Patents

Literature

77results about How to "Reduce manpower input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

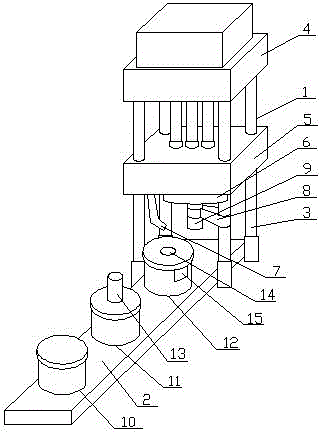

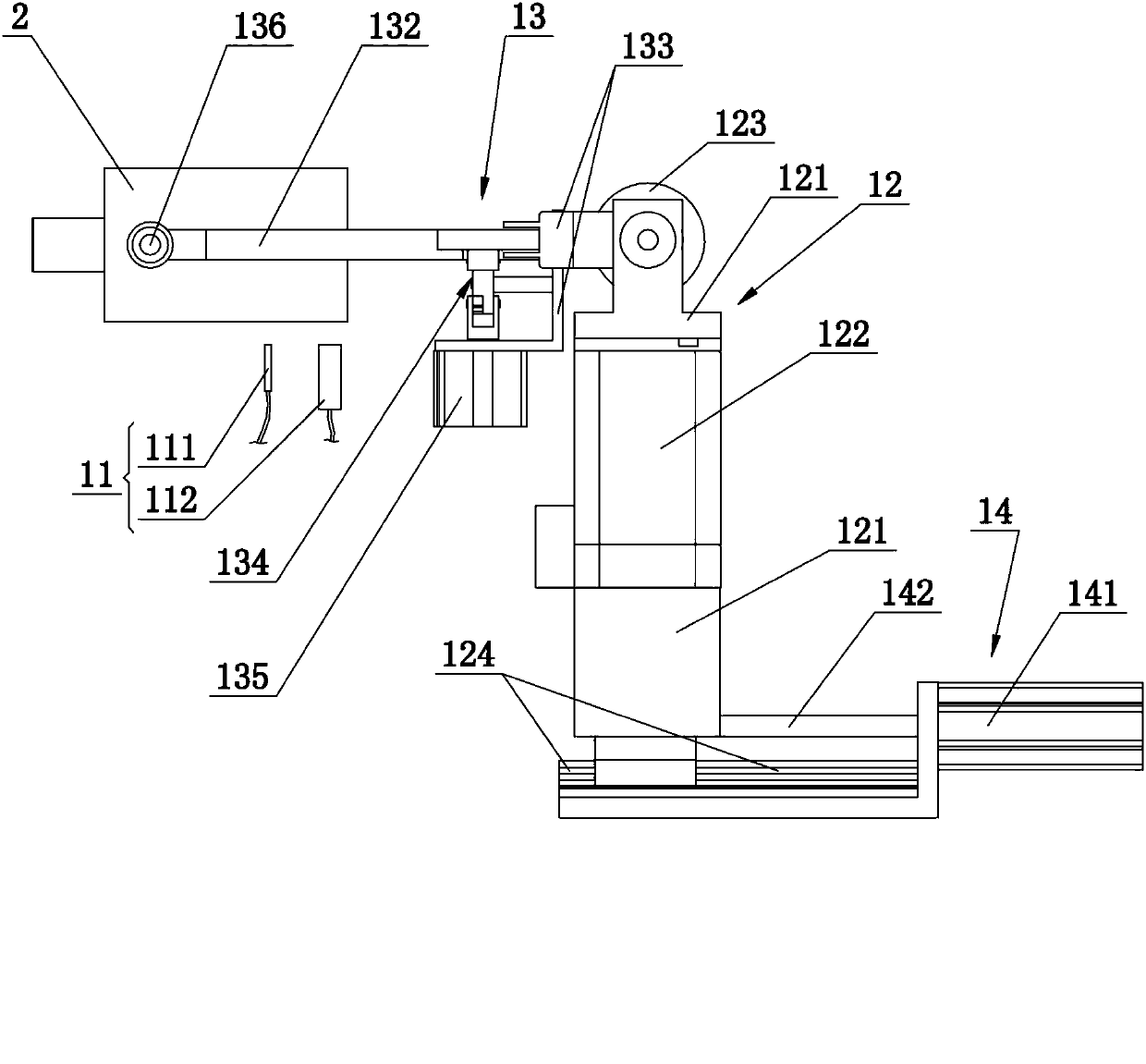

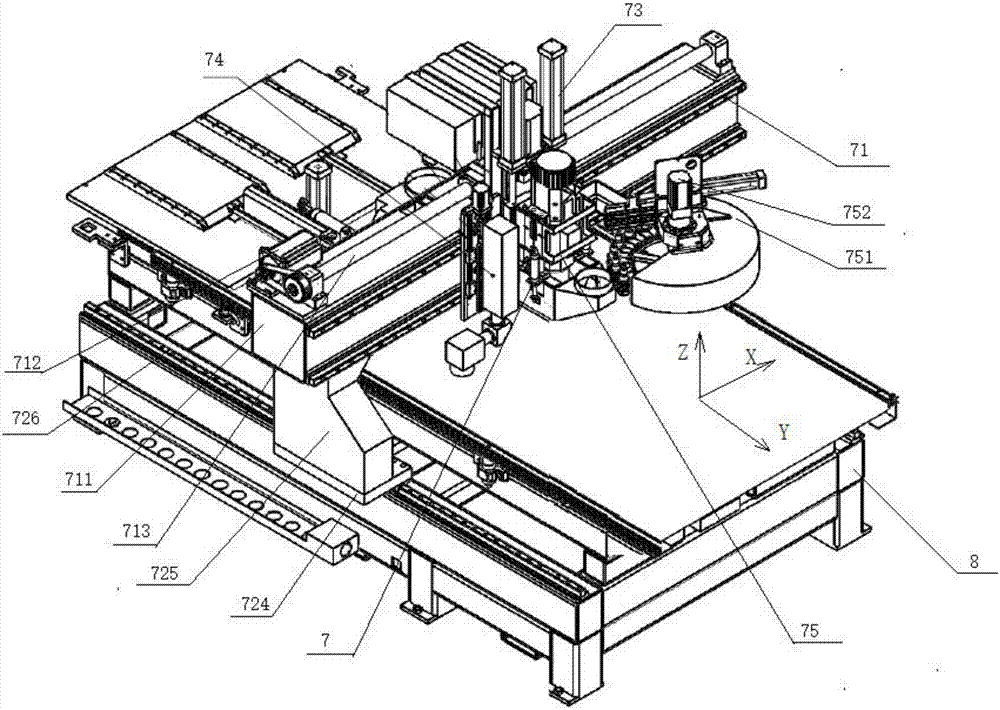

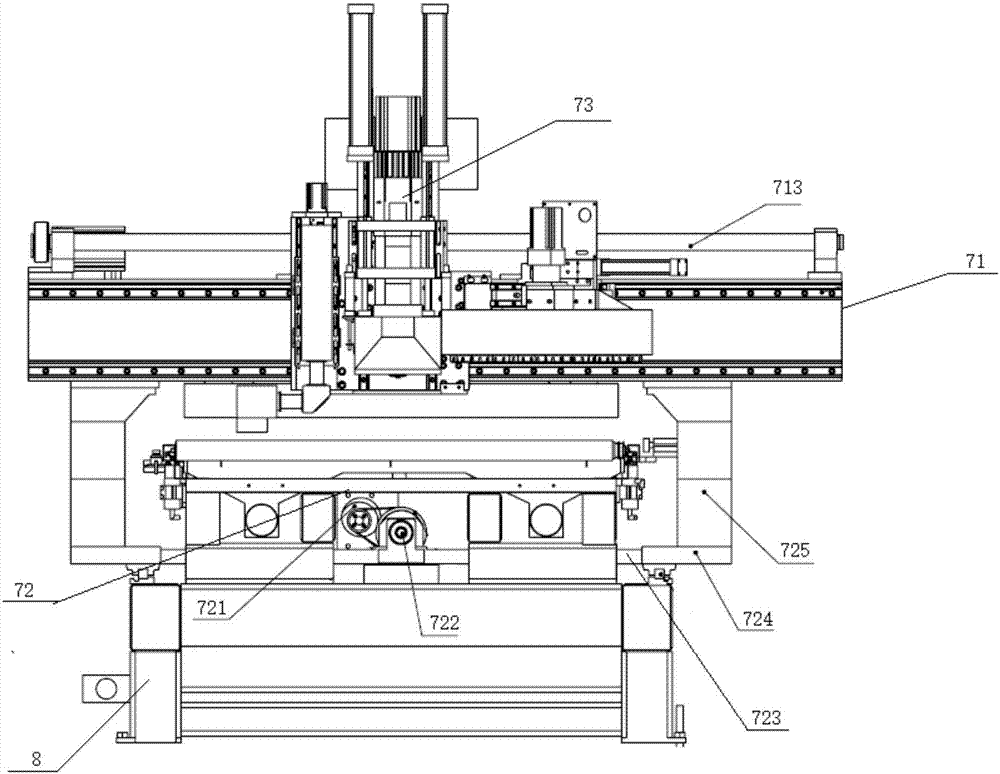

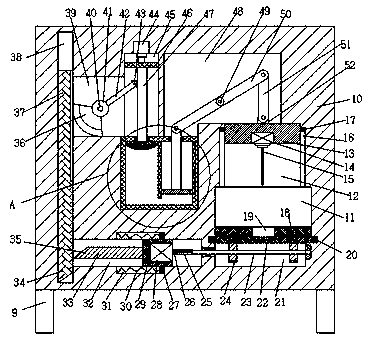

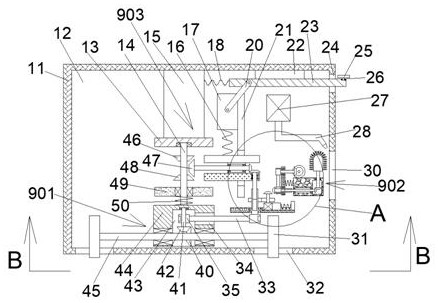

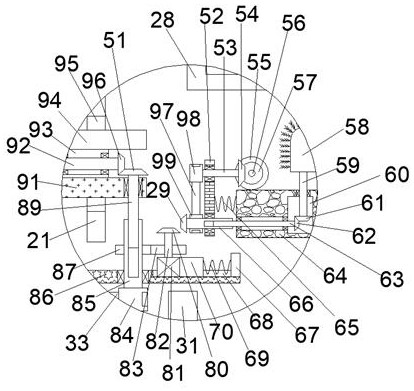

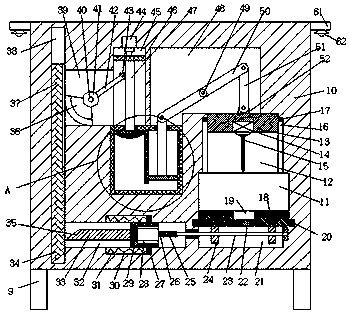

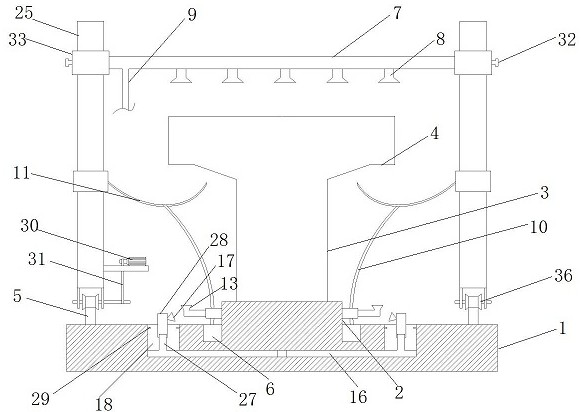

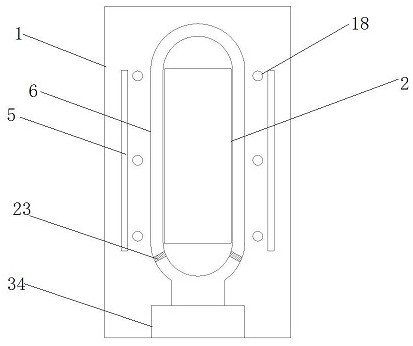

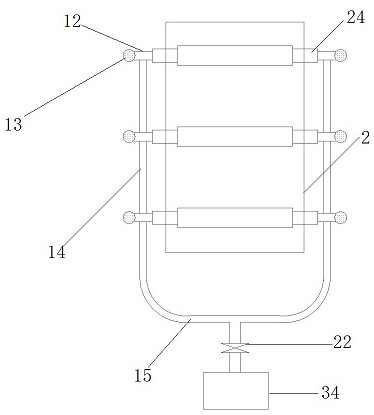

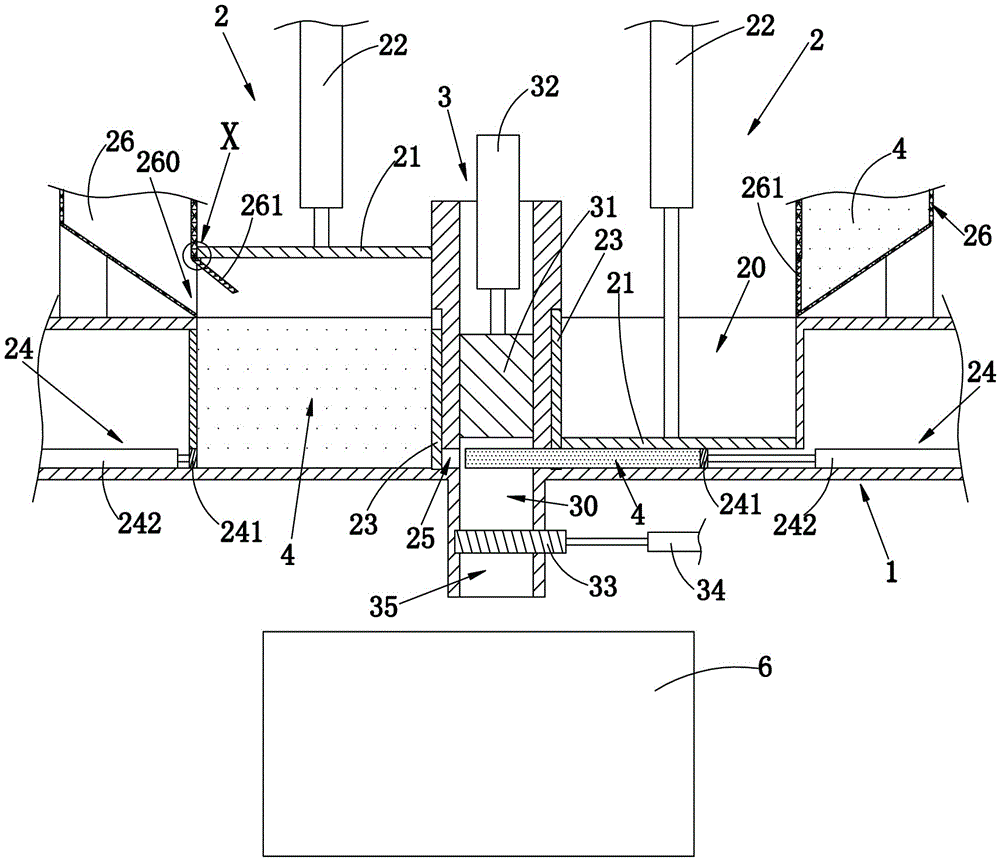

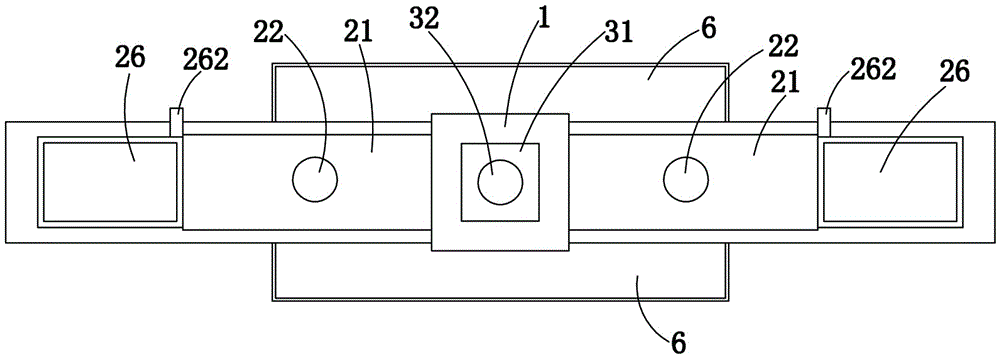

Hydraulic forging system and method for forging disk pieces with holes

The invention discloses a hydraulic forging system and method for forging disk pieces with holes, and belongs to the technical field of metal forging. The hydraulic forging system is composed of a forging and pressing device and a workbench. The forging and pressing device comprises a stand column and a sliding block arranged on the stand column in a sliding mode, the bottom of the sliding block is provided with a pressing block for stamping the forged pieces and a clamp for clamping the forged pieces, a rotating arm is connected to the stand column in a sliding mode, the other end of the rotating arm is provided with a punch matched with the pressing block, the rotating arm is connected with the sliding block through a movable connection board capable of stretching and retracting freely in the vertical direction, the workbench is arranged below the pressing block in a sliding mode, and an upsetting table, a punching table and a blanking table are arranged on the workbench in sequence in the sliding direction of the workbench and are used for achieving upsetting, punching blind holes from the bottom surface and punching through holes from the front surface respectively. By means of the hydraulic forging system and method, the thick disk pieces with the hole structures can be forged and machined, labor investment is greatly reduced in the forging process, and the forging and pressing efficiency is improved at the same time.

Owner:LUOYANG SHENGJIU FORGING

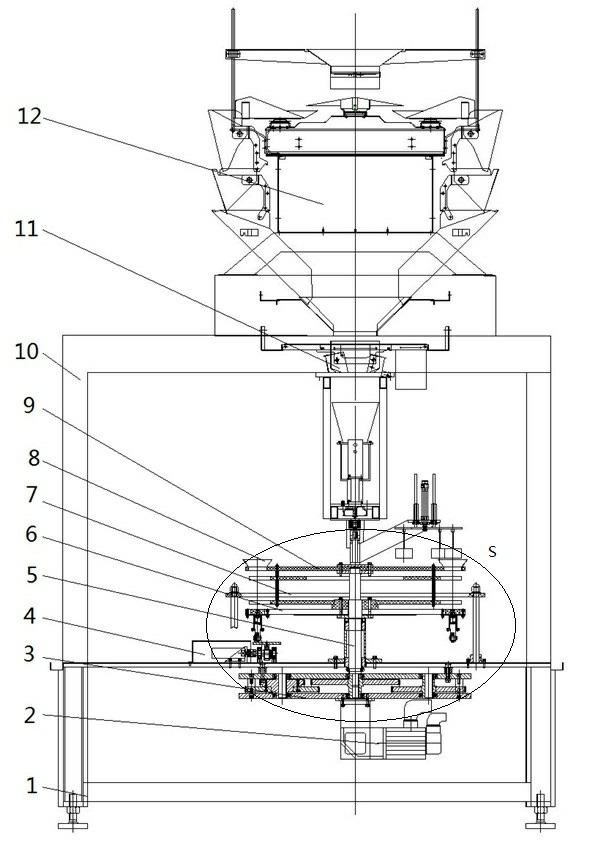

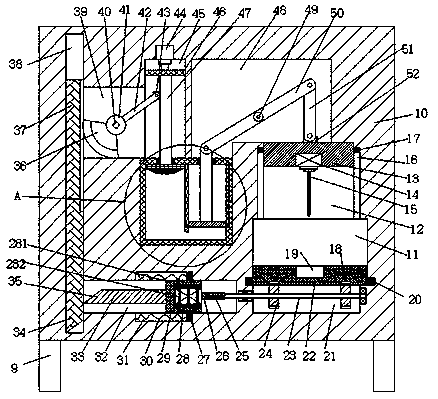

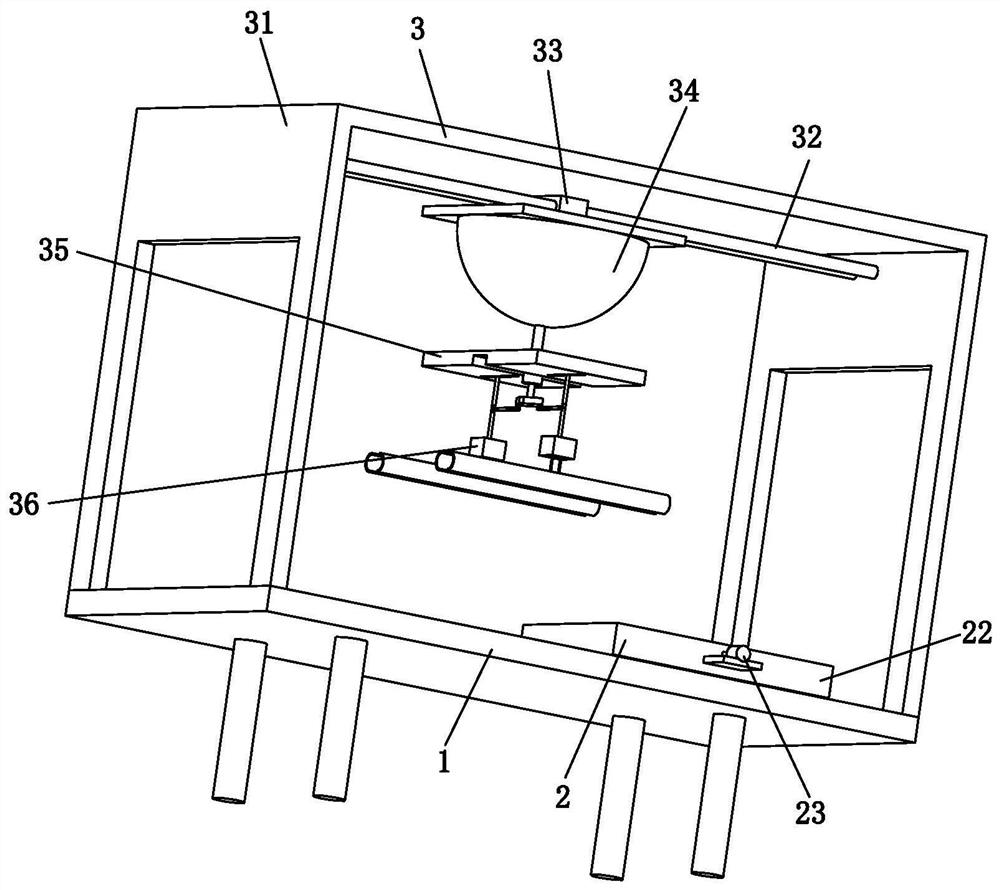

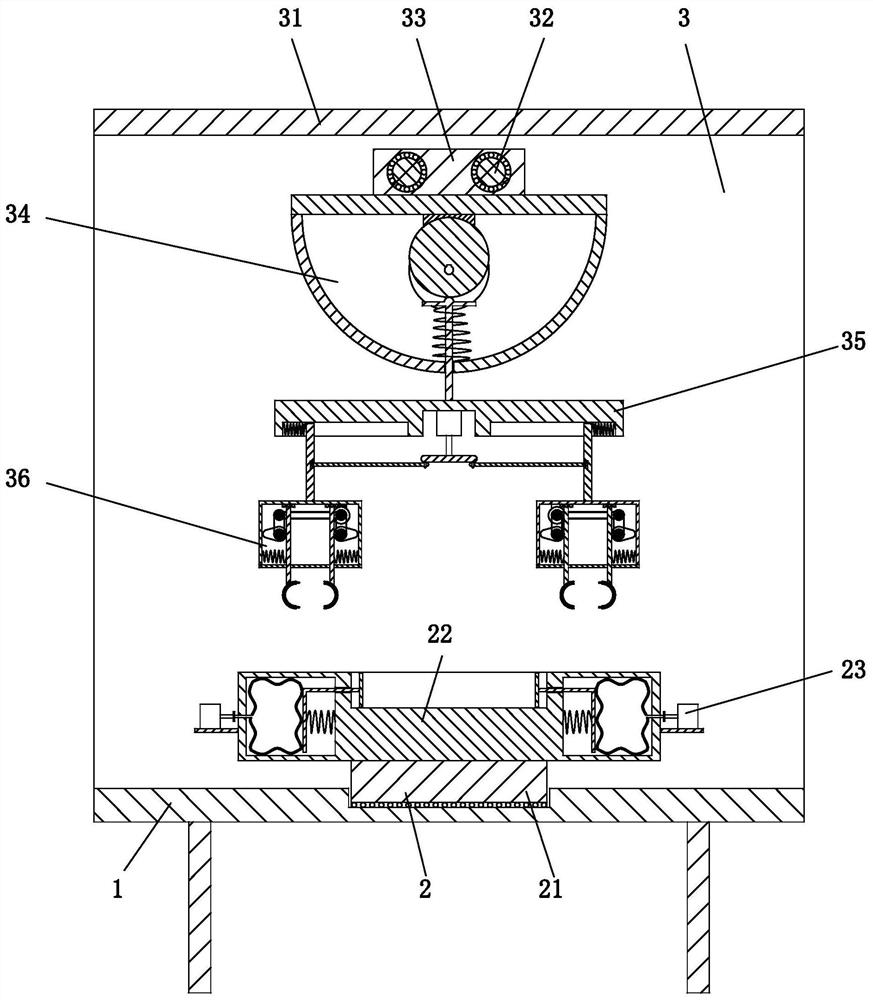

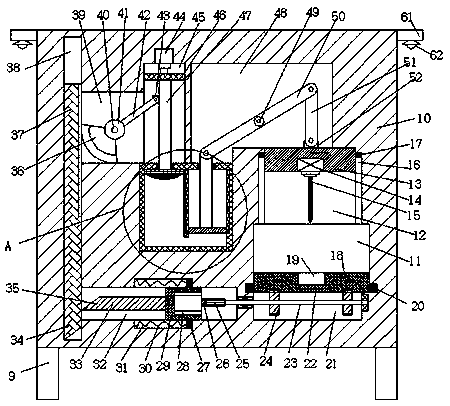

Automatic solid material weighing and canning machine

ActiveCN102616392AMaterial weighing is accurateReduce manpower inputSolid materialElectric machineryProgrammable logic controller

The invention discloses an automatic solid material weighing and canning machine. The machine comprises a frame, a transmission mechanism, a bottle conveying mechanism, a feeder and an automatic scale group, wherein the bottle conveying mechanism is arranged on the frame and connected with and driven by the transmission mechanism; an automatic scale group bracket is arranged at the lower end of the automatic scale group and fixedly arranged on the frame; and the feeder is positioned above the bottle conveying mechanism and arranged on the automatic scale group bracket. The machine has the characteristics that materials are accurately weighed and can be accurately discharged and canned at high speed according to a set weight parameter, so that waste is avoided; a large drive plate continuously runs, and the feeder is driven to quickly perform tracking feeding by a servo motor, so that mechanical wear caused by the frequent start and stop of the large drive plate is avoided, and canning efficiency is improved; the feeder is light in weight, small in inertia force and accurately positioned; and the servo motor is controlled to specify a station for feeding by a photoelectric switch and a programmable logic controller (PLC), so that empty bottles are not output, and canning is not performed at a bottle-free station.

Owner:大连林家铺子食品股份有限公司

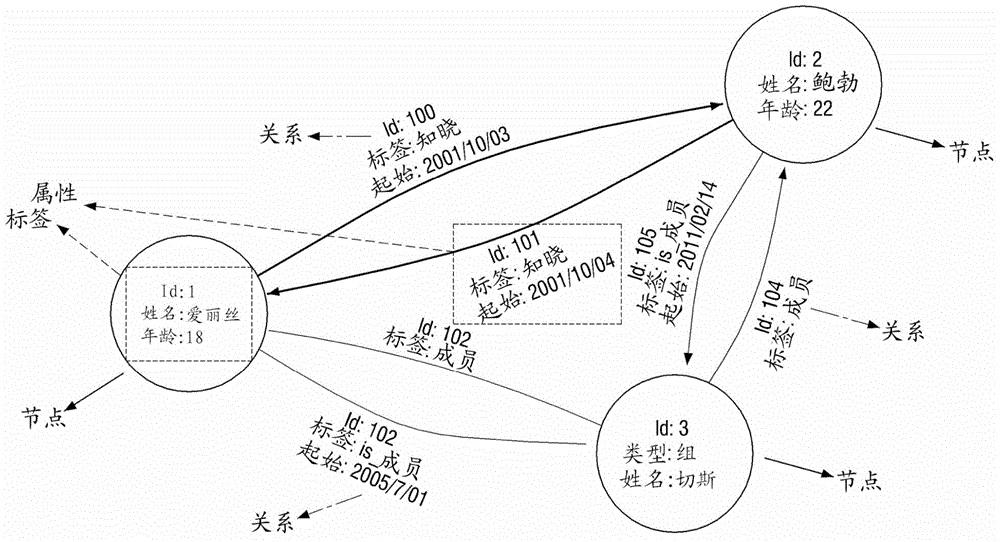

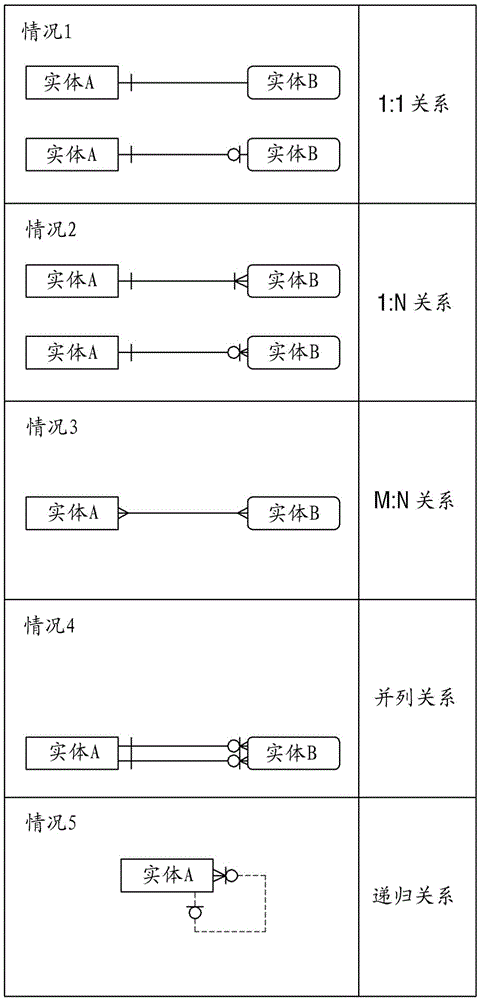

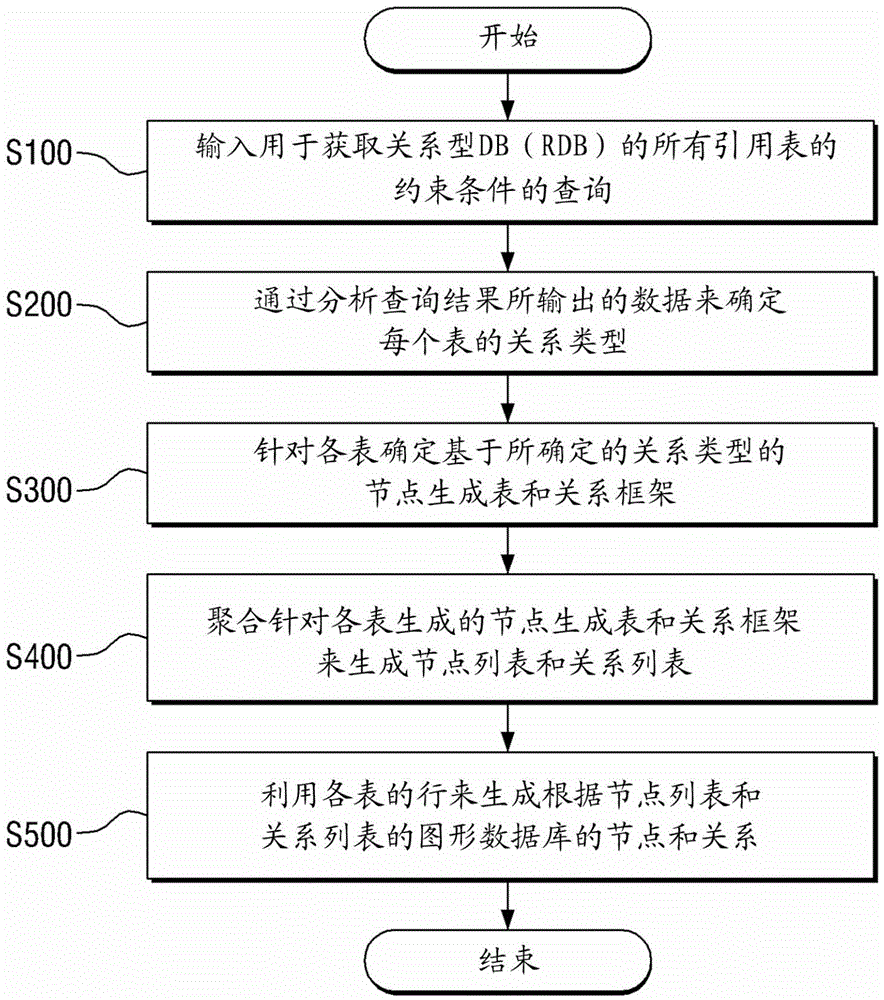

Database migration method and device thereof

InactiveCN105808553AReduce human inputReduce manpower inputDatabase distribution/replicationRelational databasesGraphicsFrame based

The invention provides a database migration method and a device thereof. The database migration method transfers a relational database to a graphic database in an automated manner. The database migration method in one embodiment comprises the following steps: aggregating constraint conditions of a referencing table, the referencing table being a table with columns which are set as foreign keys in a table of the relational database, the relational database being used as a migration source database; determining the relationship types of each referencing table by the constraint conditions of each referencing table; a database migration device determining a node generation table corresponding to the referencing table and a relation frame based on the relationship type of the referencing table; and converting each row data of the node generation table to nodes of the graphic database which is used as a migration target database, and according to the relation frame, generating relations of the graphic database, used to connect the generated nodes.

Owner:SAMSUNG SDS CO LTD

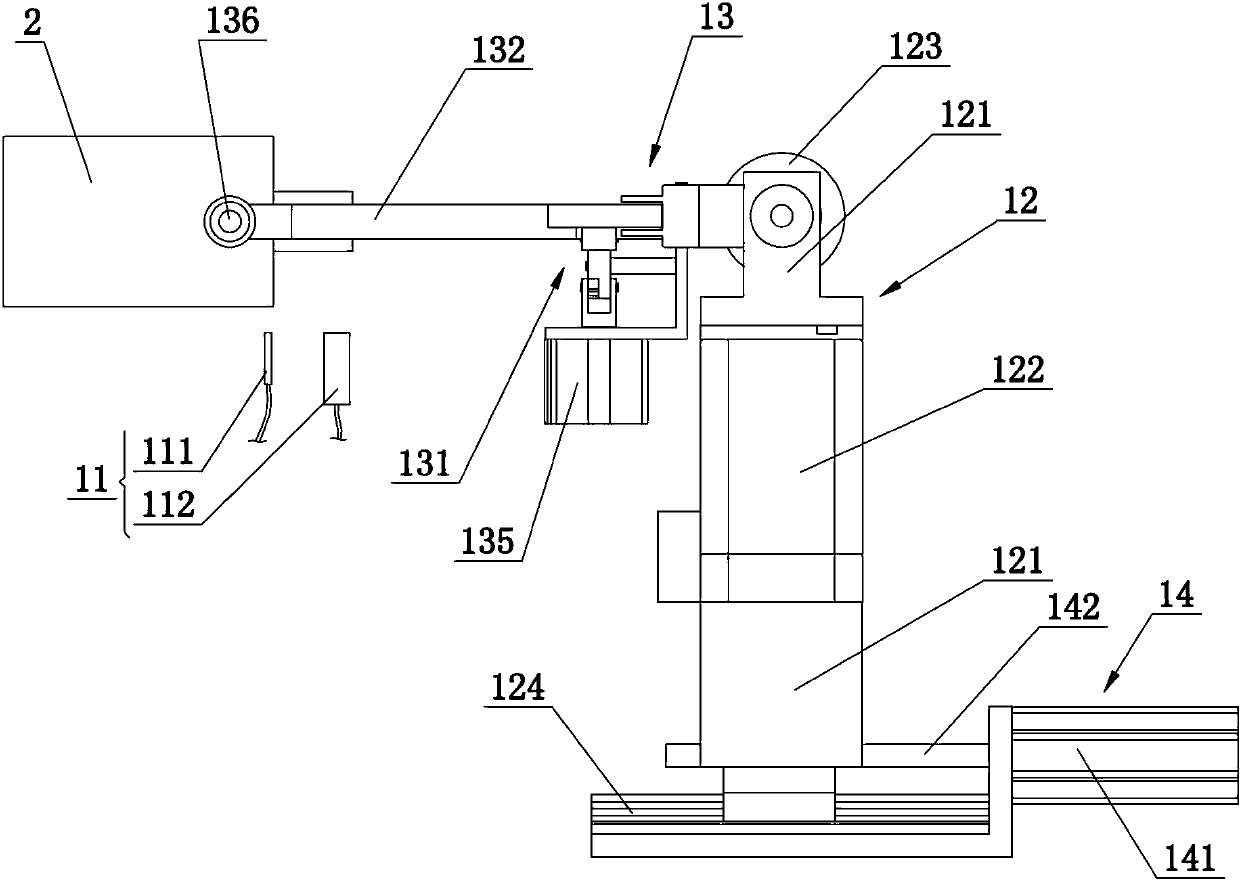

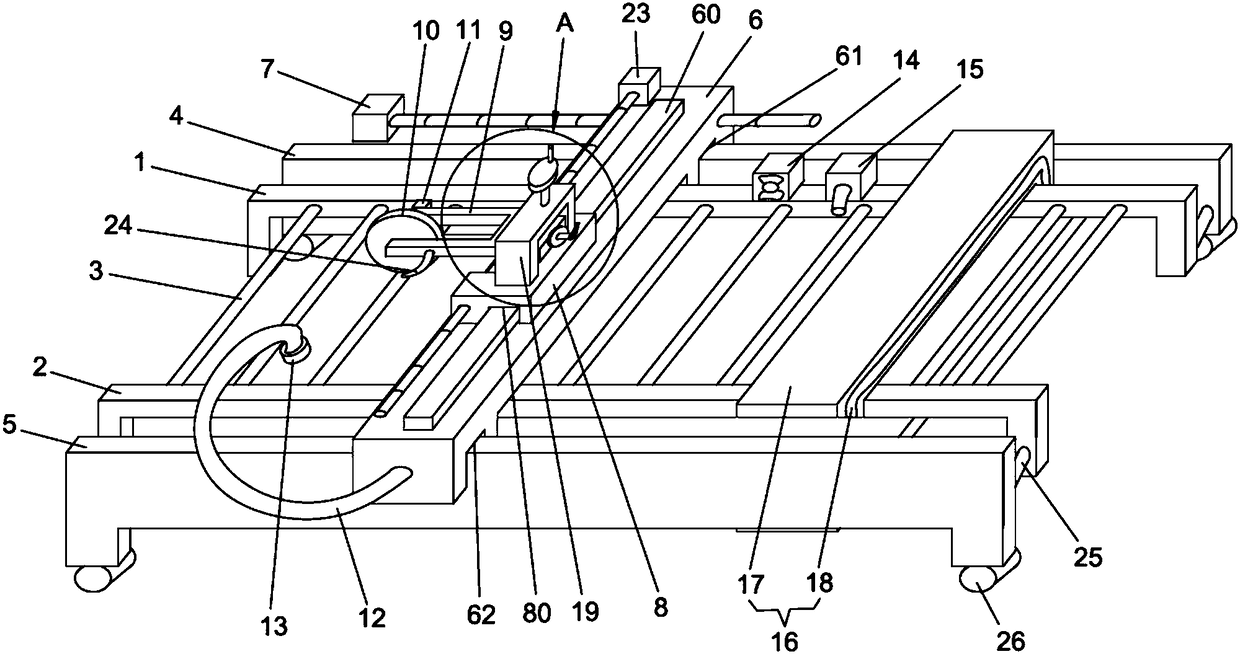

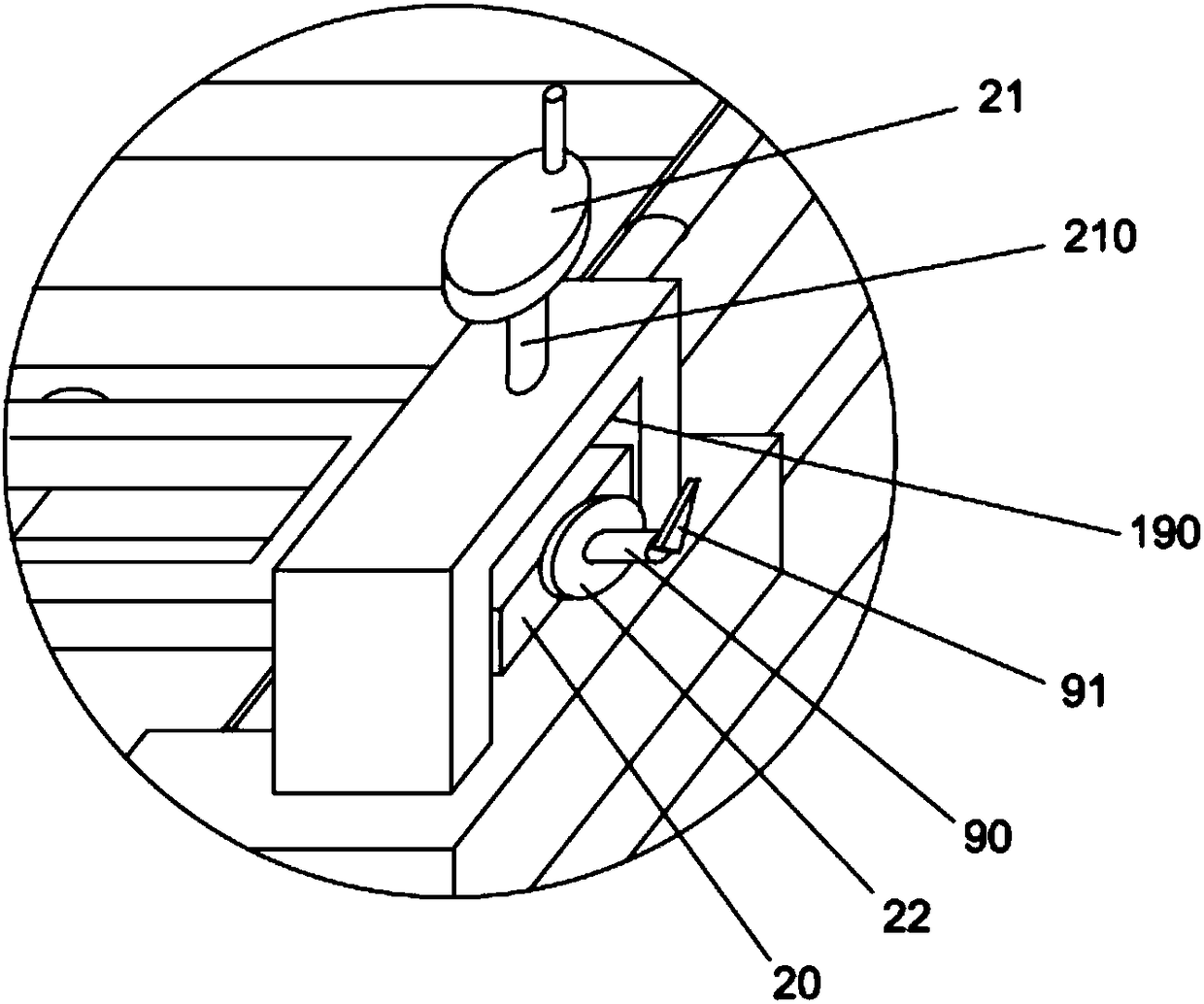

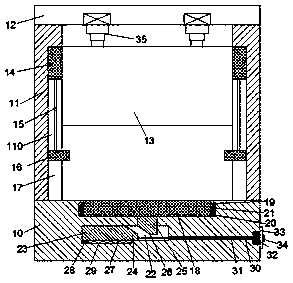

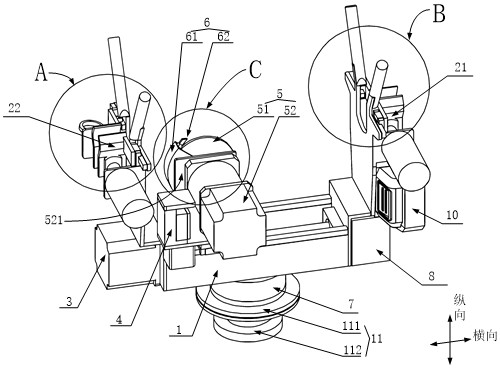

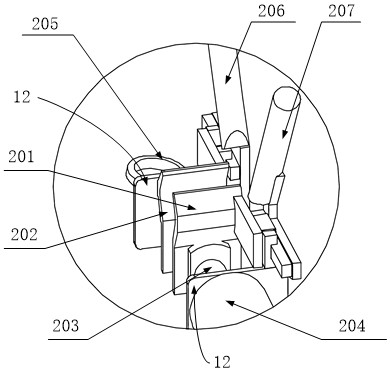

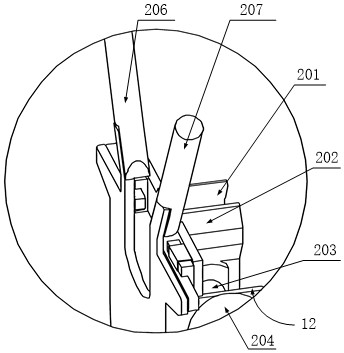

High-speed flat bottle straightening mechanical hand and bottle straightening method thereof

ActiveCN103303667AImprove bottle unscrambling efficiencyFast and accurate grabbingManipulatorConveyor partsGear wheelEngineering

The invention relates to a high-speed flat bottle straightening mechanical hand and a bottle straightening method thereof. The mechanical hand comprises a main frame body, a movement control mechanism used for controlling the mechanical hand, and a direction detection mechanism used for detecting bottle openings of flat bottles, wherein a swing arm mechanism, a clamp arm mechanism and a drive mechanism are assembled on the main frame body; the swing arm mechanism is glidingly assembled on the main frame body; the clamp arm mechanism comprises two clamp arms and an unclamping / clamping mechanism used for driving the two clamp arms to do unclamping / clamping movement; the clamp arm mechanism and a conical gear are synchronously and rotationally assembled on a supporting frame. According to the high-speed flat bottle straightening mechanical hand, the flat bottles can be quickly and accurately grabbed, the grabbing positions of different flat bottles with same specifications basically can be kept consistent, the flat bottles can be vertically arranged in a way that the bottle openings of the flat bottles are upward, and the bottle straightening effect is good; in addition, the bottle straightening speed of a single mechanical hand at least can reach 70 bottles per minute, the bottle straightening efficiency is high, the manpower input is low, and the production cost is reduced.

Owner:QUANZHOU HUASHUO IND

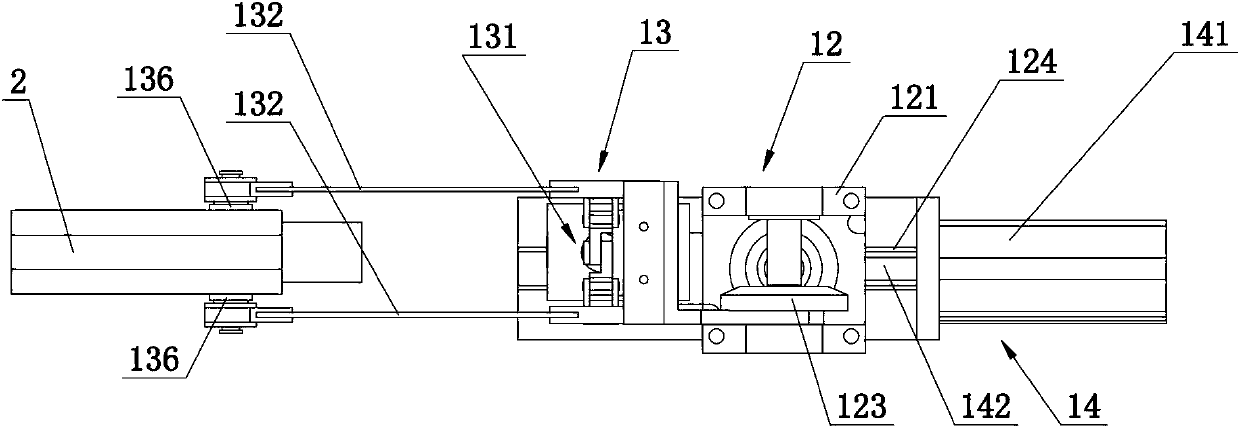

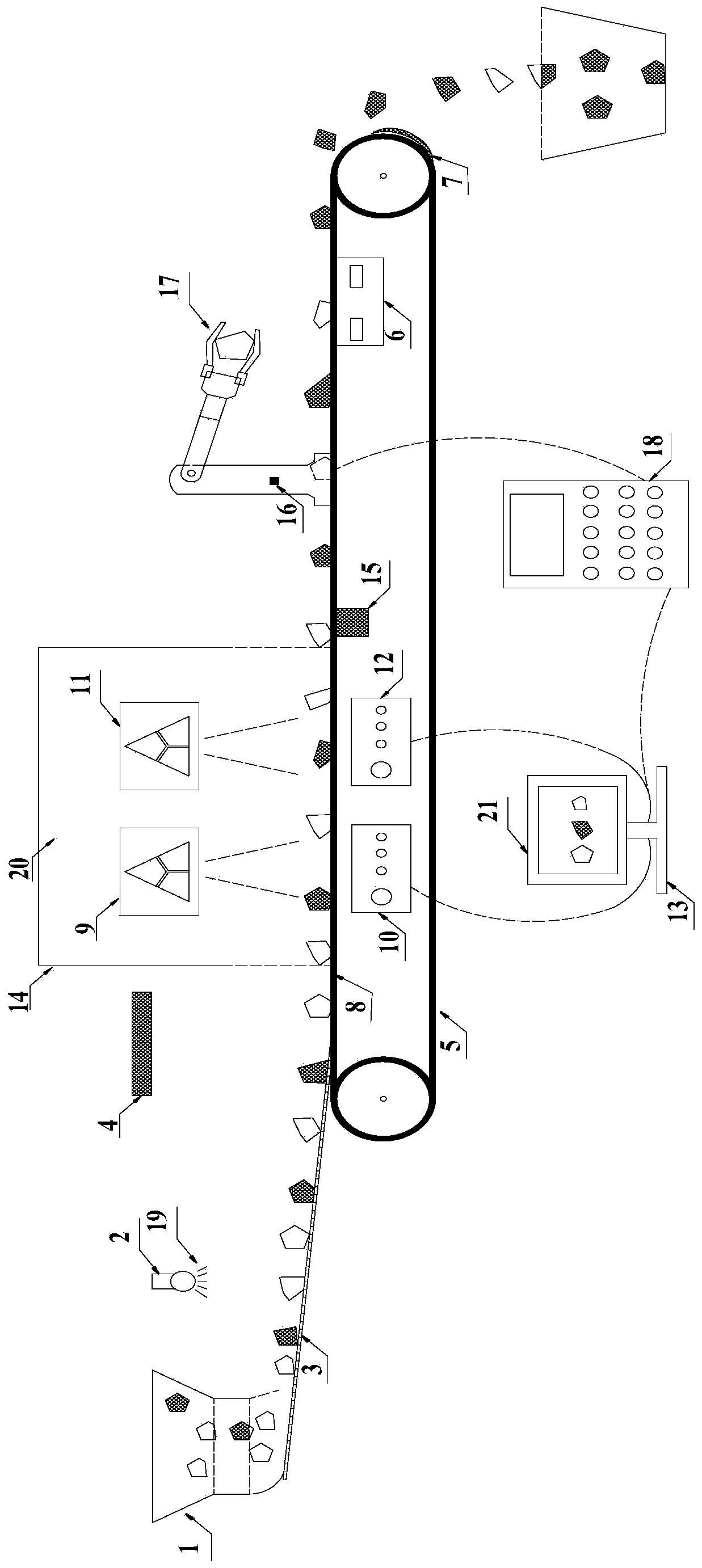

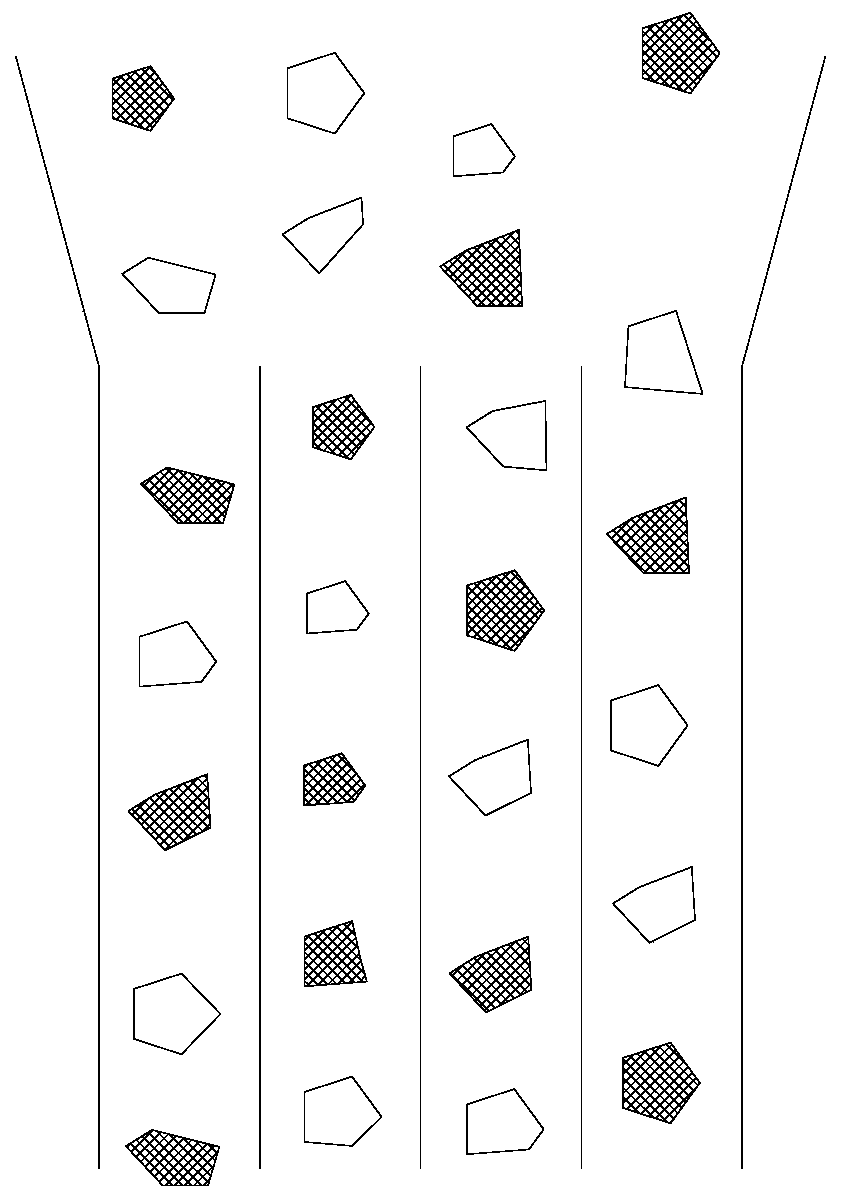

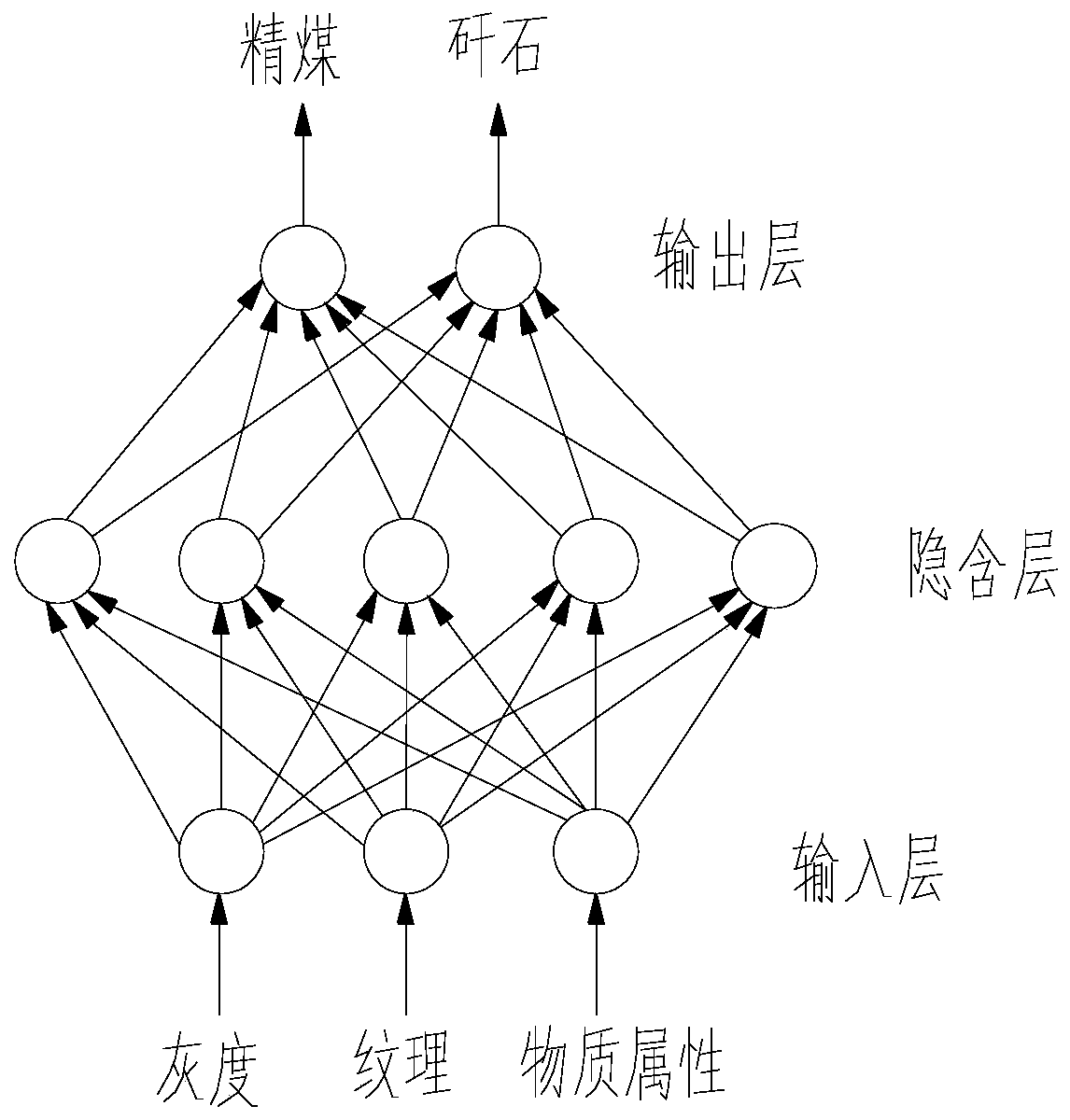

Intelligent dry waste discharge system based on true dual energy X-rays

InactiveCN110773454AStrong adaptabilityReduce manpower inputMagnetic separationSortingProcess engineeringManipulator

The invention relates to the field of coal preparation and waste discharge, in particular to an intelligent dry waste discharge system based on true dual energy X-rays. The intelligent dry waste discharge system includes a feeding mechanism, a conveying mechanism, a recognition mechanism and a sorting mechanism. The feeding mechanism is composed of a feeding funnel and a spray desliming device, the outer part of the feeding funnel is in an inverted cone shape, and the inner part of the feeding funnel is laid with wear-resistant porcelain plates which can reduce the abrasion of funnel wall surfaces; the spray desliming device is composed of spray pipes and a high-frequency sifter; the conveying mechanism is composed of an electronic belt scale which can monitor the feeding quantity in realtime, an electromagnetic iron remover which can reduce the contamination of sundries, a belt cleaner which can clean fine materials, and a lining-up device capable of forming a plurality of regular coal flows; the recognition mechanism is composed of an X-ray generator generating the X-rays with different intensity, a detector receiving the X-rays, an imaging upper computer, a BP neural network, and a lead isolation room; and the sorting mechanism is composed of a positioning device, a manipulator, and a PLC control cabinet. According to the intelligent dry waste discharge system based on thetrue dual energy X-rays, adaptability to coal is strong, intelligent recognition is realized, therecognition accuracy is high, and at the same time, coal-dust pollution is reduced.

Owner:ANHUI UNIV OF SCI & TECH

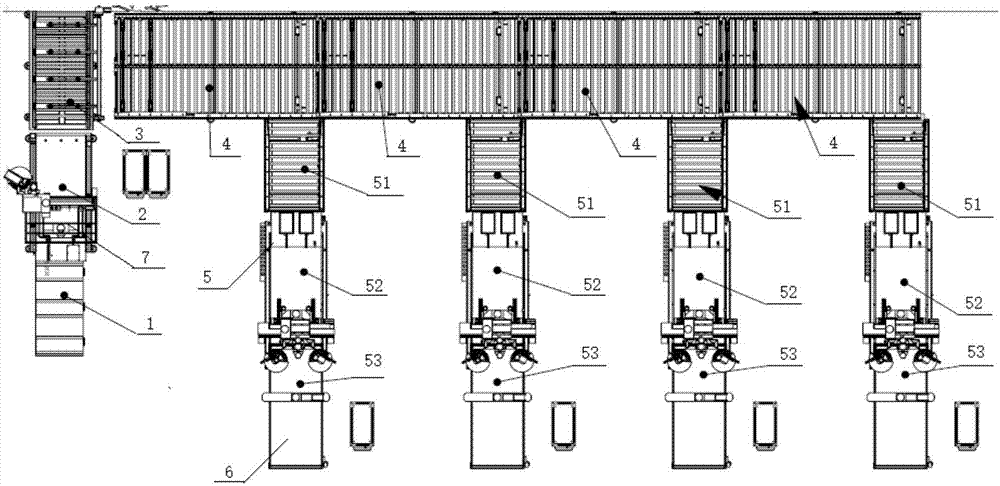

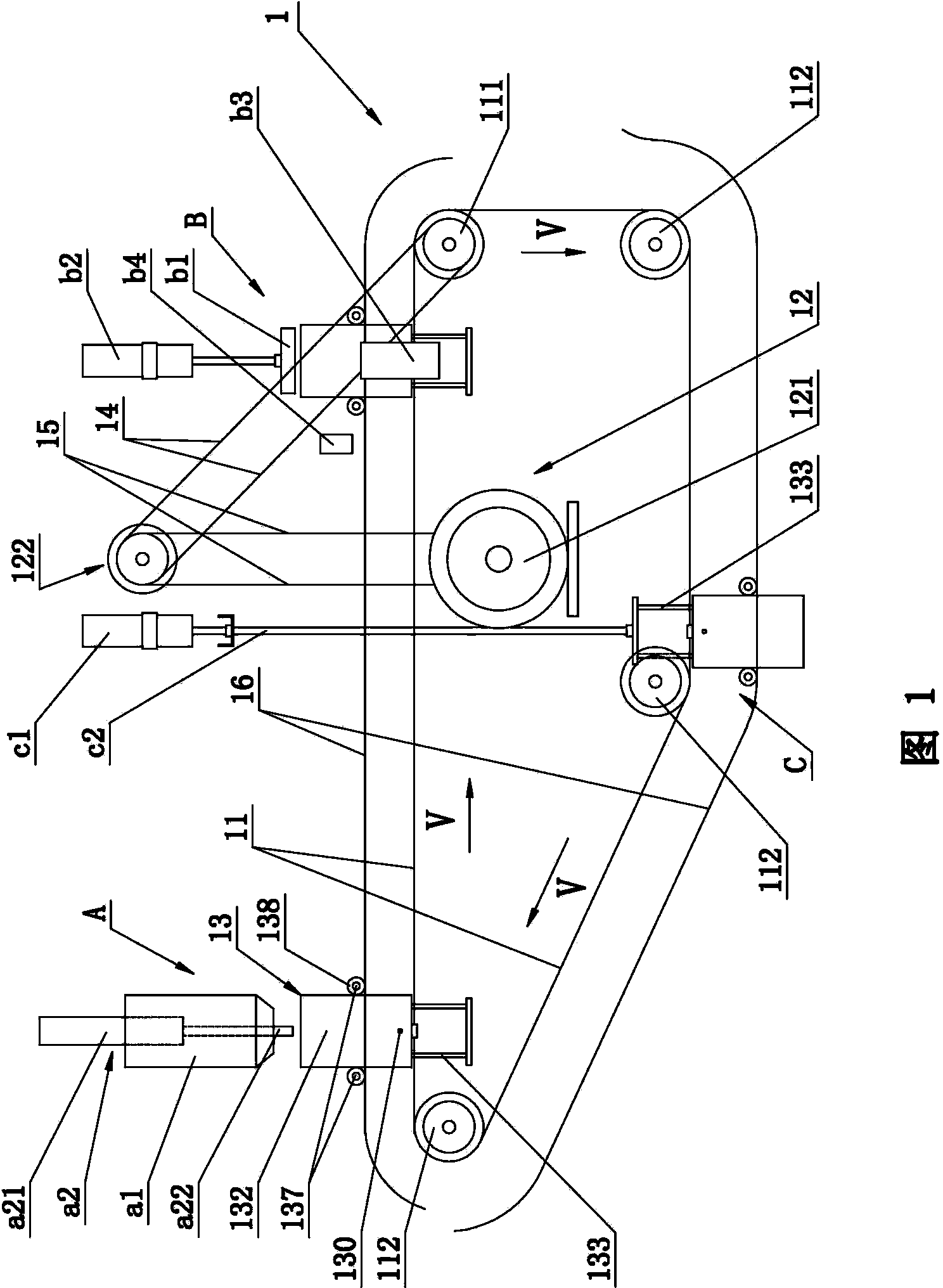

Cabinet door plate modeling automatic production process and device

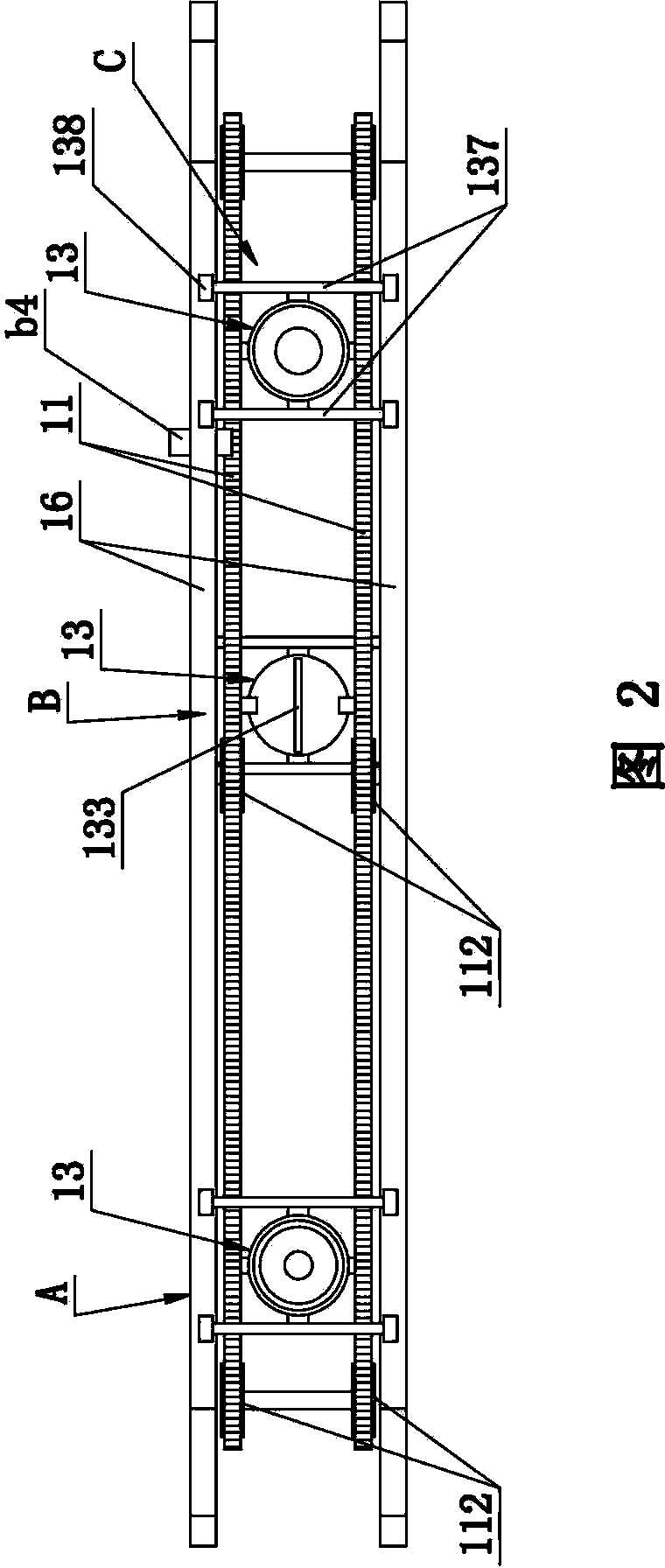

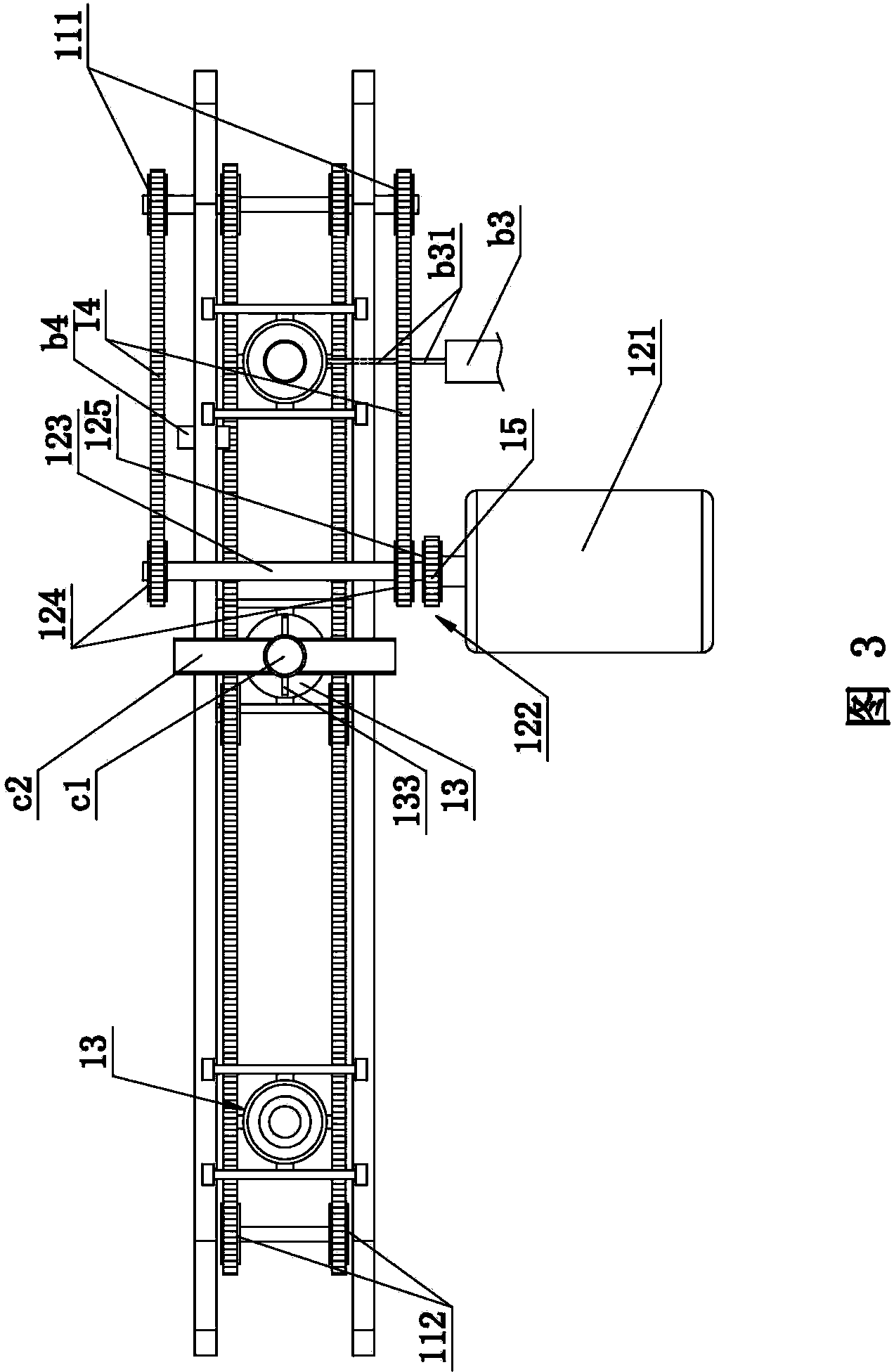

InactiveCN107322740AHigh degree of automationReduce manpower inputConveyorsMulti-purpose machinesPush outProcess systems

The invention discloses a cabinet door plate modeling automatic production process. A connection system with the following structure is used by the process, and comprises a large plate supplying system, a large plate back face machining system, a plate overturning system, a door plate conveying system, a plurality of door plate sorting machining system and a finished product sorting system. The process adopting the system to perform door plate machining includes the following steps that a to-be-machined large plate is fed into the large plate back face machining system by the large plate supplying system to be subjected to marking and hole punching; the large plate is push out to the plate overturning system, and is overturned to the front face; the large plate is conveyed into a large plate sorting system and a large plate front face machining system, and the large plate is cut into independent door plates; and the door plates are collected in a classified manner. The process system is high in automation degree, manual labeling is converted into automatic labeling by a machine, the manpower investment is reduced, and the work efficiency is improved; a correction device is arranged, and the machining precision is improved; and it can be achieved that the door plates in different shapes can be automatically machined on one device at the same time, the equipment utilizing rate is increased, and the production efficiency is improved.

Owner:NANJING DIDING NUMERICAL CONTROL TECH

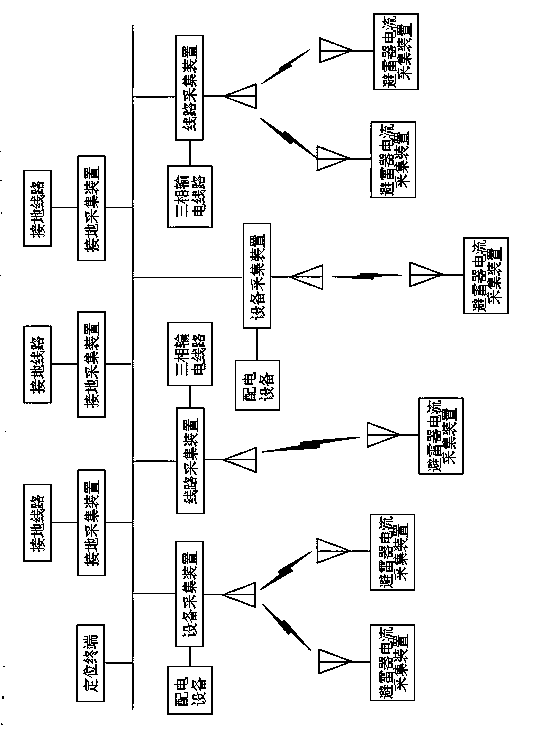

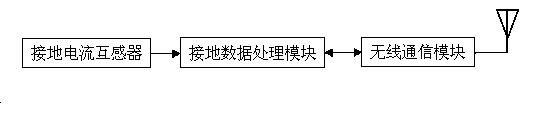

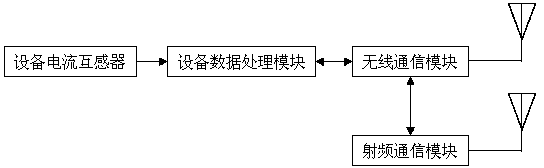

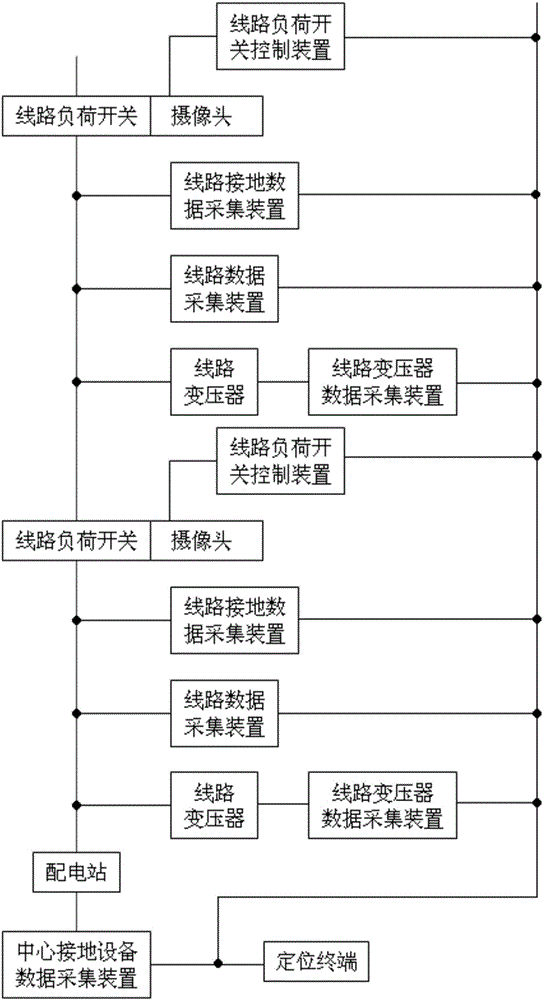

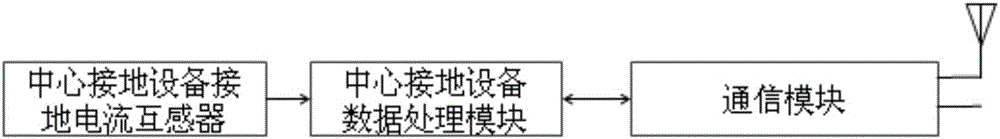

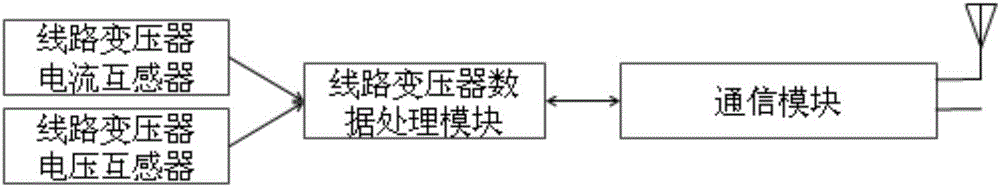

Transmission and distribution power grid fault positioning system

ActiveCN104330704AImprove search efficiencySave search timeFault locationInformation technology support systemTransformerElectric power system

The invention discloses a transmission and distribution power grid fault positioning system and relates to the technical field of electrical power systems. The transmission and distribution power grid fault positioning system aims at solving the technical problem of monitoring a power transmission line and comprises a positioning terminal, a plurality of ground connection collection devices, a plurality of device collection devices, a plurality of line collection devices and a plurality of arrester current collection devices; the ground connection devices are used for collecting current signals of ground connection lines of a main transformer of a transmission and distribution power grid; the device collecting devices are used for collecting voltage signals and current signals of power distribution devices of the transmission and distribution power grid; the line collection devices are used for collecting current signals of three-phase power transmission lines of the transmission and distribution power grid; the arrester current collection devices are used for collecting current signals of transmission and distribution power grid arresters; the arrester current collection devices and the peripheral line collecting devices are mutually connected through a radio frequency communication mode; the positioning terminal, the ground connection collection devices and the line connection devices are connected to the same Ethernet. The transmission and distribution power grid fault positioning system is applicable to transmission and distribution power grid monitoring and fault positioning.

Owner:上海萌烨电力科技有限公司

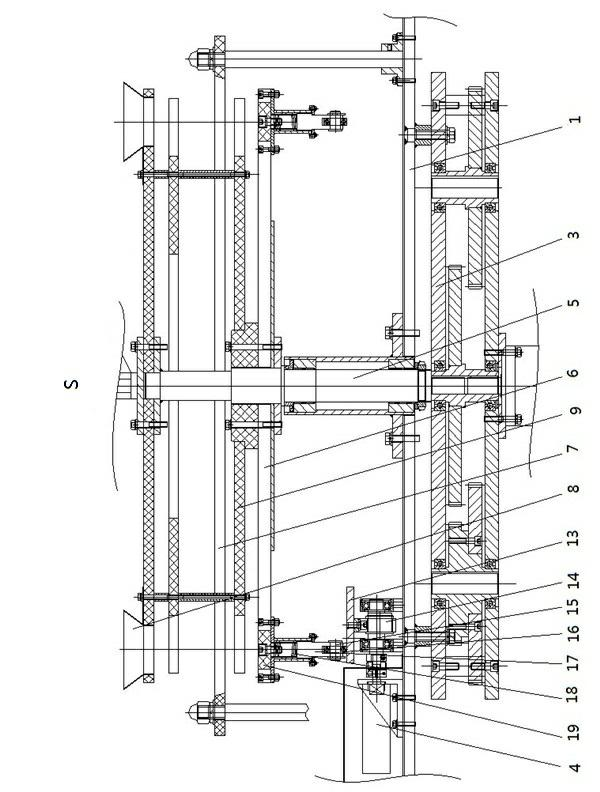

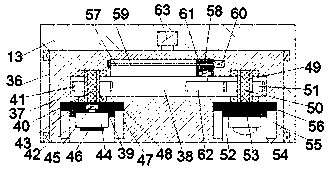

Automatic tea wafering machine and tea wafering method

ActiveCN103039638BSimple structureLow failure ratePre-extraction tea treatmentFood shapingFailure rateWafering

The invention relates to an automatic tea wafering machine and a tea wafering method. The tea wafering machine comprises a main frame body, and a control device for controlling the operation of the wafering machine, wherein first closed chains circularly rotating and a drive mechanism for driving the first chains to rotate are arranged on the main frame body; a feeding station, a tea pressing station and a discharging station are arranged on the main frame body; at least one group of molds for pressing tea is fixedly arranged on the first chains; each group of molds comprises three molds at positions corresponding to the three stations; and strokes between two adjacent molds in each group of molds are equal. The quality of the tea produced by the wafering machine and the tea wafering method is not lower than that of the handmade tea; with the adoption of the wafering machine and the wafering method, the tea can be produced automatically and continuously; the manpower input, production labor and labor intensity are effectively reduced; the production efficiency is improved obviously; and the wafering machine is simple in structure, low in failure rate, lower in price, and applicable to common manufacturers.

Owner:FUJIAN ANXI YUNHE MECHANICS

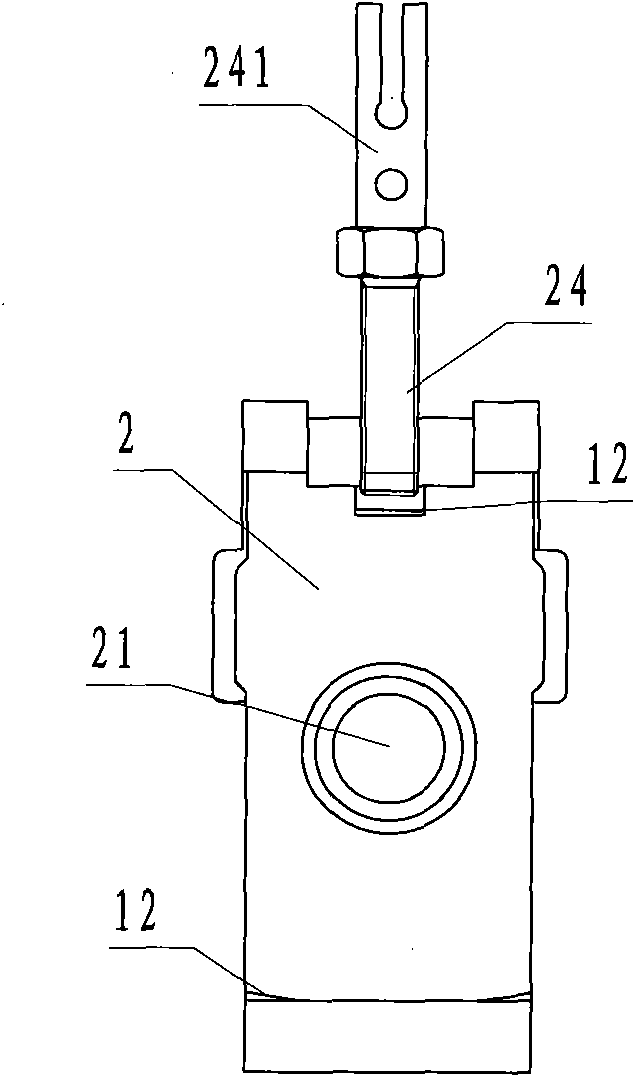

Tool for replacing JB type parallel groove clamp on live line

ActiveCN102136692AReduce manpower inputImprove ergonomics and work safetySuspension arrangements for electric cablesApparatus for overhead lines/cablesOperation safetyEconomic benefits

The invention discloses a tool for replacing a JB type parallel groove clamp on a live line, which comprises an insulating operating rod, a parallel groove clamp body dismounting device, a parallel groove clamp press plate dismounting device and a bolt dismounting device. The live replacement of the parallel groove clamp is realized through the arrangement of a unique structure. The tool can greatly reduce the investment of manpower, and also greatly improve the work efficiency and the operation safety, and has high economic benefit.

Owner:STATE GRID CORP OF CHINA +1

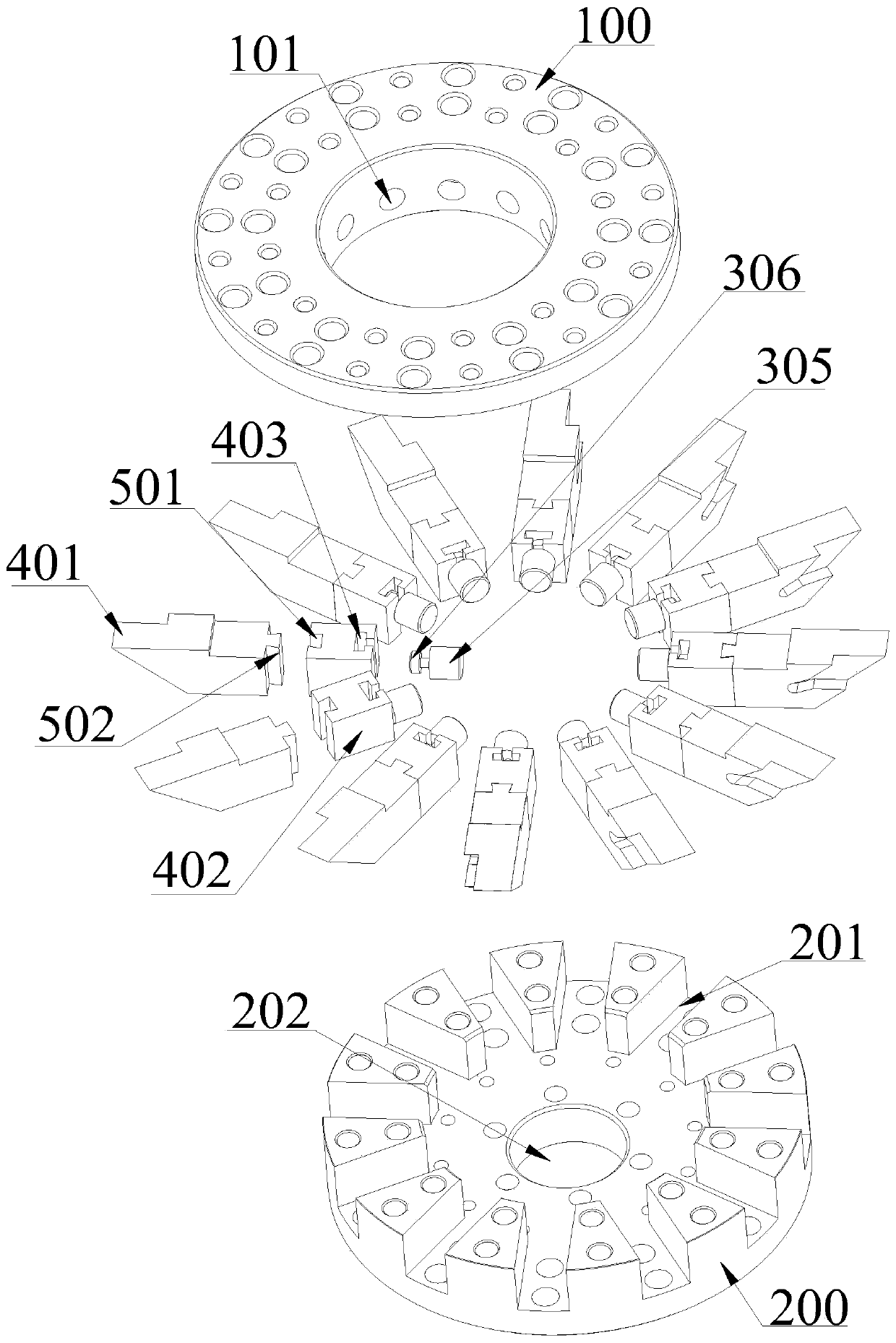

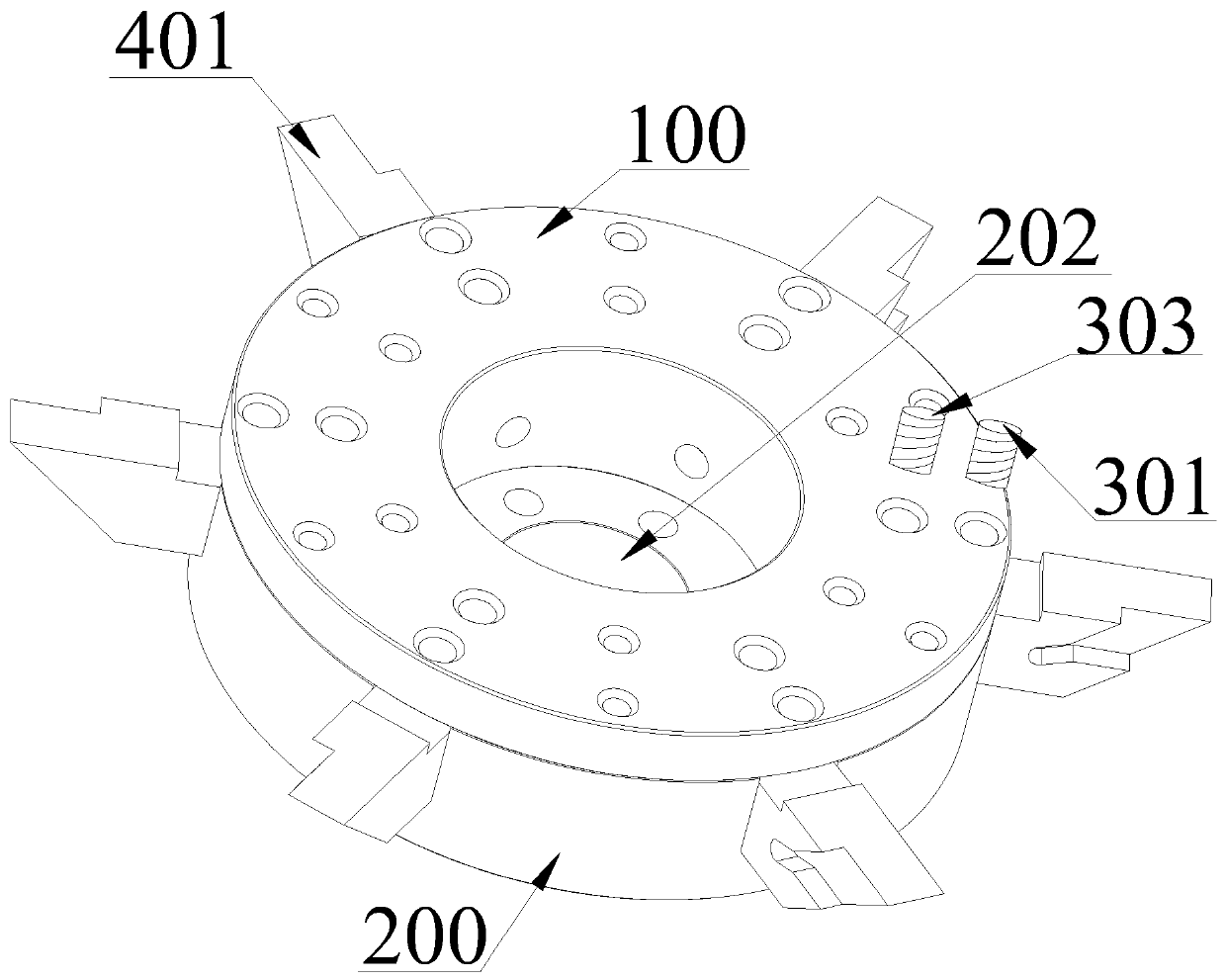

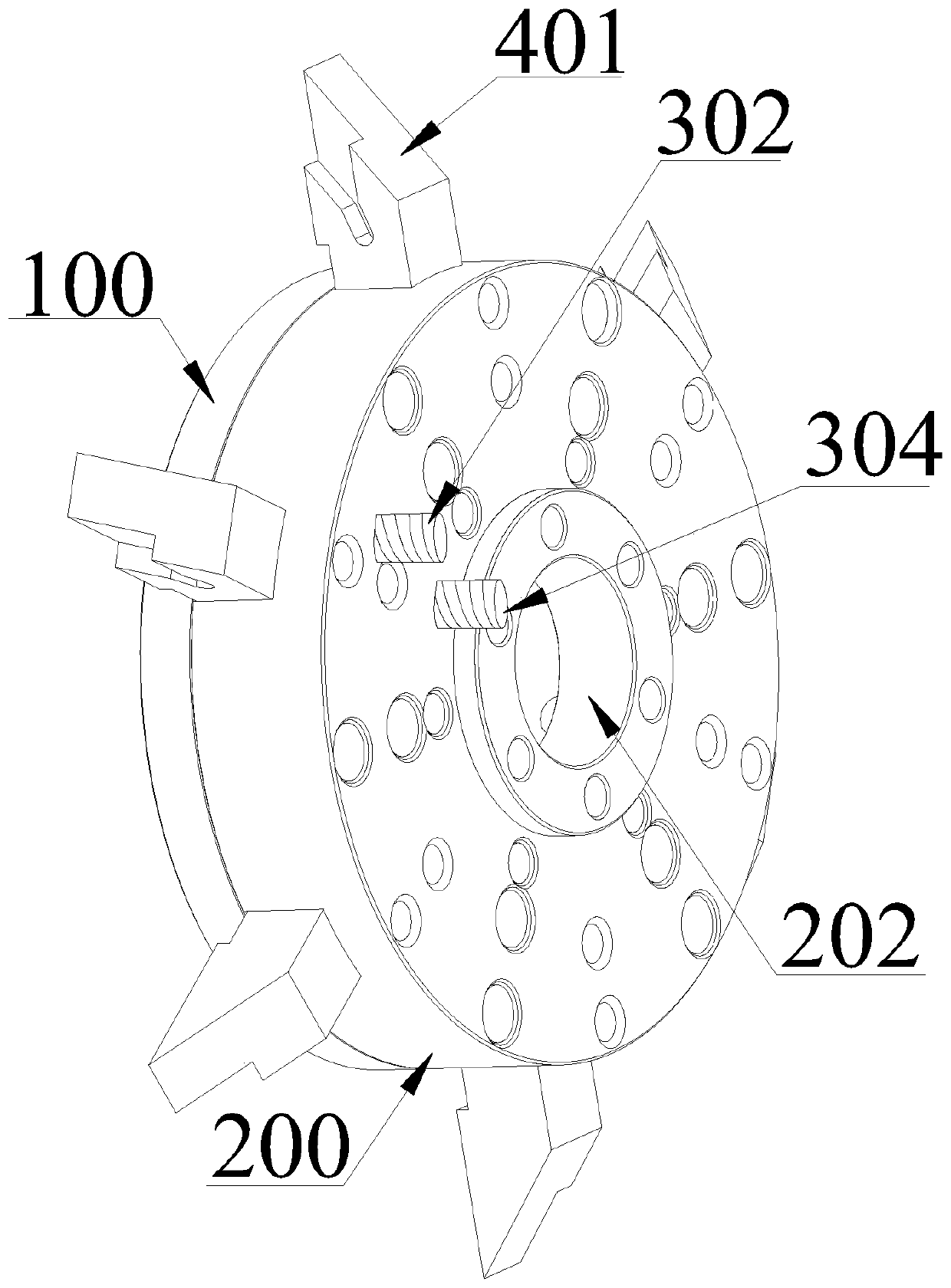

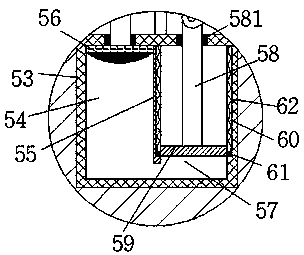

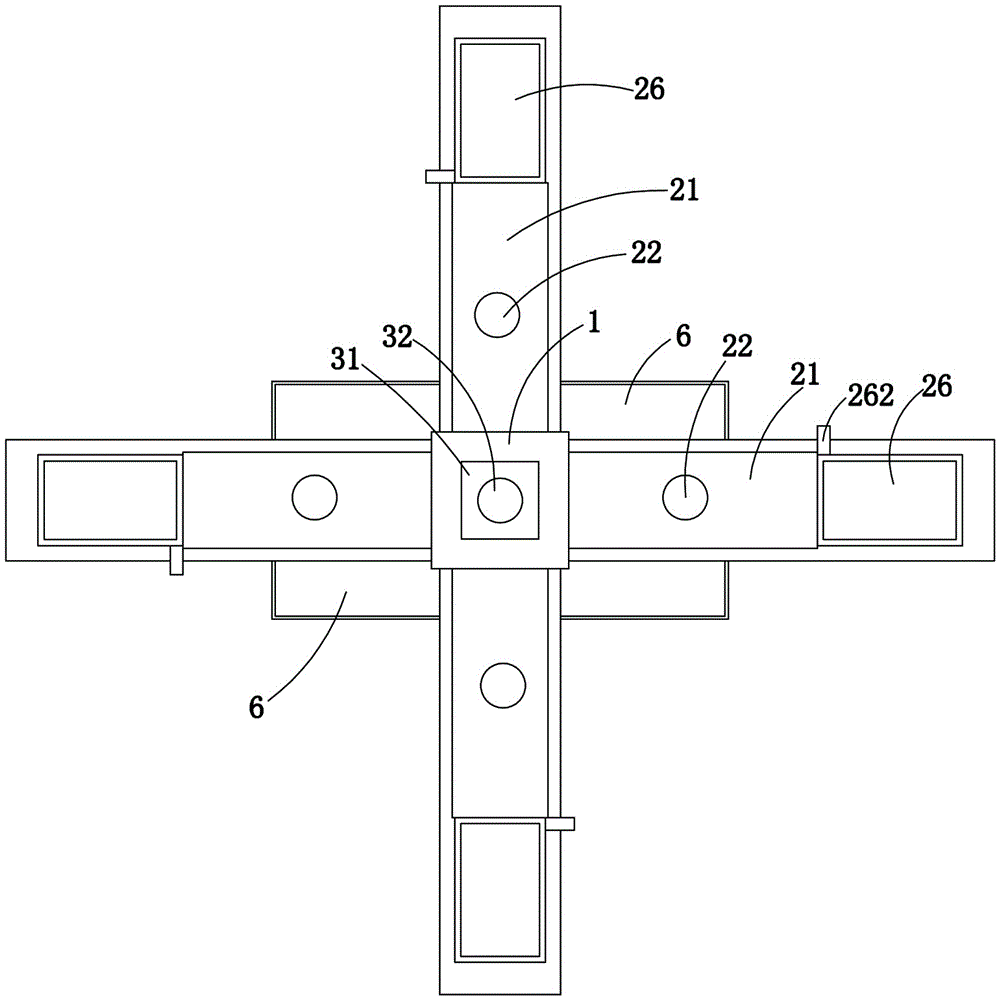

Cutter disc structure of digital controlled lathe

PendingCN109848451AWith activity adjustment spaceGuaranteed concentricityTool holdersEngineeringDigital control

The invention discloses a cutter disc structure of a digital controlled lathe. The cutter disc structure of the digital controlled lathe comprises a cutter disc body and multiple cutter rod structures, wherein each cutter rod structure is arranged to be of a separated structure comprises a front end part and a back end part; the front end parts and the back end parts are spliced through dovetail groove structures; upper outer screws and lower outer screws rotatably and tightly pressed on the front end parts are arranged on the cutter disc body; upper inner screws and lower inner screws rotatably and tightly pressed on the back end parts are arranged on the cutter disc body; and adjusting screws capable of adjusting the positions of the cutter rod structures after being screwed are arrangedon the inner side wall of the cutter disc body. According to the cutter disc structure provided by the invention, multiple lathe tools are gathered on the cutter disc body, the cutter rod structuresadopts the separated structures, the positions of the cutter rod structures are flexibly adjusted through the upper outer screws, the lower outer screws, the upper inner screws and the lower inner screws, namely, the feeding direction, the feeding angle and the feeding position of the lathe tools are adjusted, and the cutter disc structure can accomplish multiple processing procedures after processing through a common cutter at one time, so that the processing efficiency is high, the manpower is saved, and the concentricity and the smoothness of the processed product are ensured.

Owner:邹洪波

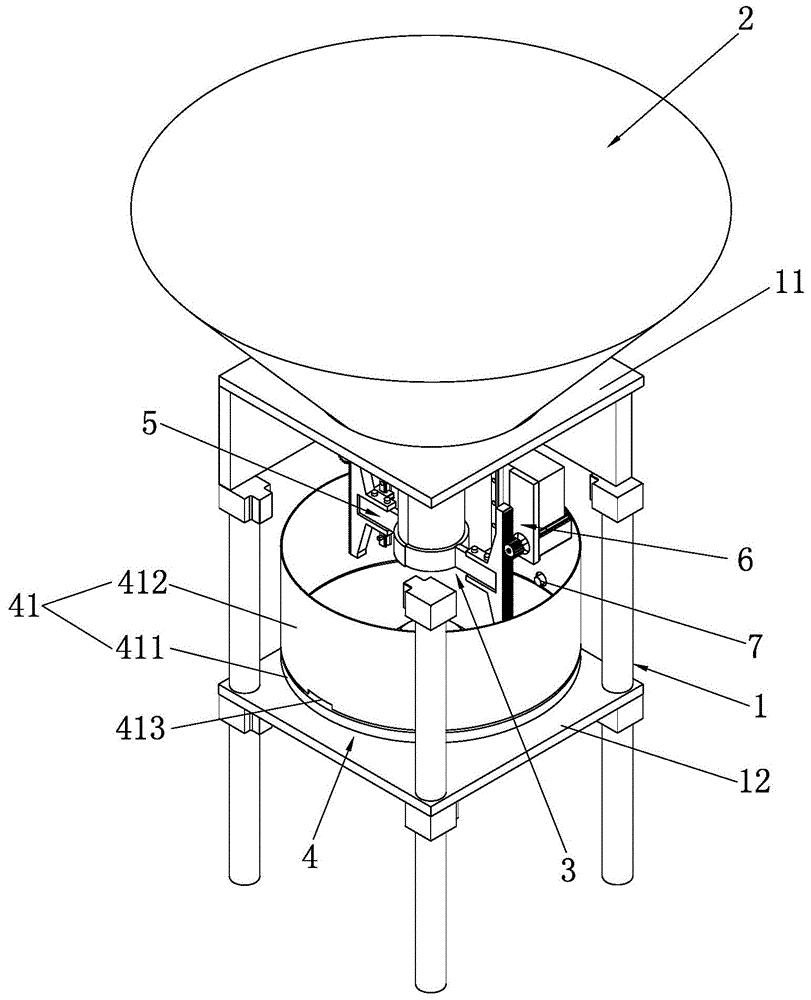

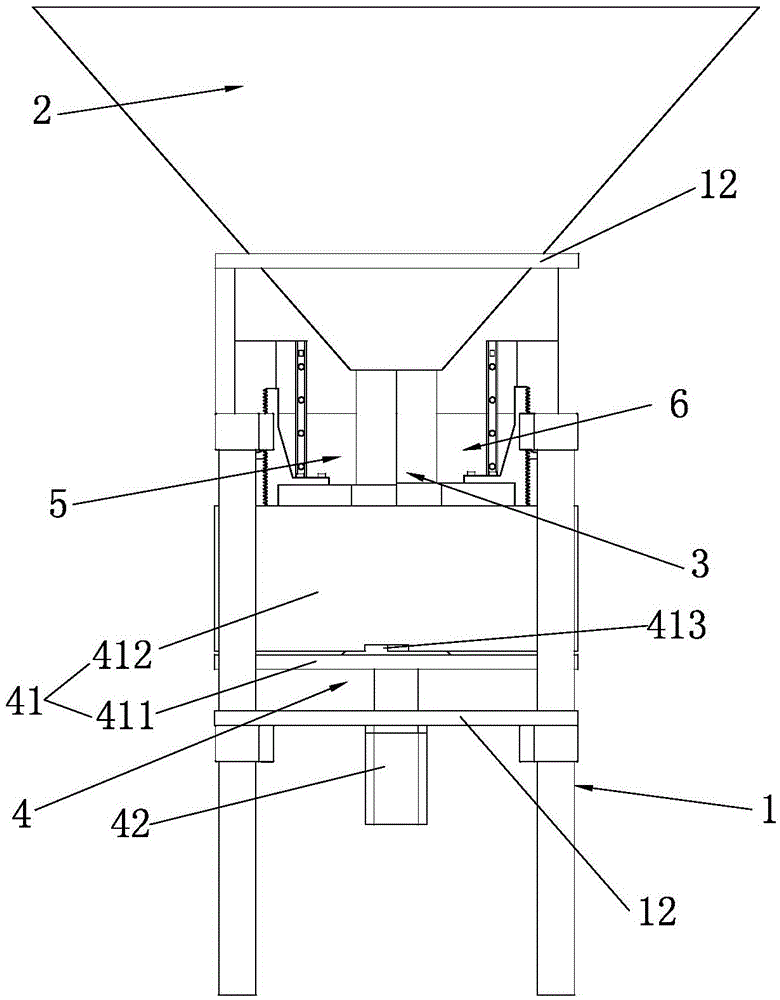

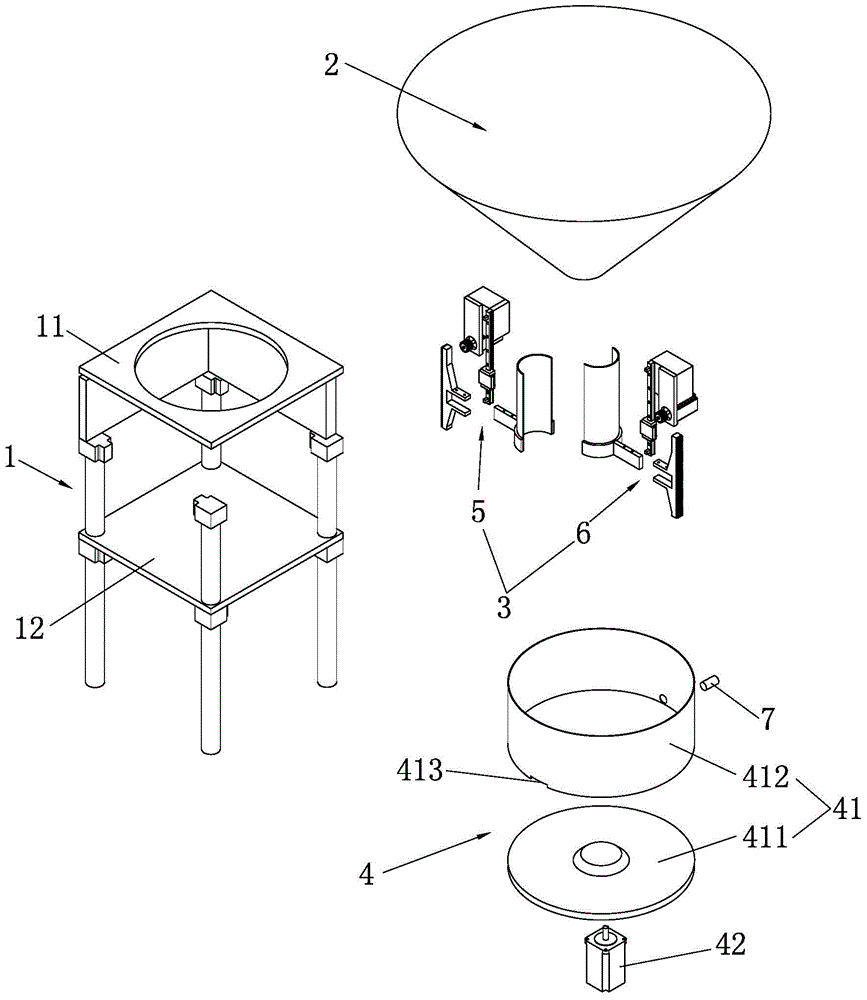

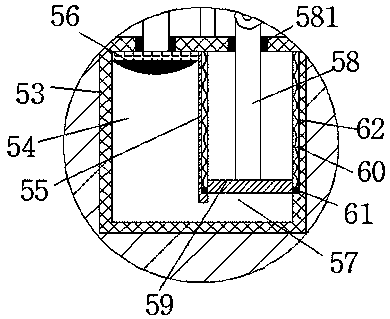

Automatic material supply device and material supply method thereof

ActiveCN104828575ASimple structureEasy to operateControl devices for conveyorsLoading/unloadingEngineeringBottle cap

The invention provides an automatic material supply device and a material supply method thereof. The automatic material supply device comprises a machine frame, a material storage hopper and a control mechanism, wherein a first flat plate and a second flat plate are arranged on the machine frame; the material storage hopper is a conical material hopper and is arranged on the first flat plate at the top of the machine frame; the control mechanism is used for controlling the operating of the material supply device; the automatic material supply device further comprises an automatic discharging mechanism which is arranged at the bottom end of the material storage hopper and is used for controlling discharging, and an automatic feeding mechanism which is arranged on the second flat plate at the bottom of the machine frame and is used for controlling feeding; the automatic feeding mechanism is arranged below the automatic discharging mechanism; the automatic discharging mechanism comprises a first discharging mechanism and a second discharging mechanism which are arranged in bilateral symmetry and cooperate with each other; the first discharging mechanism, the second discharging mechanism and the automatic feeding mechanism are respectively connected with the control mechanism. The automatic material supply device provided by the invention is simple in structure and easy to operate; bottle caps can be stored and released quickly, continuously and automatically; the production efficiency can be effectively improved; the labor intensity of a worker can be effectively reduced.

Owner:QUANZHOU HUASHUO IND

Clothes rack device capable of ascending and descending

The invention discloses a clothes rack device capable of ascending and descending. The clothes rack device comprises a rack body and a machine body fixedly arranged on the rack body. A front-and-backthrough first sliding cavity is arranged in the machine body. A second rotating cavity is arranged on the inner bottom wall of the first sliding cavity in a communicating manner. A first sliding plateextending front and back is mounted in the first sliding cavity in a sliding manner. A communicating groove extending front and back is arranged in the end face of the top of the first sliding plate.Toothed grooves extending front and back are arranged in the bottom end face of the first sliding plate in bilateral symmetry. A second sliding cavity is arranged at the position, on the left side ofthe first rotating cavity, in the machine body. A first rotating shaft is mounted between the first rotating cavity and the second sliding cavity in a running fit manner.

Owner:广州广林科技有限公司

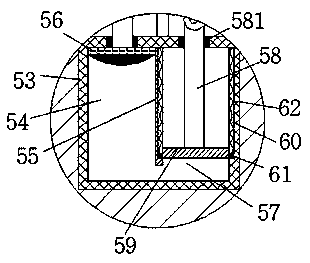

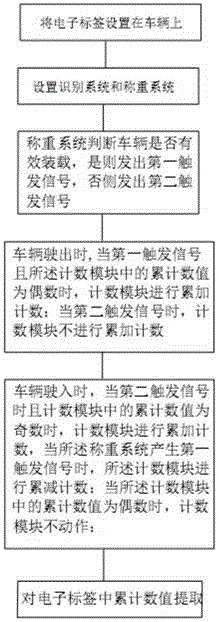

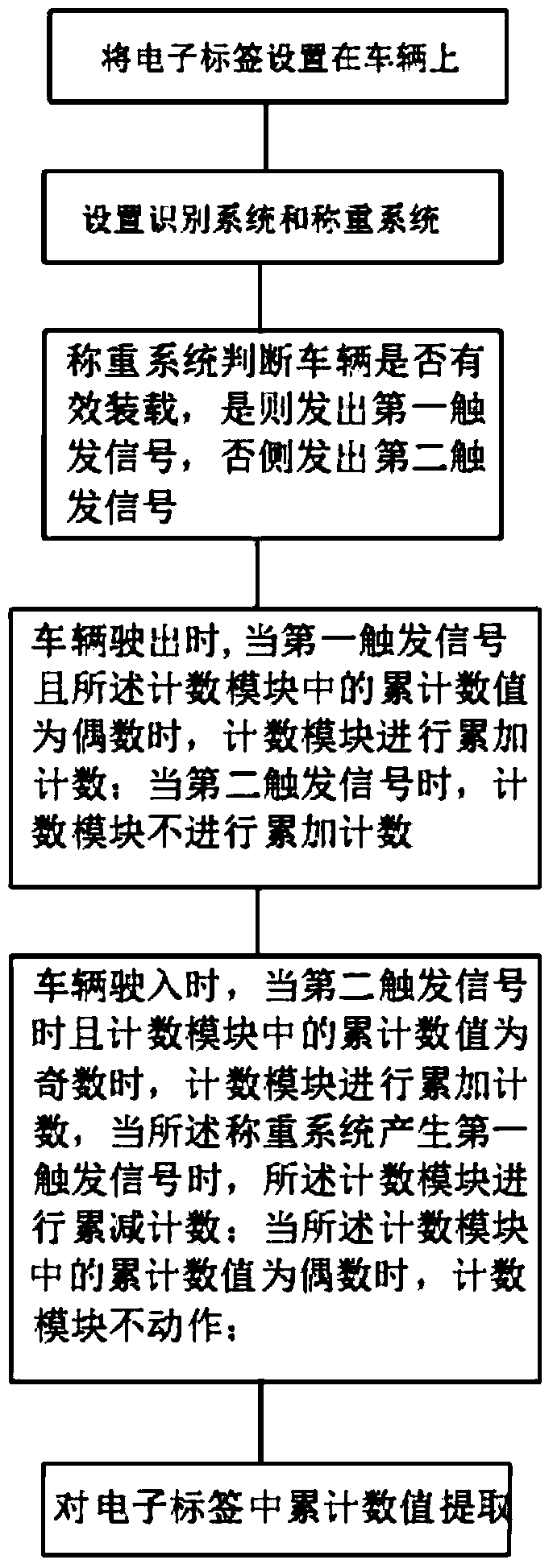

Truck counting method based on radio frequency identification

ActiveCN105046293AImprove counting efficiencyReduce manpower inputCo-operative working arrangementsIndividual entry/exit registersComputer moduleLimit value

The invention discloses a truck counting method based on radio frequency identification. The truck counting method comprises the steps that step one, an electronic tag is arranged on an access vehicle, and a counting module and a storage unit are integrated in the electronic tag; step two, when a weighing system identifies that weight of the vehicle exceeds the weight limit value, a first trigger signal is generated, or a second trigger signal is generated; step three, when the first trigger signal is generated and the cumulative value is an even number, accumulative counting is performed by the counting module, and when the second trigger signal is generated, accumulative counting is not performed by the counting module; step four, when the vehicle enters the access port and the second trigger signal is generated and the cumulative value is an odd number, accumulative counting is performed by the counting module, and when the first trigger signal is generated, accumulative subtraction is performed by the counting module; and when the cumulative value is the even number and the vehicle enters the access port, the counting module does not actuate. The technical problem of low vehicle counting efficiency is solved so that counting accuracy is enhanced.

Owner:SUZHOU MULAN ELE&TEC

Glass automatic edge grinding device

InactiveCN108406499APrecision edgingReduce manpower inputEdge grinding machinesGrinding drivesEngineeringSlide plate

The invention provides a glass automatic edge grinding device. The glass automatic edge grinding device comprises a support A and a support B which are arranged side by side. Multiple rollers arrangedside by side are arranged between the support A and the support B. A guide plate A and a guide plate B are arranged on one side of the support A and one side of the support B correspondingly. An X-axis sliding plate is erected between the guide plate A and the guide plate B and is connected with a lead screw of a motor A. A Y-axis sliding plate in sliding connection with the X-axis sliding plateis arranged on the X-axis sliding plate. A grinding wheel frame is mounted on the Y-axis sliding plate. A grinding wheel is rotationally arranged on one side of the grinding wheel frame. A grinding wheel repair mechanism is arranged on one side of the X-axis sliding plate and comprises a metal sizing hose and an abrasive wheel. A fan and a water spray device are arranged on one side of the fan A.A drying mechanism is arranged on one side of the water spray device and comprises an annular metal frame. An electromagnetic coil is arranged in the annular metal frame. The glass automatic edge grinding device is simple in structure and convenient to use, the operation process of glass edge grinding, cleaning and drying can be completed, and the production efficiency of glass edge grinding can be improved.

Owner:东莞市银泰玻璃有限公司

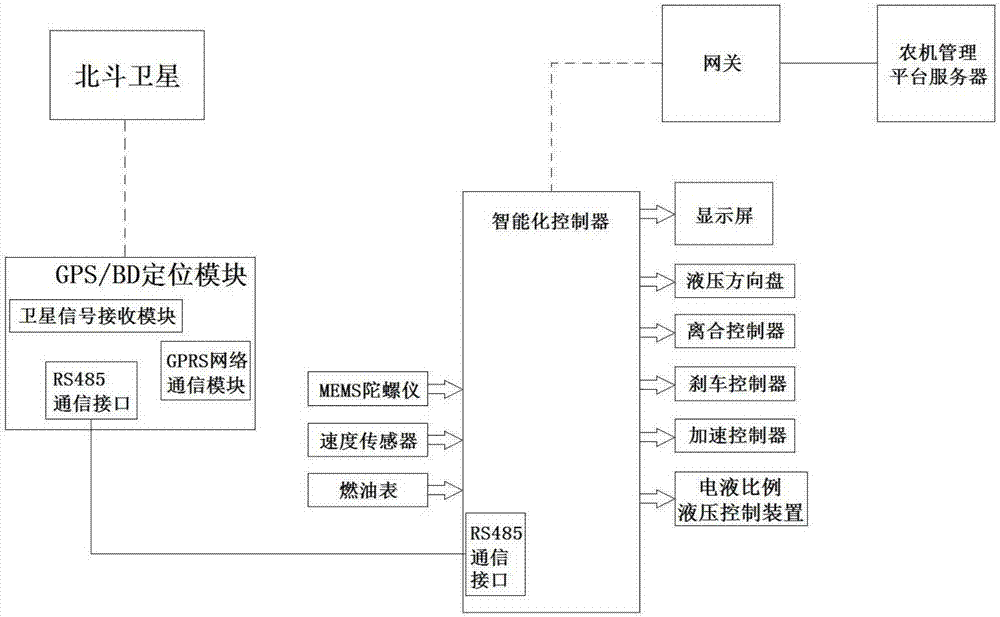

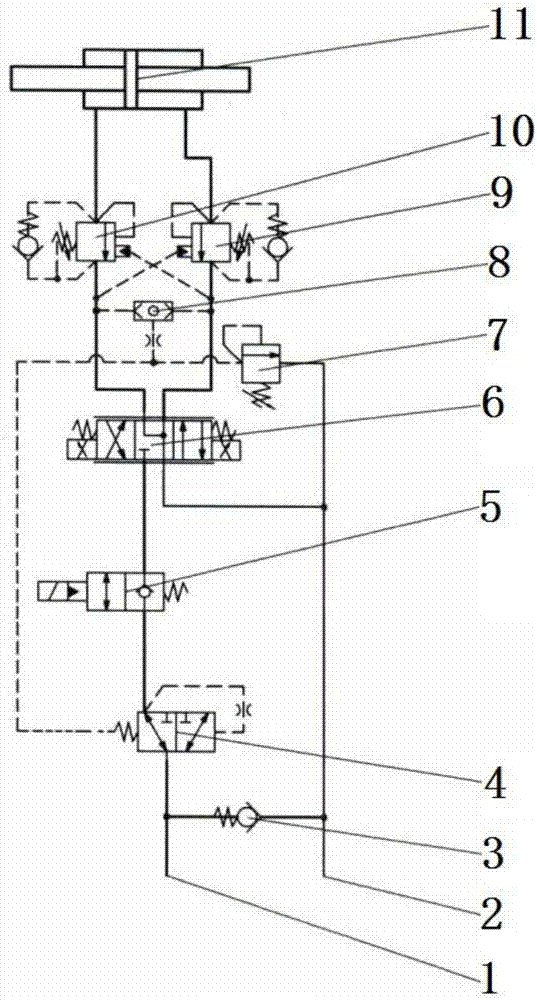

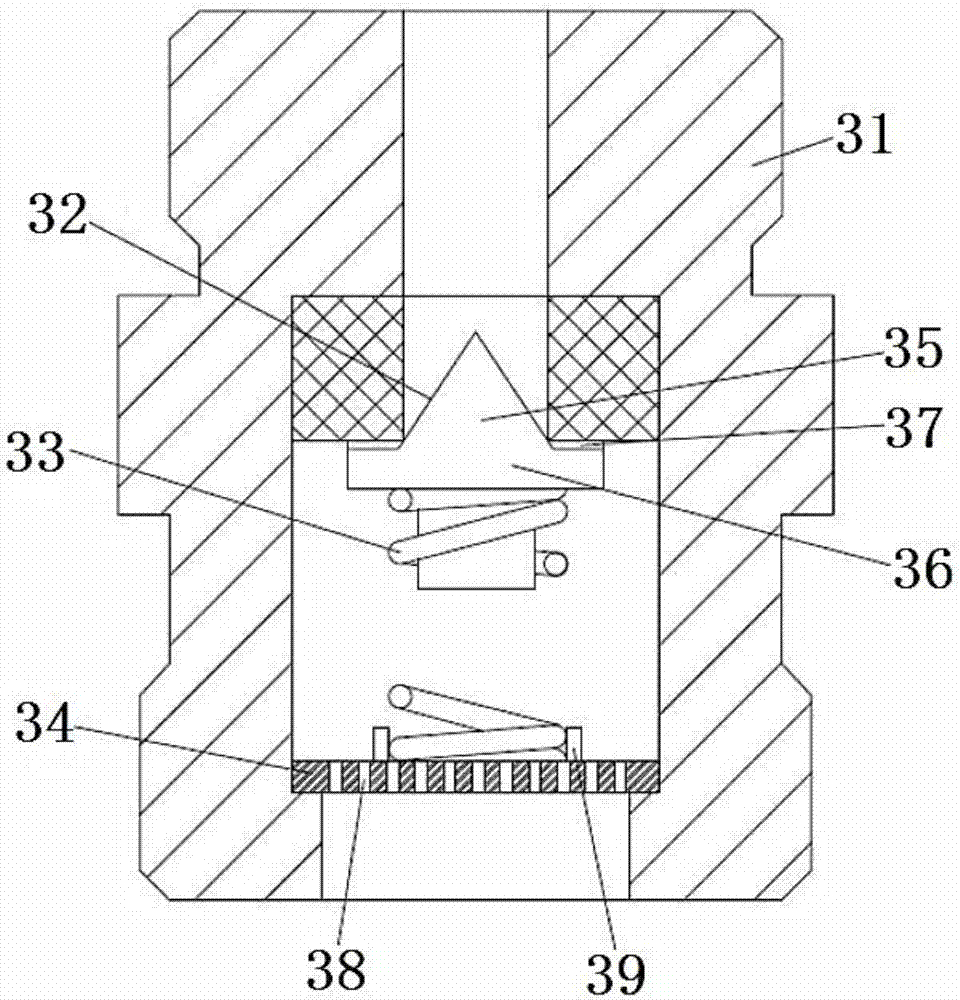

Universal type agricultural machinery automatic driving control device

InactiveCN107168307AReduce manpower inputObvious beneficial effectPosition/course control in two dimensionsVehiclesAutomatic controlAgricultural engineering

The invention discloses a universal type agricultural machinery automatic driving control device. The invention aims to solve the problems of incapability of realizing automatic driving, the consumption of manpower and low work efficiency of agricultural machinery in practical application in the prior art. According to the technical schemes of the invention, the universal type agricultural machinery automatic driving control device includes a GPS / BD positioning module, an intelligent controller and an agricultural machinery management platform server; the GPS / BD positioning module is used for acquiring the position information of a vehicle; the intelligent controller is used for collecting the operating parameters of agricultural machinery and controlling the agricultural machinery; the position information and operating parameters of the agricultural machinery are uploaded to the agricultural machinery management platform server through by a GPRS network; the server makes decisions about the operating data of the agricultural machinery; and the intelligent controller realizes automatic driving control of the agricultural machinery according to the operating data. According to the universal type agricultural machinery automatic driving control device of the invention, the position information and operating parameters of the vehicle are acquired, and therefore, the agricultural machinery can be automatically controlled to work according to formulated paths, the investment of manpower can be reduced, and obvious beneficial effects can be realized. The universal type agricultural machinery automatic driving control device is convenient to apply and popularize.

Owner:HUANGHE S & T COLLEGE

Automatic cleaning vehicle for vehicle illuminating lamps in tunnels

InactiveCN111871909AImprove efficiency and qualityReduce manpower inputCleaning using toolsRoad cleaningStructural engineeringDrive shaft

The invention discloses an automatic cleaning vehicle for vehicle illuminating lamps in tunnels. The automatic cleaning vehicle comprises a cleaning vehicle body, a working cavity is formed in the cleaning vehicle body, and a self-advancing assembly is arranged in the working cavity; and the self-advancing assembly comprises two wheel through holes formed in the inner wall of the lower side of theworking cavity and communicated with the outside, a first fixing support fixedly arranged on the inner wall of the rear side of the working cavity, a first transmission shaft rotationally connected to the first fixing support and extending up and down, and a steering adjusting support arranged on the lower side of the first fixing support and fixedly connected with the first transmission shaft. The automatic cleaning vehicle can automatically advance in the tunnels, the turning directions of wheels can be changed by changing the turning direction of the first transmission shaft at the turningposition, automatic turning of the cleaning vehicle body can be realized, and the automatic cleaning vehicle is applicable to the various complicated tunnels; and automatic cleaning can be carried out when the automatic cleaning vehicle moves to the illuminating lamps of the tunnels, so that the cleaning efficiency and quality are improved, and the manpower investment is reduced.

Owner:嵊州佳想汽车用品有限公司

High-end letter box device

InactiveCN108856778ASimple structureEasy to useKitchen equipmentLarge fixed membersEngineeringMechanical engineering

Owner:广州宝升新型材料有限公司

Power distribution network line real-time monitoring and fault locating system

PendingCN106226656AImprove search efficiencySave search timeFault location by conductor typesClosed circuit television systemsTransformerElectric power system

The invention relates to a power distribution network line real-time monitoring and fault locating system, and relates to the technical field of electric power systems, and achieves power distribution line real-time monitoring and fault locating. The power distribution network line real-time monitoring and fault locating system comprises a power distribution station, a power distribution line, a positioning terminal, a plurality of line load switches and a plurality of line transformers. Each line transformer is connected with the power distribution station through the power distribution line; each line load switch is connected in series with the power distribution line, and the mounting point of each line load switch is provided with a camera used for shooting the on-off state of the line load switch; the positioning terminal is provided with a video signal input port, and the video signal output port of each camera is connected to the video signal input port of the positioning terminal. The power distribution network line real-time monitoring and fault locating system can judge the type of line faults quickly, and can achieve line fault positioning quickly.

Owner:上海萌烨电力科技有限公司

High-end lifting clothes rack device

Owner:广州广林科技有限公司

Liquid crystal polymer material equipment

InactiveCN108480863AImprove stabilityImprove cutting efficiencyEdge grinding machinesLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses liquid crystal polymer material equipment. The liquid crystal polymer material equipment comprises a base, support columns and a cross beam, wherein the support columns are symmetrically arranged on both sides of the top of the base from left to right and extend upwards, the cross beam is fixedly arranged on the tops of the two support columns, lifting grooves which are opened inwards and extend up and down are symmetrically formed in the end surfaces of the inner sides of the two support columns, lifting blocks are installed in the lifting grooves in a sliding mode, alifting frame is fixedly arranged between the two lifting blocks, a rotating cavity with a downward opening is formed in the lifting frame, a rotating disc is rotatably installed in the rotating cavity by virtue of a rolling bearing, a driving groove horizontally extends in the rotating disc, and a first threaded sleeve and a second threaded sleeve are rotatably installed between the upper and lower inner walls of the left and right sides of the driving groove by virtue of rolling bearings respectively.

Owner:宁波市鄞州区丰余工业产品设计有限公司

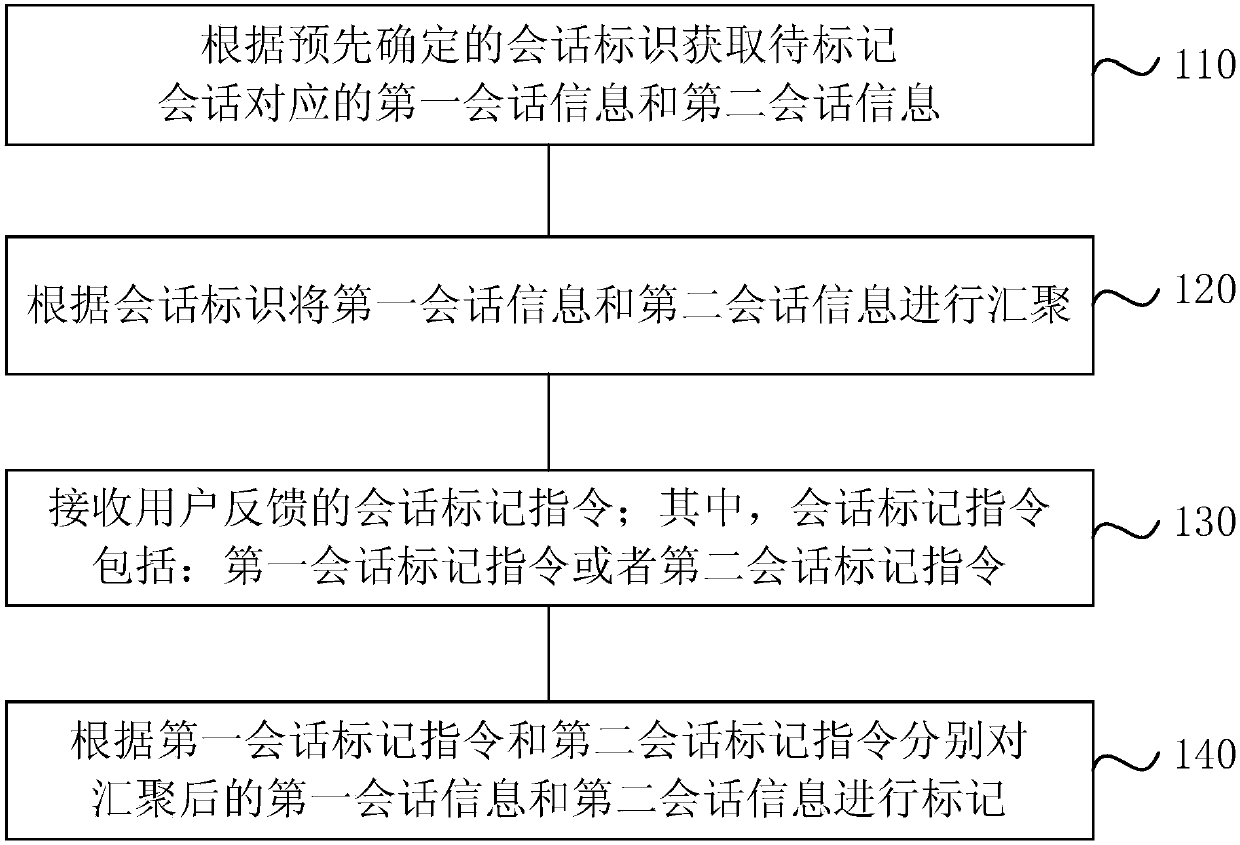

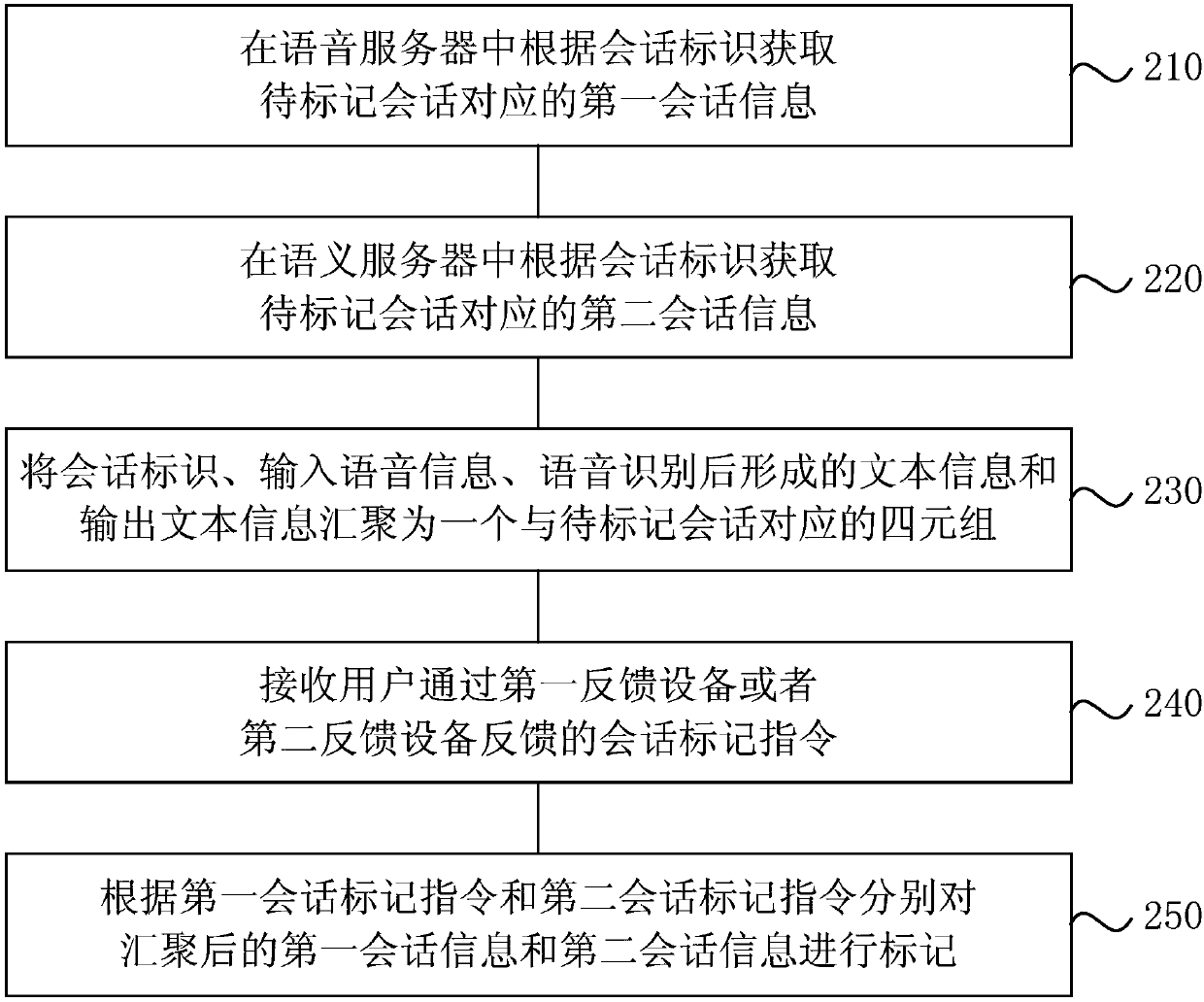

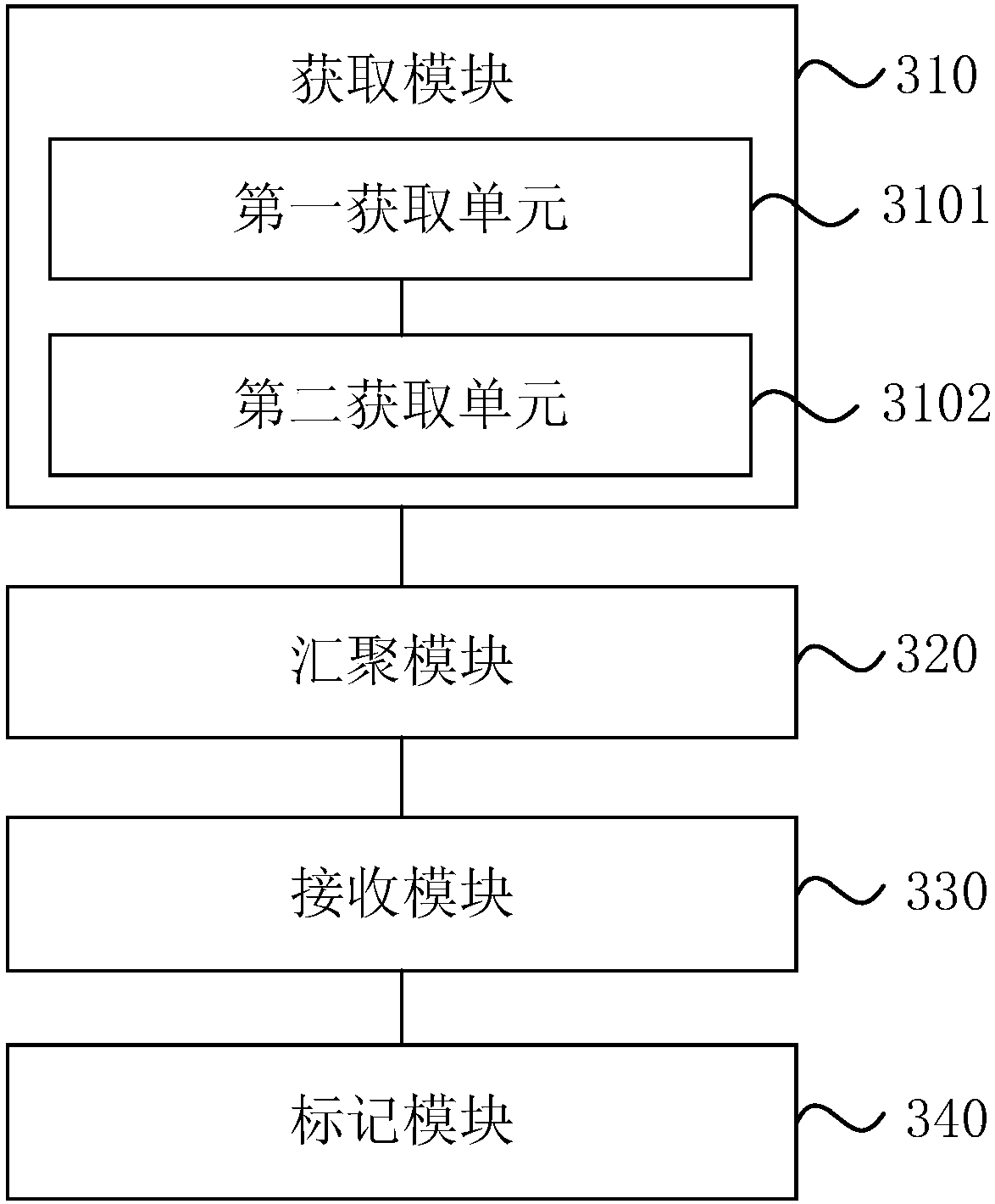

Conversation marking method and device, aggregation server and storage medium

InactiveCN107894972AReduce manpower inputImprove labeling efficiencyNatural language data processingSpeech recognitionSpeech soundSubvocal recognition

The invention discloses a conversation marking method and device, an aggregation server and a storage medium. The conversation marking method includes: acquiring first conversation information and second conversation information corresponding to a conversation to be marked according to a predetermined conversation identifier, wherein the first conversation information includes input voice information and text information formed after voice recognition is performed on the input voice information, and the second conversation information includes text information formed after voice recognition isperformed on the input voice information, and output text information; aggregating the first conversation information and the second conversation information according to the conversation identifier;receiving a conversion marking command fed back by a user, wherein the conversation marking command includes a first conversation marking command or a second conversation marking command; and markingthe aggregated first conversion information and the aggregated second conversion information according to the first conversation marking command and the second conversation marking command respectively. The manpower input can be reduced while back end data of a voice conversation system is marked, and the data processing efficiency is improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

A truck counting method based on radio frequency identification

ActiveCN105046293BImprove counting efficiencyReduce manpower inputCo-operative working arrangementsIndividual entry/exit registersLimit valueTruck

The invention discloses a truck counting method based on radio frequency identification. The truck counting method comprises the steps that step one, an electronic tag is arranged on an access vehicle, and a counting module and a storage unit are integrated in the electronic tag; step two, when a weighing system identifies that weight of the vehicle exceeds the weight limit value, a first trigger signal is generated, or a second trigger signal is generated; step three, when the first trigger signal is generated and the cumulative value is an even number, accumulative counting is performed by the counting module, and when the second trigger signal is generated, accumulative counting is not performed by the counting module; step four, when the vehicle enters the access port and the second trigger signal is generated and the cumulative value is an odd number, accumulative counting is performed by the counting module, and when the first trigger signal is generated, accumulative subtraction is performed by the counting module; and when the cumulative value is the even number and the vehicle enters the access port, the counting module does not actuate. The technical problem of low vehicle counting efficiency is solved so that counting accuracy is enhanced.

Owner:SUZHOU MULAN ELE&TEC

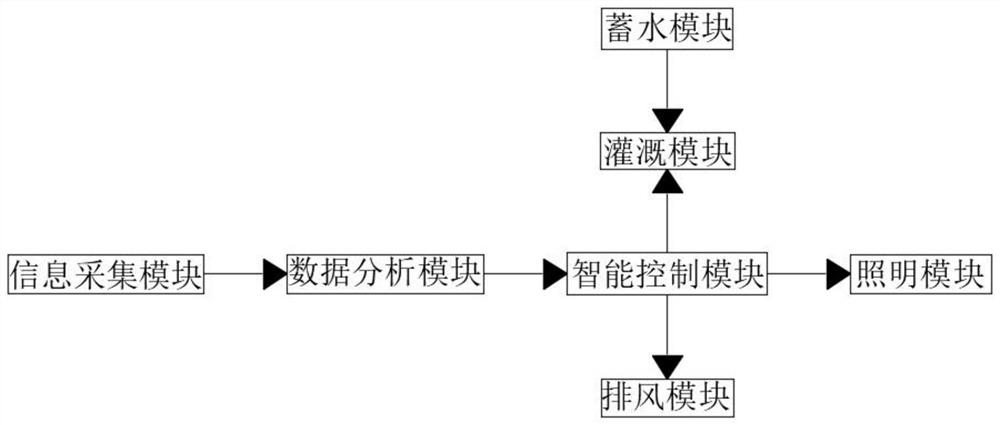

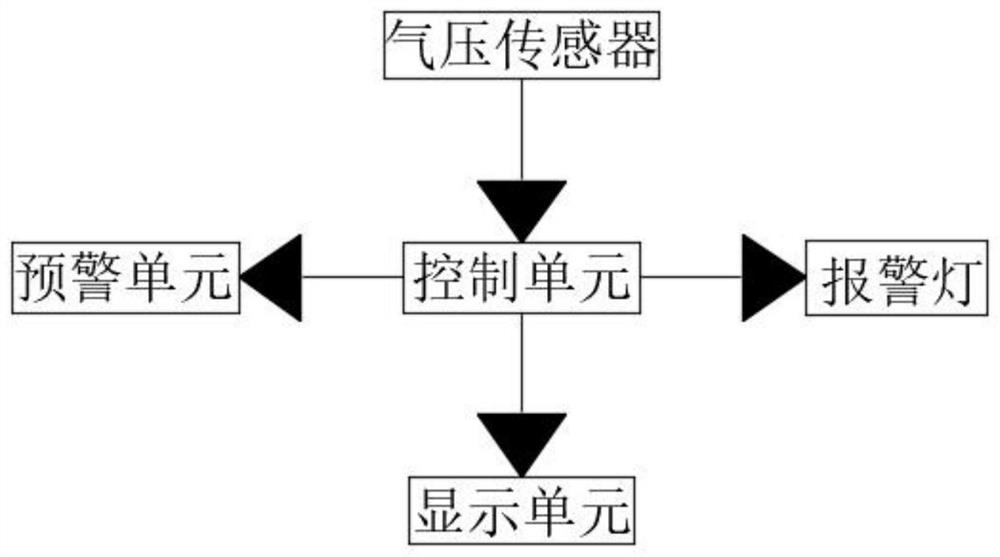

Greenhouse irrigation system based on intelligent control

InactiveCN113016446AAvoid wastingReduce manpower inputGeneral water supply conservationGreenhouse cultivationEnvironmental resource managementData analysis

The invention relates to the technical field of greenhouse irrigation, and discloses a greenhouse irrigation system based on intelligent control. The greenhouse irrigation system comprises the following modules of an information acquisition module, a data analysis module, an intelligent control module, an irrigation module, an air pressure monitoring module, a water storage module, an exhaust module and an illumination module. According to the greenhouse irrigation system based on intelligent control, through arrangement of the information acquisition module, the data analysis module, the intelligent control module, the irrigation module and the water storage module, a manager can timely know whether basic requirements of plant growth in a greenhouse are changed or not, so that timely adjustment can be performed; through mutual cooperation of the irrigation module and the water storage module, a rainwater collection module in the water storage module can effectively collect natural rainfall, the natural rainfall is stored in the water resource storage module in time, watering is conducted in the mode that a spray head is arranged in the irrigation module, it can be effectively guaranteed that plants can receive sufficient water sources, and waste of the water resources can be effectively prevented.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Medical instrument for modern medical gynecology department

InactiveCN108465840ASimple structureEasy to useBoring/drilling machinesGynecology departmentMedical treatment

The invention discloses a medical instrument for the modern medical gynecology department. The medical instrument for the modern medical gynecology department comprises a supporting frame and a base fixedly arranged on the supporting frame. A first sliding connection cavity penetrating through the base in the front-back direction is formed in the base. A first rotary connection cavity communicating with the inner bottom wall of the first sliding connection cavity is formed. A first sliding connection plate which extends forwards and backwards is mounted in the first sliding connection cavity in a sliding connection mode. A through connection groove extending forwards and backwards is formed in the top end face of the first sliding connection plate. Toothed connection grooves extending forwards and backwards are arranged in the bottom end face of the first sliding connection plate in a bilaterally symmetrical mode. A second sliding connection cavity is formed in the base and located onthe right side of the first sliding connection cavity. A first rotary connection shaft is mounted between the first rotary connection cavity and the second sliding connection cavity in a rutting fit mode.

Owner:吕晓青

Spraying maintenance system for prefabricated segmental box girder

PendingCN113733326AQuality assuranceGuarantee the quality of maintenanceCeramic shaping apparatusArchitectural engineeringWater flow

The invention relates to a spraying maintenance system for a prefabricated segment box girder, and relates to the field of concrete prefabricated part maintenance. The spraying maintenance system for the prefabricated segmental box girder comprises a supporting pedestal, a movable frame, a box girder horizontal segment spraying frame, a box girder side wall spraying frame and a water supply assembly; the supporting pedestal comprises a supporting base body and a supporting table, and a water flowing groove surrounding the supporting table is arranged at the position, connected with the supporting table, of the supporting base body; the movable frame is movably assembled on the supporting pedestal, a top spraying pipe is installed on the movable frame, the box girder horizontal section spraying frame comprises a plurality of connecting rods which are arranged in the supporting table and arranged at intervals in the front-back direction, and horizontal spraying pipes are installed at the left end and the right end of each connecting rod; the box girder side wall spraying frame comprises a spraying frame body pre-buried in the supporting pedestal and a side wall spraying head mounted on the spraying frame body; and the water supply assembly comprises a water supply tank and a water supply main pipe connected with the water supply tank. Spraying maintenance can be comprehensively conducted on the prefabricated segmental box girder, the maintenance difficulty is lowered, and water resources can be recycled and reused.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

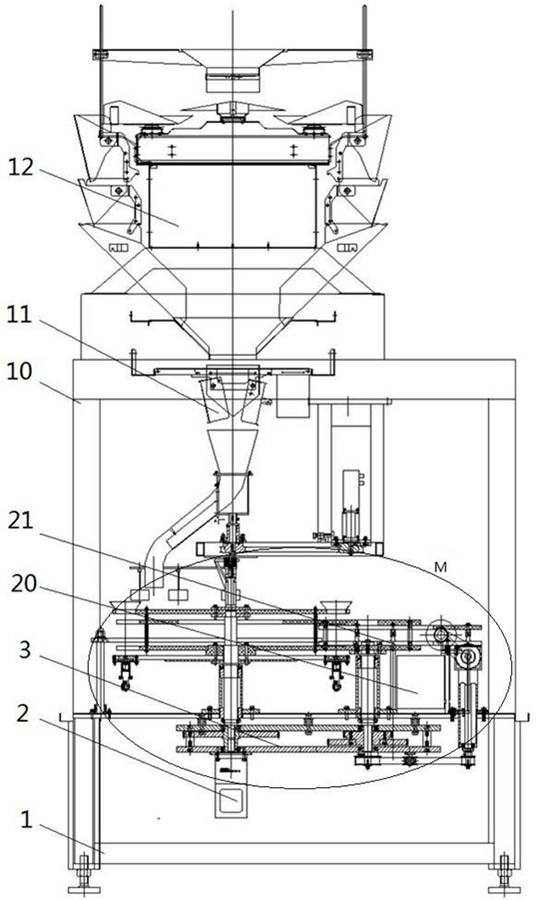

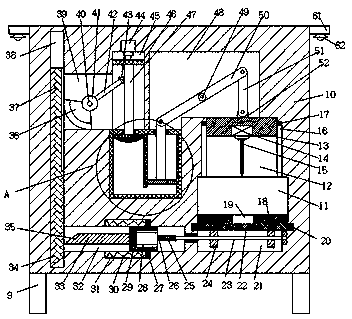

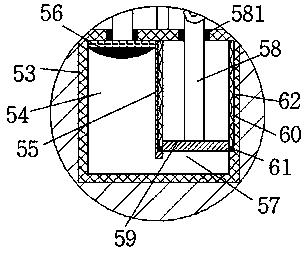

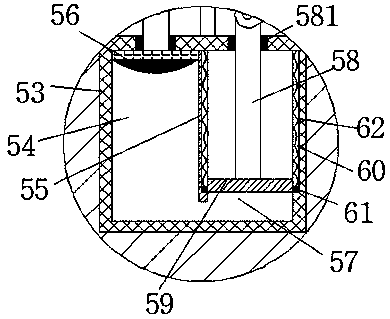

Cake pressing machine for continuously pressing tea leaves and cake pressing method thereof

ActiveCN103960383BEasy to shapeMolding stabilityPre-extraction tea treatmentFood shapingEngineeringPress cake

The invention relates to a tea cake pressing machine for continuously pressing tea and a pressing method of the machine. The tea cake pressing machine comprises a main frame body, a pre-pressing mechanism, a cake pressing mechanism and a control device, wherein the control device is used for controlling the cake pressing machine to act in sequence; the cake pressing mechanism comprises a pressing mould, a cake pressing gas / oil cylinder, a pressing cavity, a bottom plate, a pushing-pulling gas / oil cylinder and a discharging hole; the pre-pressing mechanism comprises a pre-pressing bin, a bin cover, a pre-pressing gas / oil cylinder, a gate, a pushing mechanism and a tea discharging channel. The pressing method comprises the step of sequentially performing procedures of feeding, pre-pressing, cutting, cake-pressing and the like on the tea by adopting the tea cake pressing machine to obtain a tea cake. The quality of the tea cake made by adopting the cake pressing machine through the tea cake pressing method is not second to that of a tea cake made manually, and tea can be automatically and continuously produced, the manpower input, the production labor capacity and the labor intensity are effectively reduced, and the production efficiency is remarkably increased. The tea cake pressing machine is simple in structure, low in failure rate, low in equipment price, and suitable for use by a common factory.

Owner:FUJIAN ANXI YUNHE MECHANICS

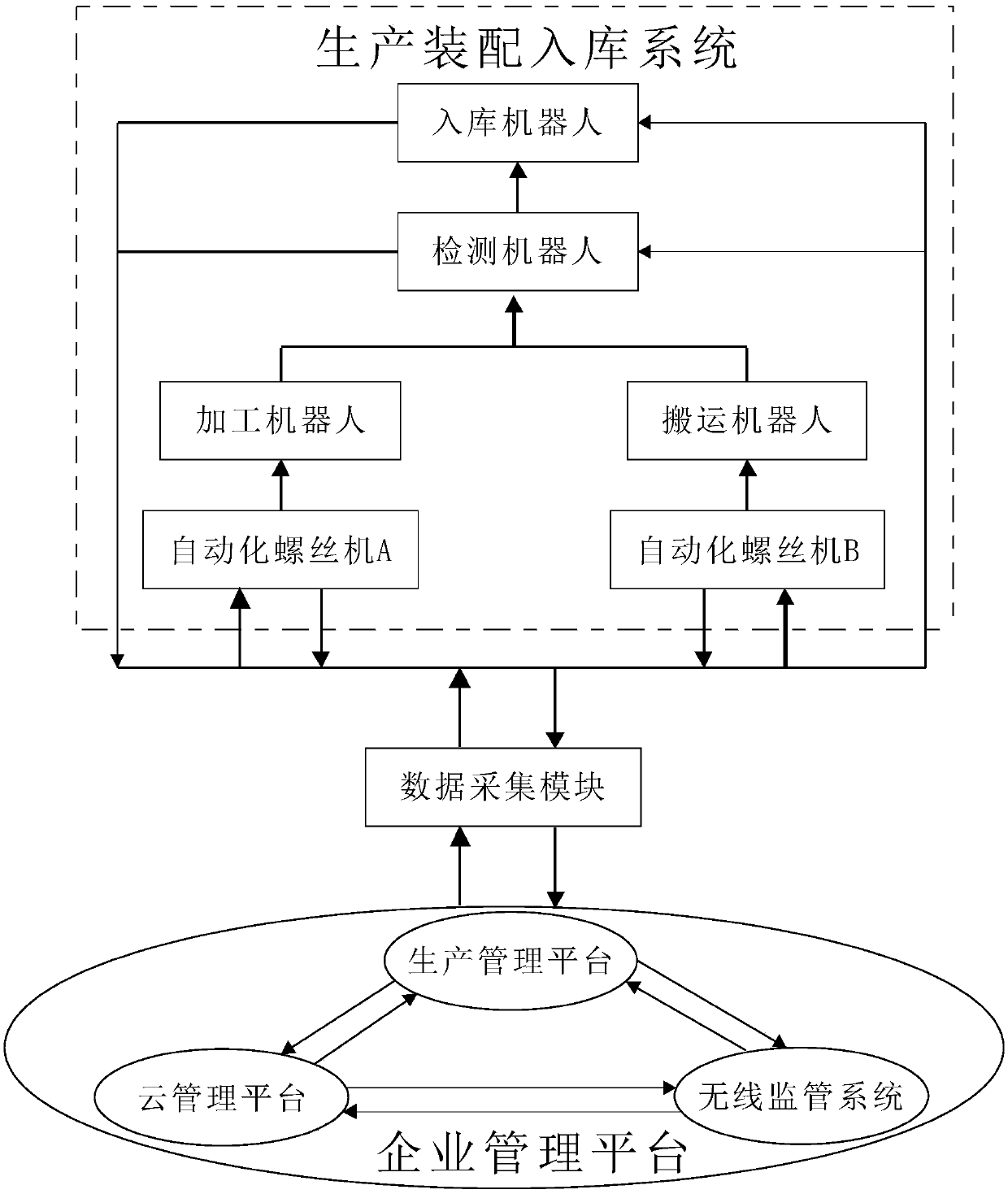

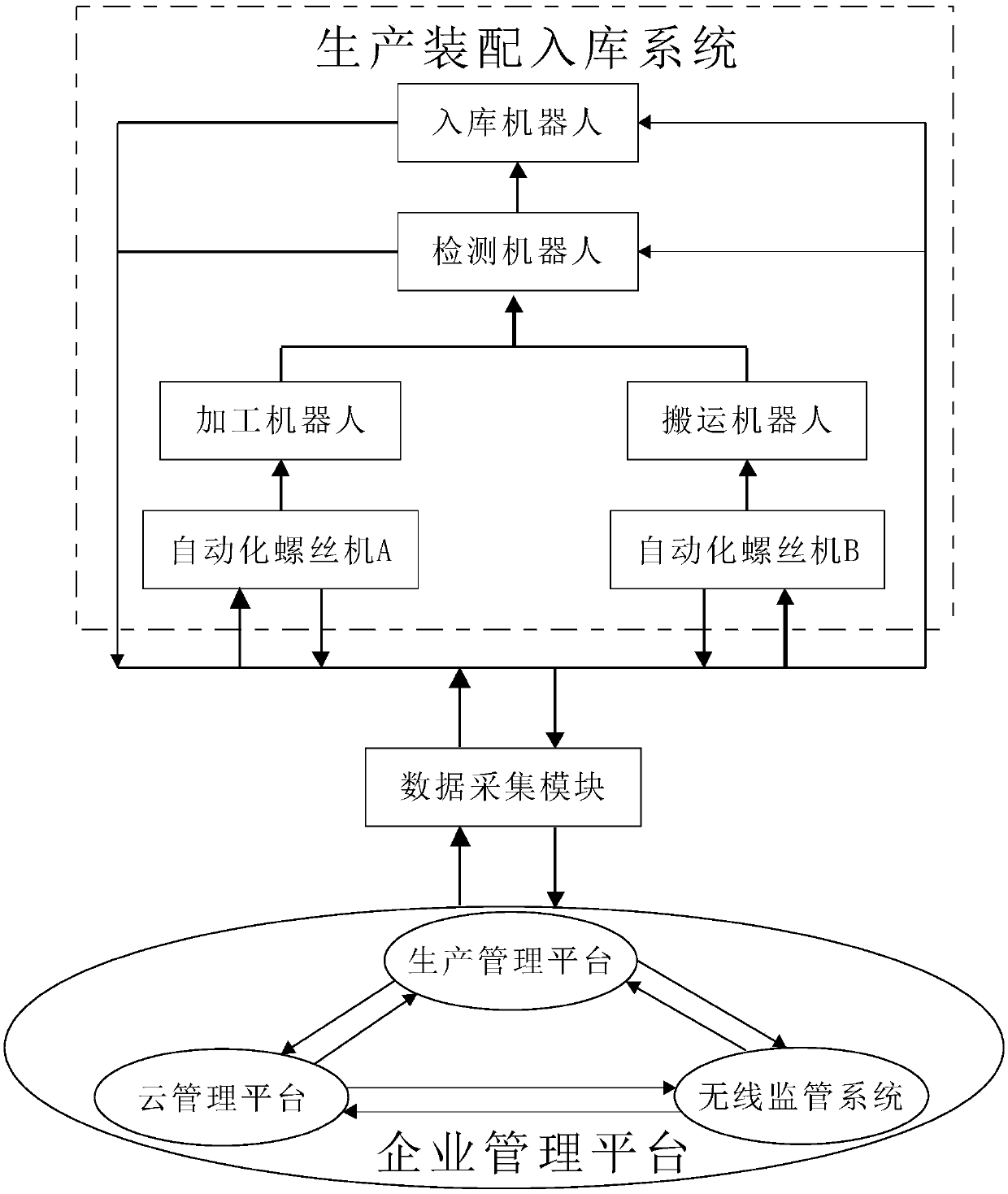

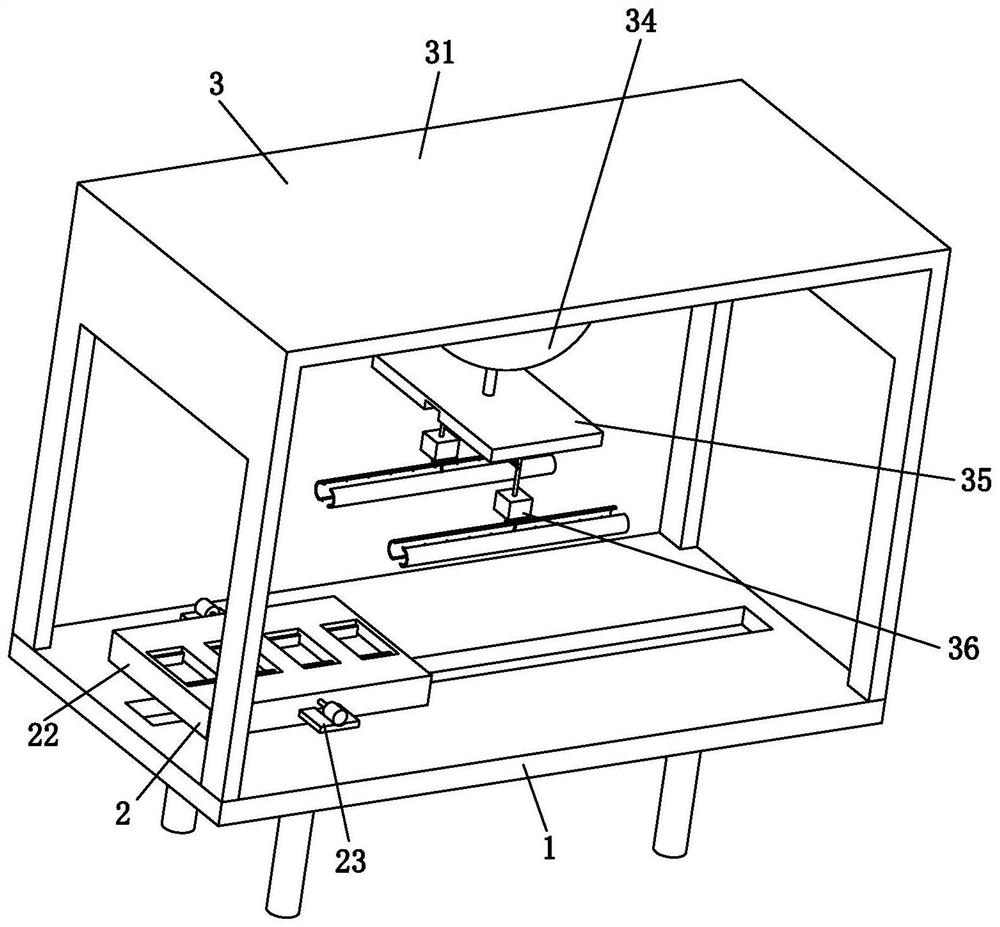

Fully-automatic screw machine and control and management system thereof

InactiveCN109960224AReduce manpower inputReduce production and management costsResourcesTotal factory controlIndustrial EthernetData acquisition

The invention discloses a fully-automatic screw machine and a control and management system thereof, which comprises a production assembly warehousing system, a data acquisition module and an enterprise management platform. The production assembly warehousing system is formed by an automatic screw machine A, an automatic screw machine B, a processing robot, a transfer robot, a detection robot anda warehousing robot, which are connected through an industrial field bus. The production assembly warehousing system generates real-time data, which is transmitted to the data acquisition module in the form of an industrial Ethernet; and the data acquisition module is connected with the enterprise management platform through an internet. The system integrates a modern automation industry 4. 0 management system, and realizes fully-automatic production from assembly to warehousing, thereby greatly improving efficiency of production and processing; and meanwhile, real-time production data is compatible to an enterprise management platform, thereby well realizing process monitoring and management of enterprises for product production, reducing production and management cost, and improving comprehensive strength of the enterprises.

Owner:湘潭顺航环保科技有限公司

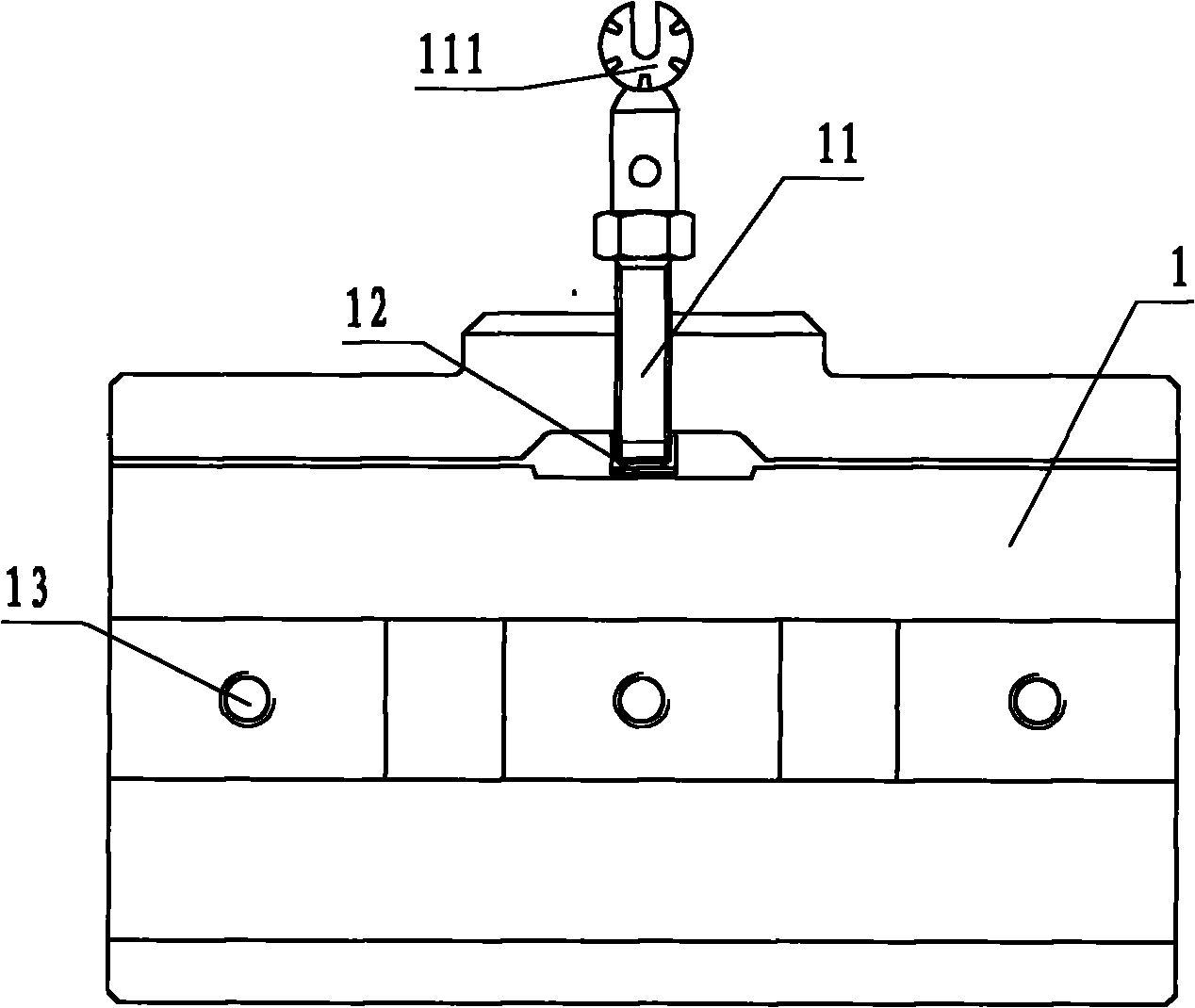

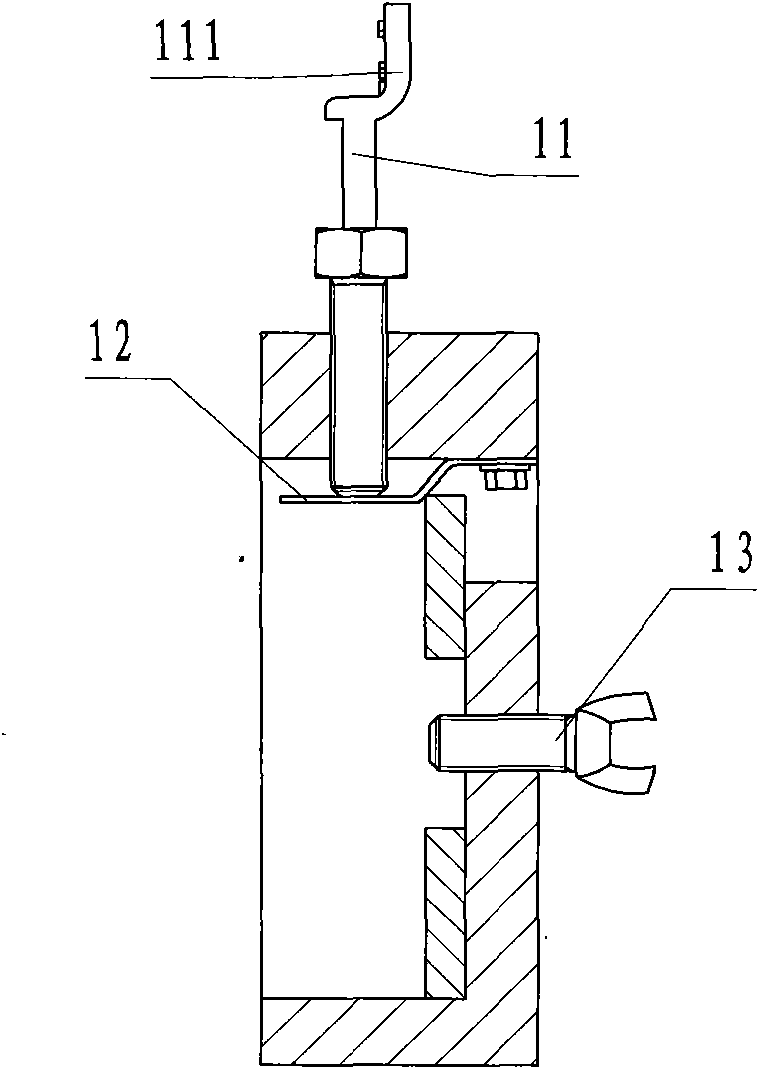

Welding forming auxiliary tool system for building construction PC embedded parts

InactiveCN113231767AGood fixed effectReduce manpower inputWelding/cutting auxillary devicesAuxillary welding devicesProcess engineeringManufacturing engineering

The invention relates to a welding forming auxiliary tool system for building construction PC embedded parts. The auxiliary tool system comprises a workbench, a conveying device and an alignment device. The system can solve the following problems possibly occurring in the welding process of existing building construction PC embedded parts: a, embedded part components are manually supported and fixed so as to complete the welding process between the embedded part components, the mode can be carried out only through cooperation of multiple persons, the welding efficiency is low, the production efficiency of enterprises is low, and thus the income of an enterprise is reduced; and b, the number of the embedded part components which are manually supported at a time is small, the fixing effect is poor, and the embedded part components are prone to shaking due to manual reasons in the welding process, so that the welding quality is affected, and the finished product quality of the building construction PC embedded parts is reduced.

Owner:武汉星润装饰工程有限公司

Insulator binding wire removal tool

ActiveCN114024254BReduce usageReduce workloadApparatus for overhead lines/cablesGrinding wheelOperation safety

The invention provides a tool for removing insulator binding wires, which relates to the technical field of electric power construction, and includes a support frame, a wire holding mechanism, a lateral movement mechanism, a longitudinal movement mechanism, and a grinding wheel rotation drive mechanism; the wire holding mechanism is connected to the support frame, and is used for Clamp or release the wire; the grinding wheel rotation drive mechanism includes a rotation drive transmission part and a grinding wheel connected to the rotation drive transmission part, the rotation drive transmission part can drive the grinding wheel to rotate; the rotation drive transmission part is connected to the longitudinal movement mechanism, and the longitudinal movement mechanism is connected to the transverse The moving mechanism and the lateral moving mechanism are connected to the supporting frame; the lateral moving mechanism can drive the longitudinal moving mechanism to move laterally, and the longitudinal moving mechanism can drive the rotating drive transmission part to move longitudinally; the supporting frame is provided with an installation connection part for connecting the mechanical arm. The invention simplifies the operation process of removing the insulator binding wires, improves the removal efficiency of the insulator binding wires, and simultaneously improves the operating safety of operators.

Owner:国网瑞嘉(天津)智能机器人有限公司

Safe semiconductor material production technical equipment

InactiveCN108568544ASimple structureEasy to useFeeding apparatusBoring/drilling componentsSemiconductor materialsEngineering

The invention discloses safe semiconductor material production technical equipment which comprises a bearing rack and a base fixedly arranged on the bearing rack, wherein a first slide cavity runningthrough front and back is formed in the base; a first turning cavity communicates to the bottom wall in the first slide cavity; a first slide plate stretching front and back is smoothly mounted in thefirst slide cavity; a transparent slot stretching front and back is formed in the end surface of the top of the first slide plate; inner tooth spaces stretching front and back are symmetrically formed in the end surface of the bottom of the first slide plate left and right; a second slide cavity is formed in the base on the left side of the first turning cavity; and a first turning shaft is mounted between the first turning cavity and the second slide cavity in a rotary fit manner.

Owner:高维维

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com