A wind power automatic adjustment device and adjustment method for a winnowing machine

An automatic adjustment and air separator technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc. problems, to achieve the effect of reducing energy consumption, reducing waste, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

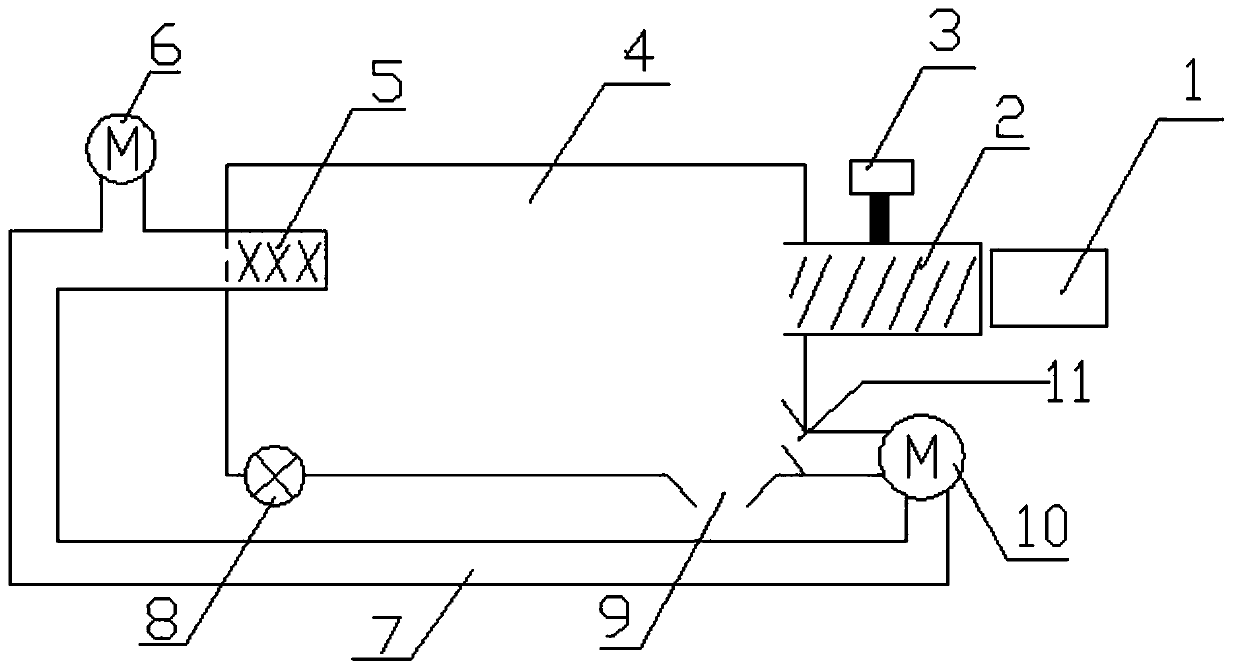

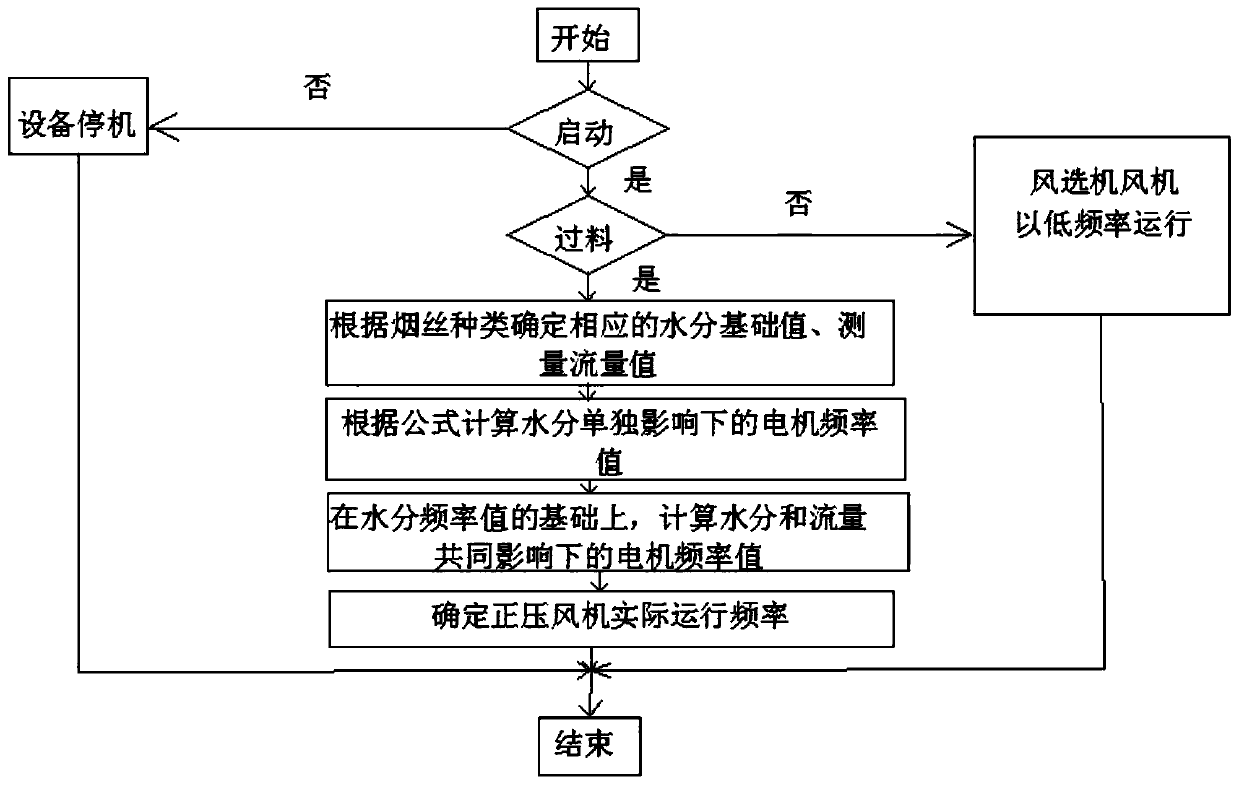

Method used

Image

Examples

Embodiment 1

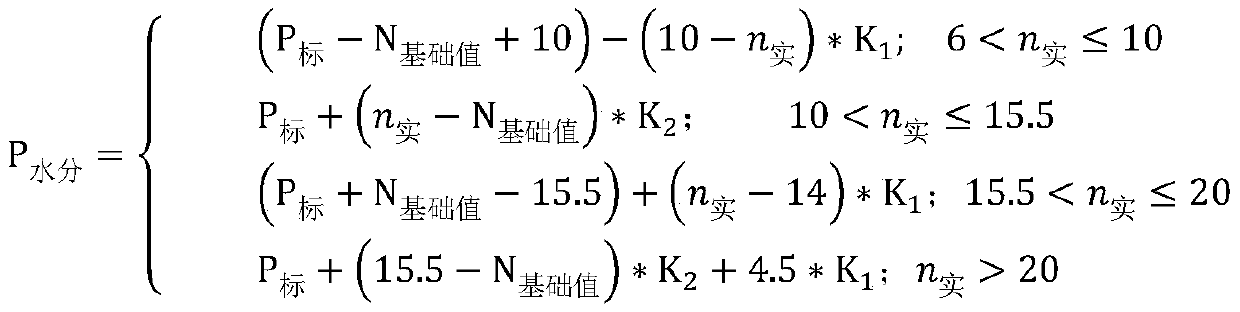

[0044] According to process standard requirements and production experience, the reference value of wind separator 4 positive pressure fan 10 operation is set to 31Hz and the basic flow rate of electronic belt scale 1 is 6000Kg / h; wind separator 4 and dust removal room are in production state, P min =20Hz, according to the actual operation of positive pressure fan 10 and negative pressure fan 6, set k 1 =0.1,k 2 = 1;

[0045] According to the production order issued by the central control, the type of shredded tobacco being produced at this time is Class A, and the basic moisture value of the preset Class A product in the database is called out to 13.3%; the real-time value of the shredded tobacco moisture detected by the infrared moisture meter 3 is 13.9% ;The real-time value of the flow measured by the electronic belt scale is 5950Kg / h;

[0046] Comparing the real-time moisture value of cut tobacco of 13.9% with the basic moisture value of 13.3%, on the basis of wind separ...

Embodiment 2

[0050] According to process standard requirements and production experience, the reference value of wind separator 4 positive pressure fan 10 operation is set at 31Hz and the basic flow rate of electronic belt scale 1 is 6000Kg / h; wind separator 4 and dust removal room are in production state, according to the on-site The actual operation of the pressure fan 10 and the negative pressure fan 6, set k 1 =0.1,k 2 = 1;

[0051] According to the production order issued by the central control, the type of shredded tobacco being produced at this time is Class B, and the basic moisture value of the preset Class B product in the database is called out to 13.6%; the real-time moisture value of shredded tobacco detected by the infrared moisture meter 3 is 14.3% ;The real-time value of the flow measured by the electronic belt scale 1 is 6050Kg / h;

[0052] Comparing the real-time moisture value of cut tobacco of 14.3% with the basic moisture value of 13.6%, the moisture frequency value P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com