Intelligent dry waste discharge system based on true dual energy X-rays

An X-ray and dry method technology, applied in the field of intelligent dry gangue discharge system, can solve the problems of difficult management of γ-ray radiation source, fast wear and tear of separation equipment, and low recognition accuracy of pseudo-dual-energy X-ray, so as to improve the separation efficiency , strong adaptability, and the effect of reducing muddy phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

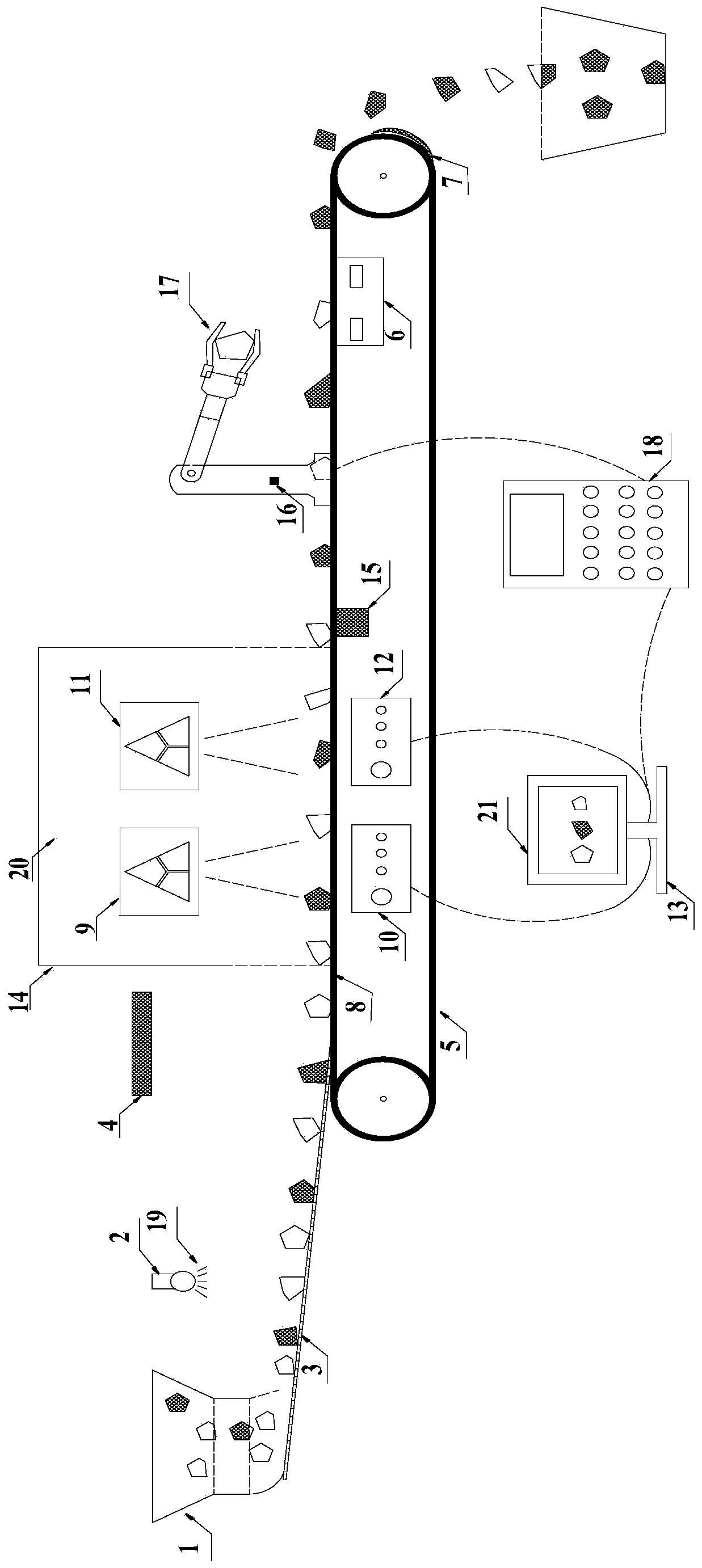

[0020] Embodiment. The present invention is applied in the coal preparation plant intelligent dry method coal preparation system:

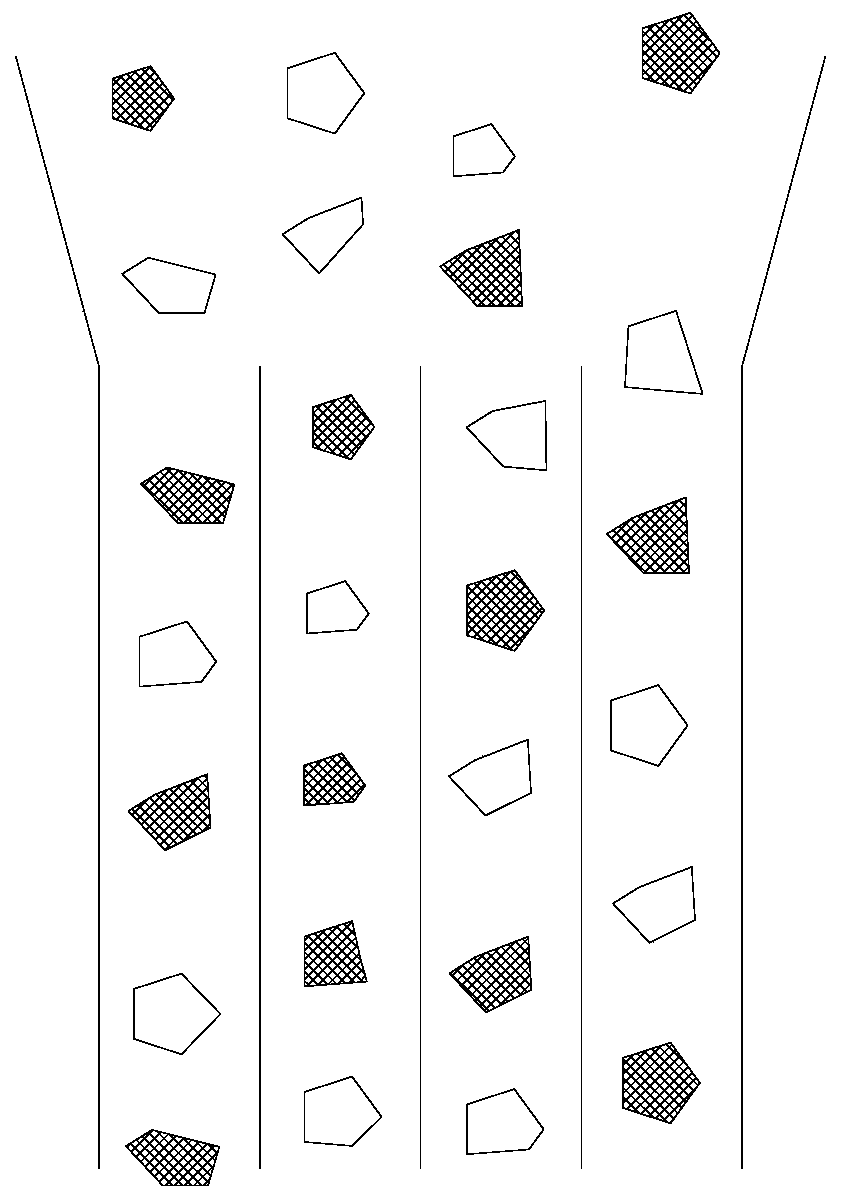

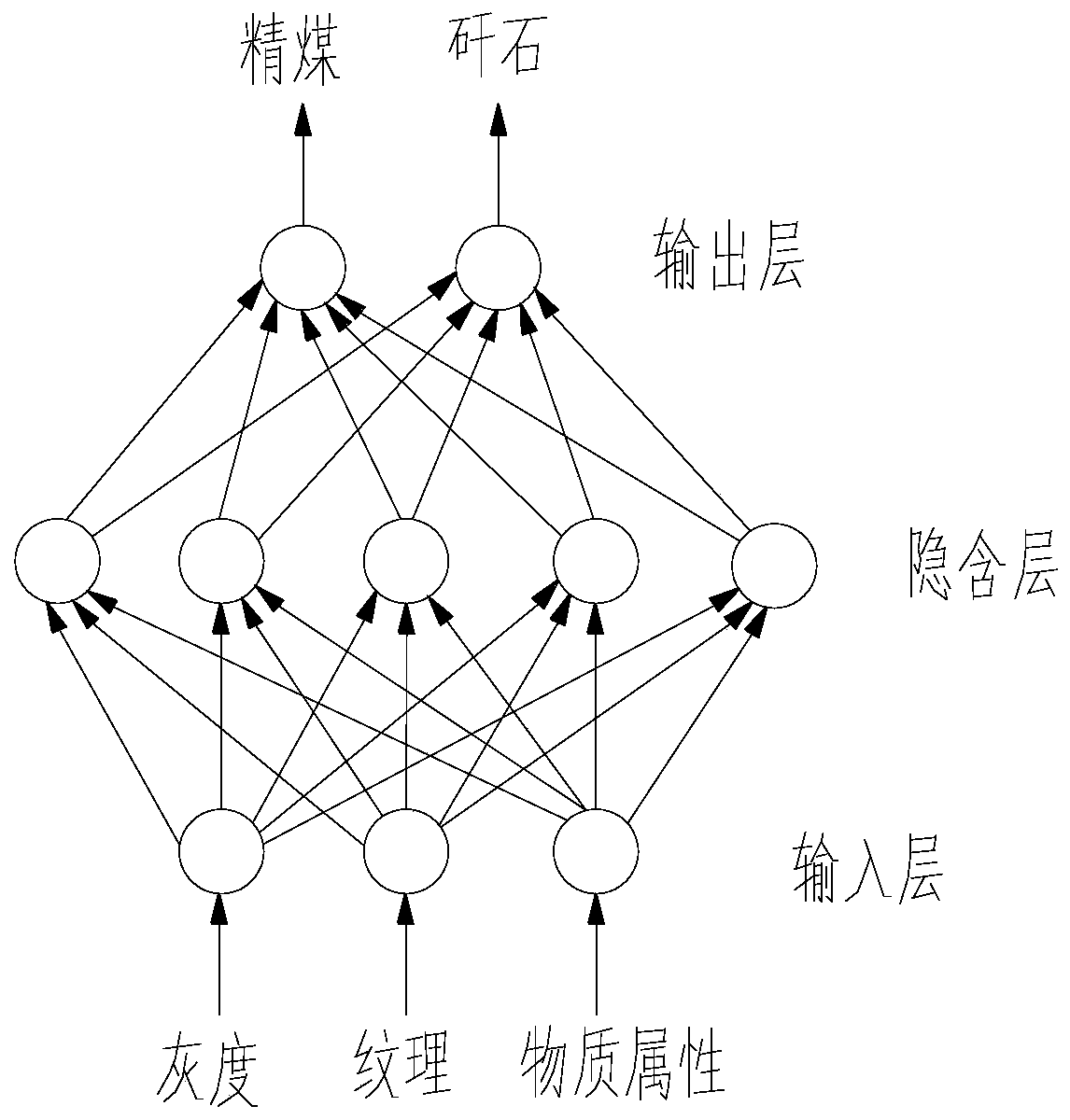

[0021] As shown in the figure, an intelligent dry gangue discharge system based on true dual-energy X-rays includes the following components:

[0022] Feeding mechanism (A), which includes a feeding funnel (1) and a spray desliming device (19); the outer part of the feeding funnel (1) is in an inverted cone shape, and a wear-resistant ceramic plate is laid inside, and the upper part of the funnel is an inlet The feed port is connected to the underground raw coal feeding belt, and the lower part of the funnel is the discharge port connected to the spray desliming device (19). The raw coal enters the spray desliming device (19) from the feeding funnel (1), and the spraying desliming device (19) It consists of a spray pipe (2) and a high-frequency screen (3). The high-frequency screen (3) is divided into two sections. The material enters the first ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com