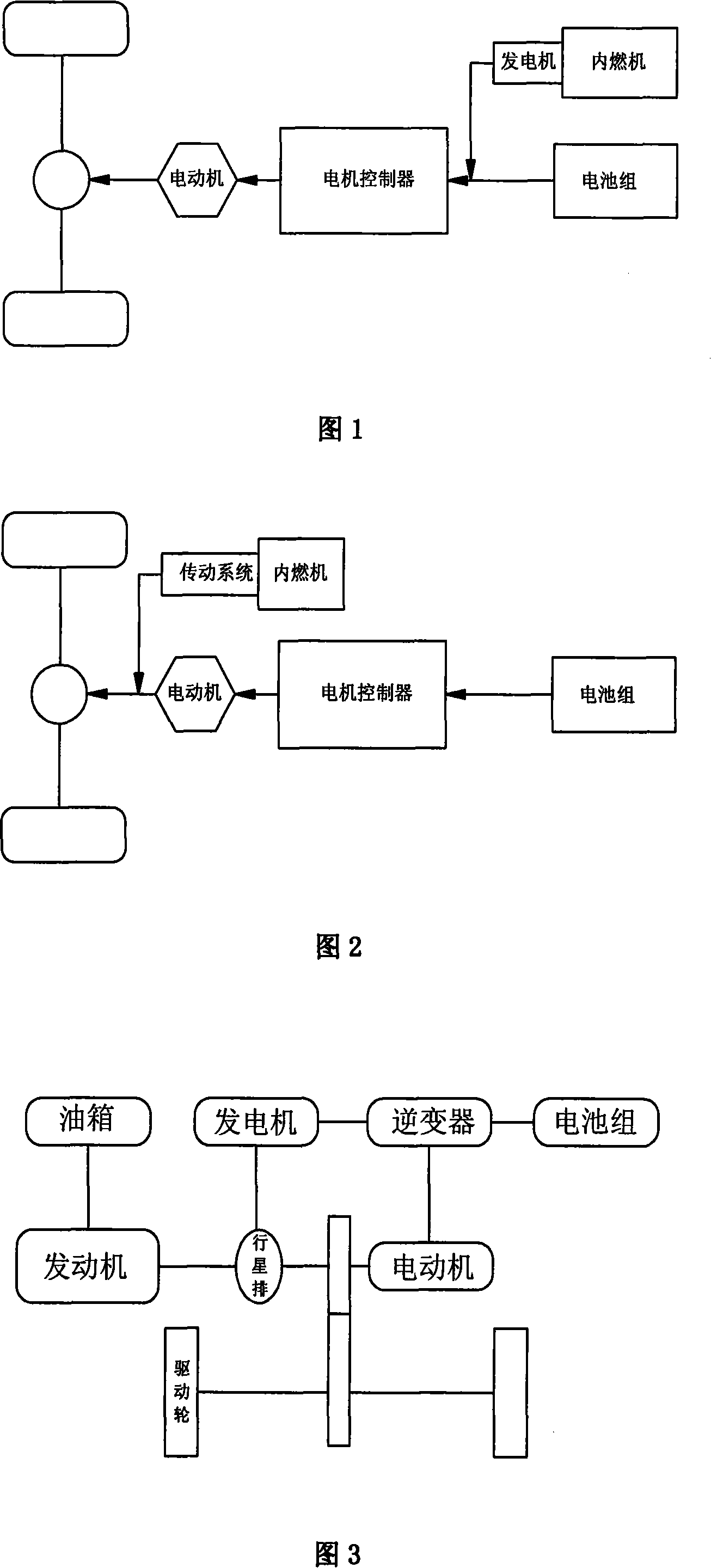

Automobile power system with double-engine and its control method

A power system, dual-engine technology, applied in the direction of control device, power device, vehicle components, etc., can solve problems such as complex structure, and achieve the effect of increasing effective load, saving development cost and use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

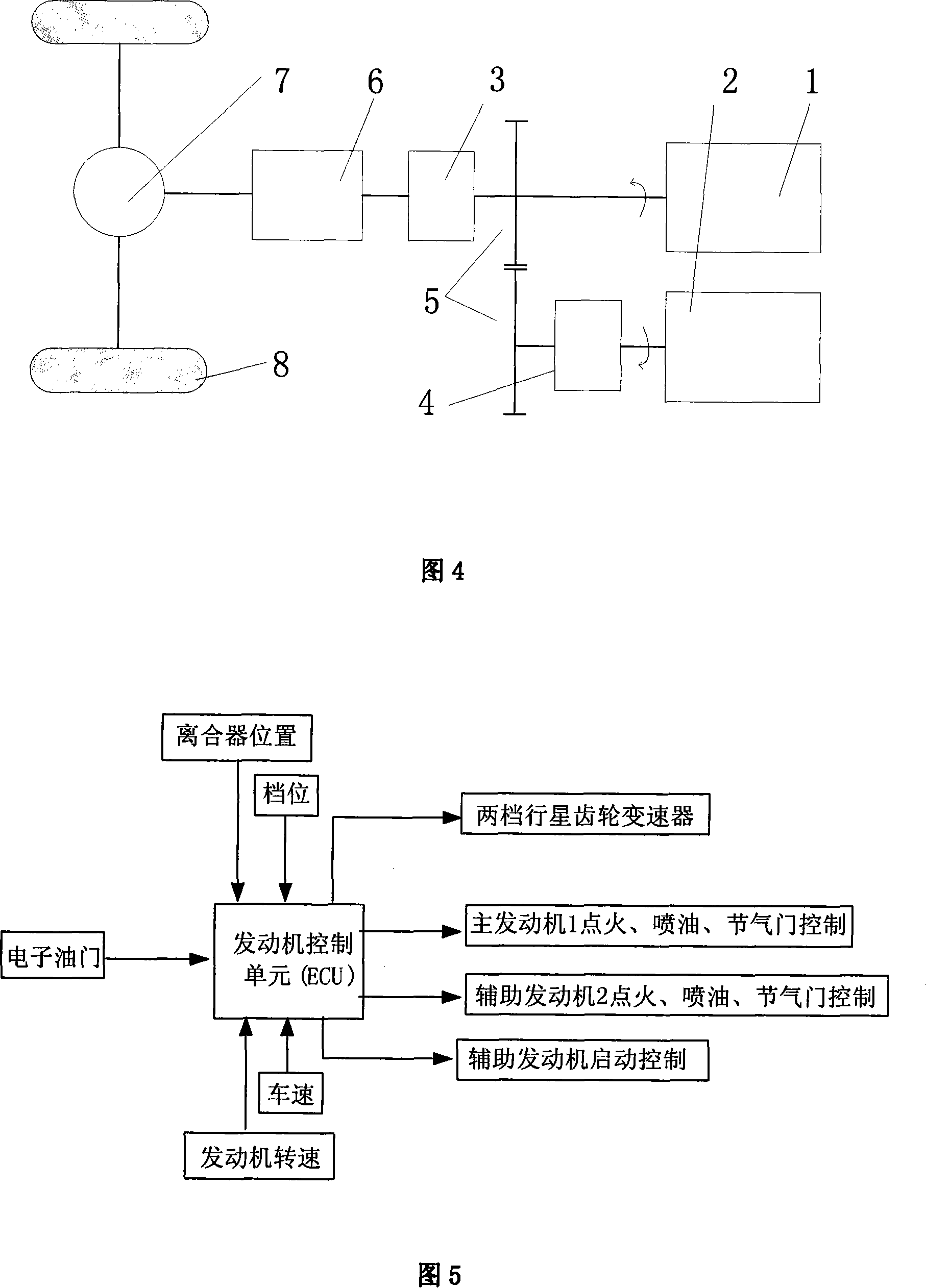

[0025] As shown in Figure 4, the dual-engine vehicle power system of the present invention includes a main power system that is connected in sequence by the main engine 1, the main clutch 3, the main transmission 6, the differential 7 and the wheels 8, which are the same as those of a traditional car. , also includes an auxiliary engine 2 connected in parallel with the main engine 1, the output shaft of the auxiliary engine 2 is connected with an auxiliary transmission 4, the auxiliary transmission can adopt a two-speed planetary gear transmission, and the output shaft of the two-speed planetary gear transmission 4 is then It is connected with the output shaft of the main engine 1 through a gear set 5 . In order to optimize the energy structure, the main engine 1 is a gasoline engine, and the auxiliary engine 2 is an ethanol engine.

[0026] When separating the clutch and the ring gear brake in the two-speed planetary gear transmission 4, the two-speed planetary gear transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com