Method for calculating supercritical reverse-flow economizer process heat transfer coefficient

A technology of heat transfer coefficient and economizer, which is applied in the field of calculation of heat transfer coefficient of supercritical counter-flow economizer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing and example.

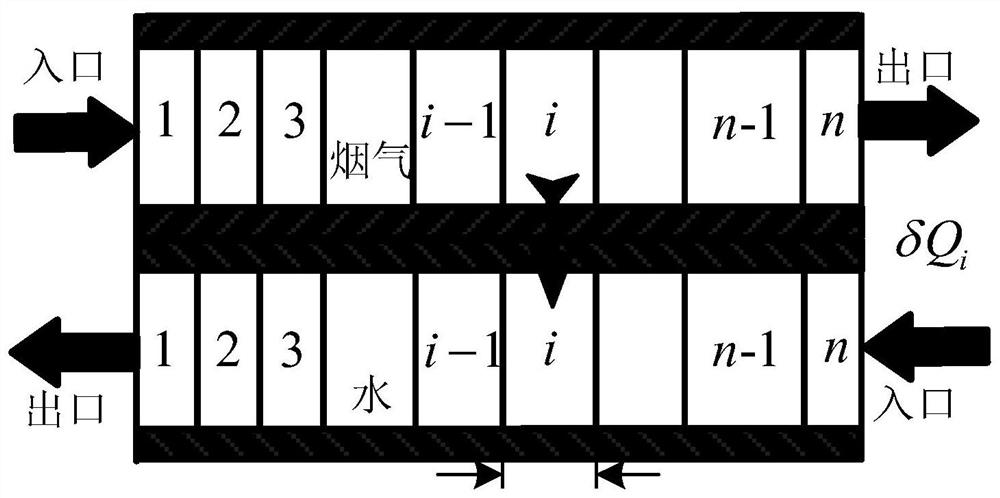

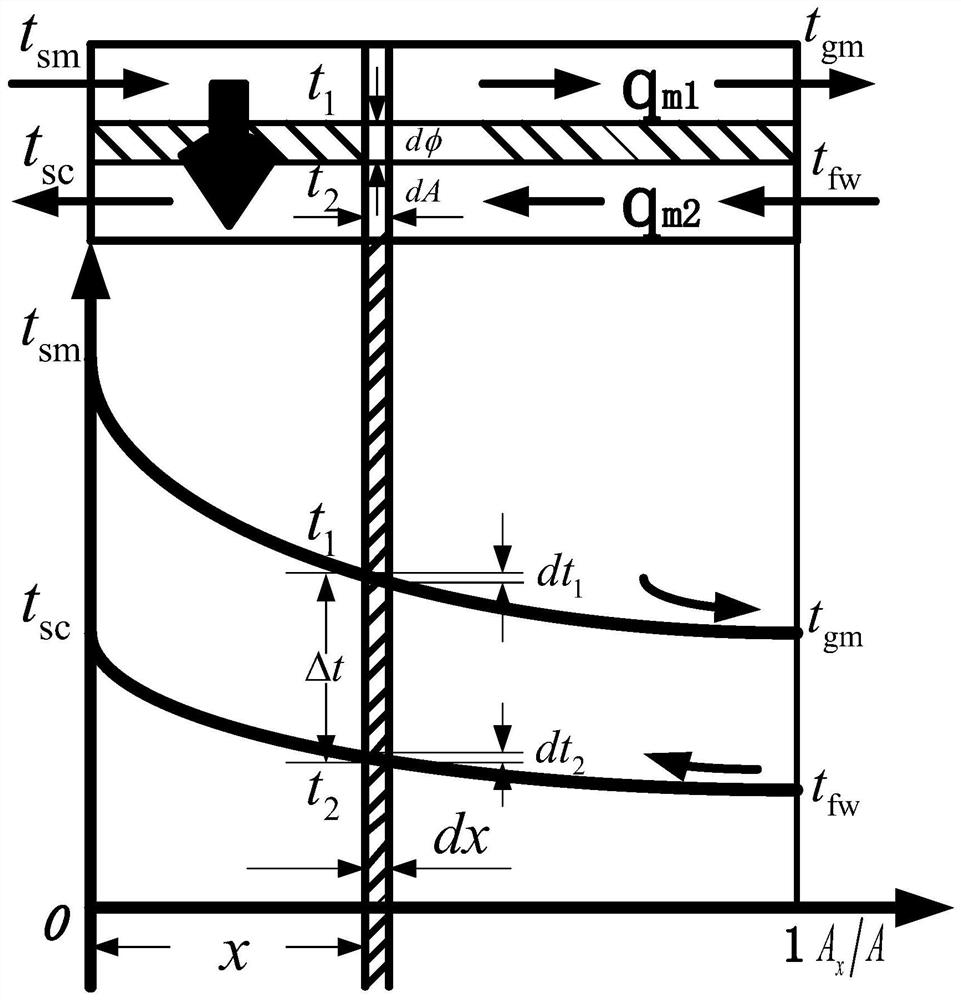

[0038] refer to Figure 1 ~ Figure 3 , a method for calculating the heat transfer coefficient of a supercritical counterflow economizer process of the present invention, comprising the following:

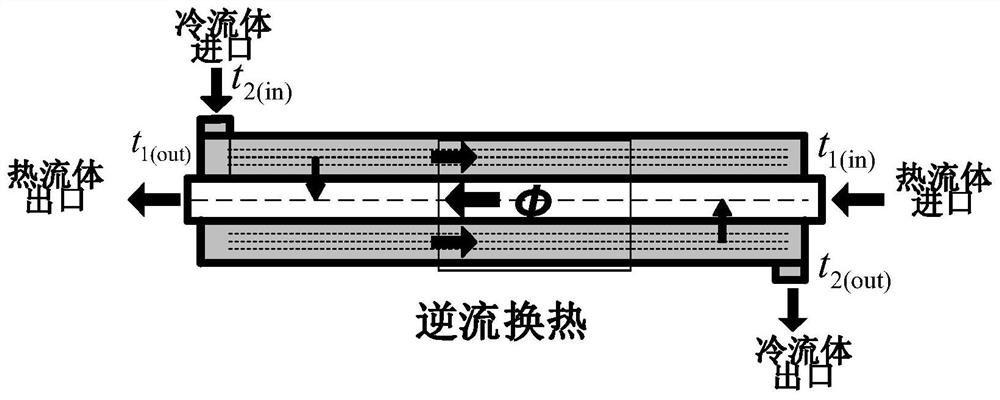

[0039] (a) Simplification and assumptions of the mathematical model of heat transfer of counterflow economizer

[0040] The schematic diagram of the heat transfer of the counter-flow economizer is as follows: figure 1 shown. Before constructing the mathematical model for calculating the heat transfer of the countercurrent economizer, it is necessary to make the following assumptions about the heat transfer process of the economizer: (1) The mass flow rate q of the hot and cold fluids in the model m1 ,q m2 It is constant on the entire heat exchange surface; (2) the heat dissipation coefficient in the model is constant on the entire heat exchange surface of the econ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com