Method for accurately checking electronic belt scale

An electronic belt scale and belt technology, which is applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of enterprise implementation difficulties and take up a lot of time, achieve considerable economic and social benefits, improve equipment operation rate, and improve equipment production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

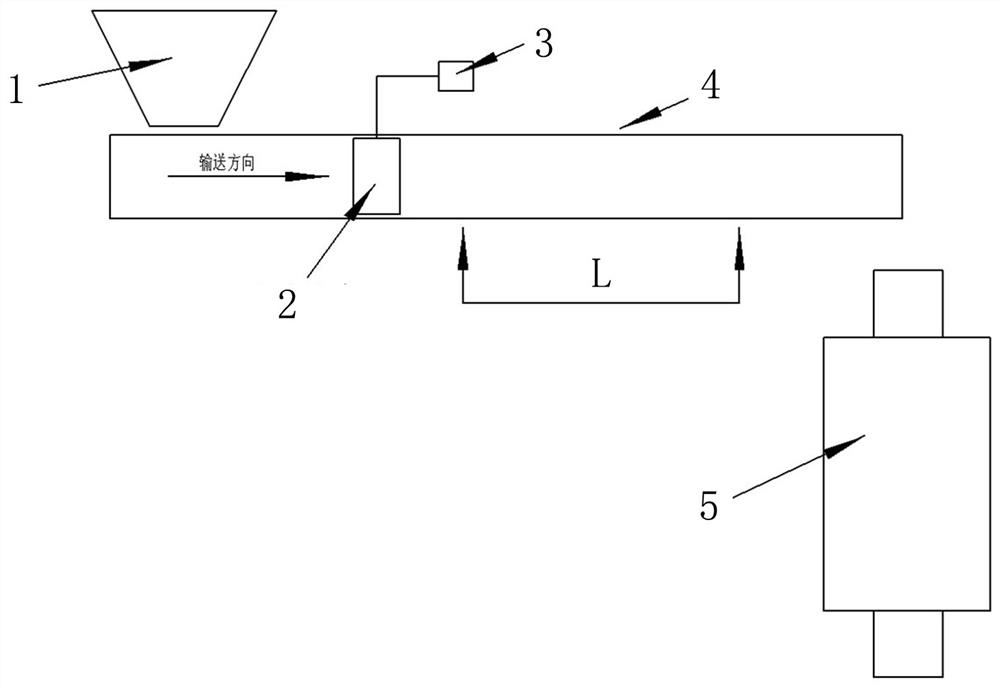

[0027] Embodiment 1: Take a mineral processing plant in the south as an example, as figure 1 As shown, a method for accurately verifying an electronic belt scale is characterized in that it comprises the following steps:

[0028] (1) Determine the length of the check section

[0029] After the mineral material flows down from the hopper 1 to the electronic belt scale 4, and passes through the sensor 2 along with the belt, take a section of belt length L=15 meters after the sensor 2;

[0030] (2) Record data

[0031] The speed V=1.2 m / s and the weighing data A=278 tons / hour displayed by the electronic belt scale integrator 3;

[0032] (3) Sampling

[0033] After the data recording is completed, the belt conveyor is powered off, and the interlocked raw ore lower hopper is also powered off. The sampling personnel will take away all the materials on the belt surface with a determined length, and record the total weight M=850 kg; after confirming safety, the belt conveyor and T...

Embodiment 2

[0042] Embodiment 2: Take a mineral processing plant in the south as an example, as figure 1 As shown, a method for accurately verifying an electronic belt scale is characterized in that it comprises the following steps:

[0043] (1) Determine the length of the check section

[0044] After the mineral material flows down from the hopper 1 to the electronic belt scale 4, and passes through the sensor 2 along with the belt, take a section of belt length L=20 meters after the sensor 2;

[0045] (2) Record data

[0046] The speed V=1.3 m / s and the weighing data A=310 tons / hour displayed by the electronic belt scale integrator 3;

[0047] (3) Sampling

[0048] After the data recording is completed, the belt conveyor is powered off, and the interlocked raw ore lower hopper is also powered off. The sampling personnel will take away all the materials on the belt surface with a determined length, and record the total weight M=1260 kg; after confirming safety, the belt conveyor and ...

Embodiment 3

[0057] Embodiment 3: Take a mineral processing plant in the south as an example, as figure 1 As shown, a method for accurately verifying an electronic belt scale is characterized in that it comprises the following steps:

[0058] (1) Determine the length of the check section

[0059] After the mineral material flows down from the hopper 1 to the electronic belt scale 4, and passes through the sensor 2 along with the belt, take a section of belt length L=20 meters after the sensor 2;

[0060] (2) Record data

[0061] The speed V=1.3 m / s and the weighing data A=278 tons / hour displayed by the electronic belt scale integrator 3;

[0062] (3) Sampling

[0063] After the data recording is completed, the belt conveyor is powered off, and the interlocked raw ore lower hopper is also powered off. The sampling personnel will take away all the materials on the belt surface with a determined length, and record the total weight M=1260 kg; after confirming safety, the belt conveyor and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com