Patents

Literature

32 results about "Electronic leash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electronic leash is the pairing (“leashing”) of one or more wireless devices to a host device that allows the user to find misplaced or out-of-sight objects by activating the host device such that the “leashed” object identifies itself. The system is identical in concept to a key pager, but offers multiple codes that allow a single user-operated device to send codes to a large number of objects. Leash systems generally also offer a form of distance measurement that raises an alarm if the leashed object travels more than a selected distance from the operator. An electronic leash with a paired devices usually includes a power source, transmitter and receiver. Optional elements can include tactile, auditory, or visual indicators to help the user realize the distance traveled from the object is past the maximum. Along with the physical elements, it is very common to have a computer program or mobile application to allow for modification of factory settings of distance allowed from source to receiver and the indication of this event occurring.

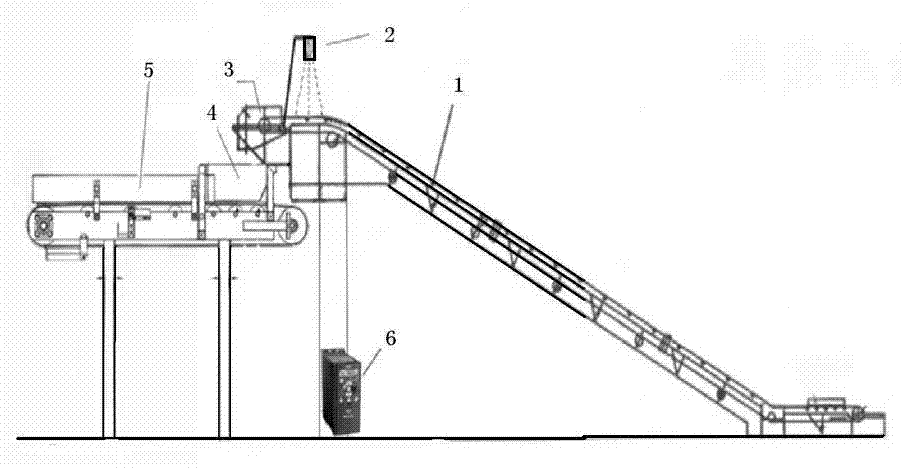

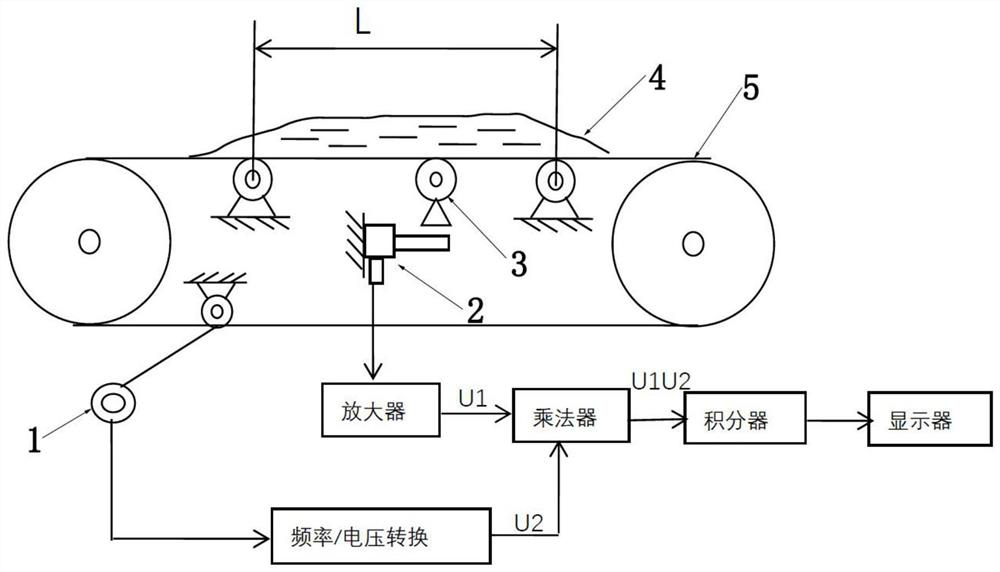

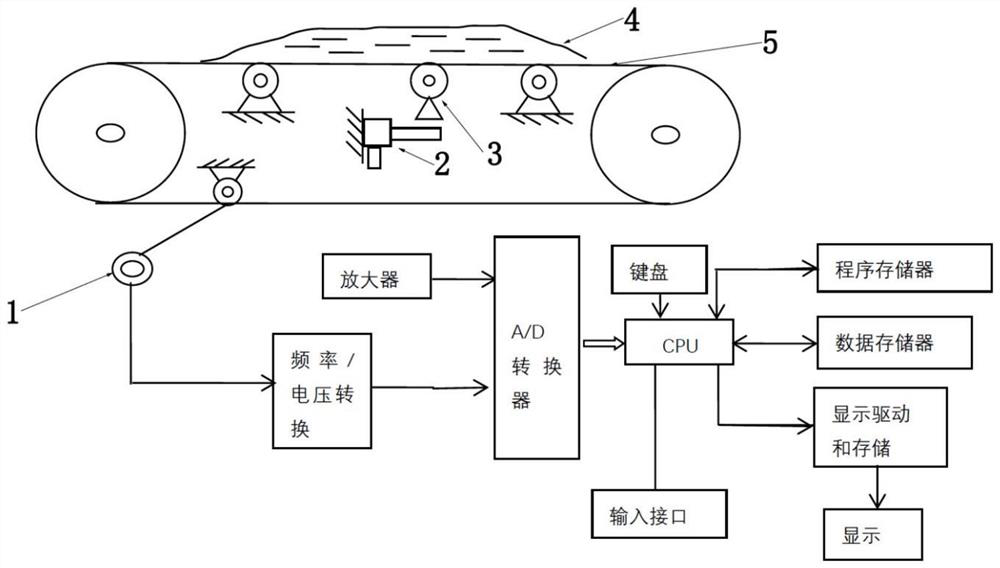

Method for metering travelling belt material and its device

InactiveCN101285697ASave costSave maintenance troubleMass flow measurement devicesWeighing apparatus for continuous material flowEngineeringLoad cell

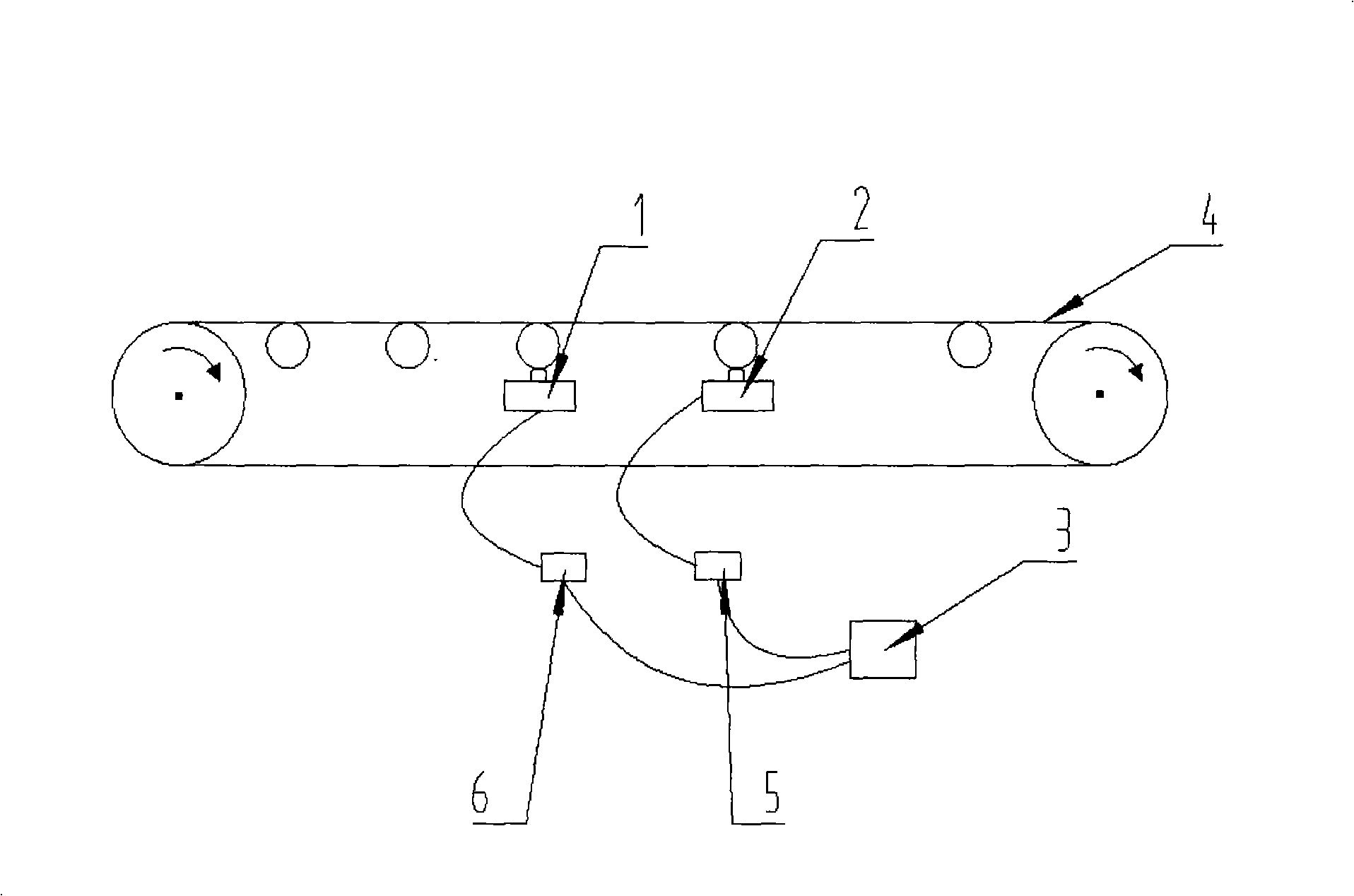

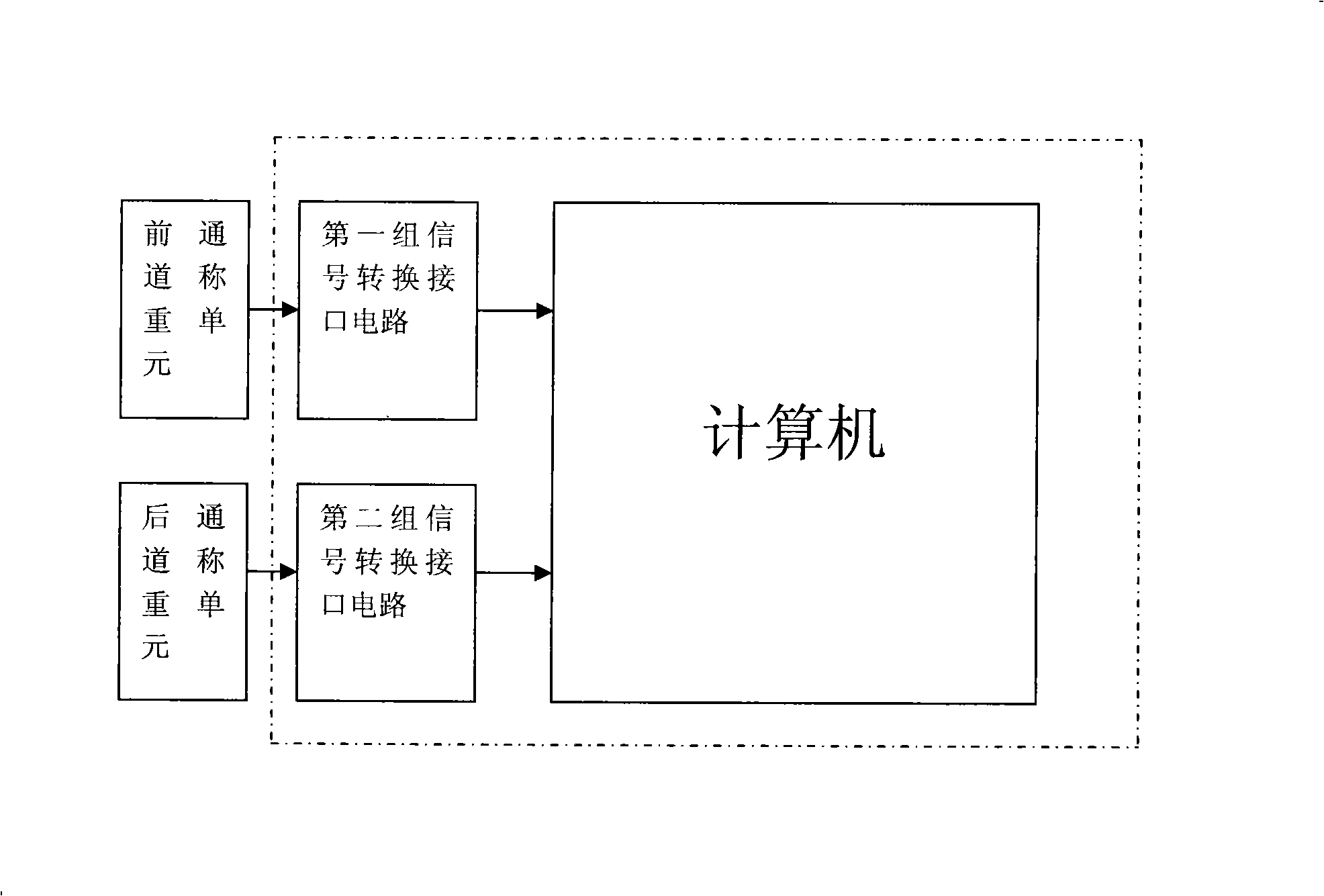

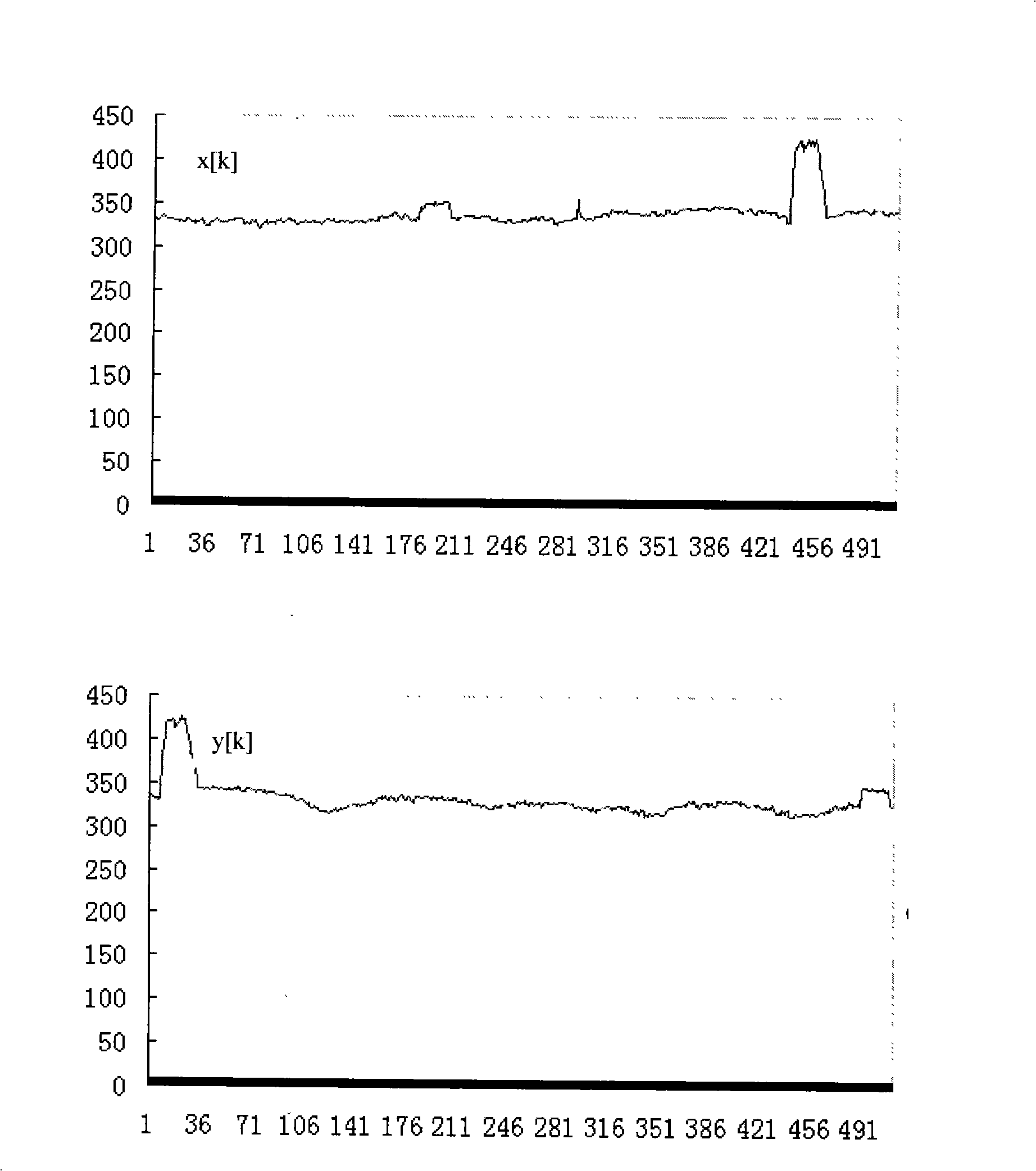

The invention discloses a method and a device for metering materials on conveying belts, which belongs to the electronic belt scale field and solves the technical problem that inaccurate signal transmission of speed sensors of belt scales causes the metering distortion of the belt scales. The method is based on a scale frame structure of an electronic belt scale with double weighing channels, uses no speed measurement sensor and only sets a weighing sensor in a weighing unit, and has a computer use some algorithm to process signals by comparing the weighing sampling values of two weighing channels, so as to obtain the running speed of the belt scale. The method can avoid using speed sensors, thereby reducing the loss of sensors and the probability of artificial cheating. The invention simultaneously provides a method of metering the flow rate and weight of materials conveyed on conveying belts under the condition with no speed measurement sensor and a device for realizing the method.

Owner:SHANXI XINYUAN AUTOMATIC INSTR

Condition monitoring system for electronic belt scale

ActiveCN104019881AGuaranteed smoothnessWeighing apparatus testing/calibrationDevice MonitorEngineering

The invention discloses a condition monitoring system for an electronic belt scale. The condition monitoring system comprises the electronic belt scale, a monitoring device and a processing device. When tobacco leaves pass through the electronic belt scale, the monitoring device monitors the instantaneous flow P of the tobacco leaves; when P is larger than or equal to 2000 kg / h and less than or equal to 2300 kg / h, the processing device sends out a fault signal; when the P is larger than or equal to 2300 kg / h, the processing device sends out a major fault signal. The instantaneous flow of the tobacco leaves when the tobacco leaves pass through the electronic belt scale is effectively guaranteed, and the situation that the tobacco leaves are incompletely processed due to excessive quantity is avoided.

Owner:CHINA TOBACCO GUANGDONG IND

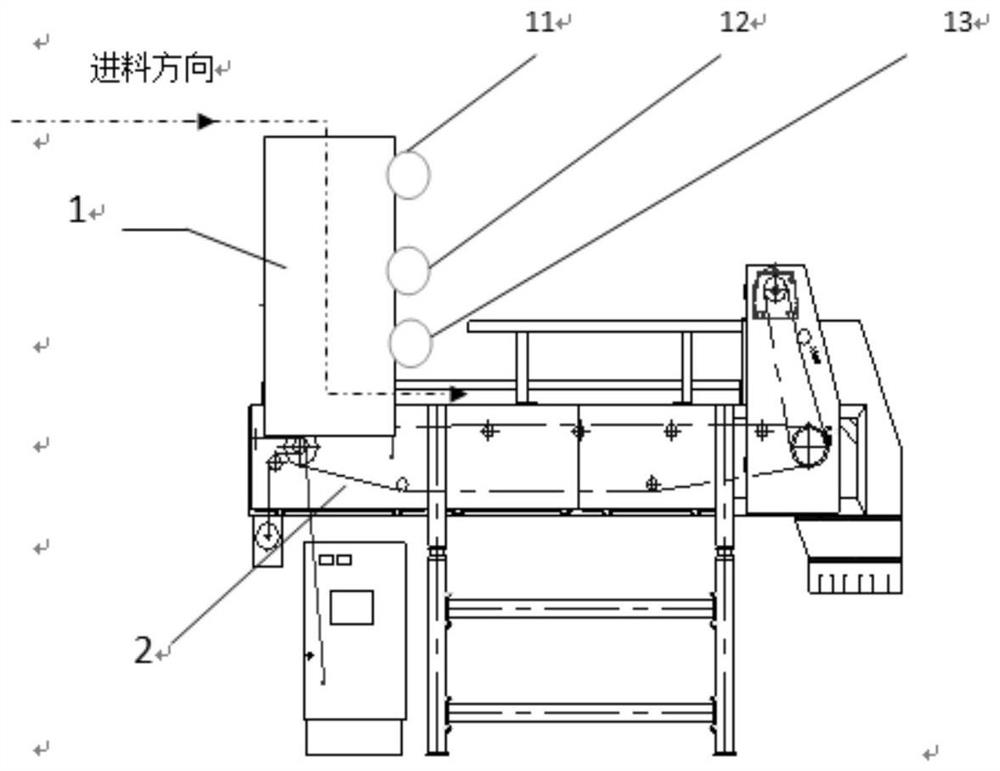

Even material supplying device and even material supplying method thereof

ActiveCN103787052ASimple structureEasy to operateControl devices for conveyorsElectronic leashControl engineering

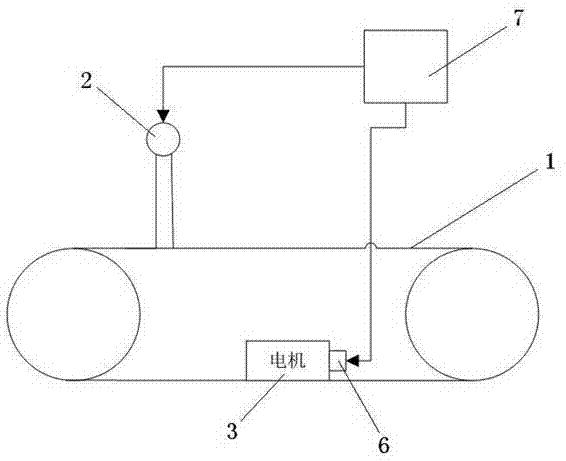

The invention provides an even material supplying device. The even material supplying device comprises a material conveying mechanism, a material height detector and a conveying speed controller, wherein the material height detector sends detected material height signals to a material supplying controller, the conveying speed controller sends speed signals of the material conveying mechanism to the material supplying controller, the material supplying controller determines the adjusted speed of the material conveying mechanism through calculation according to the signals and then sends an adjustment instruction to the conveying speed controller, the conveying speed controller controls and adjusts the speed of the material conveying mechanism, and therefore the stability of material discharging flow is kept. By means of the technical scheme, the technical problems in the prior art that a material supplying device of an electronic belt scale is high in flow fluctuation, and an added feeding machine raises the cost, is difficult to match and wastes materials are solved, and the even material supplying device with no feeding machine is simple in structure, convenient to operate, low in manufacturing cost of equipment and good in use effect.

Owner:CHINA TOBACCO GUANGXI IND

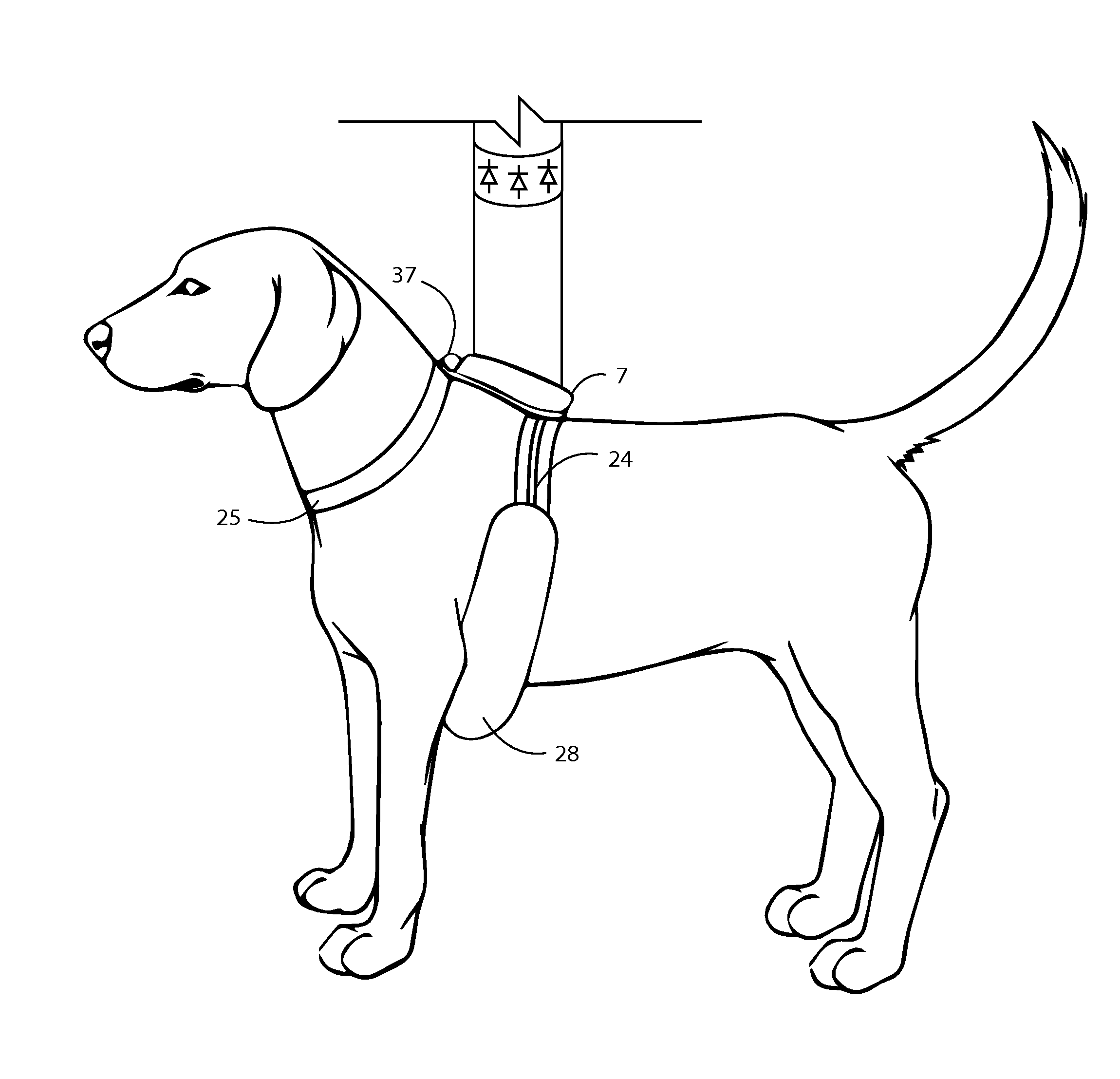

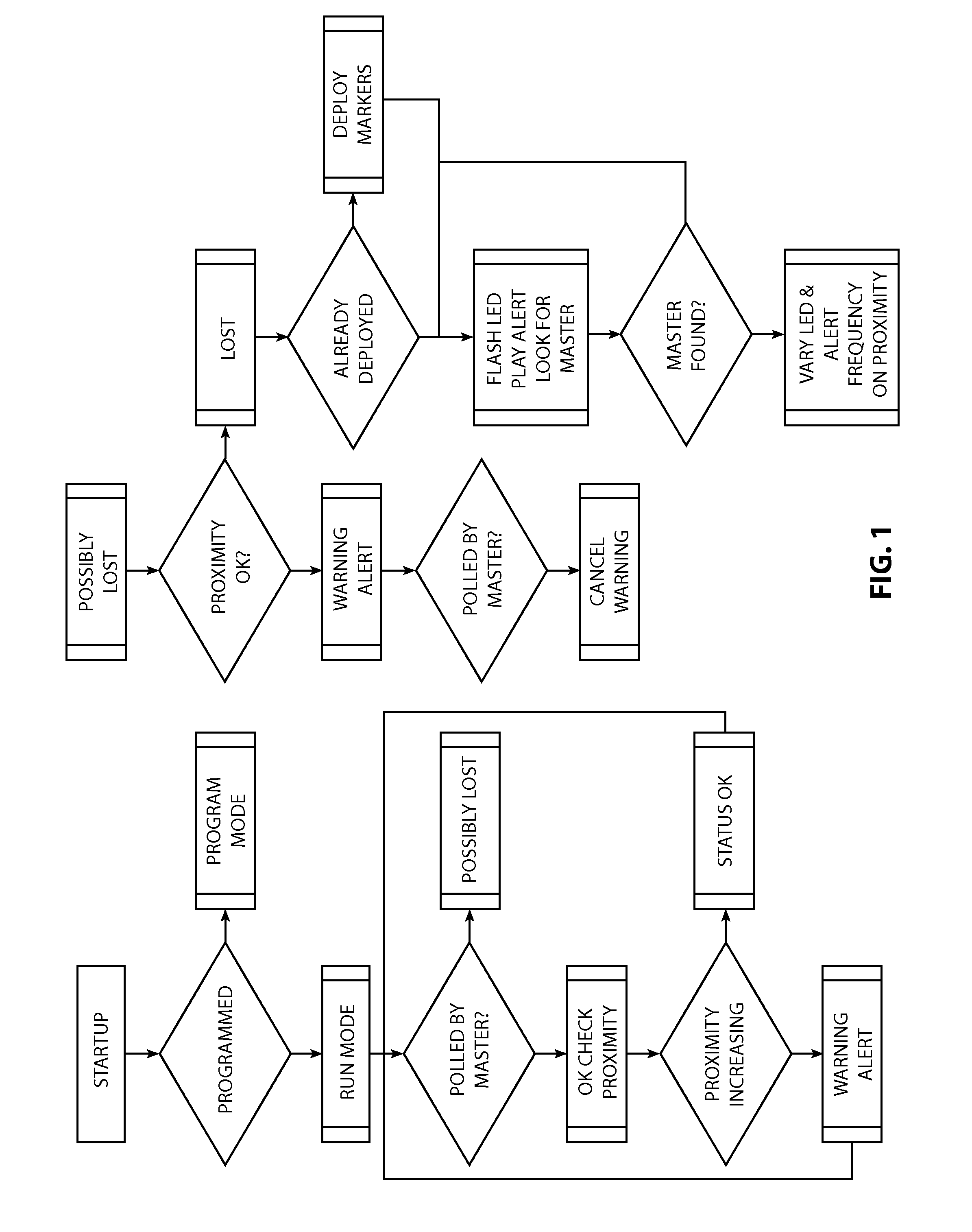

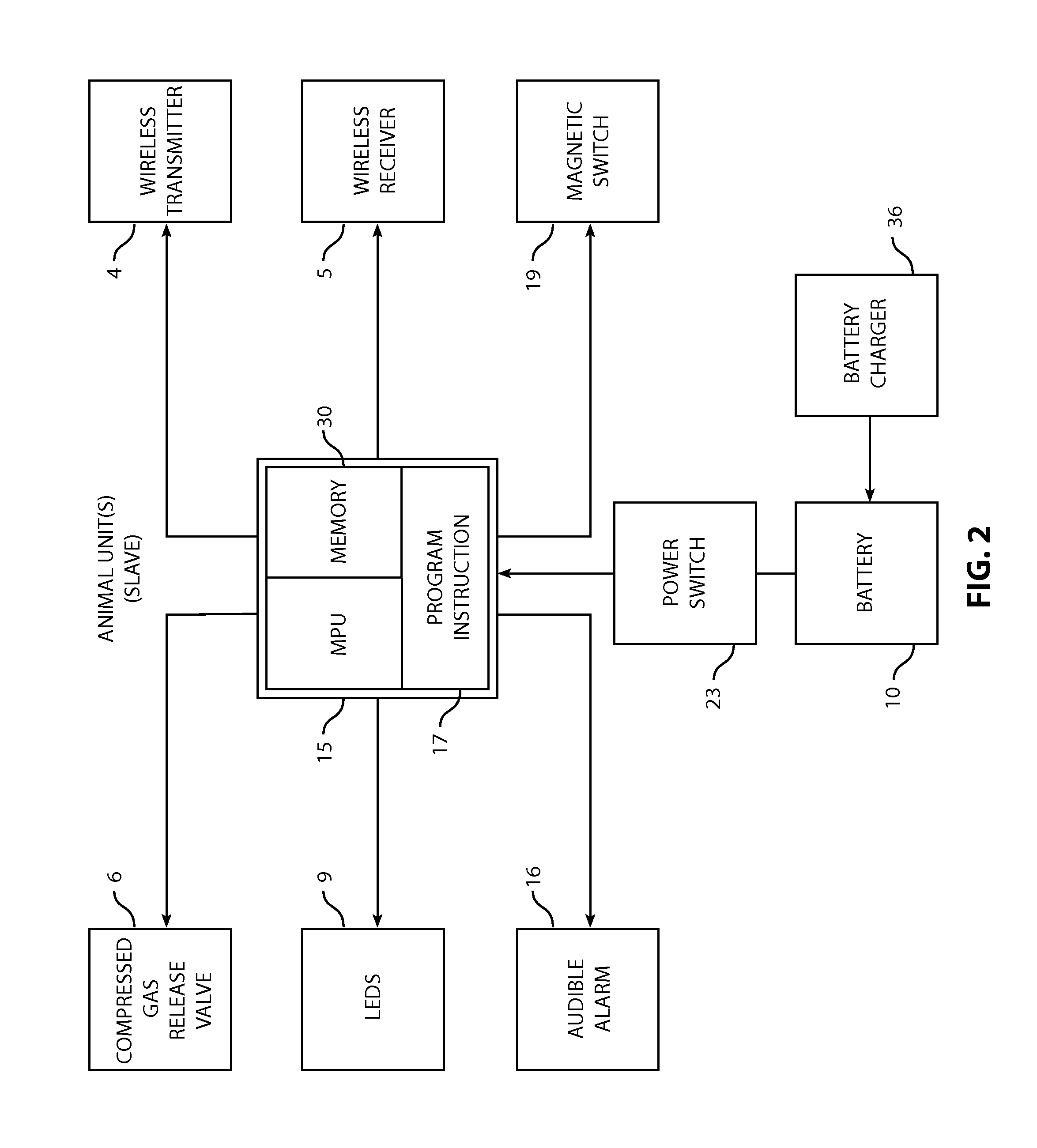

Lost animal safety device

InactiveUS20170006834A1Reduce travel requirementsEasy to moveTaming and training devicesElectronic systemsTransceiver

A lost animal safety device is disclosed, comprising a harness having embedded features that reduce injury to, and enable fast recovery of, lost animals. The inventive device comprises a singular or plurality of fixed, portable or mobile wireless electronic leashes to transmit and receive wireless signals linked, paired or other wised matched by frequency, phase, algorithm, code or combination thereof to a singular or a plurality of corresponding animal harness-mounted transceiver units wherein detection of proximity is accomplished and logic determines sequence of events such as sounding an alarm, delivering a warning alert, deploying an instantly human recognizable safety marker and / or deploying a run inhibiting inflatable bladder to alert the owner, motorists, Samaritans and rescuers to the instant location and plight of the animal as well as slowing the animal to aid in recovery.

Owner:WATERS DAVID BOYKIN

Portable electronic device leash and associated use thereof

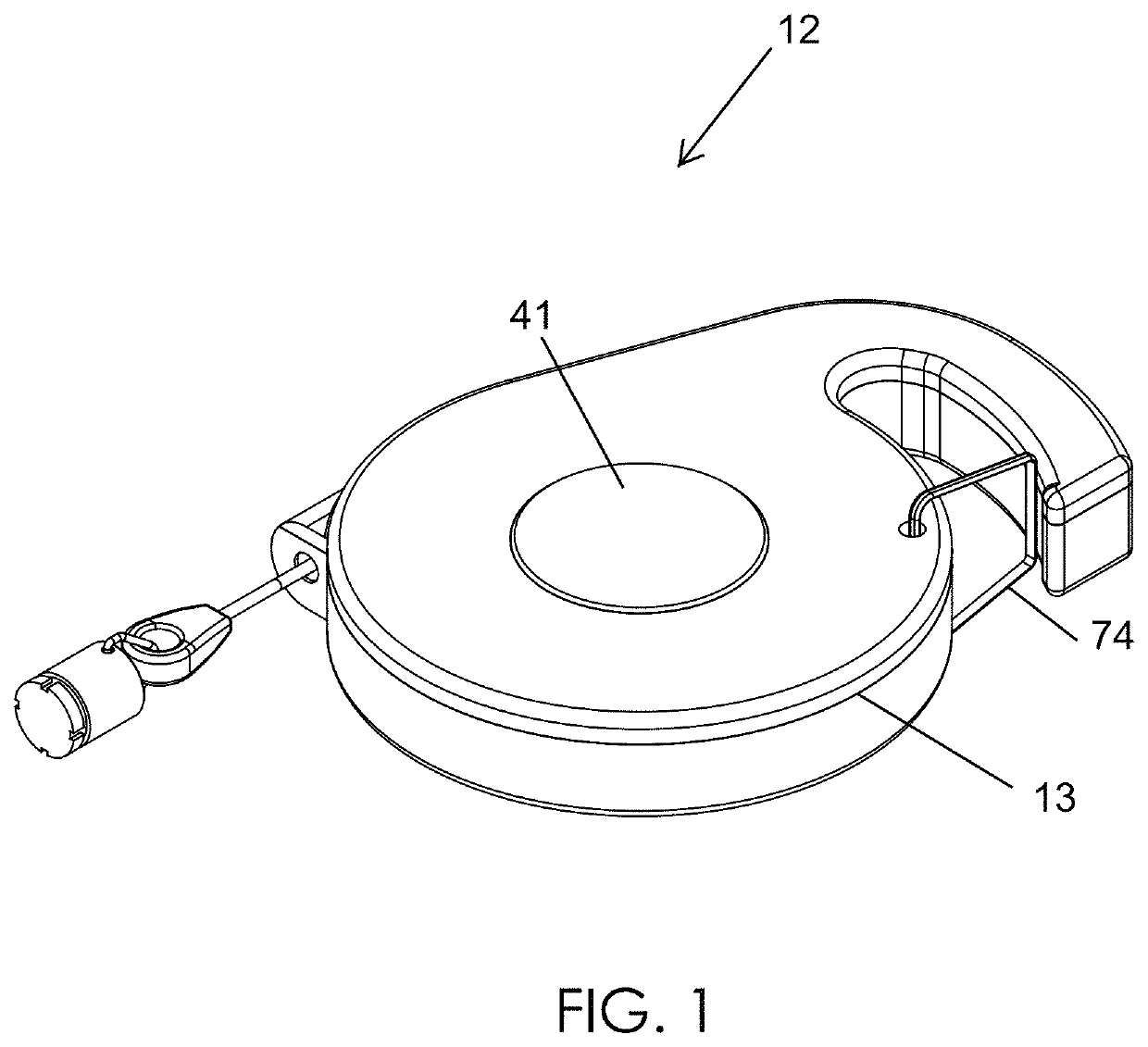

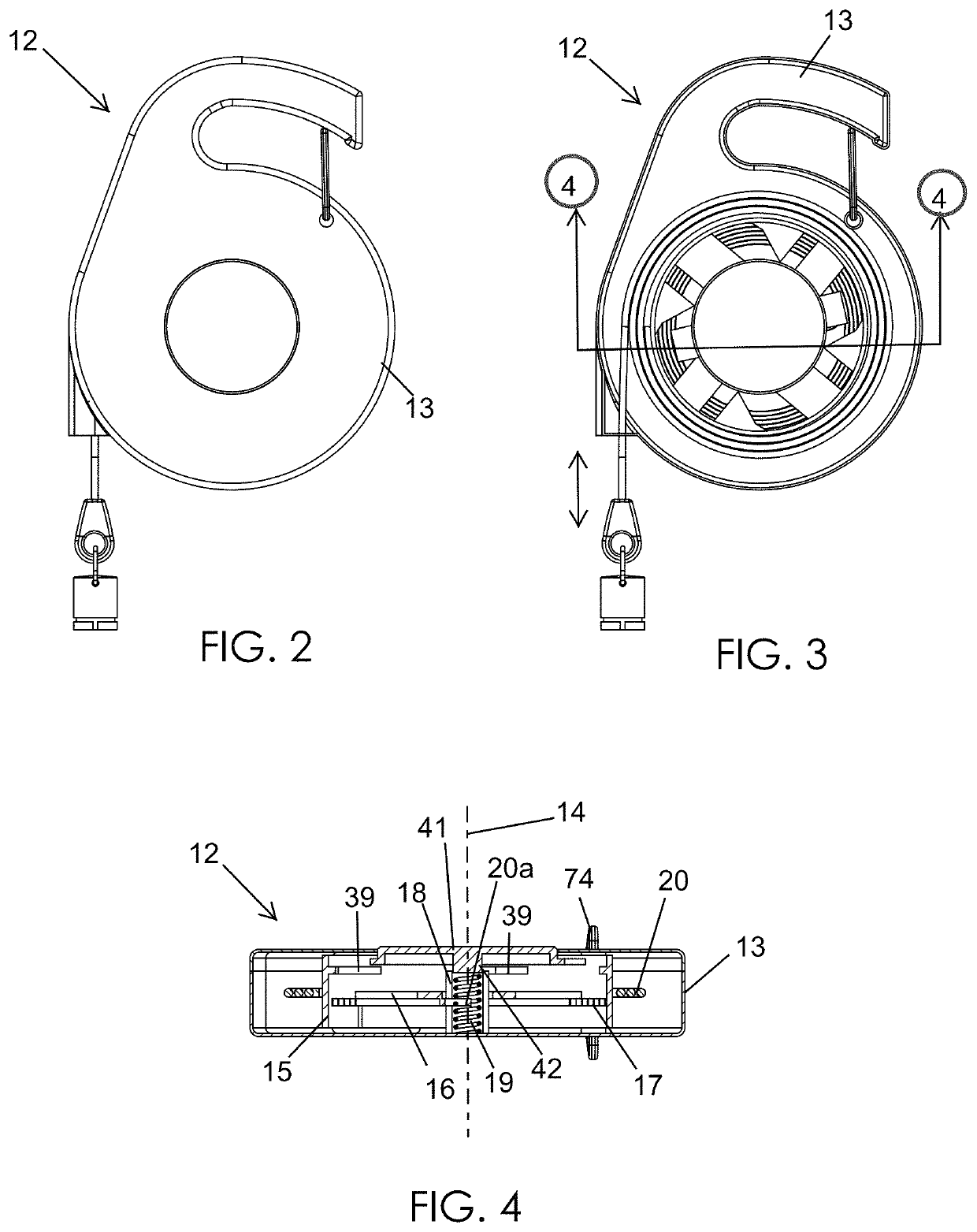

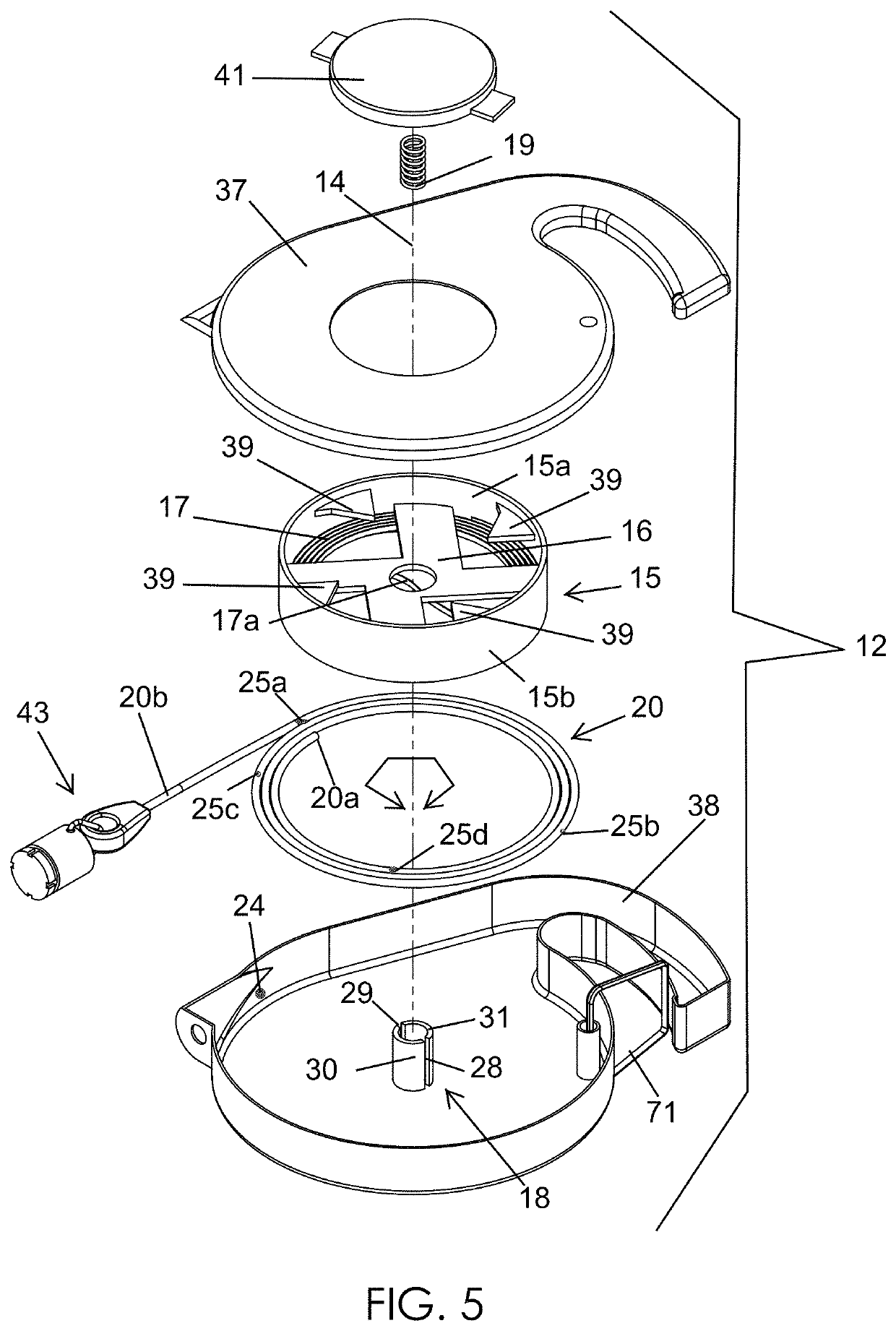

ActiveUS11026502B1Efficiently securing and operatingAvoid damageTravelling carriersHoldersRotational axisElectronic leash

A combined portable electronic leash and mobile phone case includes a mobile phone case, and a portable leash. The leash includes a housing including a centrally registered rotational axis, a spool having a plurality of stationary spokes fixedly attached thereto, a primary spring member anchored to the spokes and wound along a circumferential inner surface of the spool, a central bracket and a secondary spring located therein, a flexible cable having a proximal end anchored to the bracket and wrapped about a circumferential outer surface of the spool, a fastener attached to a distal end of the flexible cable and detachably connected to the mobile phone case, and a mechanism for transmitting an alert signal when the flexible cable is extracted beyond a maximum threshold distance outwardly away from the housing. The alert signal transmitting mechanism is coupled to the housing and the flexible cable.

Owner:EROLD FRANCISCO

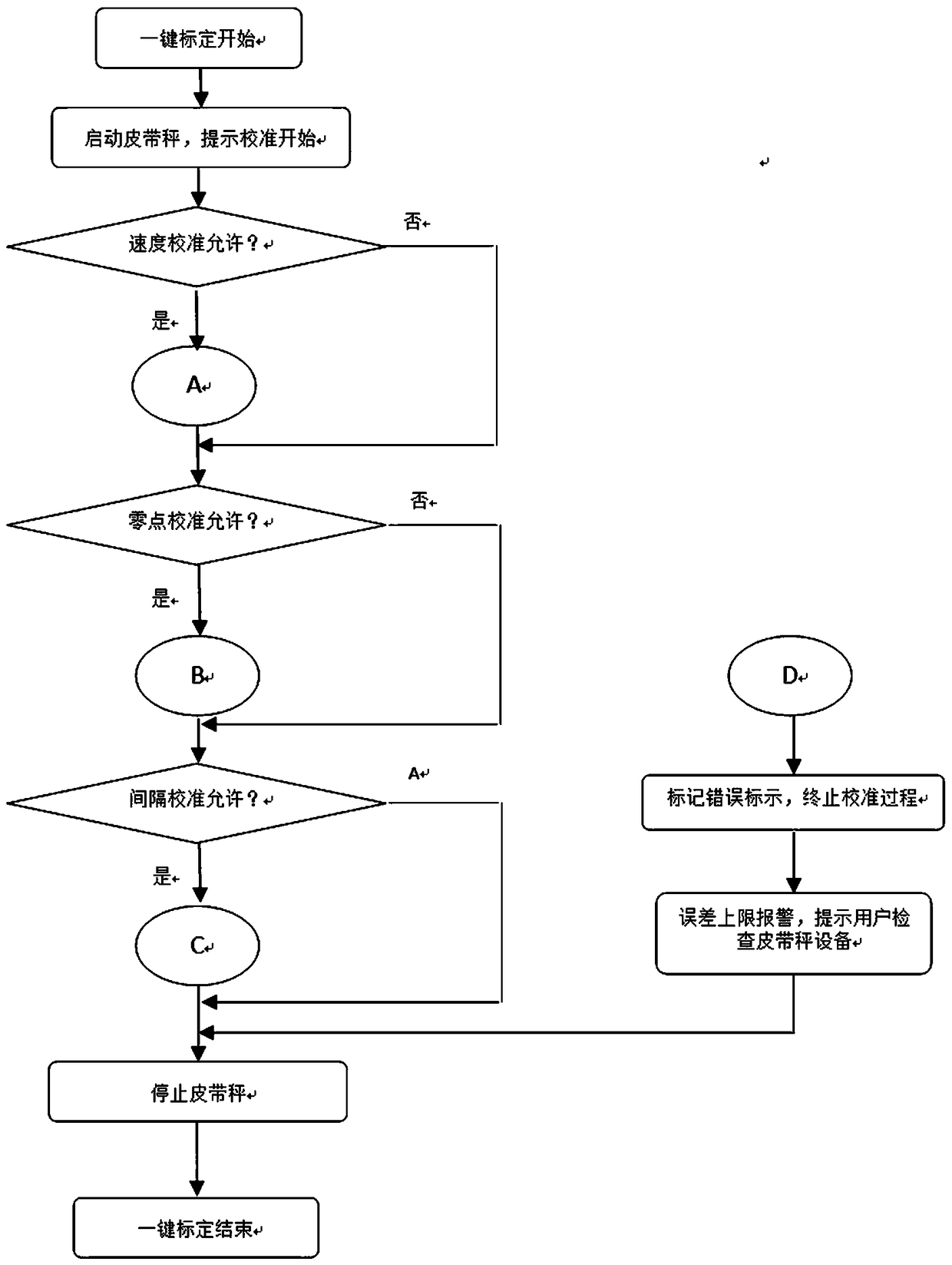

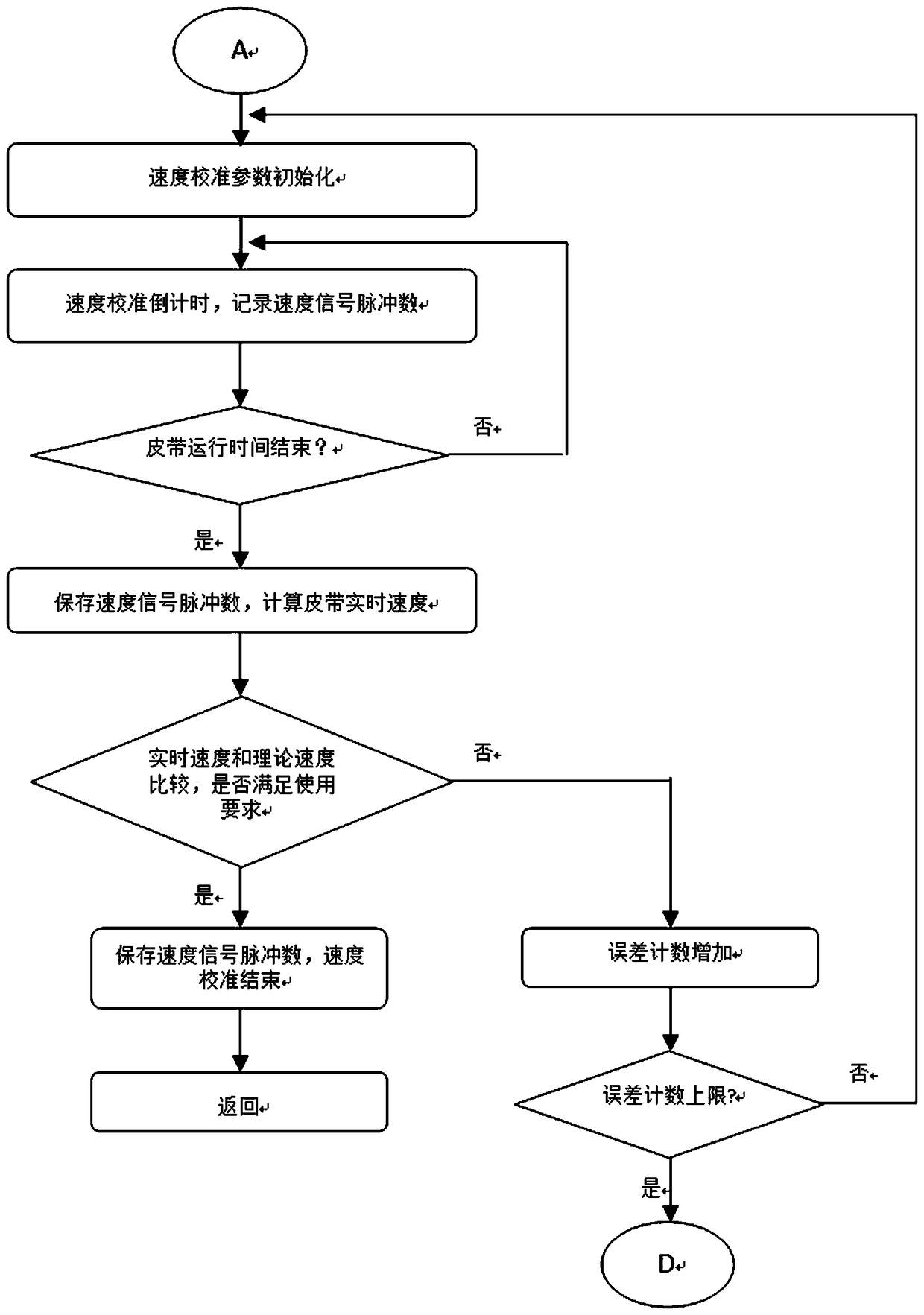

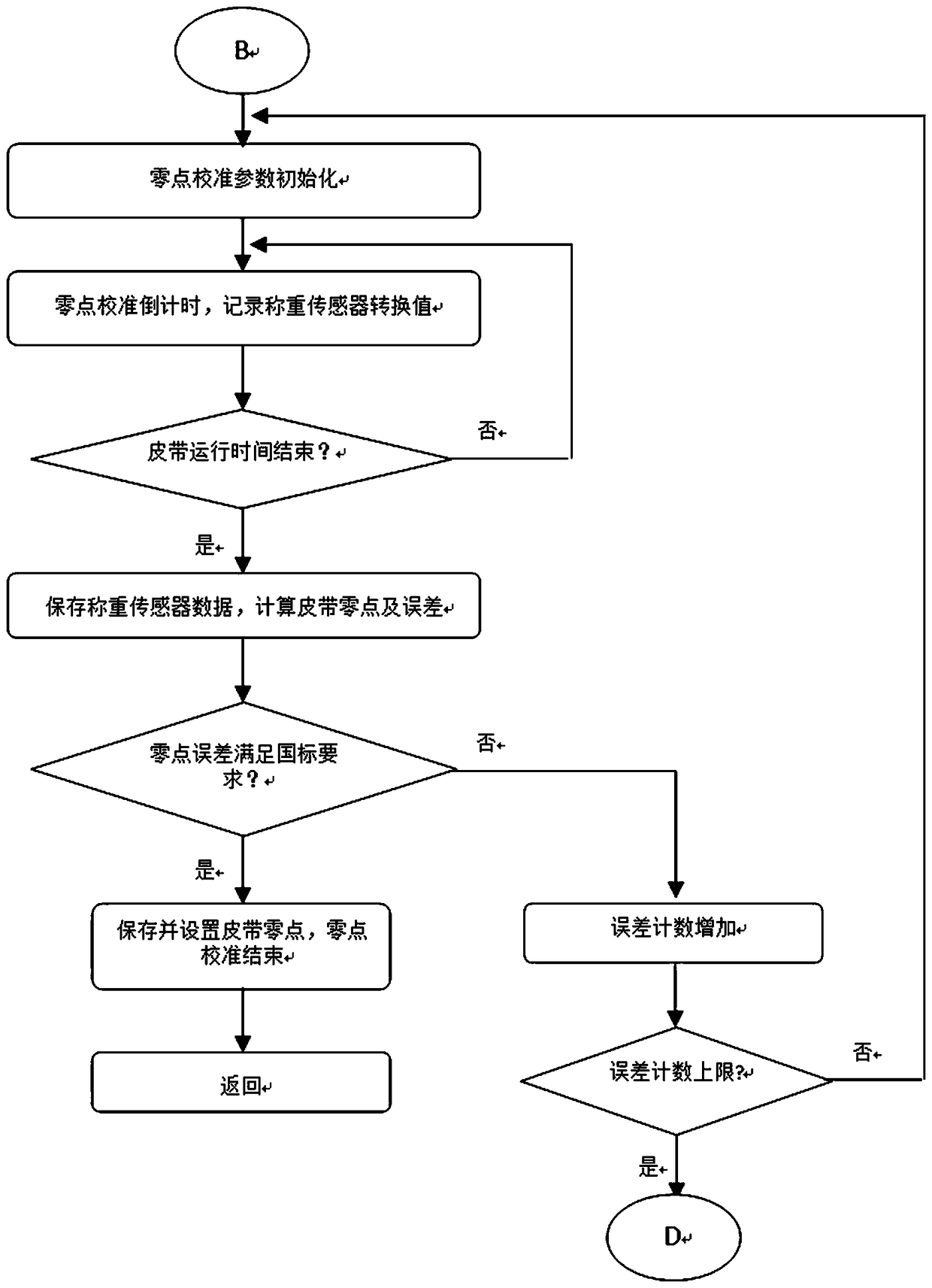

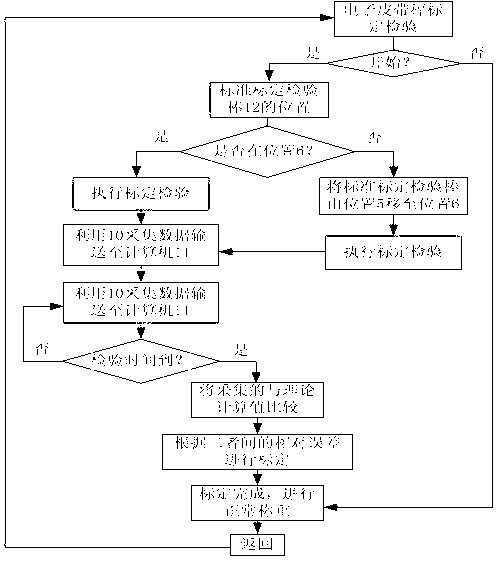

Method for one-key calibration of electronic belt scale and belt scale applying method

The invention belongs to the electronic weighing field and relates to a new calibration method of an electronic belt scale and supporting devices for implementing the method. According to the new calibration method of the invention, an electronic belt scale calibration algorithm is simplified, so that the electronic belt scale calibration method can be simplified, and therefore, the long-term stable and precise operation of the electronic belt scale can be realized, and the overall level of the electronic belt scale can be improved. According to the electronic belt scale, an electronic belt weighing controller with a one-key calibration function is adopted; and the weighing controller includes a main controller for ensuring high speed and high accuracy of data calculation, a weighing sensor for acquiring output signals, an instrumentation amplifier for amplifying acquired signals, a display screen which queries and modifies the internal parameters of instruments to complete calibrationcontrol, a digital quantity input and output port which can realize the programmability of different kinds of field control logic, an analog quantity input and output port which sets other analog variables, an extended installation slot for installing more functional modules, and one-key calibration system for embedded multitasking real-time operation.

Owner:威斯顿智能科技徐州有限公司

Electronic belt scale with multiple accumulative quantities

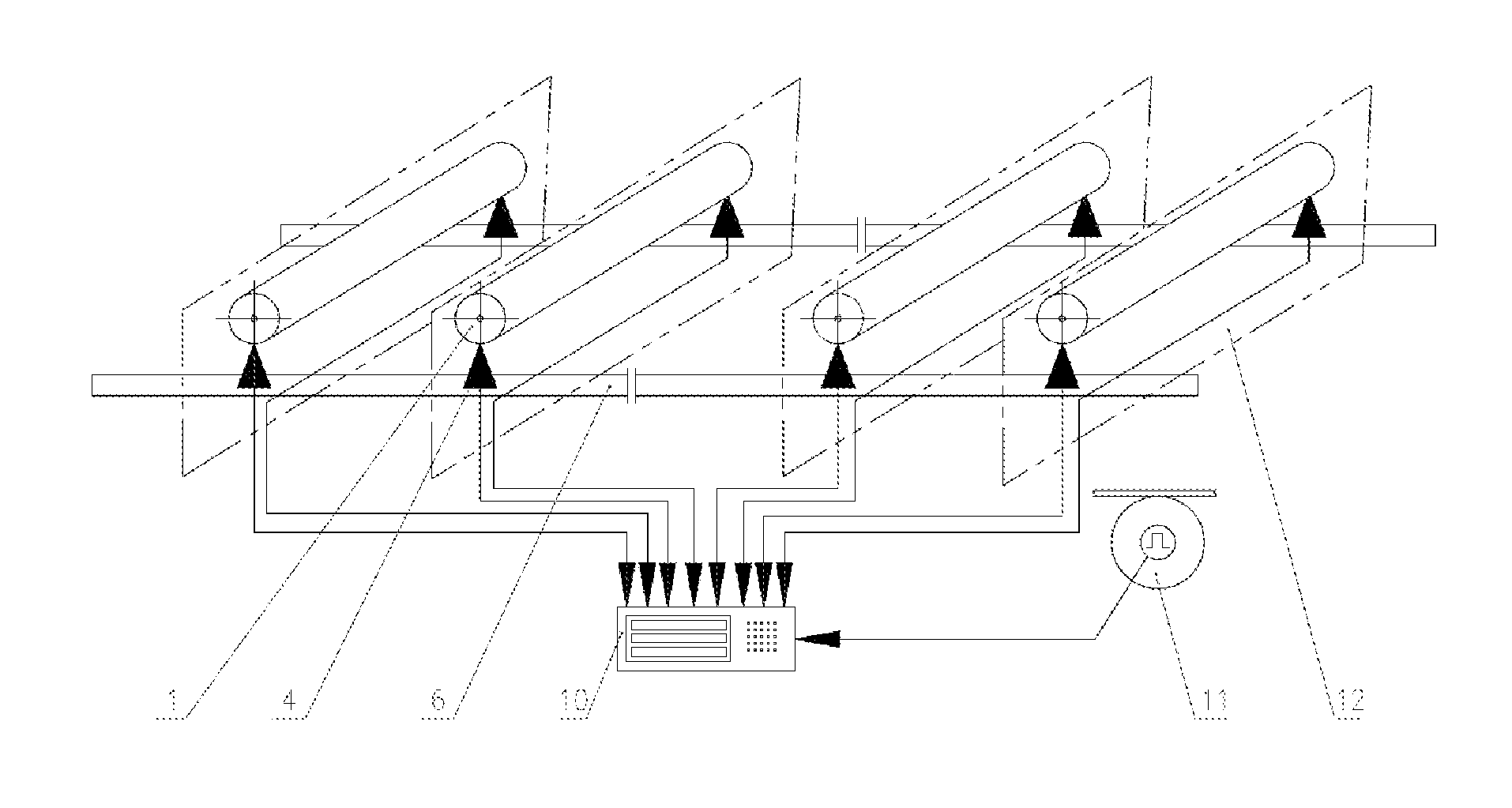

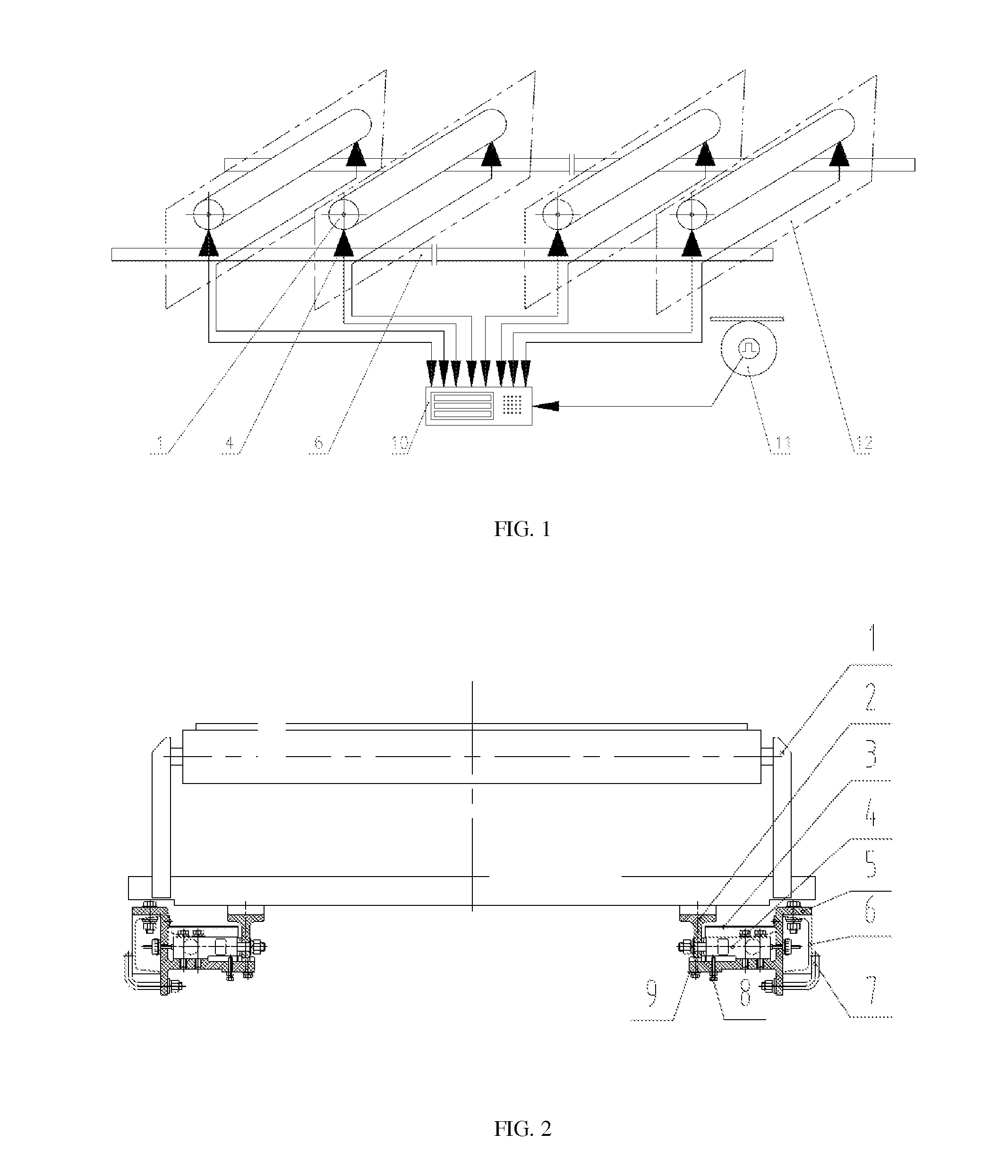

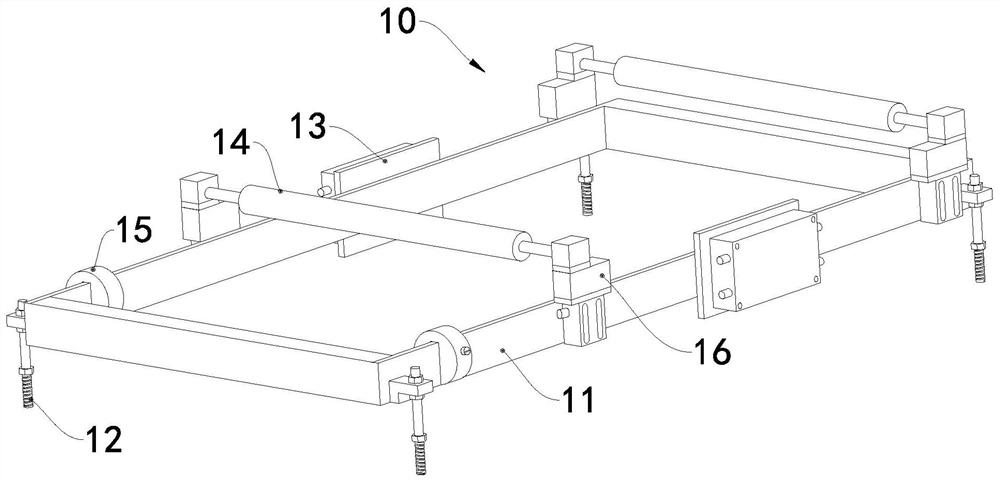

InactiveUS20120111644A1Easy to installConvenient debuggingWeighing apparatus for continuous material flowWeighing apparatus with automatic feed/dischargeElectronic leashControl theory

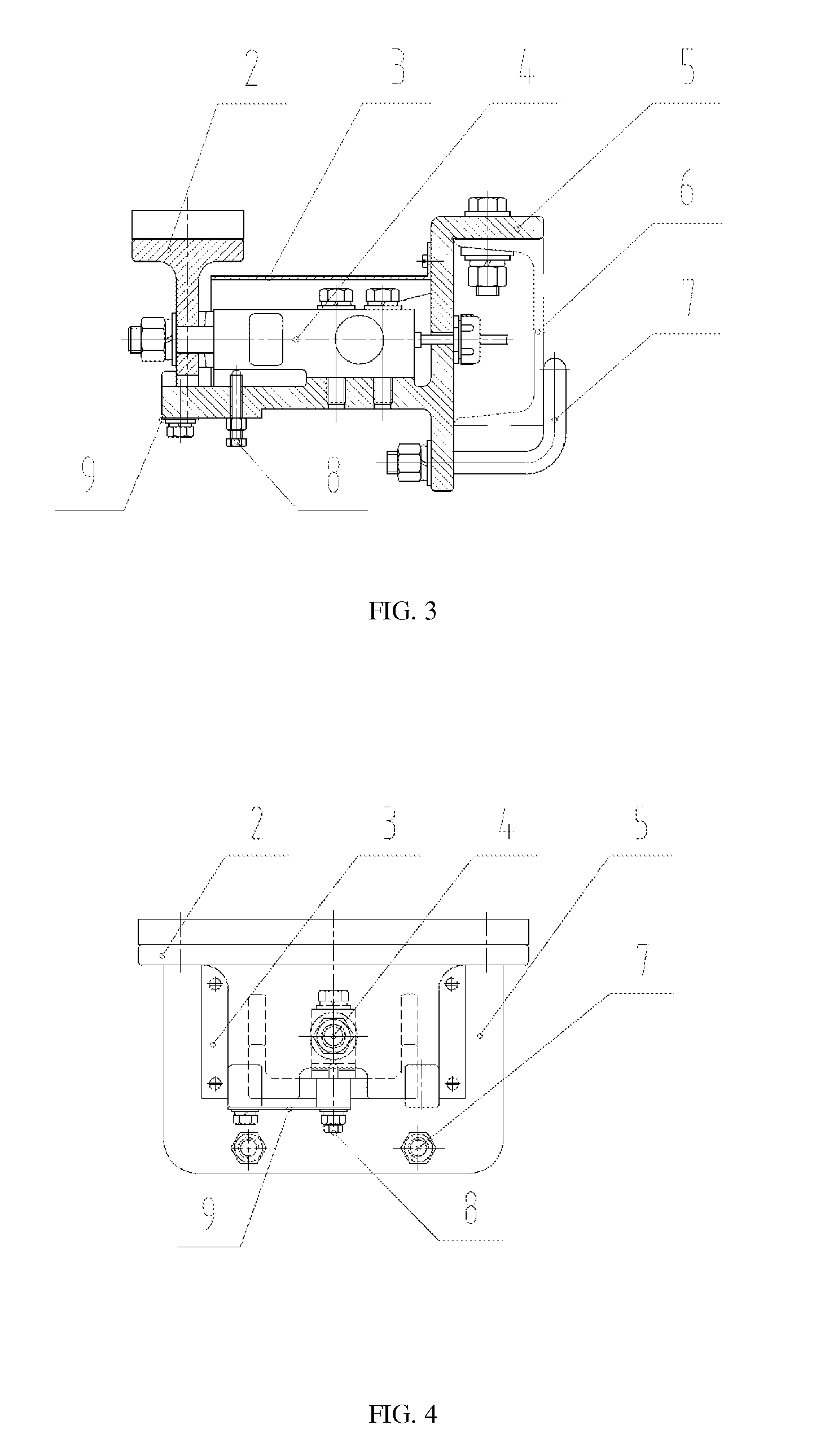

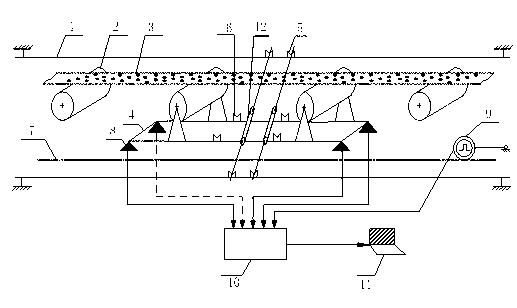

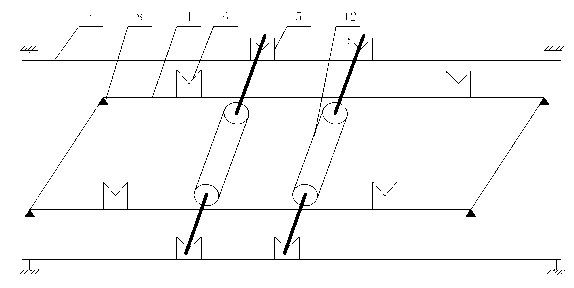

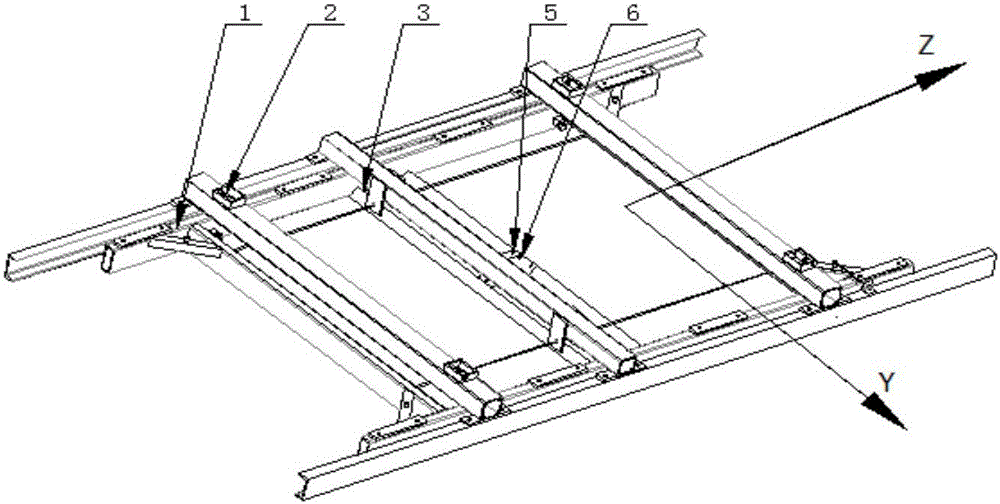

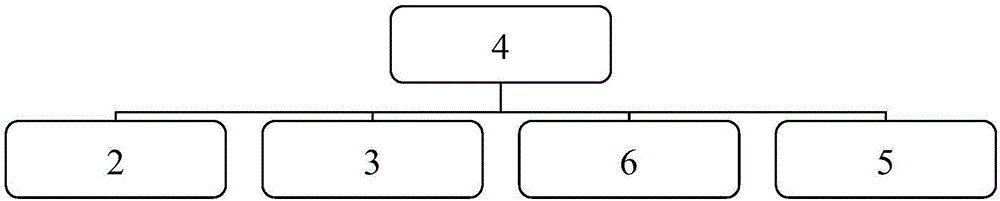

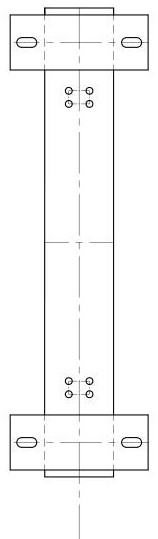

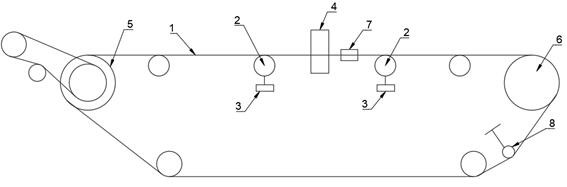

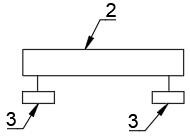

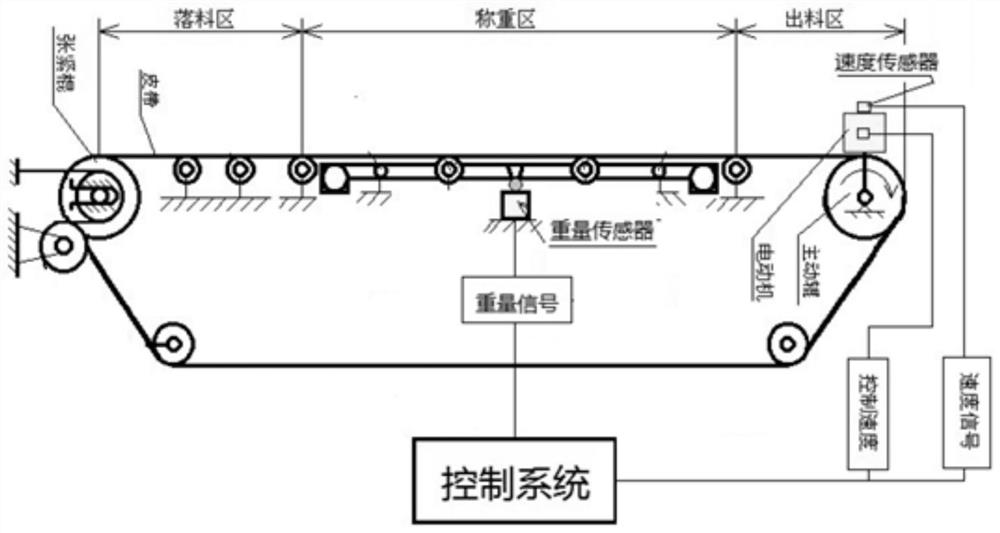

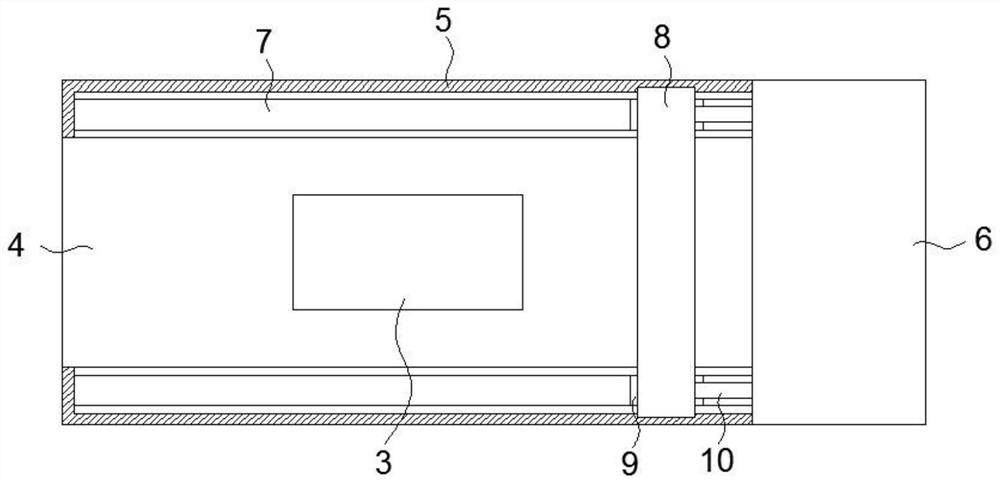

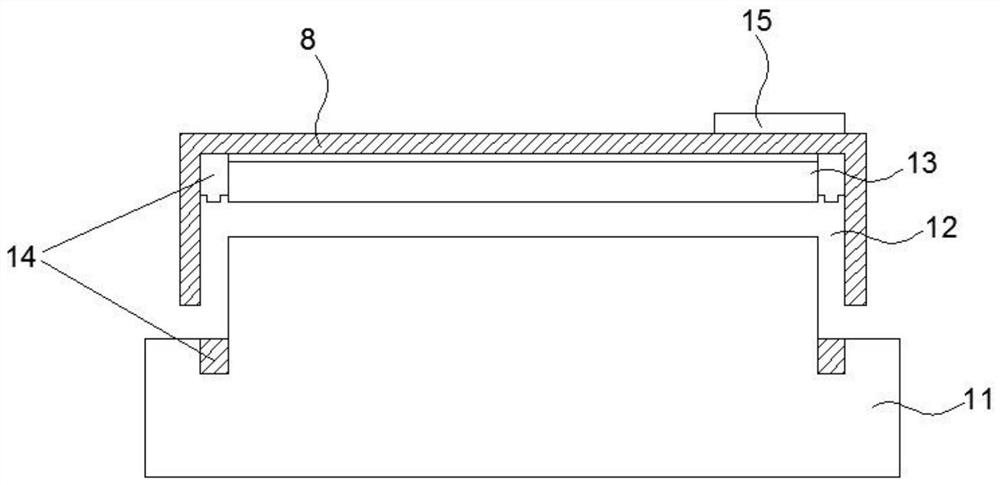

An electronic belt scale with multiple accumulative quantities comprises: multiple groups of weighing units (12), an accumulator (10) and a speed measuring sensor (11). The weighing unit (12) includes a weighing sensor bracket (5), a cantilever type weighing sensor (4) provided on the weighing sensor bracket (5), a support (2) hinged at the suspending arm side of the weighing sensor (4), and a limiting body (9) connected with the weighing sensor bracket (5) under the weighing sensor (4). A weighing signal wire of the weighing sensor (4) and a speed measuring signal wire of the speed measuring sensor (11) are connected with the accumulator (10). Weighing signals and speed signals are accumulated and combined to one group of main accumulative quantities and at least two groups of auxiliary accumulative quantities by the accumulator (10) so as to display and control the main and the auxiliary accumulative quantities of weight.

Owner:SAIMO ELECTRIC

Calibration device of electronic belt scale

InactiveCN102980645AImprove versatilityEasy to operateWeighing apparatus testing/calibrationElectronic leashEngineering

The invention relates to calibration device of an electronic belt scale. The calibration device comprises a belt periphery fixed steel frame, a carrier roller, a belt, a weigh scale frame, a standard calibration check rod support I, a calibration check rod support II, a return belt, a weighing sensor, a speed sensor, a signal processing and measuring meter, a computer and standard calibration check rods. An electronic belt scale weighing device is fixed through the belt periphery fixed steel frame, the belt is loaded on the carrier roller, the weighing sensor is fixed below the weigh scale frame, and the speed sensor is arranged on the return belt. A signal output end of the speed sensor is connected with the signal processing and measuring meter, and the signal processing and measuring meter is connected with the computer. The standard calibration check rod supports are arranged on the periphery fixed steel frame and the weigh scale frame, the standard calibration check rods can be arranged on the standard calibration check rod supports, and therefore the calibration device is convenient and capable of saving a great deal of manpower and enlarging generality of a check device. In addition, the calibration device can be used for calibration in multiple points, and is simple in structure and convenient to use.

Owner:KUNMING UNIV OF SCI & TECH

Device suitable for data collection of electronic belt conveyor scale of ore dressing plant

InactiveCN106932061AEnsure consistencyAchieve sharingWeighing apparatus for continuous material flowModbusElectronic leash

A device suitable for data collection of an electronic belt conveyor scale of an ore dressing plant relates to the field of mining in the open air, especially to data collection of the electronic belt conveyor scale of the ore dressing plant. The device comprises a Modbus master station and a Modbus slave station, and the electronic belt conveyor scale serves as the Modbus slave station. Thus, the problem that data of the electronic belt conveyor scale of the ore dressing plant is inconsistent with remote data can be solved.

Owner:YUNNAN HUALIAN ZINC & INDIUM

Online real-time calculation and evaluation method for electronic belt scale

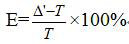

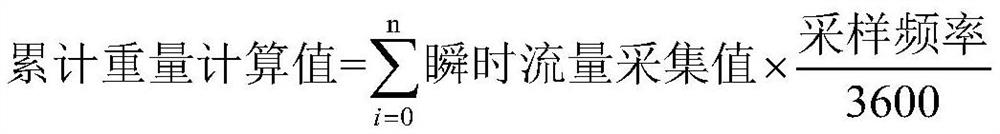

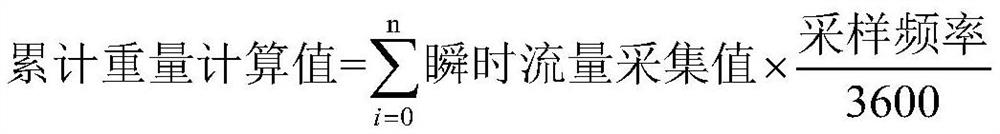

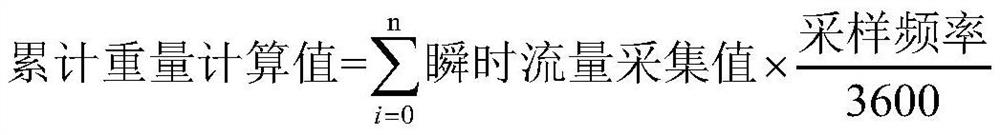

ActiveCN110806256AReal-time monitoring of weighing accuracyEstimated Risk of Weighing ErrorsWeighing apparatus testing/calibrationElectronic leashSimulation

The invention discloses an online real-time calculation and evaluation method for an electronic belt scale. With a material signal of an electronic belt scale as a triggering condition, a weight collection value, a speed collection value, an instantaneous flow collection value and an accumulated weight collection value that are outputted by the electronic belt scale are collected and an instantaneous flow calculation value and an accumulated weight calculation value are calculated; and a ratio of a collection point to total collection points of the instantaneous flow collection value within upper and lower limits of the instantaneous flow calculation value and a ratio of a collection point to total collection points of the accumulated weight collection value within upper and lower limits of the accumulated weight collection value are calculated to obtain qualification rates of the instantaneous flow collection value and the accumulated weight collection value. According to the method disclosed by the invention, the real-time monitoring of the weighing accuracy of the electronic belt scale is realized and the weighing error risk is estimated; alarm shutdown can be conducted in timethrough real-time judgment; the damage of the production material quality is reduced; and the process monitoring strength of the electronic belt scale is greatly enhanced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

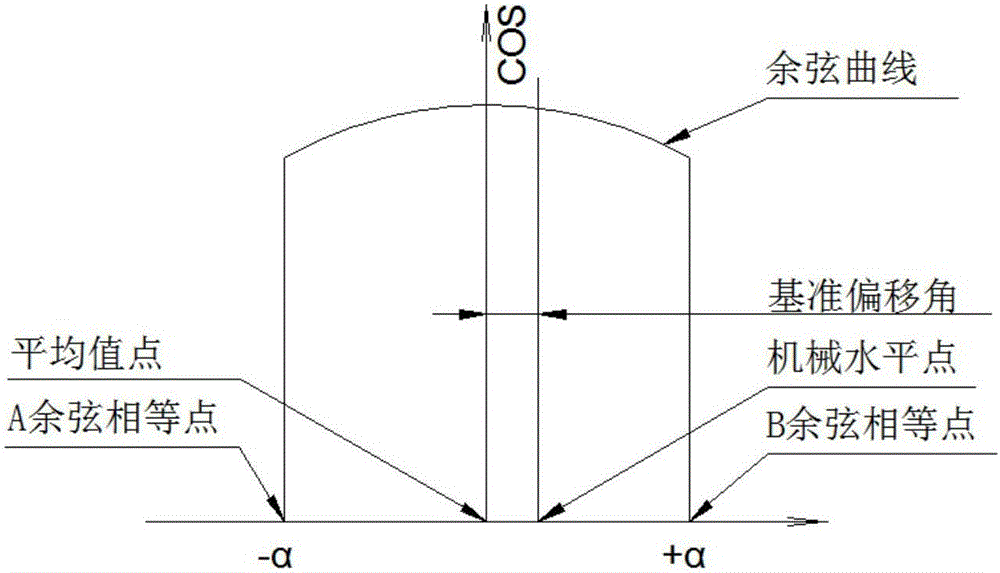

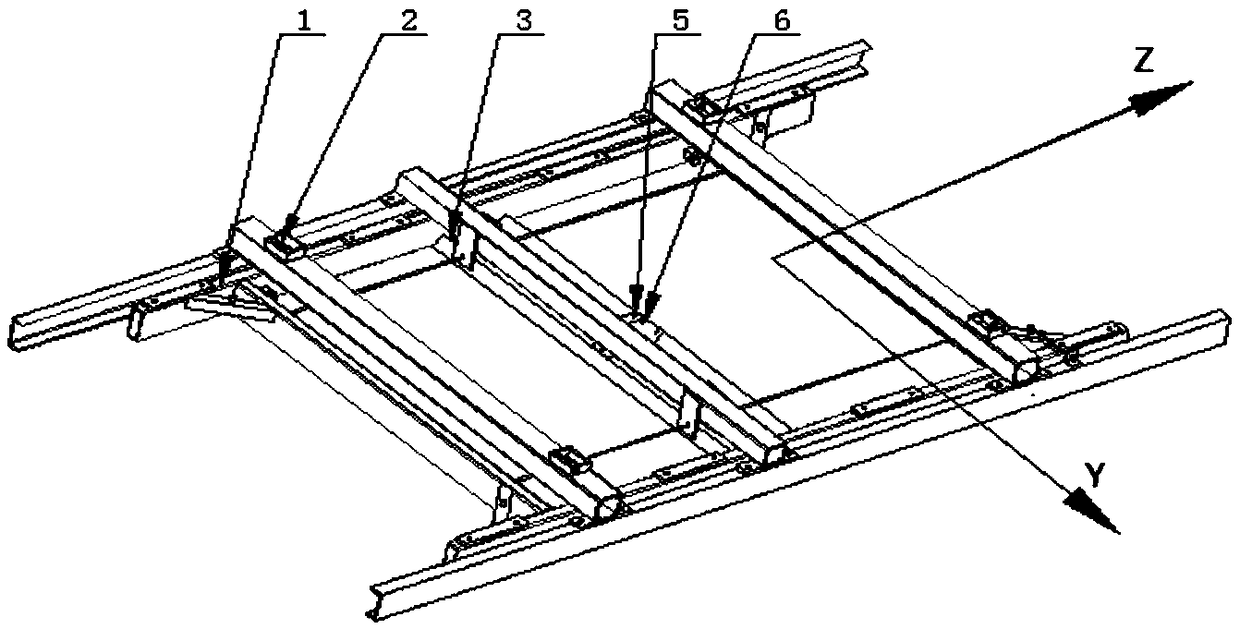

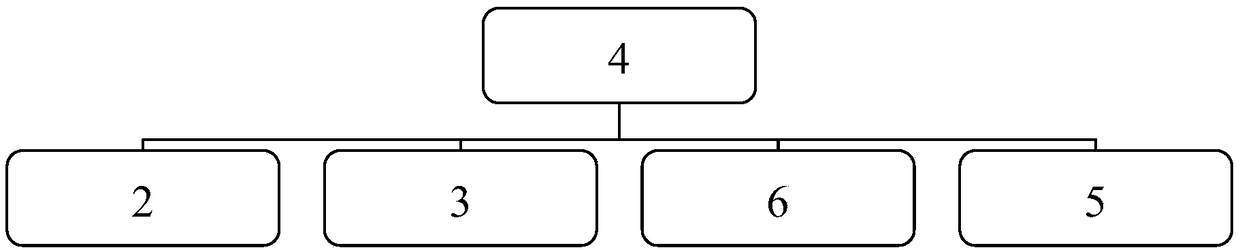

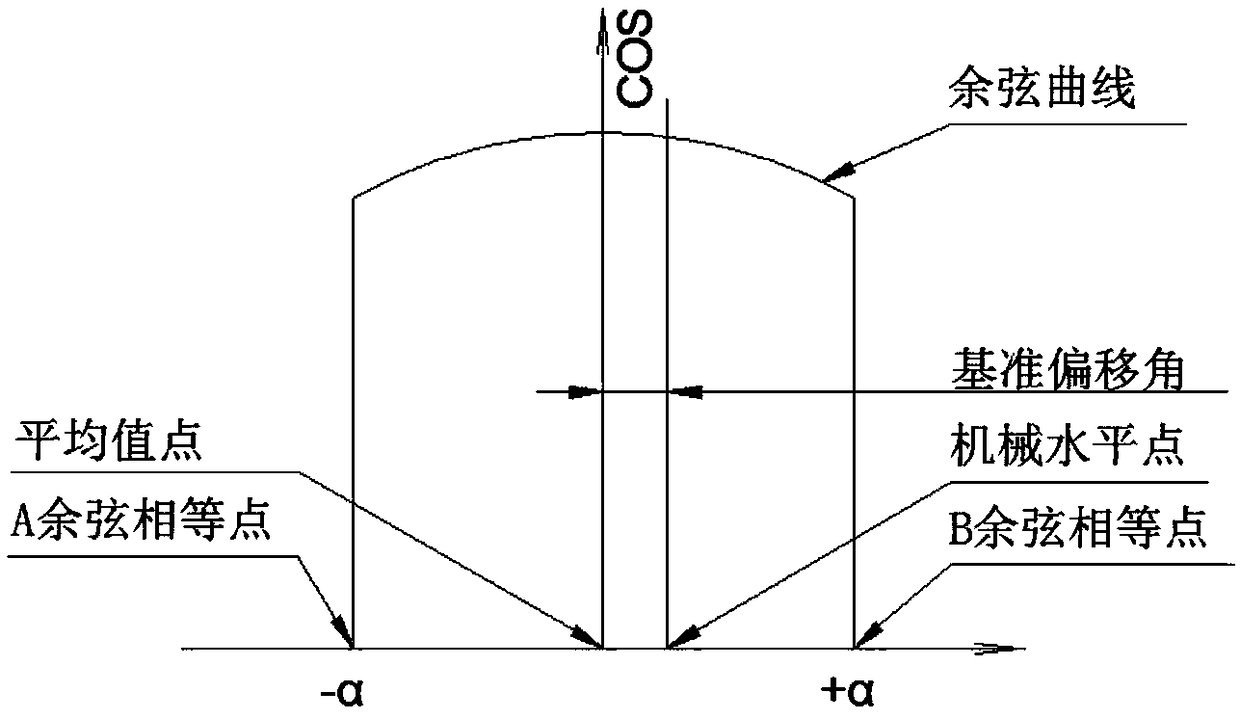

Two-dimension angle-variable electronic belt scale weighing compensation method and system

ActiveCN106289494AImprove compensation accuracyAvoid measurement errorsWeighing apparatus testing/calibrationAngular degreesEngineering

The invention discloses a two-dimension angle-variable electronic belt scale weighing compensation method and system. The method includes: utilizing a method that cosine values of positive and negative angles are equal to acquire a datum offset angle; calculating compensation accumulation quantity Q according to the datum offset angle and angles between Y and Z directions and a horizontal straight line to correct compensation angle offset caused by actual stressed structure state of a scale frame for compensation. By the method, compensation accuracy is improved greatly. The system is characterized in that a load sensor, a speed sensor, a Z-direction angle sensor and a Y-direction angle sensor are all fixedly mounted on the electronic belt scale frame and all connected with a two-dimension angle-variable belt scale instrument. The problem of metering errors caused by changing of two-dimension inclination angle of an angle-variable electronic belt scale in the process of metering is solved effectively, and application range is wide.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

A Condition Monitoring System of Electronic Belt Scale

ActiveCN104019881BGuaranteed smoothnessWeighing apparatus testing/calibrationAgricultural scienceElectronic leash

The invention discloses a condition monitoring system for an electronic belt scale. The condition monitoring system comprises the electronic belt scale, a monitoring device and a processing device. When tobacco leaves pass through the electronic belt scale, the monitoring device monitors the instantaneous flow P of the tobacco leaves; when P is larger than or equal to 2000 kg / h and less than or equal to 2300 kg / h, the processing device sends out a fault signal; when the P is larger than or equal to 2300 kg / h, the processing device sends out a major fault signal. The instantaneous flow of the tobacco leaves when the tobacco leaves pass through the electronic belt scale is effectively guaranteed, and the situation that the tobacco leaves are incompletely processed due to excessive quantity is avoided.

Owner:CHINA TOBACCO GUANGDONG IND

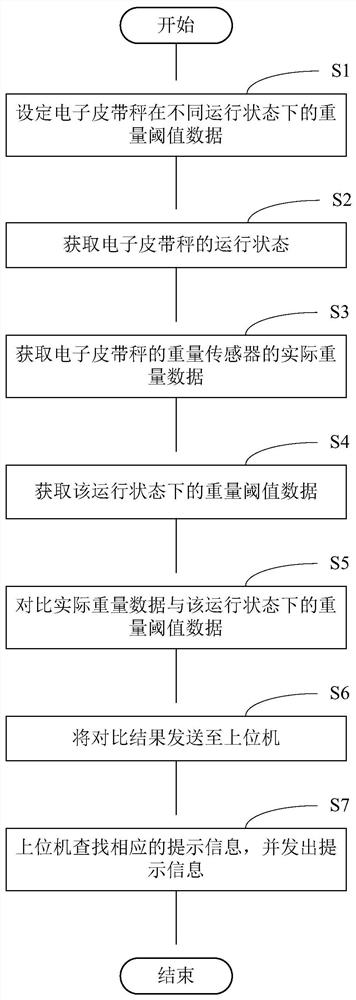

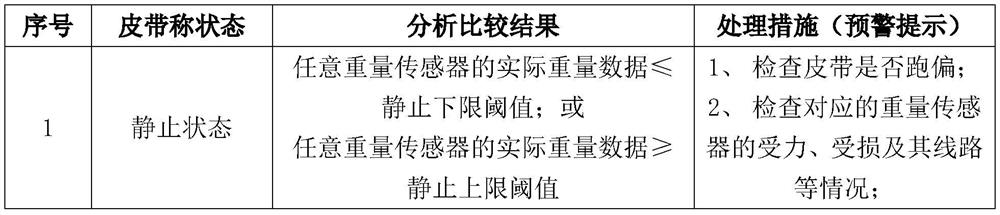

State monitoring and fault judging method of electronic belt scale

InactiveCN112082635AImprove accuracyReduce manufacturing costWeighing apparatus testing/calibrationElectronic leashHigh electron

The invention provides a state monitoring and fault judging method of an electronic belt scale. The method comprises the steps of presetting weight threshold data of the electronic belt scale in various operating states; obtaining the operating state of the electronic belt scale; acquiring actual weight data of a weight sensor of the electronic belt scale, acquiring the weight threshold data in the operating state according to the operating state of the electronic belt scale, comparing the actual weight data with the corresponding weight threshold data, judging whether the electronic belt scale has a fault or not according to a comparison result, if a fault occurs, sending prompt information according to the comparison result. The method provided by the invention can reduce the workload ofcalibration of the electronic belt scale, reduces the manpower investment, avoids the analysis of faults of the electronic belt scale by human factors, and improves the accuracy of calibration of theelectronic belt scale.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

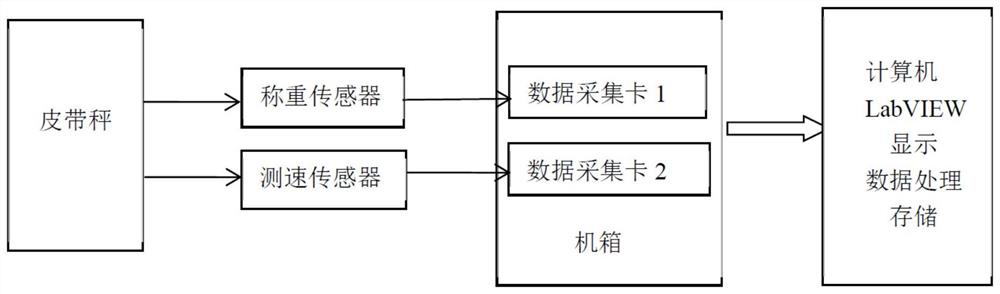

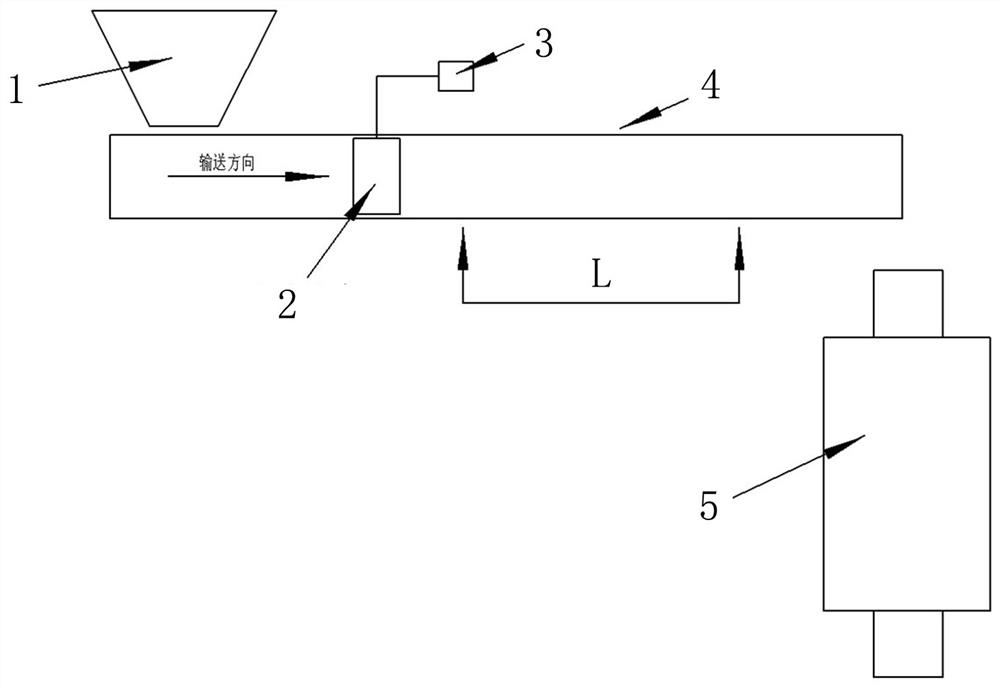

Electronic belt scale electrical parameter testing method based on virtual instrument

InactiveCN112985551AEasy maintenanceGood man-machine interfaceWeighing apparatus for continuous material flowWeighing auxillary devicesHuman–machine interfaceElectronic leash

The invention provides an electronic belt scale electrical parameter testing method based on a virtual instrument, and the method comprises the following steps: S1, connecting a system, installing a speed measurement sensor and a gravity sensor on rotating shafts of a plurality of carrier rollers for rotation of a belt, respectively connecting two data collection cards with the gravity sensor and the speed measurement sensor, merging the data collection cards into a case and connecting the data collection cards into a PC (Personal Computer) through a USB (Universal Serial Bus) interface, and using LabVIEW software installed in the PC; S2, deducting the dead weights of the belt and a scale frame, and measuring the weight by adopting a weighing bridge frame and a resistance strain type sensor; and S3, accumulating the flow M of the materials within the time interval t. According to the invention, a virtual instrument graphical software programming technology and a powerful mathematical function library of the LabVIEW are adopted to display and integrate the acquired data, so that the instrument not only has the basic functions of a traditional instrument, but also fully utilizes the advantages of graphical language programming of the LabVIEW to develop a good human-computer interface.

Owner:ANHUI XINHUA UNIV

Method for accurately checking electronic belt scale

InactiveCN111854912AAccurate CalibrationDoes not affect continuous operationWeighing apparatus testing/calibrationSocial benefitsElectronic leash

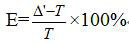

The invention discloses a method for accurately checking an electronic belt scale. The invention relates to an electronic belt scale physical verification technology. According to the method, six steps of calibration section length determination, data recording, sampling, electronic belt scale weighing data calculation, precision calculation and basis judgment are carried out, the problem that theconventional calibration time is long is solved, the equipment operation rate is greatly improved, the equipment production efficiency is well exerted, and considerable economic benefits and social benefits are brought to enterprises.

Owner:YUNNAN HUALIAN ZINC & INDIUM

A weighing compensation method and system for a two-dimensional variable-angle electronic belt scale

ActiveCN106289494BImprove compensation accuracyAvoid measurement errorsWeighing apparatus testing/calibrationElectronic leashControl theory

The invention discloses a two-dimension angle-variable electronic belt scale weighing compensation method and system. The method includes: utilizing a method that cosine values of positive and negative angles are equal to acquire a datum offset angle; calculating compensation accumulation quantity Q according to the datum offset angle and angles between Y and Z directions and a horizontal straight line to correct compensation angle offset caused by actual stressed structure state of a scale frame for compensation. By the method, compensation accuracy is improved greatly. The system is characterized in that a load sensor, a speed sensor, a Z-direction angle sensor and a Y-direction angle sensor are all fixedly mounted on the electronic belt scale frame and all connected with a two-dimension angle-variable belt scale instrument. The problem of metering errors caused by changing of two-dimension inclination angle of an angle-variable electronic belt scale in the process of metering is solved effectively, and application range is wide.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

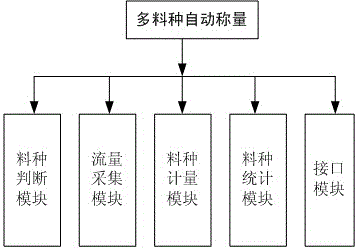

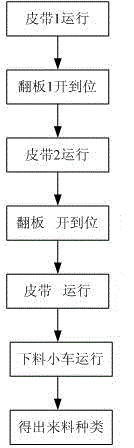

Automatic weighing method and device for various materials

ActiveCN102213610BAvoid landingReduce manual operationsWeighing apparatus for continuous material flowInformatizationMaterial classification

Multi-material automatic weighing device is an automatic weighing detection technology, which includes an electronic belt scale, a programmable controller, a computer, the output of the electronic belt scale is connected to the input of the programmable controller, and the output of the programmable controller Connect to the input of the computer, connect the output of the computer to the input of the server, connect the output of the server to the input of the display, the electronic belt scale collects the flow signal of the material transported by the belt; the programmable controller collects the running signal of the belt, and collects the instantaneous Quantity, material identification is carried out through the material type judgment module, and classification measurement is performed through the material type measurement module; the computer runs the material type statistics module, and the material measurement data is classified and queried according to the number of shifts and days; the material measurement data is calculated through the interface module. The data is automatically uploaded to the information system. The invention realizes automatic classification and measurement according to materials, and provides automatic statistics and query functions and automatic data uploading at the same time.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

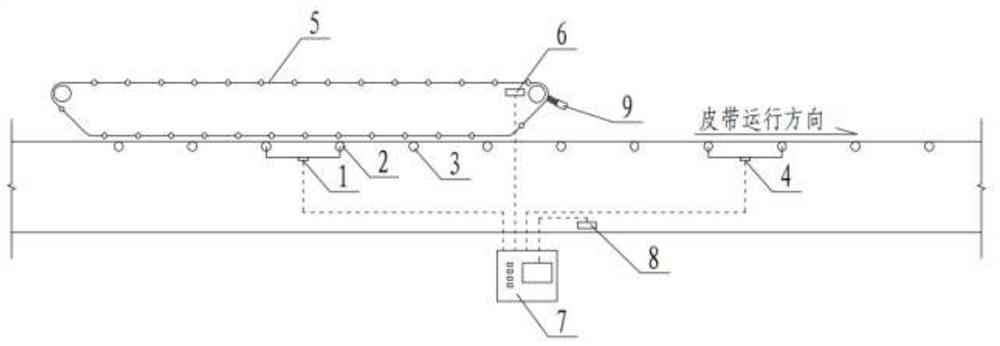

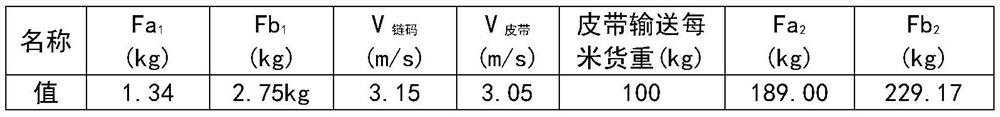

Assembly for real-time dynamic verification of electronic belt scale and verification method of assembly

PendingCN112146742AConfidenceFull calibrationWeighing apparatus testing/calibrationElectronic leashEngineering

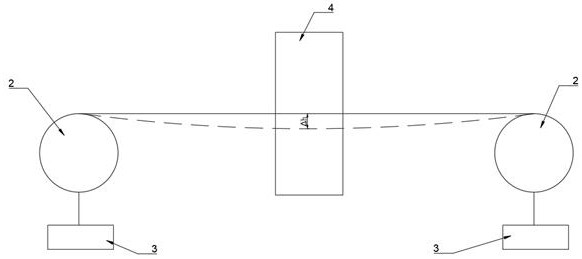

The invention relates to an assembly for real-time dynamic verification of an electronic belt scale and a verification method of the assembly. The assembly for real-time dynamic verification of the electronic belt scale comprises a belt arranged on the electronic belt scale and a cycling chain code device arranged above the electronic belt scale, wherein the cycling chain code device comprises a chain code arranged above the belt, and conveying carrier rollers and weighing carrier rollers are arranged below the belt; weighing scale frames are arranged below the weighing carrier rollers, the cycling chain code device is arranged above the weighing scale frames, and the plurality of weighing carrier rollers are arranged in the running direction of the belt; and a chain code speed measuring device is arranged on the inner side of the cycling chain code device, a belt speed measuring device is arranged on the inner side of the electronic belt scale, and the plurality of weighing scale frames, the chain code speed measuring device and the belt speed measuring device are connected with a weighing instrument through communication cables.

Owner:安徽省交通勘察设计院有限公司

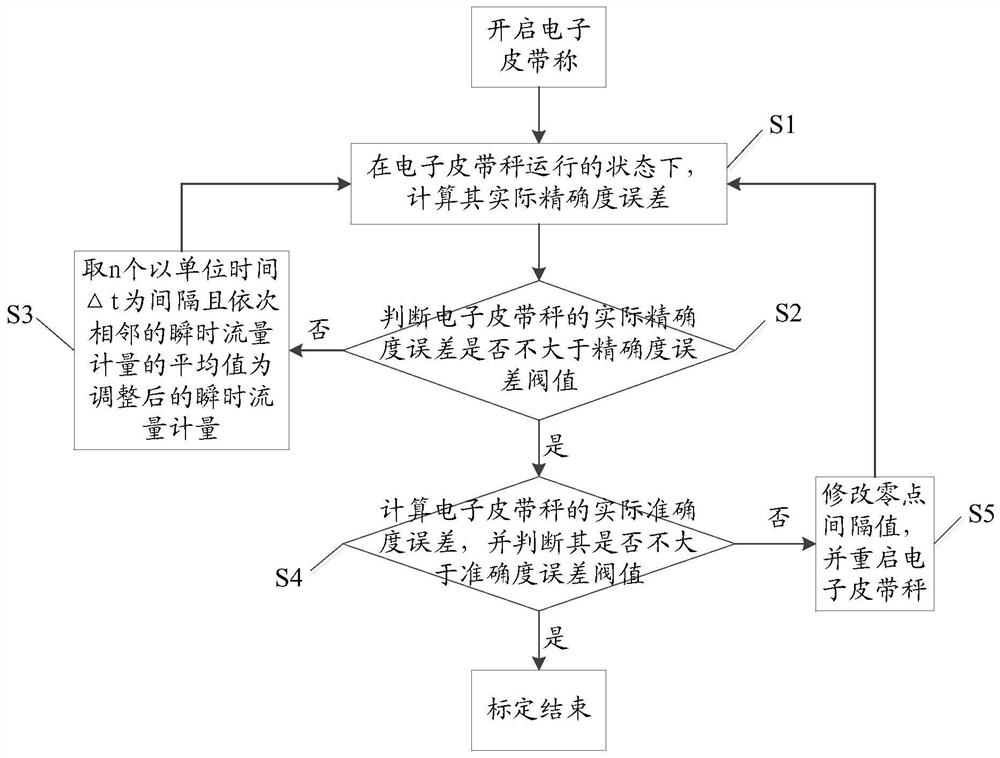

An online calibration method for an electronic belt scale

ActiveCN110031079BIncrease credibilityImprove stabilityWeighing apparatus testing/calibrationProduction lineAutomatic control

The invention discloses an online calibration method for an electronic belt scale provided by the invention, which includes performing an accuracy calibration on the electronic belt scale, and if the actual accuracy error value is greater than the accuracy error threshold value, then by "selecting n instantaneous flow rate measurement The average value is the adjusted instantaneous flow measurement, and the number and time of calibration detection are extended to reduce the calibration accuracy error of the electronic belt scale and improve the calibration stability of the electronic belt scale. In addition, it also includes the accuracy calibration of the electronic belt scale; The stability composite index fills the gap in the stability calibration and adjustment of the electronic belt scale. Through the composite calibration and adjustment, the stability and accuracy of the electronic belt scale can be accurately distinguished and improved, and then the material fluctuation and measurement error of the batching production line can be correctly distinguished. , to achieve the goal of precise batching, and the operation steps during online calibration are relatively simple. It can be combined with the current general electronic belt scale automatic control facilities for automatic control settings, simplifying front-line operations and facilitating promotion.

Owner:SHANDONG IRON & STEEL CO LTD

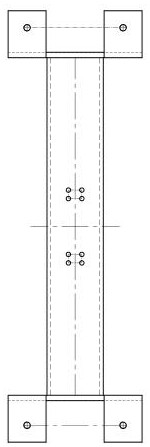

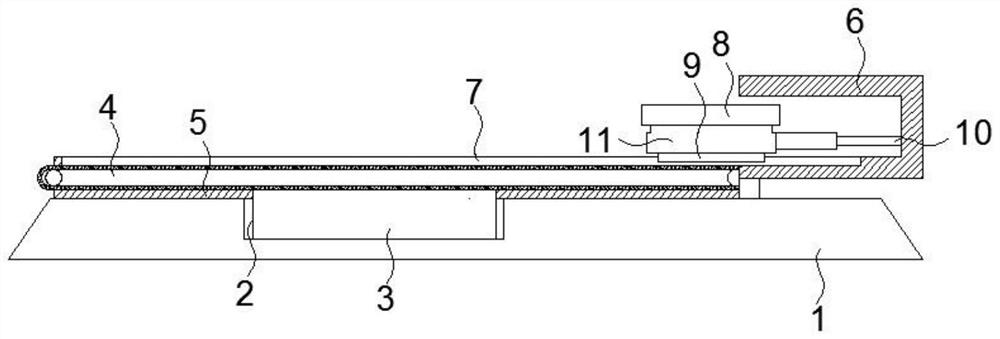

Novel electronic belt scale

PendingCN114838792AEasy to replaceSimple structureWeighing apparatus detailsWeighing apparatus for continuous material flowElectronic leashEngineering

The invention belongs to the technical field of electronic belt scales, and particularly relates to an electronic belt scale which is installed on a belt conveyor, used for metering materials passing through the belt conveyor, easy and convenient to install, high in precision, stable to use and easy to maintain. The existing electronic belt scale in the background technology has the following problems: 1, the overall structure is complex; 2, the size is large, and the installation difficulty is high; therefore, in order to solve the problem, the invention provides a novel electronic belt scale which is simple in structure, simple to install and simple to maintain. The invention aims to solve the problems in the background technology. The novel electronic belt scale provided by the invention is simple in structure and easy to install. The novel electronic belt scale is arranged below a group of carrier roller brackets of the belt conveyor and is in bolted connection with a frame of the belt conveyor on two sides. According to the novel electronic belt scale, the base, the weighing sensor, the supporting plate and the V-shaped pressing device form a weighing structure main body of the novel electronic belt scale, and the novel electronic belt scale is simple and convenient to install and maintain. In order to achieve the purpose, the invention provides the following technical scheme that the novel electronic belt scale comprises four parts: a base of the novel electronic belt scale, a weighing sensor, a supporting plate and a V-shaped pressing device.

Owner:承德市威盛科技有限公司

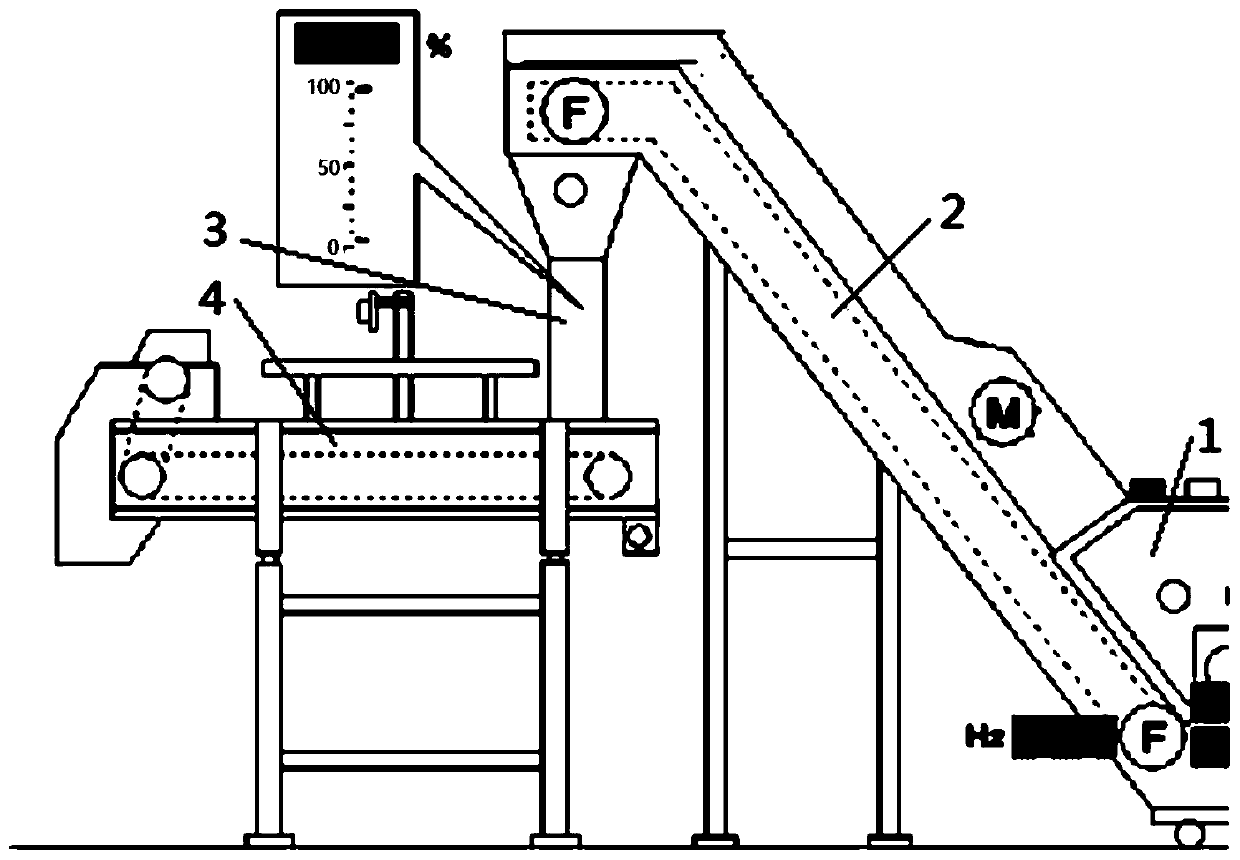

Electronic belt scale with pre-filling function

InactiveCN111678574ALower head volumeStable moisture contentWeighing apparatus for continuous material flowElectronic leashStructural engineering

The invention provides an electronic belt scale with a pre-filling function. The electronic belt scale comprises a metering tube and an electronic belt scale body, the metering pipe is arranged over the feeding end of the electronic belt scale and used for conveying cut stems in the metering pipe to the electronic belt scale; moreover, the metering pipe is provided with a material level indicatingelement used for detecting the height of the material in the metering pipe, so that the electronic belt scale operates in the feeding direction only when the height of the material in the metering pipe reaches a preset height, and the electronic belt scale is uniformly paved with the material through the program.

Owner:CHINA TOBACCO GUANGXI IND

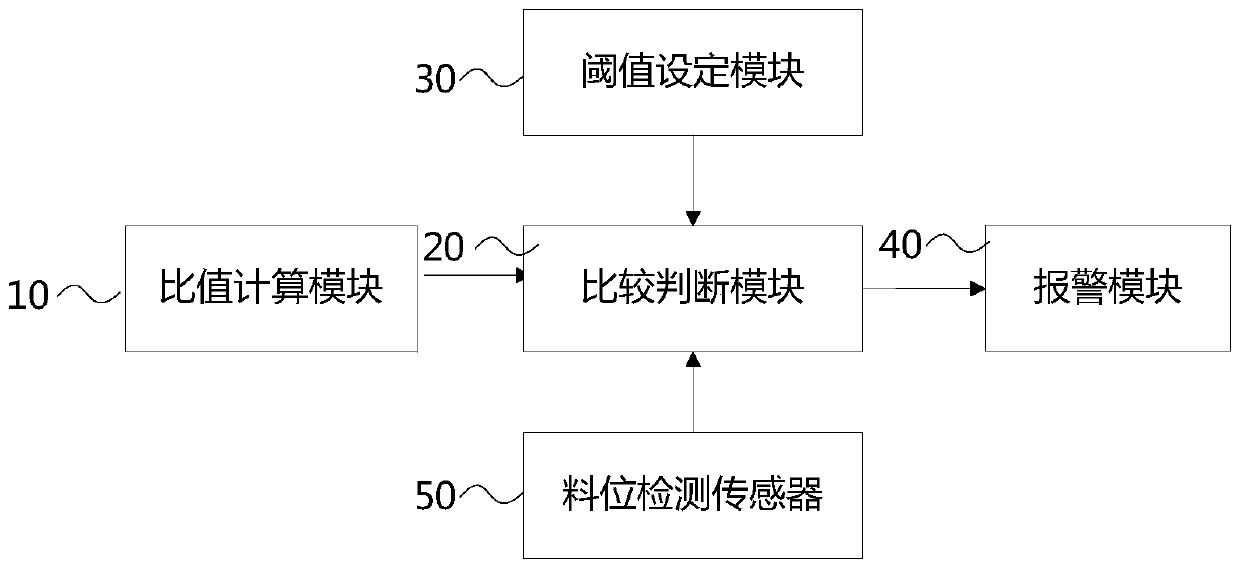

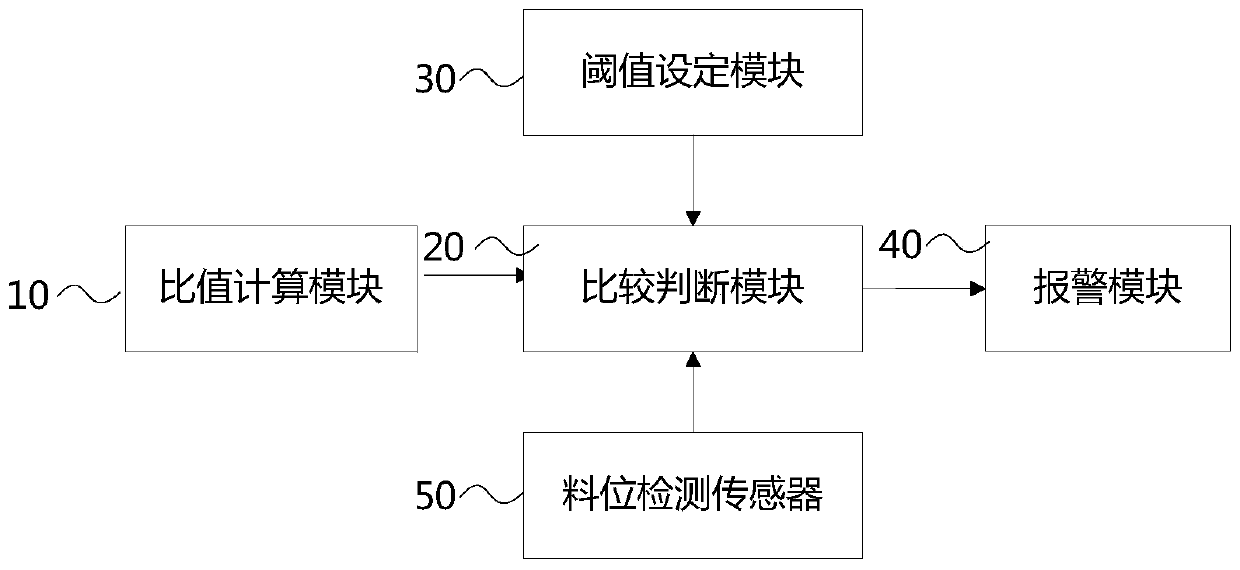

Electronic belt scale operating state monitoring system, method and tobacco processing system

ActiveCN107777292BGuaranteed accuracyImprove product qualityConveyorsControl devices for conveyorsFrequency changerElectronic leash

The invention relates to a monitoring system and method for the operating state of an electronic belt scale, the electronic belt scale and a tobacco processing system. The monitoring system comprisesa ratio calculating module (10) and a comparative judgment module (20), wherein the ratio calculating module (10) is used for calculating a ratio of instantaneous flow rate of material conveying of the electronic belt scale to working frequency of a frequency converter; the comparative judgment module (20) is used for judging whether the ratio of the instantaneous flow rate to the working frequency exceeds a preset range, and if the ratio exceeds the preset range, failure of the electronic belt scale is determined. The monitoring system can judge whether the electronic belt scale fails by monitoring the ratio of the instantaneous flow rate to the working frequency, so that the electronic belt scale can convey and weigh materials normally, weighing accuracy and precision of the electronic belt scale are guaranteed, and the product quality is improved.

Owner:LONGYAN CIGARETTE FACTORY

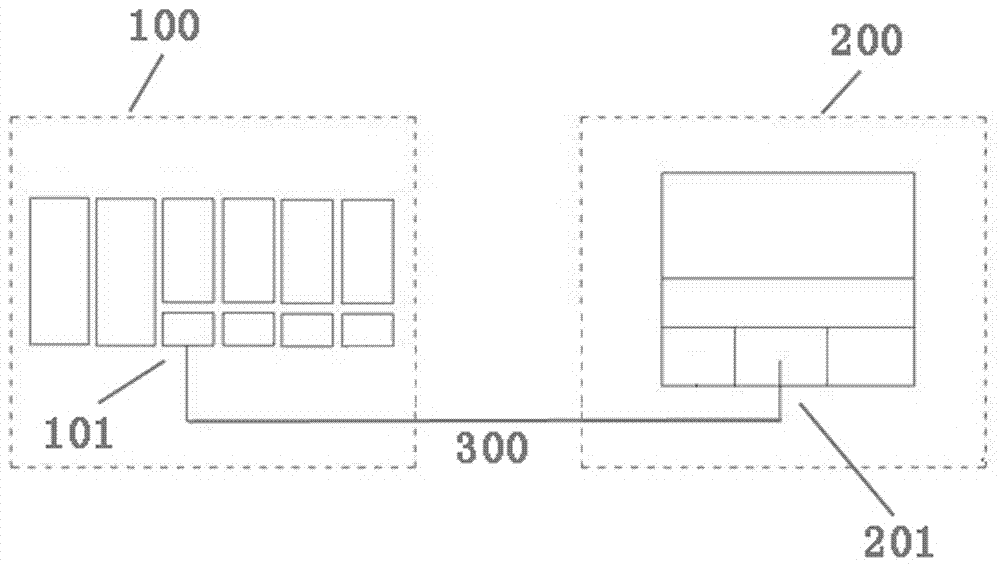

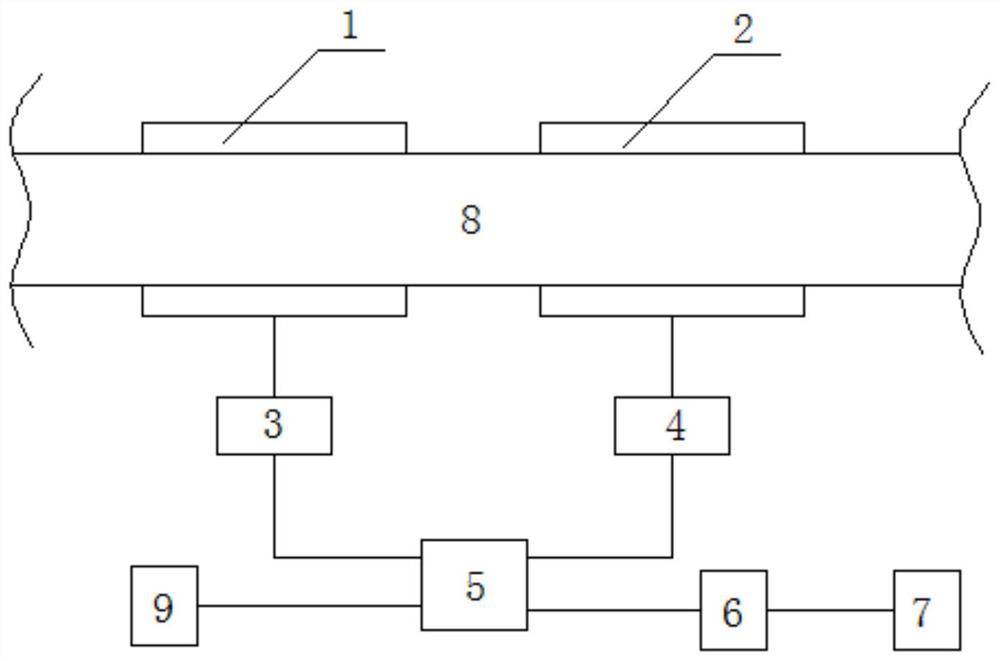

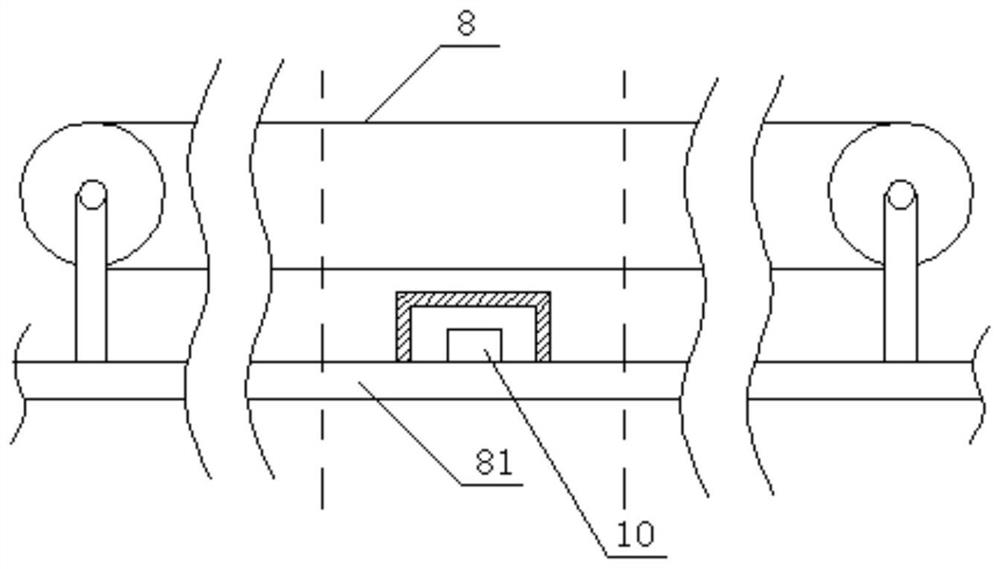

A high-accuracy real-time monitoring method for electronic belt scales

ActiveCN110455393BGuaranteed uptimeEliminate errorsWeighing apparatus testing/calibrationElectronic leashAlarm device

The invention belongs to the technical field of weight measurement of materials in the transmission state, and in particular relates to a high-accuracy real-time monitoring method for electronic belt scales. Two electronic belt scales are installed in series on the same belt conveyor, respectively being the first electronic belt scale. The scale and the second electronic belt scale realize simultaneous measurement. The first electronic belt scale is connected to the first on-site signal acquisition unit, the second electronic belt scale is connected to the second on-site signal acquisition unit, and the first on-site signal acquisition unit is connected to the second on-site signal acquisition unit. The signal acquisition unit is connected to a terminal processor at the same time, and the terminal processor is connected to the alarm device through the controller.

Owner:国家能源集团谏壁发电厂 +1

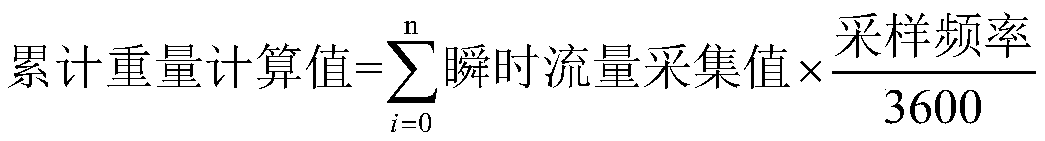

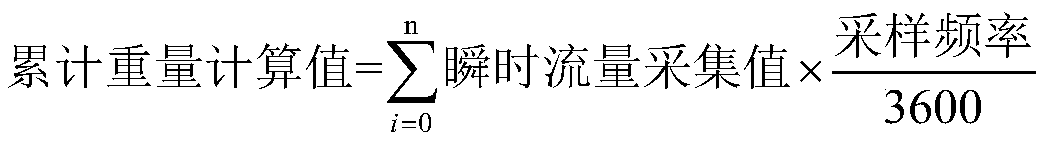

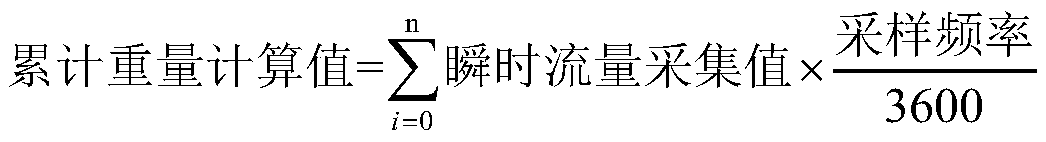

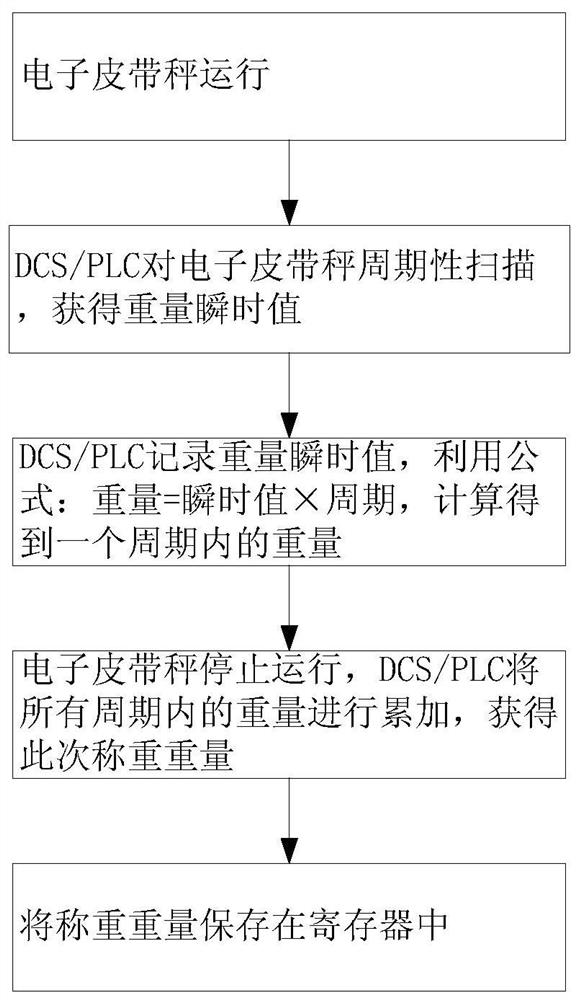

Electronic belt weigher weight accumulation method based on DCS/PLC

InactiveCN112985553ASolve the problem of large calculation errorsThe calculation result is accurateWeighing apparatus for continuous material flowElectronic leashControl engineering

The invention relates to the field of electronic belt weighers, and in particular relates to an electronic belt weigher weight accumulation method based on DCS / PLC. The method comprises the steps of periodically acquiring analog signals of an electronic belt weigher, calculating the weight in the same period, and accumulating to obtain the weight of this time. The problem that the calculation error of the weighing result of the electronic belt weigher is large is solved, furthermore, the set value is corrected by calculating the correction value, the total weight obtained during multiple times of weighing is more accurate, and the method is suitable for the electronic belt weigher based on DCS / PLC.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

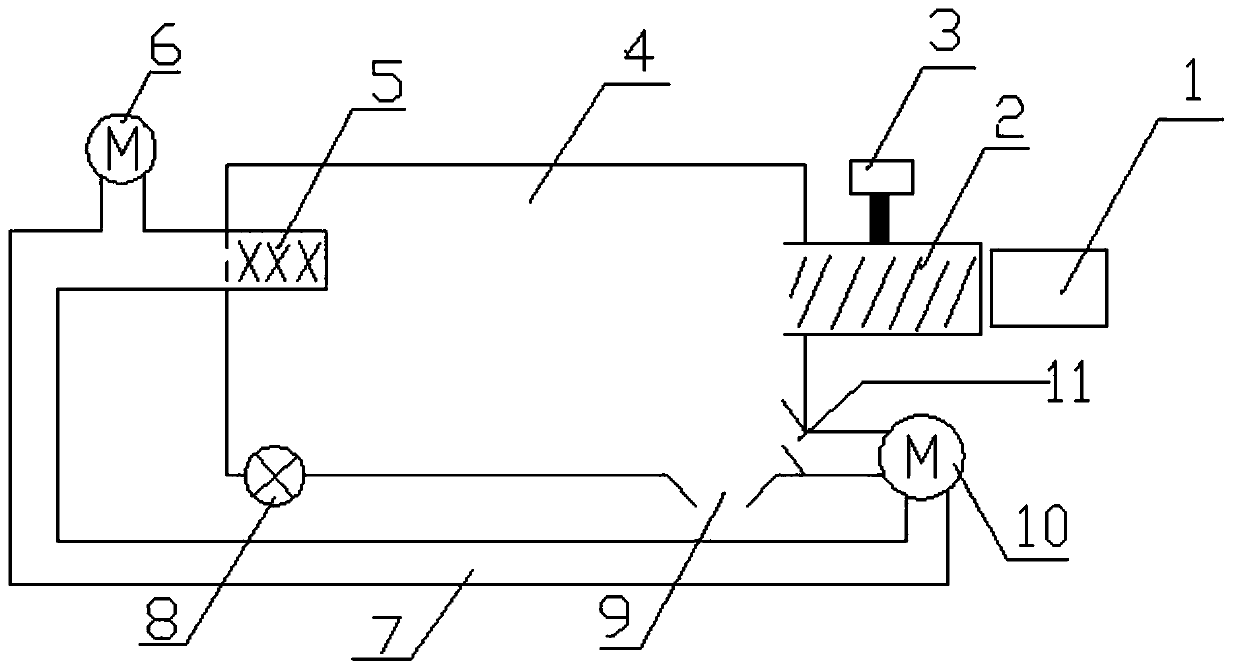

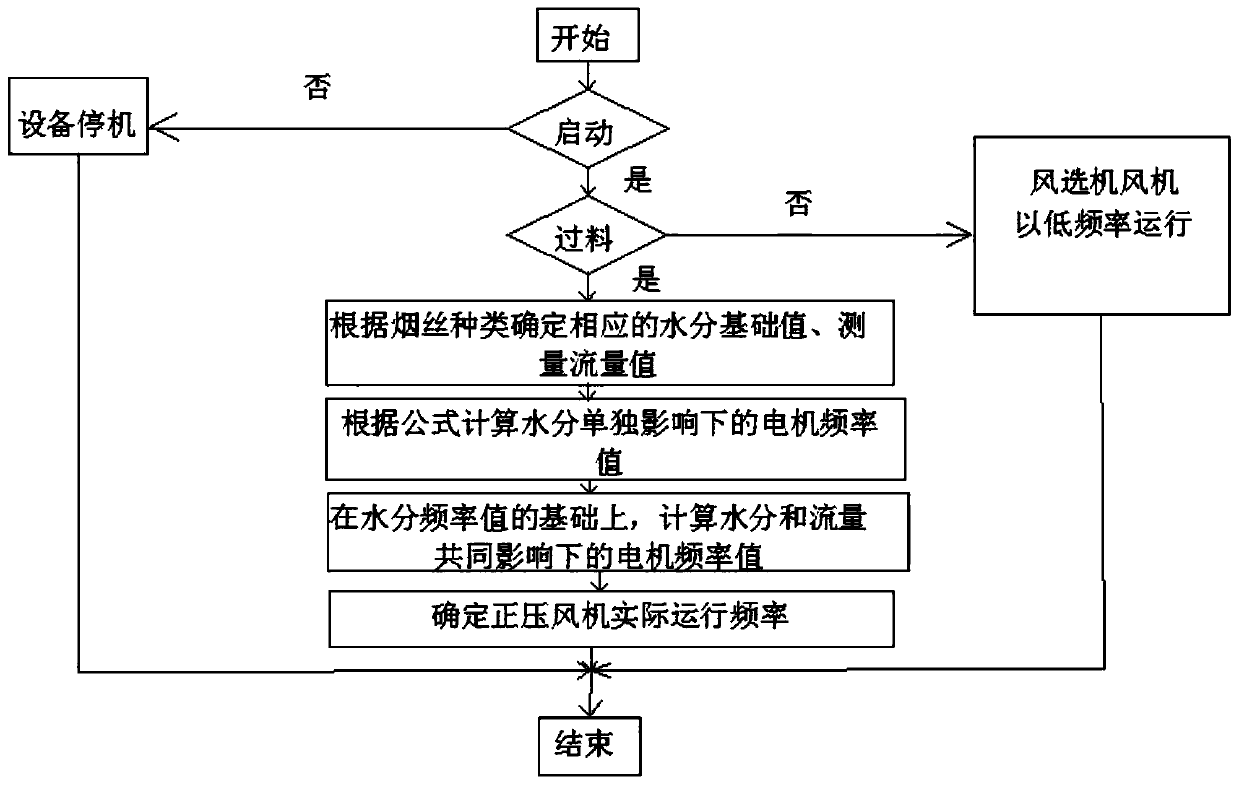

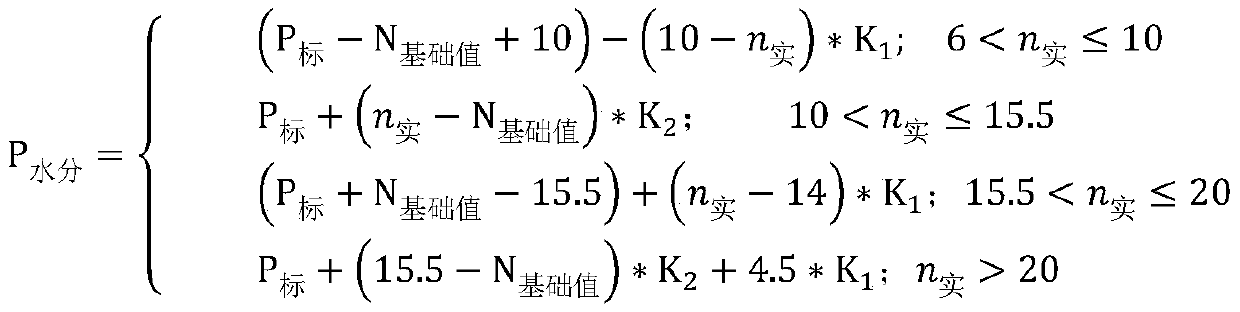

A wind power automatic adjustment device and adjustment method for a winnowing machine

ActiveCN109622383BReduce wasteAchieve precise separationGas current separationReal-time dataElectronic leash

The invention discloses a power automatic adjusting device and method for a winnowing machine. A feeding vibration groove is arranged at the front end of a feed inlet of the winnowing machine, the front end of the feeding vibration groove is connected with an electronic belt scale, an infrared moisture meter is arranged near the feeding vibration groove, a detecting portion of the infrared moisture meter is aligned with the feeding vibration groove, an air inlet is formed below the feed inlet of the winnowing machine, the upstream pipeline, connected with the air inlet, of an air return pipeline is provided with a positive pressure fan, the tail end of the air return pipeline communicates with an air outlet of the winnowing machine, the downstream pipeline close to the air outlet is provided with a negative pressure fan, the position, close to the air inlet, of the bottom of the winnowing machine is provided with an impurity outlet, the position, away from the air inlet, of the bottomof the winnowing machine is provided with a discharge gas lock, and the electronic belt scale, the infrared moisture meter, the positive pressure fan and the negative pressure fan are all connected with a controller. The power automatic adjusting method comprises the steps of setting of basic materials, collection of real-time data and automatic adjusting. The power automatic adjusting device andmethod can adjust wind power according to practical conditions so as to achieve precise separation of cut tobacco and impurities. The device is simple in structure, and the method is easy and convenient to operate and easy to implement.

Owner:CHINA TOBACCO JIANGSU INDAL

Error self-compensation method of electronic belt scale for cigarette production

PendingCN114543952ARealize error self-compensationAccurate weighingWeighing apparatus testing/calibrationWeighing apparatus for continuous material flowHidden layerElectronic leash

The invention relates to an error self-compensation method of an electronic belt scale for cigarette production, and belongs to the technical field of cigarette weighing. Comprising the following steps: (1) additionally installing a displacement sensor and an offset sensor; (2) defining initial positions of a displacement sensor and a conveyor belt offset sensor; (3) acquiring calibration data of the sensor; (4) establishing an artificial neural network which comprises one hidden layer, one input layer and one output layer; (5) using the data obtained in the step (3) as a training set to train a neural network; (6) carrying out artificial neural network deployment; and (7) verifying the error automatic compensation effect. The weighing process of the electronic belt scale is modeled by using the artificial neural network, and the model is deployed in the edge computing equipment, so that error self-compensation of the electronic belt scale can be realized, accurate weighing of the electronic belt scale is ensured, small difference between the actual blending proportion and the theoretical weight of the formula is ensured in the tobacco shred making and blending process, and the uniformity of the smoking flavor of cigarettes can be ensured.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

A method for judging the durability of a 0.2-grade electronic belt scale

ActiveCN111174891BImprove long-term stabilityTest time is shortWeighing apparatus testing/calibrationElectronic leashProcess engineering

The invention discloses a method for judging the durability of a 0.2-grade electronic belt scale, which includes the following steps: each set of 0.2-grade electronic belt scales is regarded as a high-precision measurement system, and two of the electronic belt scales are selected to be defined as A scales The state of scale A and scale B is the same as that of scale B. When passing the first verification of level 0.2, record the system parameters at this time. When running in empty mode, the difference Δ between the accumulated values of scales A and B running integer n cycles, Compared with the difference Δ' when the electronic belt scale is normally conveying materials at the last time of the assessment period of the electronic belt scale, the beneficial effect of the present invention is that the direct detection that cannot be realized is converted into two electronic belt scales of the same batch of electronic belt scales The indirect comparison test with short verification time greatly saves the cost of the assessment and also saves the site and space of the production site; it can be carried out online without stopping production and does not affect normal production.

Owner:铜陵市三爱思电子有限公司

An online real-time calculation and evaluation method for electronic belt scales

ActiveCN110806256BReal-time monitoring of weighing accuracyEstimated Risk of Weighing ErrorsWeighing apparatus testing/calibrationElectronic leashSimulation

The invention discloses an online real-time calculation and evaluation method of an electronic belt scale, which uses the electronic belt scale's material signal as a trigger condition to collect the weight collection value, speed collection value, instantaneous flow collection value and cumulative weight collection value output by the electronic belt scale. And calculate the instantaneous flow calculation value and the cumulative weight calculation value; calculate the ratio of the collection points where the instantaneous flow collection value is within the upper and lower limits of the instantaneous flow calculation value to the total collection points, and the cumulative weight collection value is within the upper and lower limits of the cumulative weight calculation value The ratio of the collection points to the total collection points is used to obtain the pass rate of the instantaneous flow collection value and the cumulative weight collection value. The invention is a method for judging the matching between the instantaneous flow rate and the cumulative weight of the electronic belt scale, which realizes the real-time monitoring of the weighing accuracy of the electronic belt scale, estimates the risk of weighing errors, and can timely alarm and shut down through real-time evaluation, reducing the quality of production materials In the case of damage, the process monitoring of the electronic belt scale is greatly enhanced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

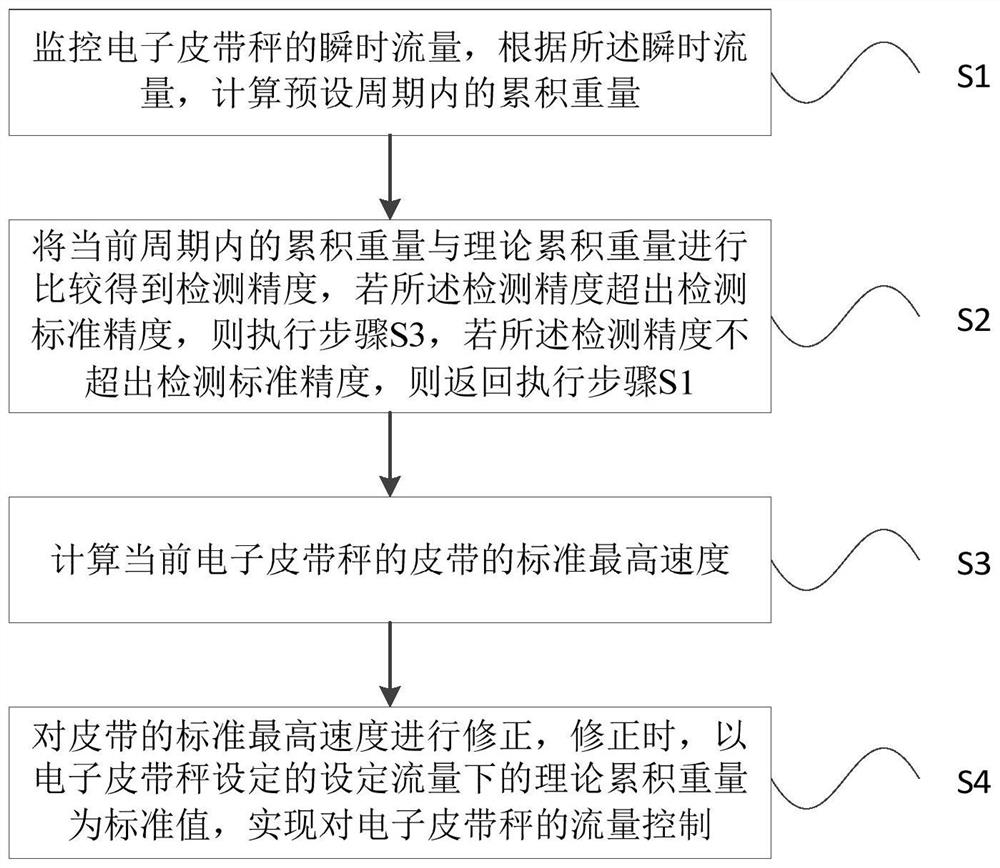

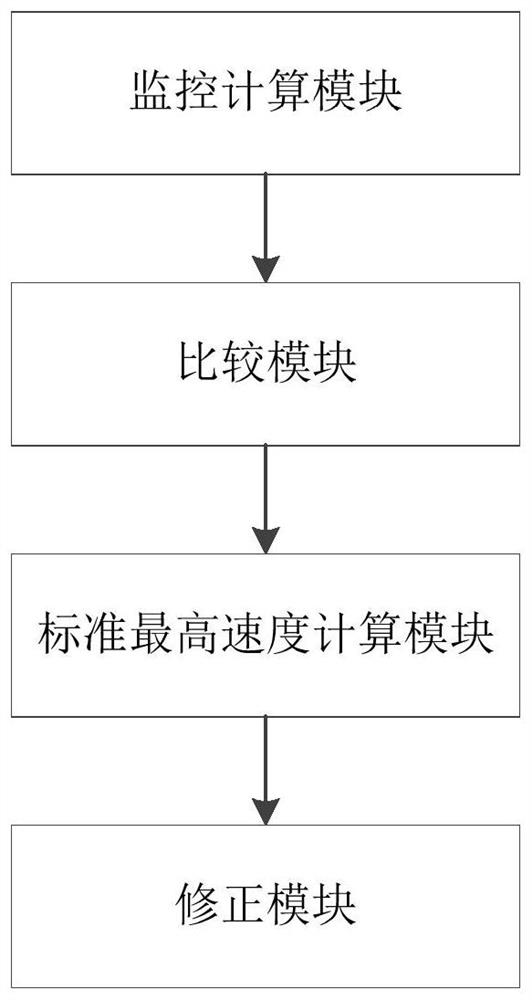

Controllable electronic belt scale flow control precision self-adaption method and system and computer medium

ActiveCN114719945AMake up for output errorsGuaranteed control accuracyWeighing apparatus testing/calibrationWeighing apparatus for continuous material flowPERQElectronic leash

The invention discloses a controllable electronic belt scale flow control precision self-adaption method and system and a computer medium, and the method comprises the following steps: S1, monitoring the instantaneous flow of an electronic belt scale, and calculating the accumulated weight in a preset period according to the instantaneous flow; s2, comparing the accumulated weight in the current period with the theoretical accumulated weight to obtain detection precision, if the detection precision exceeds the detection standard precision, executing the step S3, and if the detection precision does not exceed the detection standard precision, returning to execute the step S1; s3, calculating the standard maximum speed of the belt of the current electronic belt scale; and S4, correcting the standard maximum speed of the belt, and during correction, taking the theoretical accumulated weight under the set flow set by the electronic belt scale as a standard value to realize flow control of the electronic belt scale. The output error of the belt weigher control system caused by characteristic variation of components is compensated, and the flow control precision is ensured.

Owner:CHINA TOBACCO GUANGDONG IND

An adjustable electronic belt scale physical verification hanging code verification device

InactiveCN109443511BEasy to carryEasy to detectWeighing apparatus testing/calibrationElectronic leashEngineering

The invention relates to the technical field of mechanical equipment, and particularly to an adjustable electronic belt conveyor scale object detecting hanging weight calibrating device. The device comprises a base, a mounting trough, a pressure sensor, an electronic belt scale body, a mounting board, a chamber, a chute, a top board, a connecting block, an electric push rod, a hanging weight, a groove, an electromagnet, an infrared opposed switch and a controller. The hanging weight is mounted on the top board when not in use. Furthermore the top board is in the chamber. Therefore the electronic belt scale is not affected by the top board in an operation process, and convenient conveying is realized. Furthermore when the electronic belt scale needs calibration, the electric push rod can move the top board to surface of the mounting board, thereby making the hanging weight be arranged above the electronic belt scale. Simultaneously the electromagnet is powered off, and the hanging weight is arranged on the surface of the electronic belt scale. Through the pressure sensor, dynamic verification and calibration of the electronic belt scale are realized.

Owner:青岛市计量技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com