Cutter disc structure of digital controlled lathe

A technology of CNC lathes and cutterheads, applied in the direction of tool holders, etc., can solve problems such as poor product concentricity and smoothness, inability to adjust the tool bar, and inability to achieve processing, so as to reduce manpower input, shorten processing time, and improve processing efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

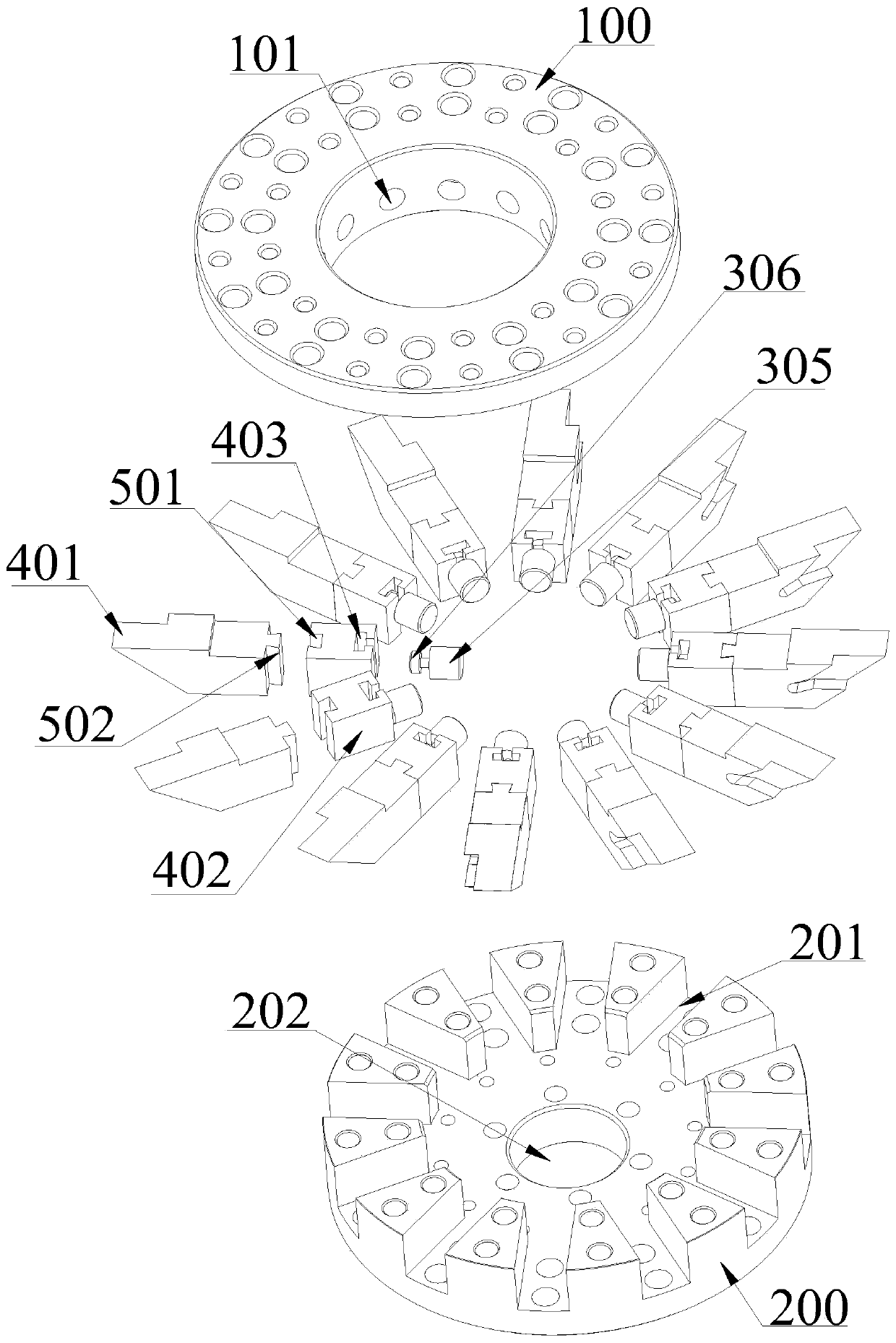

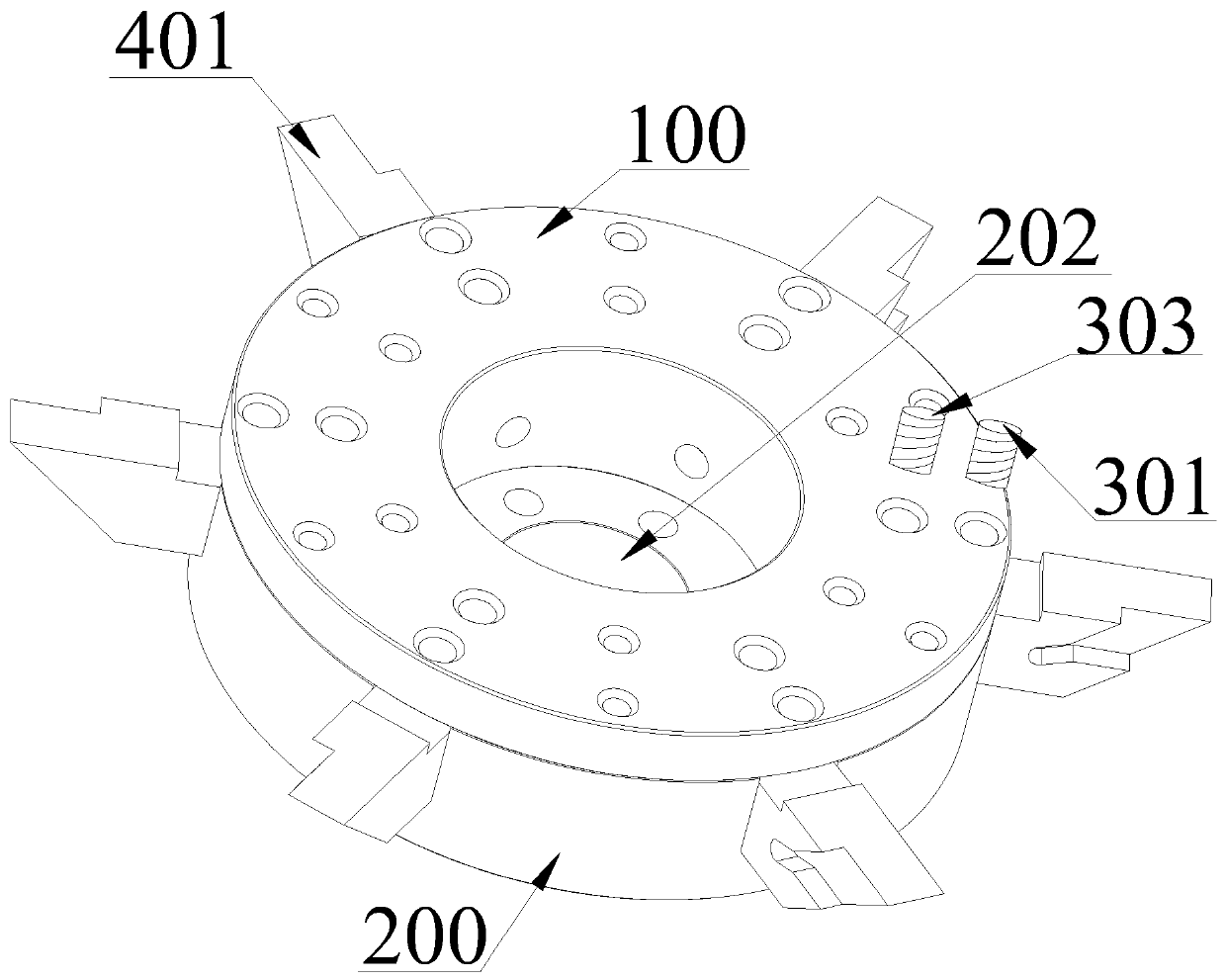

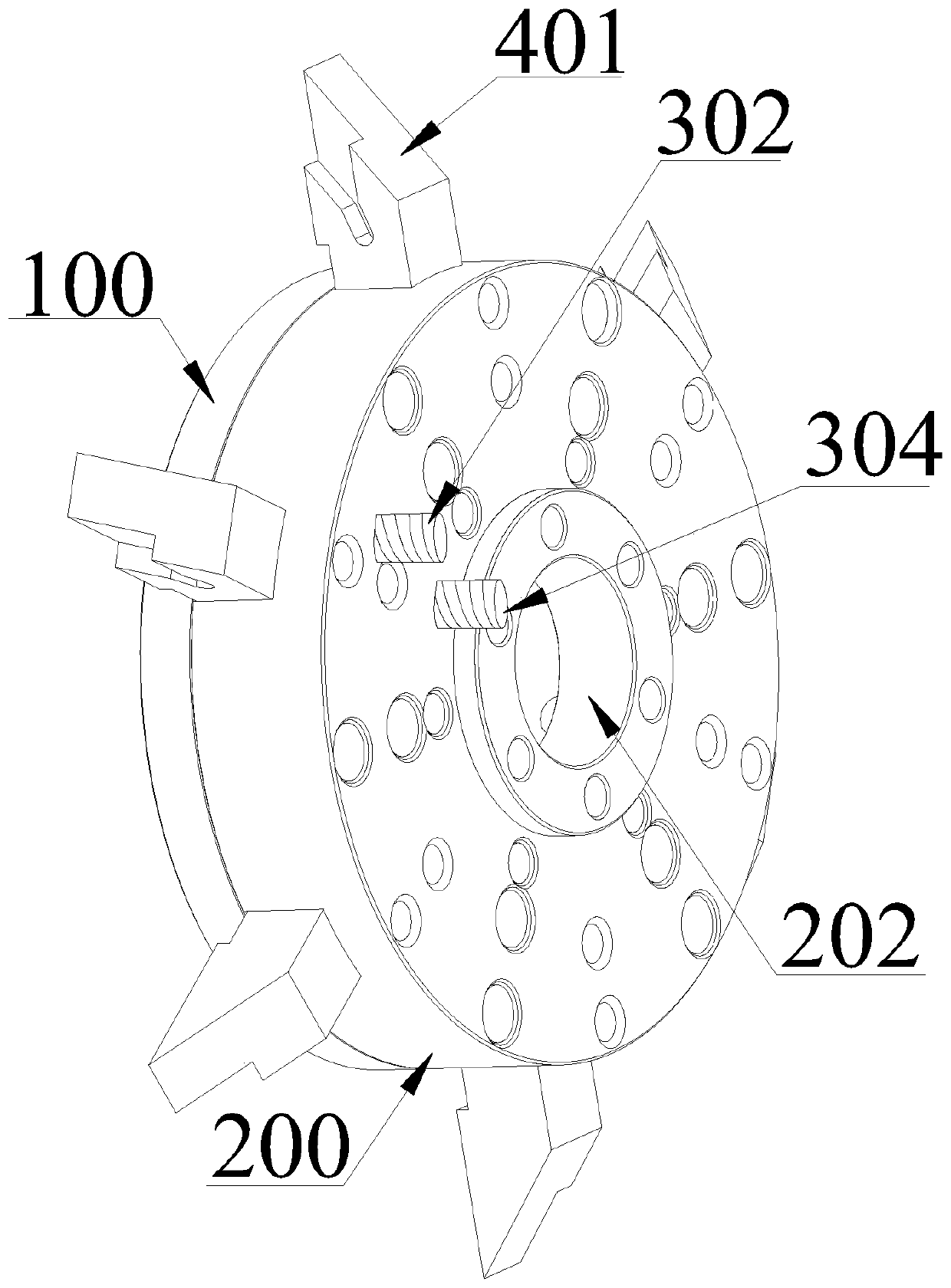

[0020] refer to Figure 1 to Figure 4 , an embodiment of the cutterhead structure of a CNC lathe according to the present invention is proposed. The cutterhead structure is set on the electric spindle 600 of the CNC lathe and processes the workpiece 800 on the spindle 700 of the lathe. The cutterhead structure includes a cutterhead body and several cutter bar structures clamped in the cutterhead body. The cutterhead body includes a fixed disk 100 and a cutterhead back seat 200, wherein the fixed disk 100 and the cutter head back seat 200 are connected by screws. Locking and fixing, compact structure and firm connection.

[0021] A plurality of installation slots 201 are provided on the cutterhead rear seat 200 , and the cutter bar structure is embedded in the installation slots 201 . The cutter bar structure is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com