Automatic solid material weighing and canning machine

An automatic weighing and solid material technology, applied in the direction of solid material, packaging, transportation and packaging, etc., can solve the problems of material leakage, inaccurate feeding, material waste, etc., to save manpower investment and reduce start-up and stop Time and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

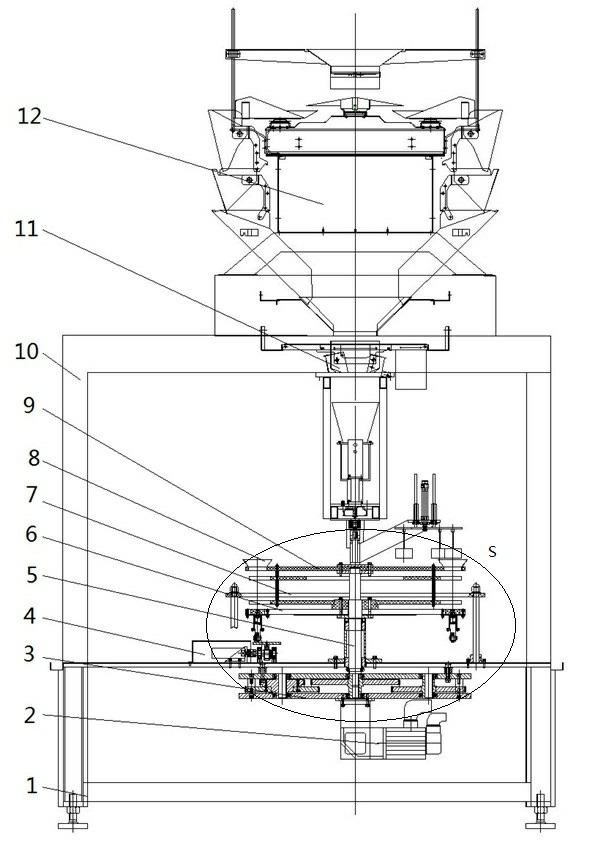

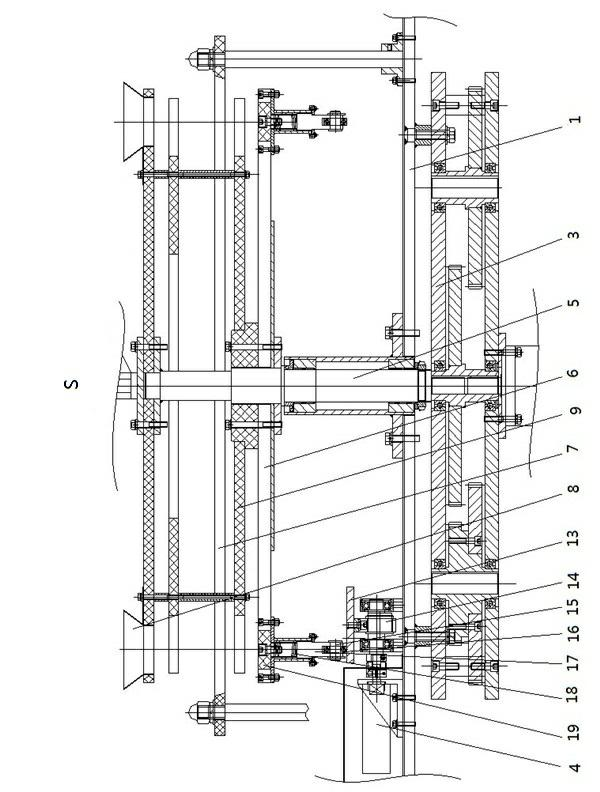

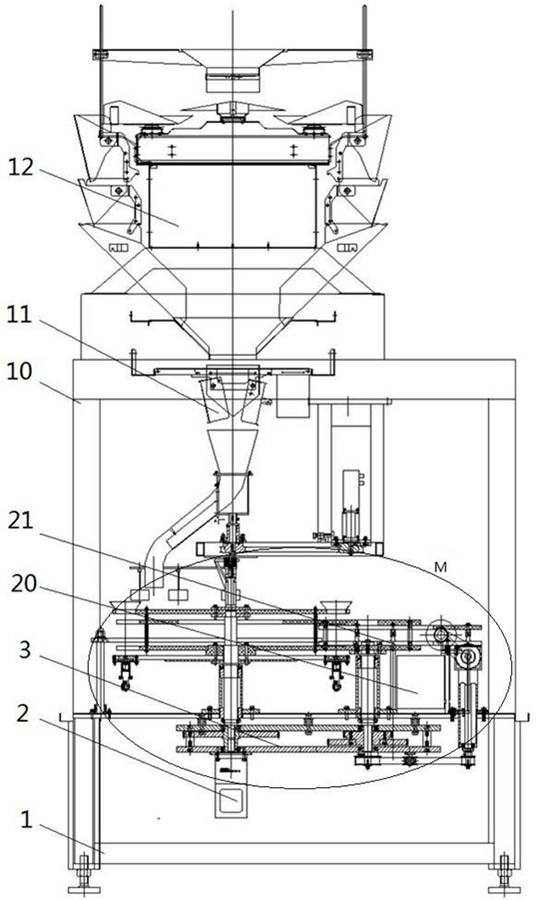

[0028] Such as Figure 1-15As shown, the present invention comprises a frame, a transmission mechanism, a bottle-can conveying mechanism, a feeder, and an automatic scale group 12, and the bottle-can conveying mechanism is successively composed of a small feeding dial 21, a large rotary dial 9, and a small discharging dial. Dials 24 are connected, and the feeding small dial 21 and the discharging small dial 24 are all located on the top of the conveyor belt 20, and a guide plate 23 is installed on one side of the conveyor belt 20 to ensure the direction of transmission, and the conveyor belt 20 is transported to the position before the small feed dial 21 is installed with a tank-separating screw 22, the outside of the large rotary dial 9 is provided with a guardrail 7, and the guardrail 7 is fixed on the frame 1 by bolts to prevent bottles and cans from Sliding sideways, the main shaft 5 of the large rotary dial is also equipped with a tank tray 6, the tank tray 6 is located b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com