Hydraulic forging system and method for forging disk pieces with holes

A disk-like technology with holes, which is applied in the field of metal forging, can solve the problems of affecting the forging efficiency of workpieces and increasing manpower expenditure, so as to achieve the effect of reducing manpower input and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

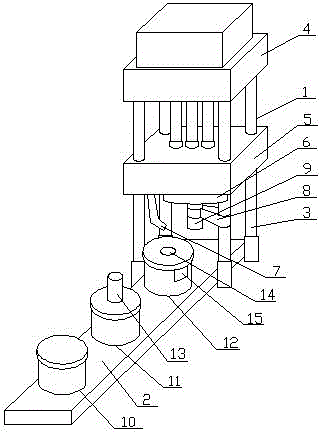

[0012] Such as figure 1 As shown, the hydraulic forging system for forging discs with holes is composed of a forging device 1 and a workbench 2. The forging device 1 includes a column 3, a crossbeam 4 arranged on the top of the column 3, and a beam 4 slidingly arranged on the column 3. The slider 5 is driven by the hydraulic cylinder arranged on the beam 4 to move up and down along the column 3, and the bottom of the slider 5 is provided with a pressing block 6 for stamping forgings and a clip for clamping forgings device, a rotating arm 8 is slidably connected on the column 3, the other end of the rotating arm 8 is provided with a punch 9 that cooperates with the pressing block 6, and the rotating arm 8 is provided with a movable connecting plate connected with the slider 5, The movable connecting plate can freely expand and contract in the vertical direction, so that the briquetting block 6 can apply pressure to the punch 9 for punching. An upsetting table 10, a punching ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com