Error self-compensation method of electronic belt scale for cigarette production

An electronic belt scale and self-compensation technology, applied in the direction of continuous material flow weighing equipment, instruments, measuring devices, etc., can solve the problems of complex composition of gravity weighing errors, difficult process control, difficult to analyze, etc., to achieve automatic error Effects of compensation, improvement of process stability, and prevention of equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited in any way, and any transformation or replacement based on the teachings of the present invention belongs to the protection scope of the present invention.

[0043] This embodiment adopts 0.5 grade electronic belt scale experiment:

[0044] An error self-compensation method for an electronic belt scale for cigarette production, comprising the following steps:

[0045] (1) Install displacement sensor 4 and offset sensor 7;

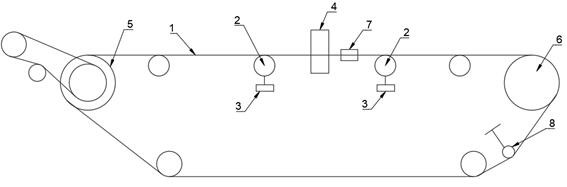

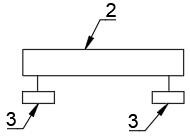

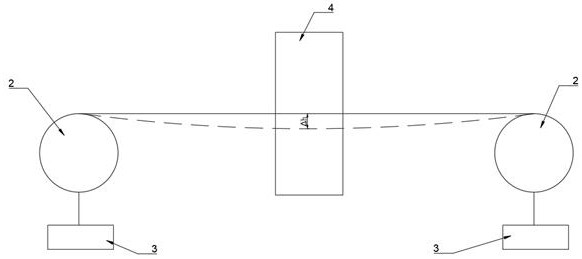

[0046] like Figure 1-4 As shown in the figure, the double weighing roller electronic belt scale conveyor is equipped with two weighing rollers 2, and two weighing sensors 3 are installed under each weighing roller 2, a total of four weighing sensors 3, which are numbered in sequence; The machine also has its own belt speed detector 8 . A displacement sensor 4 is installed between the two weighing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com