Method for metering travelling belt material and its device

A technology for conveying belts and materials, which is applied to the field of measuring materials on conveying belts, can solve the problems of inaccurate transmission signals of speed sensors and distortion of belt scale measurement, and achieve the effects of improving weight measurement accuracy, convenient maintenance and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A method of metering material on a transport belt comprising the steps of:

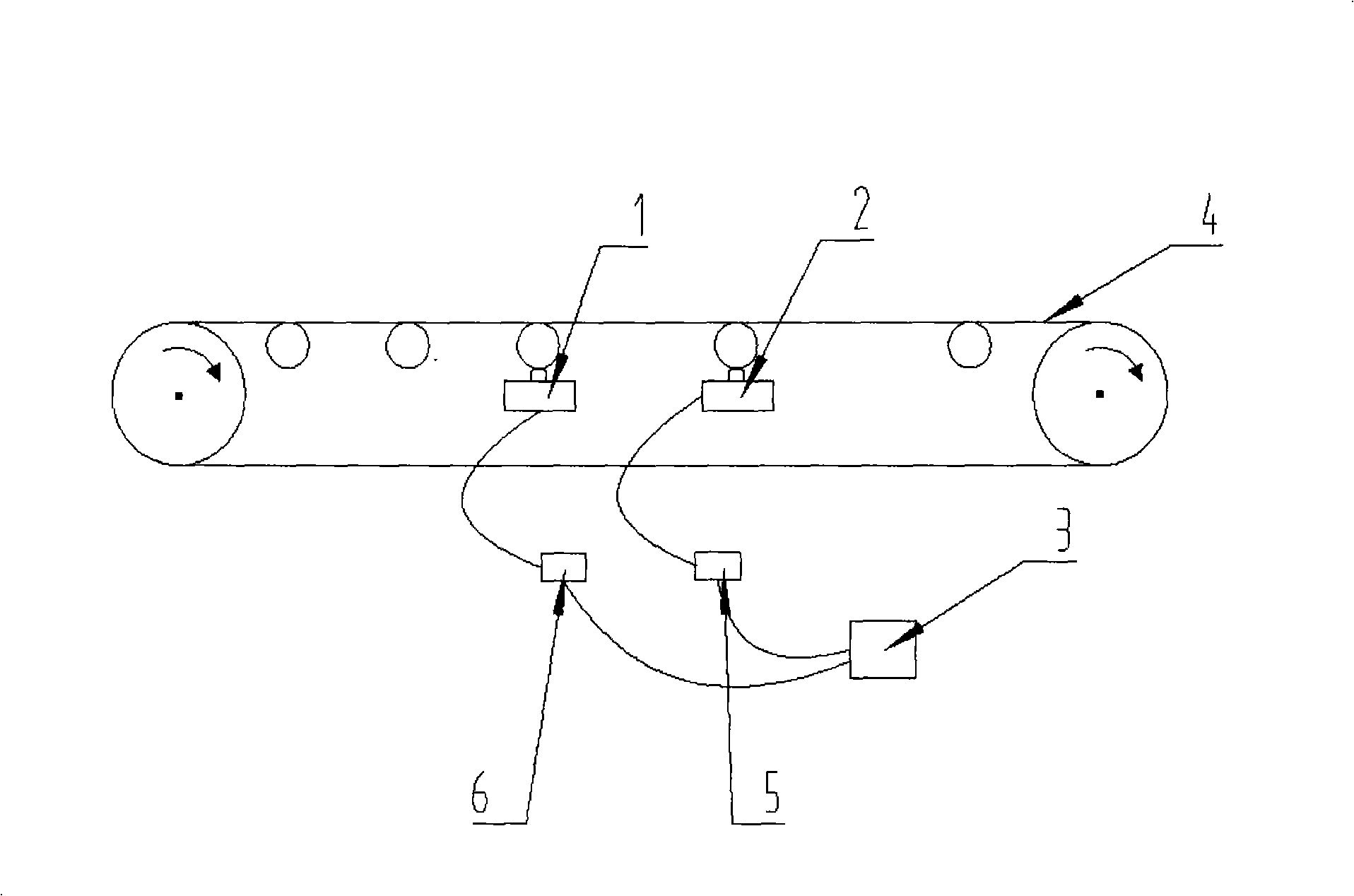

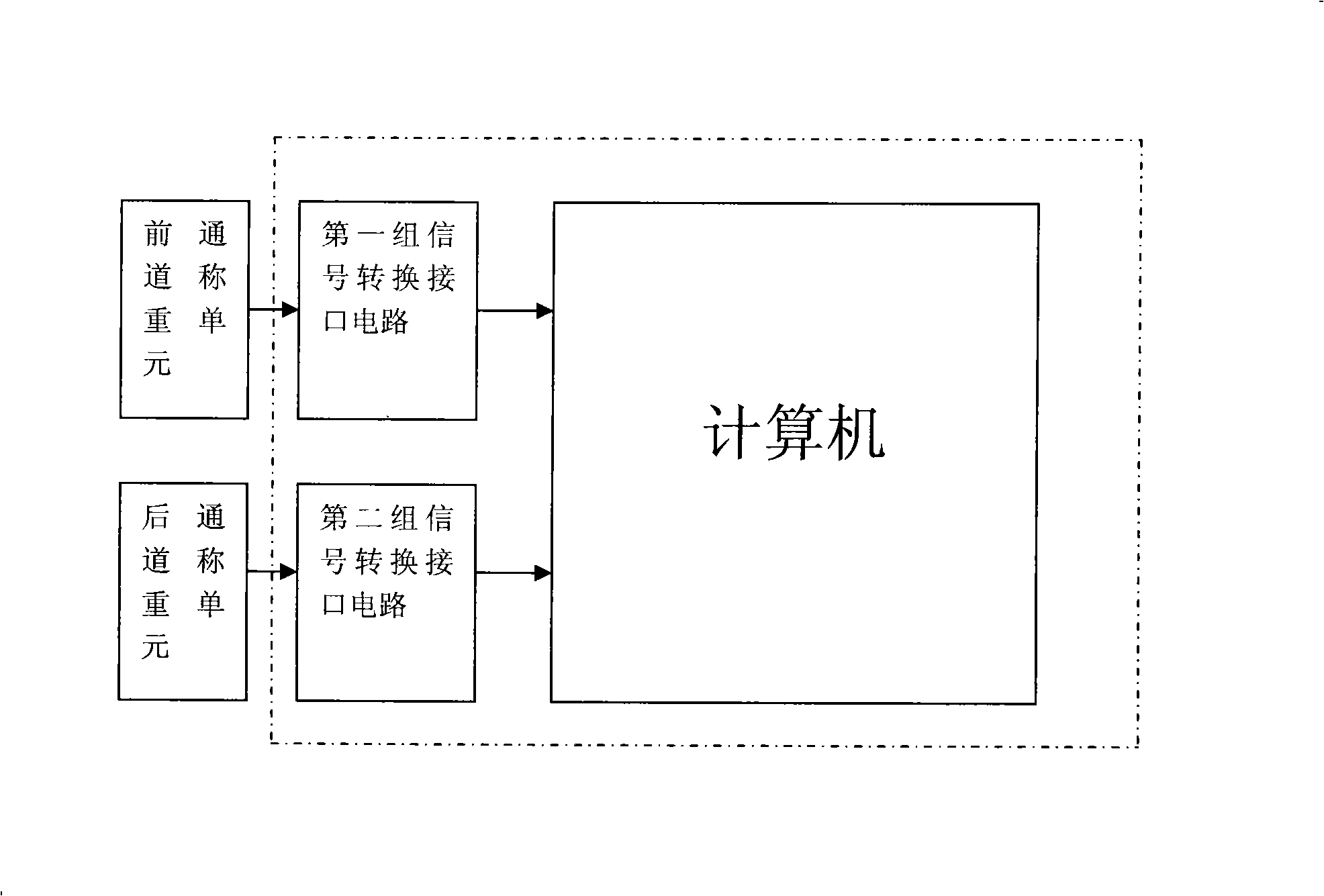

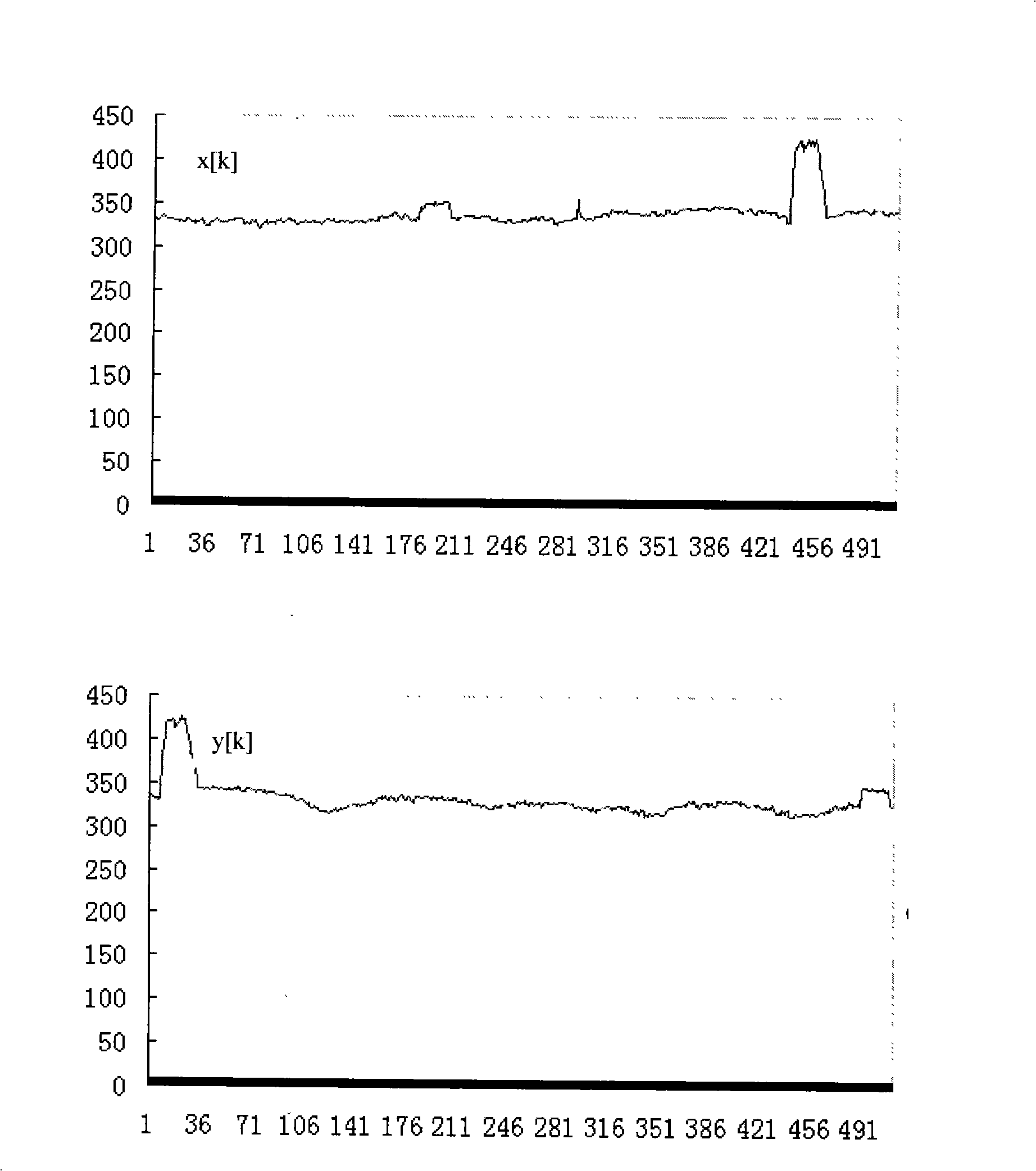

[0021] a. Two groups of weighing units, namely the front weighing unit and the rear weighing unit, are respectively set on the same belt for transporting materials. The two groups of weighing units are separated by L, and these two weighing units are only equipped with The weighing unit of the weighing force transmission mechanism, the front weighing unit weighs the weight of the material passing through the belt in real time and obtains the weighing signal of the material, and the weighing signal is transmitted to the first weighing unit electrically connected to the front weighing unit A set of signal conversion interface circuits converts the signal sequence x[k] that can be collected by the computer. At the same time, the rear weighing unit weighs the weight of the material on the belt from the front weighing unit in real time and obtains the weighing signal of the material. The weighing si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com