Device suitable for data collection of electronic belt conveyor scale of ore dressing plant

An electronic belt scale and data acquisition technology, which is applied in the direction of measuring devices, continuous material flow weighing equipment, instruments, etc., can solve the problem of inconsistency between the data of the electronic belt scale and the remote data in the mineral processing plant, so as to ensure consistency and realize data , The effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

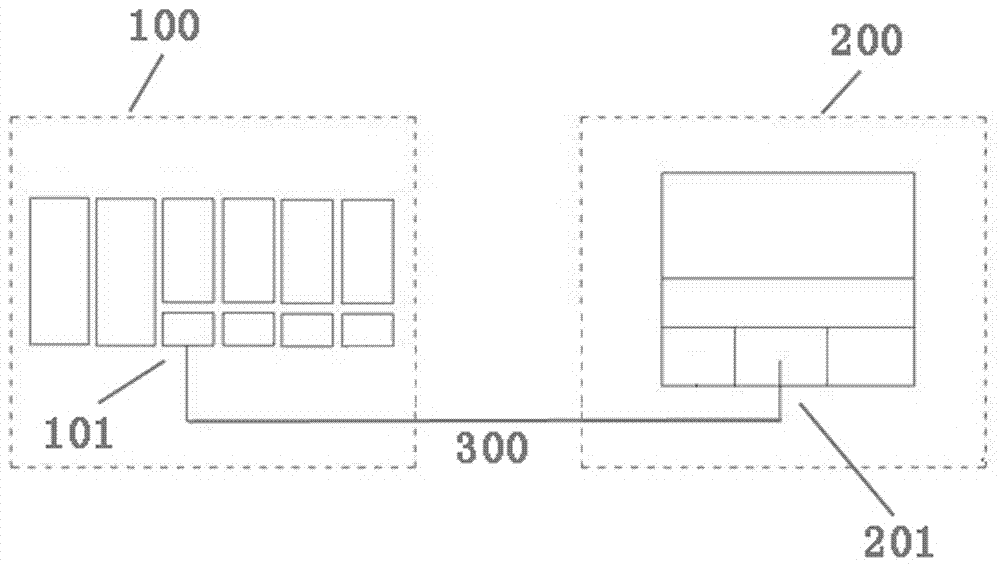

Embodiment 1

[0037] Embodiment 1: a kind of device that is applicable to the data acquisition of the electronic belt scale of mineral processing plant, comprises the Modbus master station that selects Emerson DCS system 100, selects the Modbus slave station of Siemens electronic belt scale 200, and described Siemens electronic belt scale 200 includes bearing device , a weighing sensor, a speed sensor, an arithmetic unit, an amplifier, and a weighing display instrument. The weighing device transmits the gravity of the material on the belt to the weighing sensor, and the weighing sensor will output a voltage signal proportional to the gravity of the material. After the amplifier is amplified, it is sent to the analog-to-digital converter to become a digital quantity A, which is sent to the arithmetic unit; the speed of the material is input to the speed sensor, and the speed sensor outputs the pulse number B, which is also sent to the arithmetic unit; The amount of material in this measuremen...

Embodiment 2

[0062] Embodiment 2: a kind of device that is applicable to the data acquisition of the electronic belt scale of mineral processing plant, comprises the Modbus master station that selects Emerson DCS system 100, selects the Modbus slave station of Siemens electronic belt scale 200, and described Siemens electronic belt scale 200 includes bearing device , a weighing sensor, a speed sensor, an arithmetic unit, an amplifier, and a weighing display instrument. The weighing device transmits the gravity of the material on the belt to the weighing sensor, and the weighing sensor will output a voltage signal proportional to the gravity of the material. After the amplifier is amplified, it is sent to the analog-to-digital converter to become a digital quantity A, which is sent to the arithmetic unit; the speed of the material is input to the speed sensor, and the speed sensor outputs the pulse number B, which is also sent to the arithmetic unit; The amount of material in this measuremen...

Embodiment 3

[0087] Embodiment 3: a kind of device that is applicable to the data acquisition of the electronic belt scale of mineral processing plant, comprises the Modbus master station that selects Emerson DCS system 100, selects the Modbus slave station of Siemens electronic belt scale 200, and described Siemens electronic belt scale 200 includes bearing device , a weighing sensor, a speed sensor, an arithmetic unit, an amplifier, and a weighing display instrument. The weighing device transmits the gravity of the material on the belt to the weighing sensor, and the weighing sensor will output a voltage signal proportional to the gravity of the material. After the amplifier is amplified, it is sent to the analog-to-digital converter to become a digital quantity A, which is sent to the arithmetic unit; the speed of the material is input to the speed sensor, and the speed sensor outputs the pulse number B, which is also sent to the arithmetic unit; The amount of material in this measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com