Process for producing ti through ca reduction and apparatus therefor

A manufacturing method and technology of a manufacturing apparatus, which are applied in the field of manufacturing and manufacturing equipment of Ti reduced by Ca, can solve problems such as unsuitability for high-purity Ti manufacturing, and achieve the effects of realizing operation, realizing continuity, and increasing supply speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

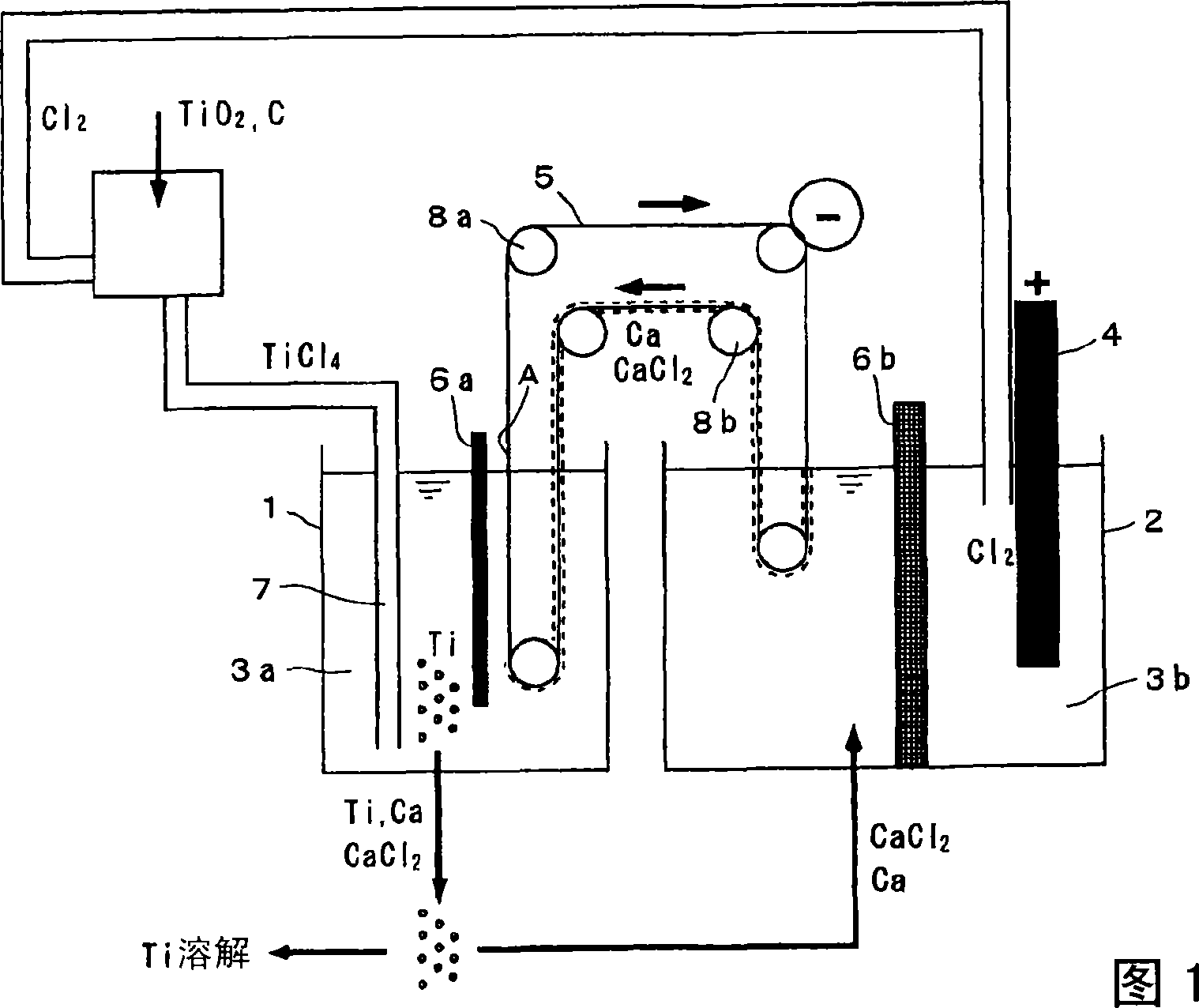

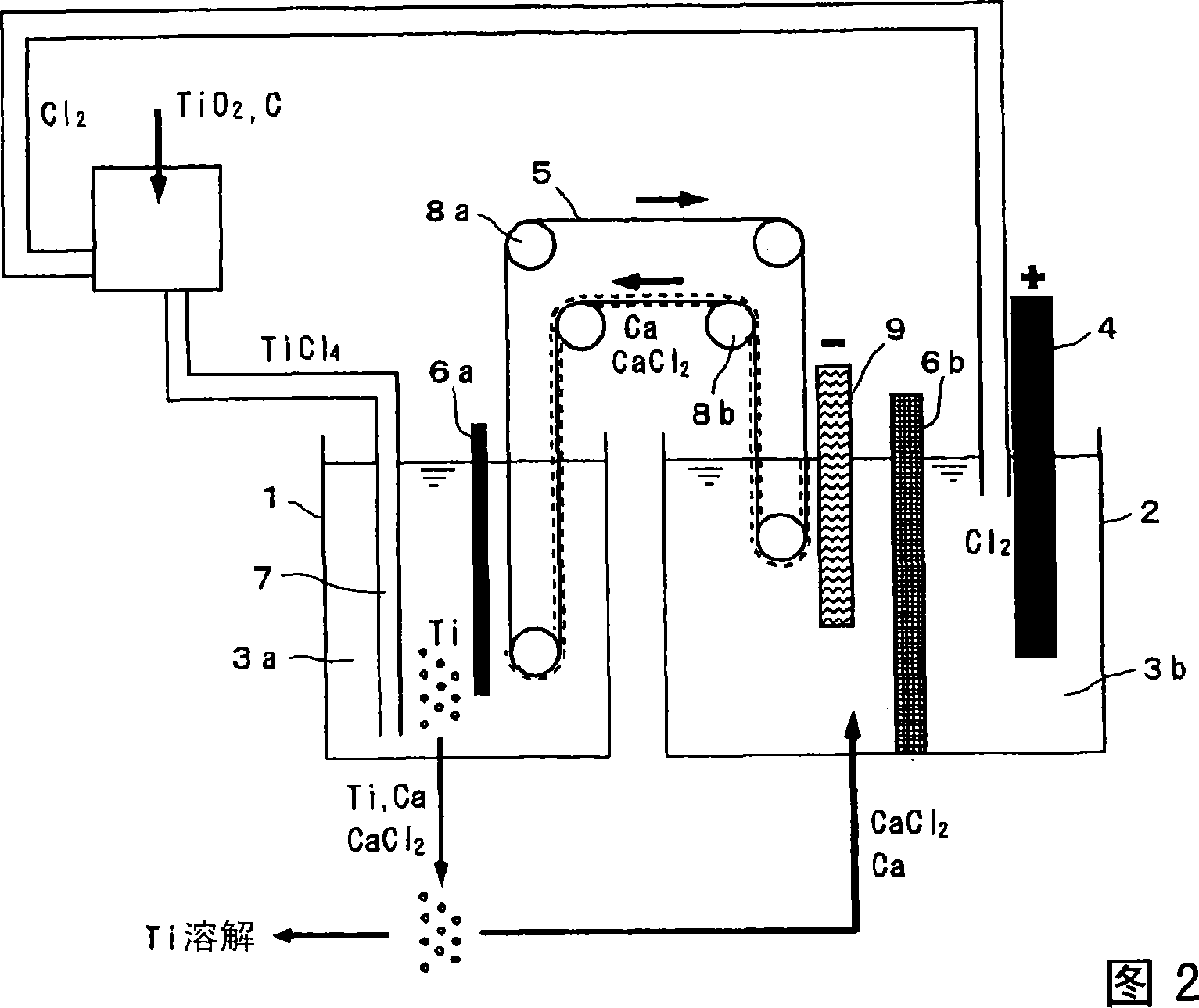

[0039] Next, the method and apparatus for producing Ti reduced by Ca according to the present invention will be described with reference to the drawings.

[0040] FIG. 1 is a diagram showing a configuration example of an apparatus capable of implementing the Ti production method of the present invention (Ti production apparatus of the present invention). As shown in the figure, this device has: TiCl used to make the TiCl supplied in the molten salt 3a 4 Reaction tank 1 that reacts with the above-mentioned Ca to generate Ti; holds CaCl 2 The molten salt 3b has an anode 4 and a cathode (in this example, the continuum 5 constitutes the cathode), electrolysis is performed in the molten salt 3b, and an electrolytic cell 2 that generates Ca on the cathode side; the continuum 5 is partly immersed in the reaction The tank 1 and the molten salts 3a, 3b in the electrolytic tank 2 are configured to be movable, and the above-mentioned generated Ca is separated and attached to the dipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com