Cake pressing machine for continuously pressing tea leaves and cake pressing method thereof

A technology for a cake press and tea, which is applied to the field of cake presses for continuous pressing of tea, can solve the problems of difficulty in automatic production, large labor input, and large production labor, and achieves reduction of labor input and small footprint. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

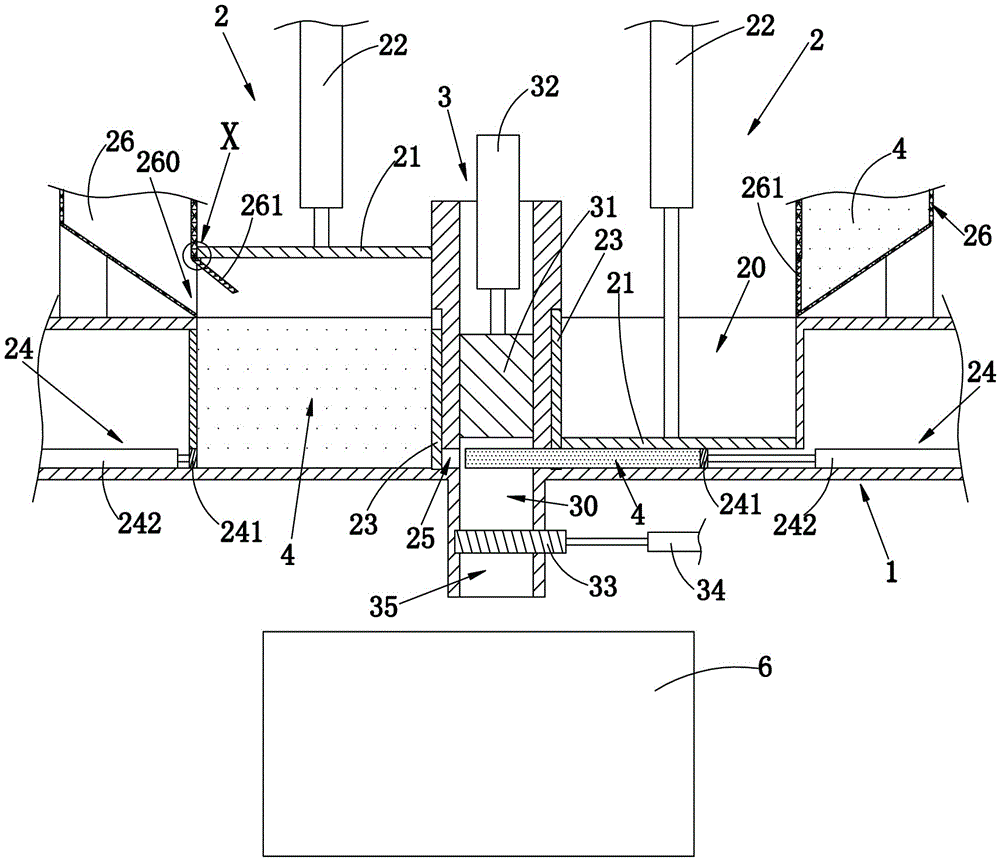

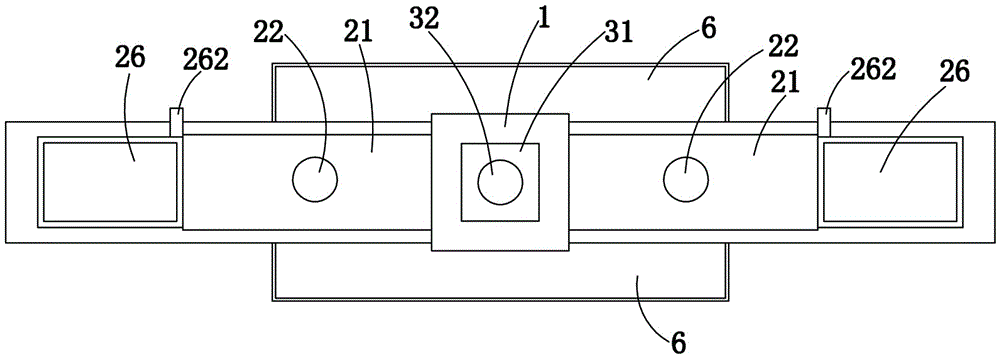

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

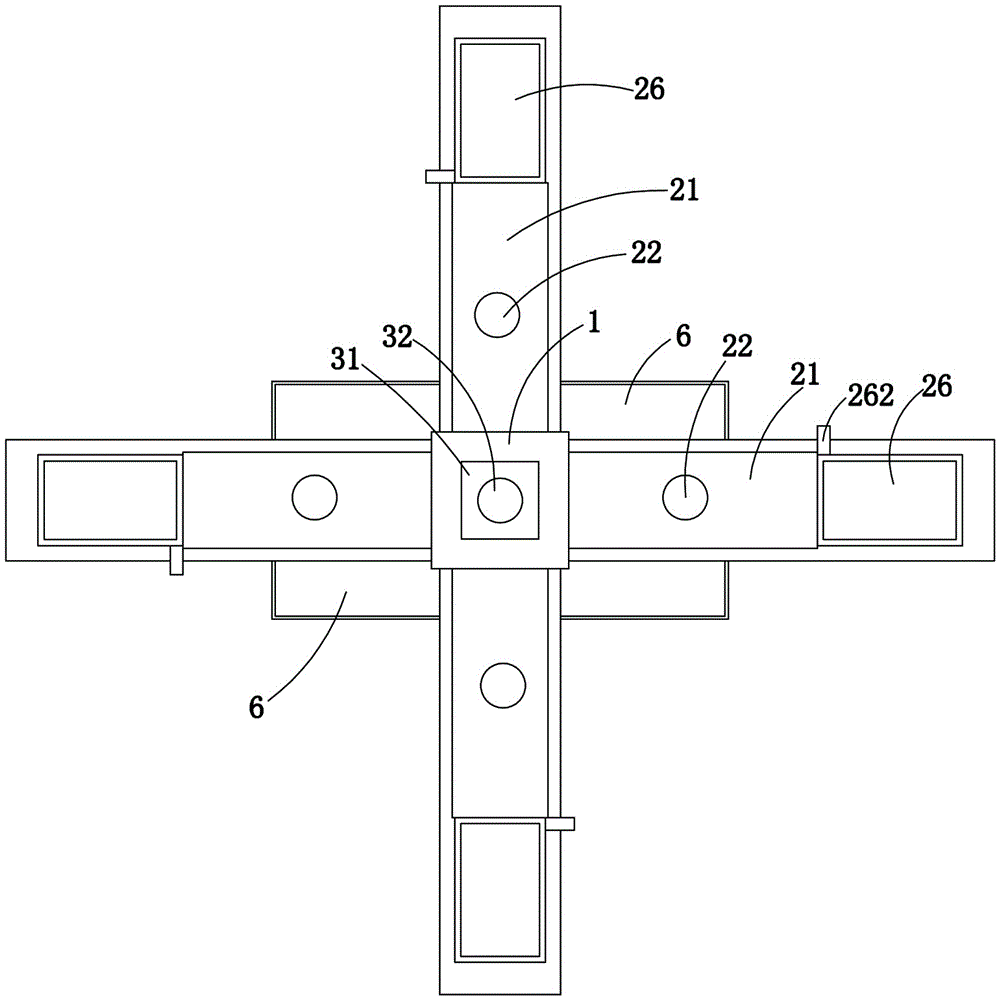

[0024] refer to figure 1 , figure 2 A cake press machine for continuously pressing tea leaves includes a main frame body 1, a pre-press mechanism 2, a cake press mechanism 3 and a control device. The control device is used to control the cake press machine to operate in sequence. Such as figure 1 , figure 2 As shown, the cake press machine includes one above-mentioned cake press mechanism 3 and two above-mentioned pre-press mechanisms 2 , and the tea outlet channel 25 of each pre-press mechanism 2 communicates with the pressure cavity of the cake press mechanism 3 . The heights of the tea outlet passages 25 of all pre-compression mechanisms 2 do not have to be the same, but are preferably set at the same height. The quantity of preloading mechanism 2 can also be adjusted according to the efficiency demand of actual production, as image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com