Electronic belt weigher weight accumulation method based on DCS/PLC

An electronic belt scale and weight technology, which is applied in the direction of continuous material flow weighing equipment, weighing, and measuring devices, can solve the problems of large calculation errors in the weighing results of electronic belt scales, achieve accurate total weight, and solve calculation errors Larger, more accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

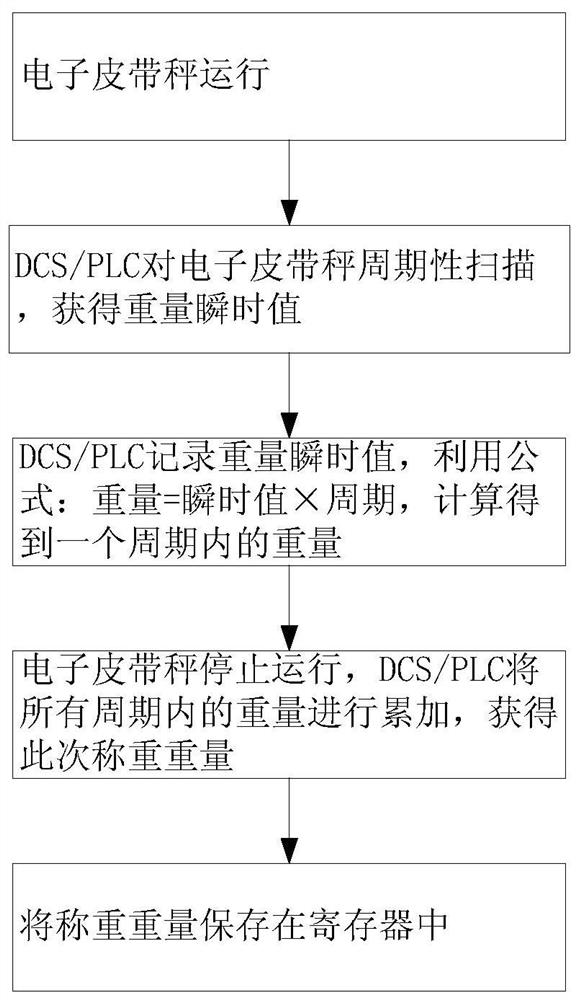

[0042] An embodiment of the electronic belt scale weight accumulation method based on DCS / PLC of the present invention comprises the following steps:

[0043] Step 1: DCS / PLC receives the operation signal of the electronic belt scale, and the operation signal is a continuous high level, which is fitted with a continuous high level to form a pulse signal. Reset to 0, DCS / PLC controls the operation of the electronic belt scale;

[0044] The second step: DCS / PLC scans the electronic belt scale in a cycle of 50ms to obtain the instantaneous value of weight in each cycle;

[0045] The third step: DCS / PLC records the instantaneous value of weight in each cycle, and uses the formula: weight=instantaneous value × cycle to calculate the weight in one cycle, and complete the weight calculation in each scanning cycle;

[0046] Step 4: Every time the electronic belt scale runs for a cycle, the DCS / PLC will accumulate the weight to obtain the current total weight until the electronic belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com