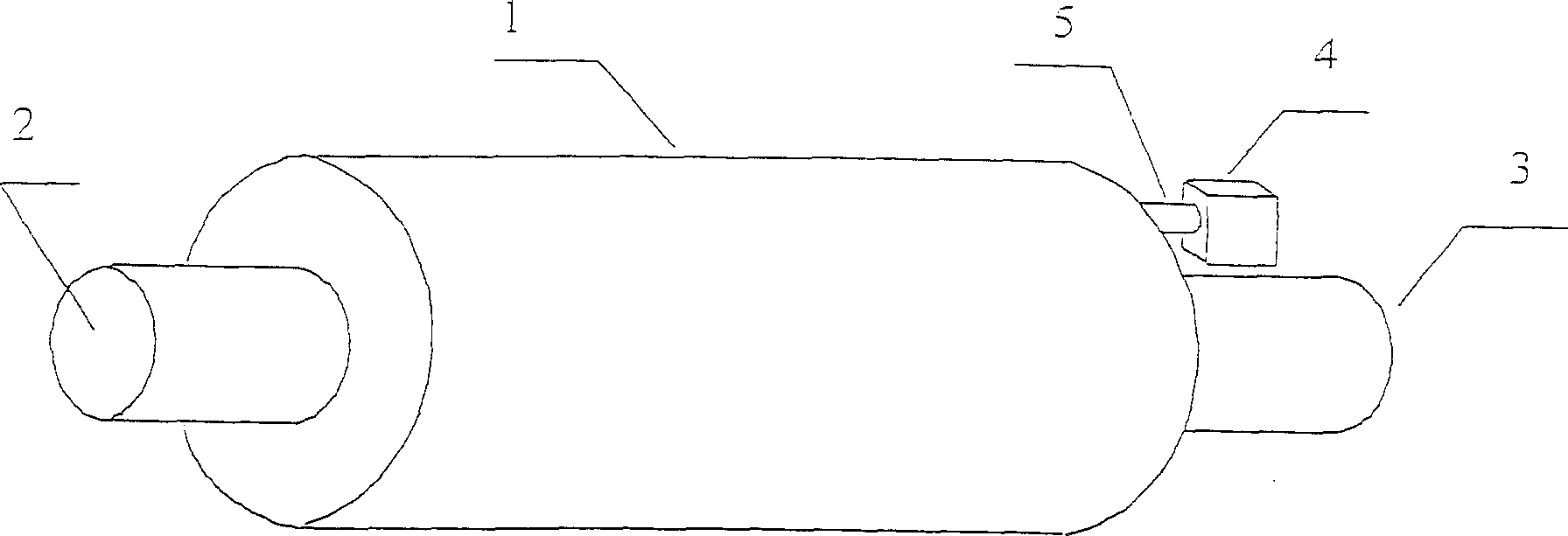

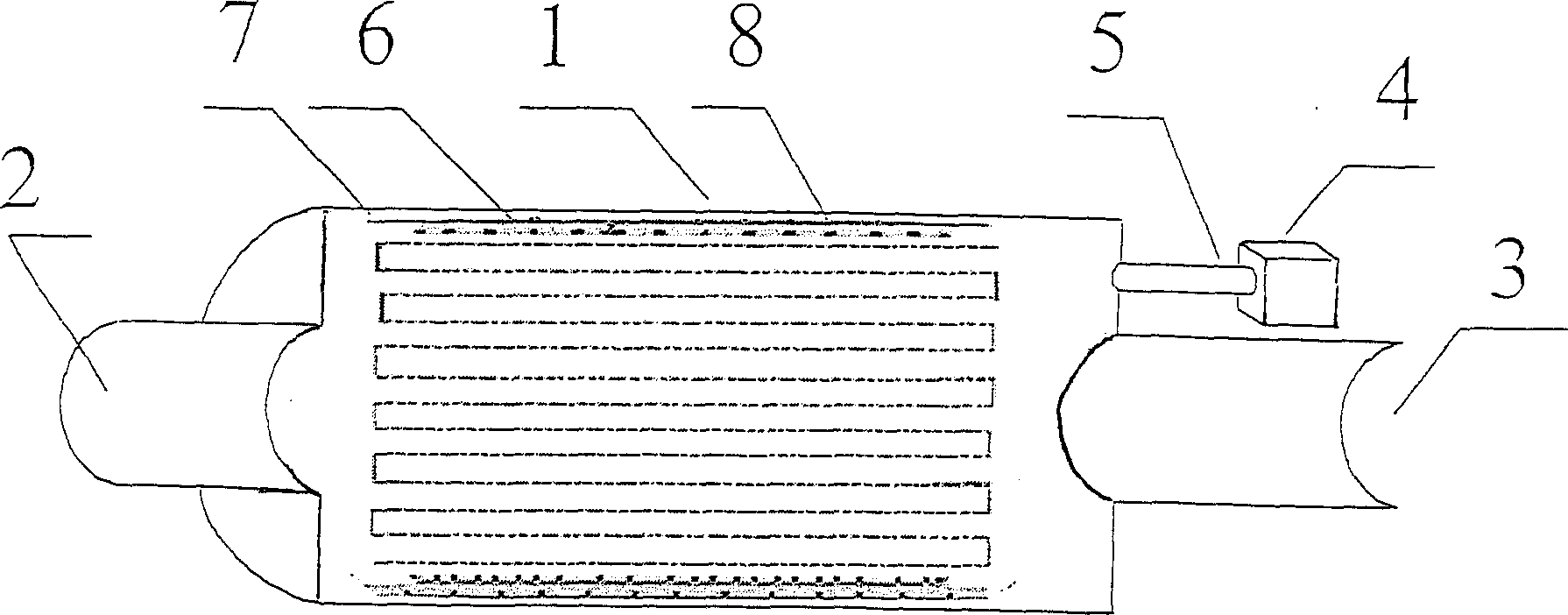

Engine tail gas treater with microwave technology used and the catalyst and its prepn process

An exhaust gas treatment and engine technology, applied in chemical instruments and methods, physical/chemical process catalysts, engine components, etc., can solve the problems of catalyst aging, poor exhaust gas purification effect, and high light-off temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

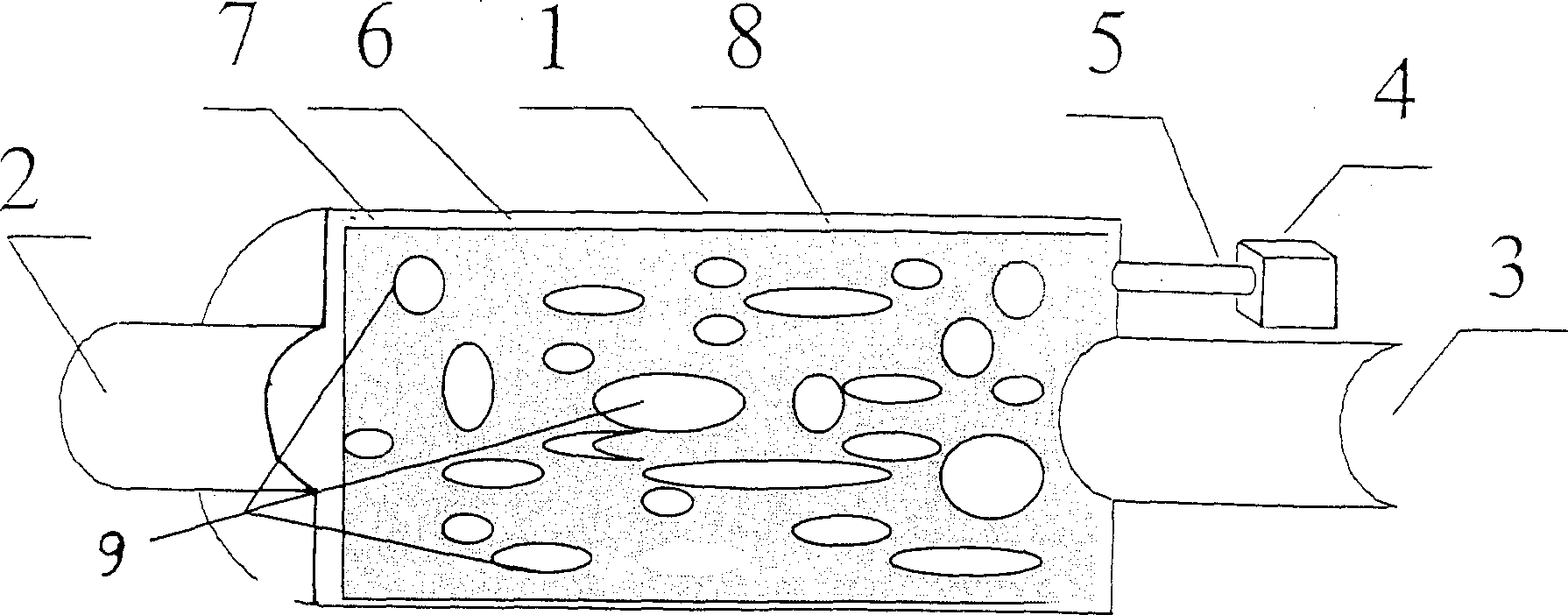

Embodiment 1

[0051] Take a certain amount of cerium nitrate to make a 4% solution, put the porous ceramic carrier into it, soak for 5 hours, then take it out, use absorbent cotton to make it dry in the air at room temperature for 12 hours, then place it in the air at 60 Dry in an oven for 3 hours at a temperature of ℃, and then calcinate in a high-temperature furnace for 2 hours at a temperature of 250°C. Take it out after cooling with the furnace, then put it into a mixed solution of copper nitrate and manganese nitrate (the concentration of copper nitrate is 3%, and the concentration of manganese nitrate is 1.5%) to soak for 5 hours, then take it out, and use absorbent cotton to make it dry in the air. Dry in the shade at room temperature for 12 hours, dry in an oven at 60°C for 3 hours, and then calcinate in a high-temperature furnace at 250°C for 2 hours. Take it out after cooling with the furnace, so that the catalyst of the present invention is prepared on the carrier. After detecti...

Embodiment 2

[0053] Take a certain amount of cerium nitrate to make a 4% solution, put the porous ceramic carrier into it, soak for 5 hours, then take it out, use absorbent cotton to make it dry in the air at room temperature for 12 hours, then place it in the air at 60 Dry in an oven for 3 hours at a temperature of ℃, and then calcinate in a high-temperature furnace for 2 hours at a temperature of 250°C. Take it out after cooling with the furnace, and then take a certain amount of copper nitrate, platinum nitrate, rhodium nitrate and palladium nitrate to make 8%, 1%, 1.5% and 2% solutions respectively, and mix them. Then put the carrier into it, soak for 15 hours, then take it out, use absorbent cotton to dry it in the air at room temperature for 20 hours, then dry it in the air at 150°C for 2 hours, and then dry it in the air at 300°C Calcined at high temperature for 1 hour, then took out after cooling with the furnace. Finally, at a temperature of 400°C, it was reduced with hydrogen fo...

Embodiment 3

[0055] Take a certain amount of cerium nitrate to make a 12% solution, then put the carrier into it, soak for 7 hours, then take it out, use absorbent cotton to dry it in the air at room temperature for 18 hours, and then put it in the air at 70 ° C Dry it in an oven at high temperature for 2 hours, then calcinate it in a high-temperature furnace at a temperature of 300°C for 2.5 hours, and take it out after cooling with the furnace. Then, put it into the mixed solution of copper nitrate and palladium chloride (the concentration of copper nitrate is 15%, the concentration of palladium chloride is 2.5%) and soak for 7 hours, then take it out, utilize absorbent cotton to make it in the air at room temperature Dry in the shade for 18 hours, dry in an oven at 70°C for 2 hours, and then calcinate in a high-temperature furnace at 300°C for 2.5 hours. Take it out after cooling with the furnace, and finally reduce it with hydrogen at a temperature of 350°C for 1.5 hours. In this way,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com