A bag counting device

A counting device and goods technology, applied in the field of bag-by-bag counting counting technology, can solve the problems of error-prone and low work efficiency, and achieve the effects of improving accuracy, controllable conveying state, and improving counting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

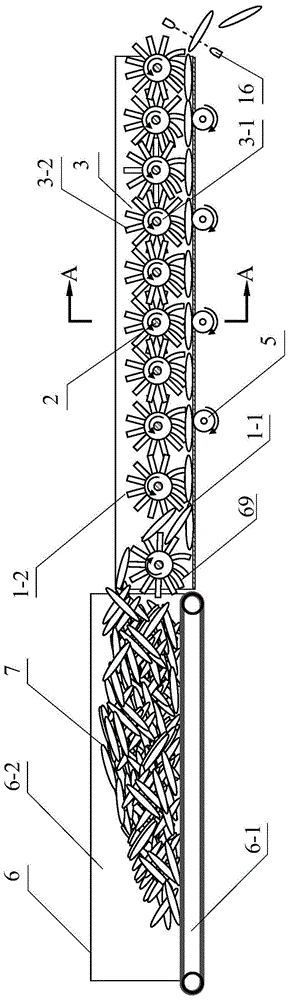

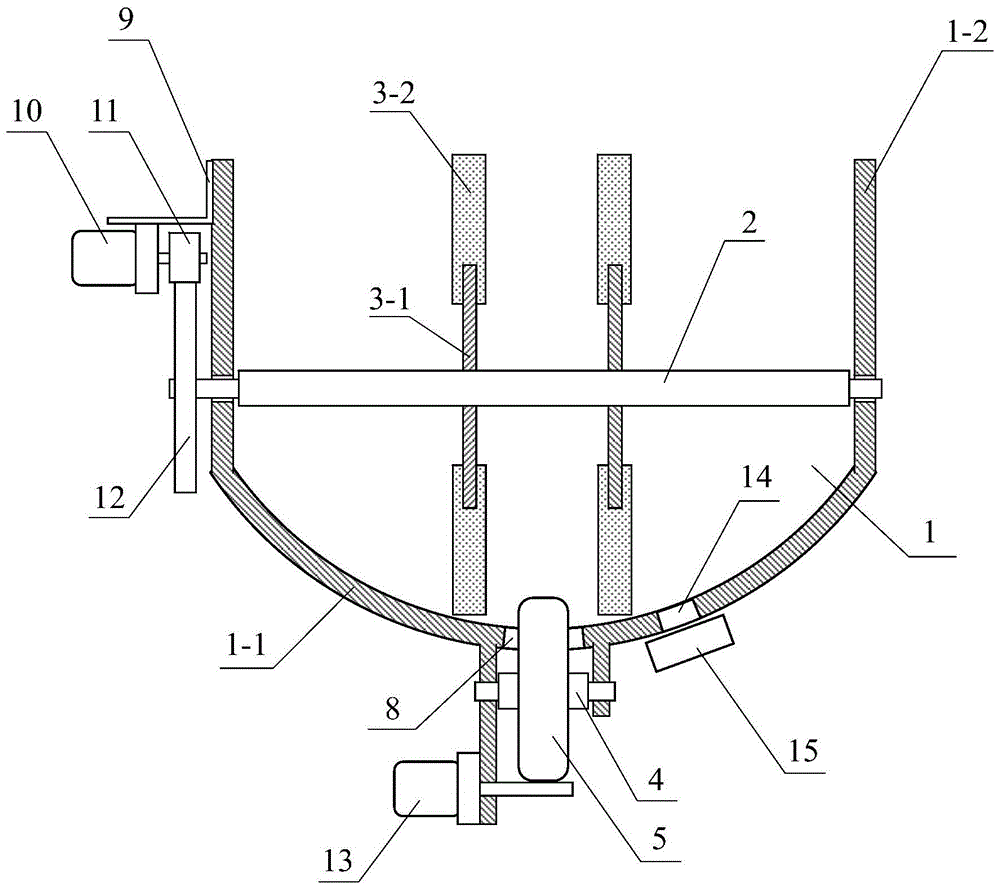

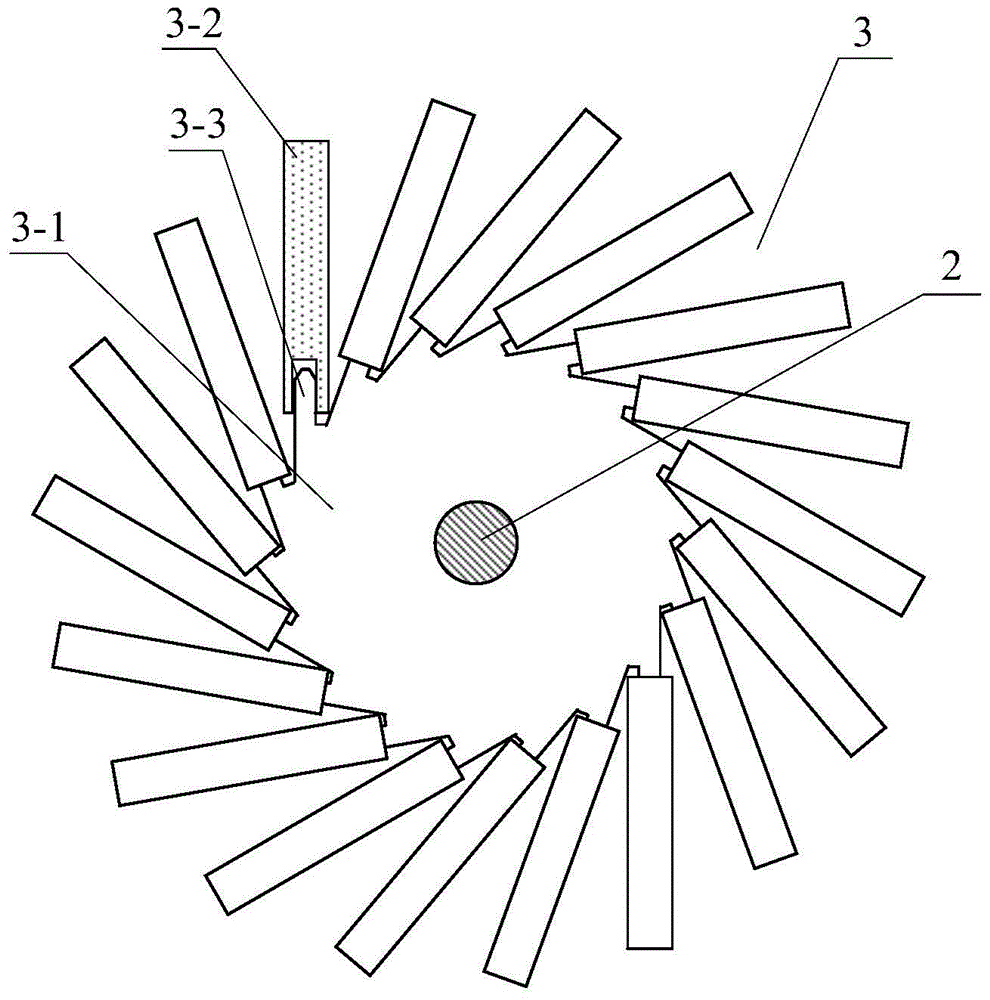

[0074] Such as figure 1As shown, a counting device for bagged goods 7 includes a sorting tank 1. One end of the sorting tank 1 is the bag-in end, and the other end is the bag-out end. The sorting tank 1 includes a tank bottom 1-1 and The groove wall 1-2, wherein, the groove wall 1-2 is an upright plate, the groove bottom 1-1 is an arc panel, and the cross section of the whole finishing groove 1 is U-shaped, of course, the groove bottom 1-1 can also be a flat plate, here When the cross-section of the finishing tank 1 is a rectangle with an open upper end, or the tank bottom 1-1 is a trapezoidal tank bottom 1-1, and the tank wall 1-2 is not necessarily an upright plate, the main function of the tank wall 1-2 is to Support the bag-turning wheel shaft 2, therefore, the groove wall 1-2 can be an inclined flat plate, and also can be a curved plate, as long as it can support the bag-turning wheel shaft 2 and facilitate the delivery of the bagged goods 7. In addition, according to th...

Embodiment 2

[0088] The structure of this embodiment is basically the same as that of Embodiment 1, except that the separation device for folded bags is different. The separation device for folded bags in this embodiment does not use the counter-runner wheel 5 , but uses the conveying roller 19 . The stacked bag separation device includes several conveying rollers 19 arranged at the bottom 1-1 of the sorting tank 1 along the length direction, the conveying rollers 19 are connected with the conveying roller driving device, and the conveying rollers 19 and the bag pulling wheel 3 rotate oppositely , There is a speed difference between the linear velocity of the rim of the conveying roller 19 and the linear velocity of the rim of the bag-turning wheel 3 corresponding to the top, and its rim linear velocity is greater than or smaller than the linear velocity of the rim of the bag-turning wheel 3 . And this moment, the shape of the finishing tank 1 is changed, the tank wall 1-2 is changed into t...

Embodiment 3

[0091] The structure in this embodiment is basically the same as that in Embodiment 1, except that the bag separation device is different, which includes a transmission wheel arranged on the bag-turning wheel shaft 2 of each stage, and a transmission wheel on the bag-turning wheel shaft 2 of each stage. Between step-by-step transmission connections, one of the bag-turning wheel shafts 2 is connected with the bag-turning wheel driving device, and the outer edge linear speeds of the bag-turning wheels 3 at all levels are gradually increased from the bag-in end to the bag-out end. Wherein, the transmission wheel can be selected from a transmission pulley, a transmission sprocket, and a transmission gear, and its pocket wheel 3 can be driven by a pocket wheel driver, or can be driven in groups by a plurality of pocket wheel drivers. The rotation speed of the bag-turning wheel 3 increases step by step, and the delivery speed of the bagged goods 7 in the sorting tank 1 is getting fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com