Control method, robot and storage medium of crawling welding robot

A welding robot and control method technology, applied in the field of measurement and control, can solve the problem of difficult to reflect the change of arc length in real time, and achieve the effects of accurate automatic adjustment of welding torch height, accurate automatic adjustment of robot moving speed, and accurate calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

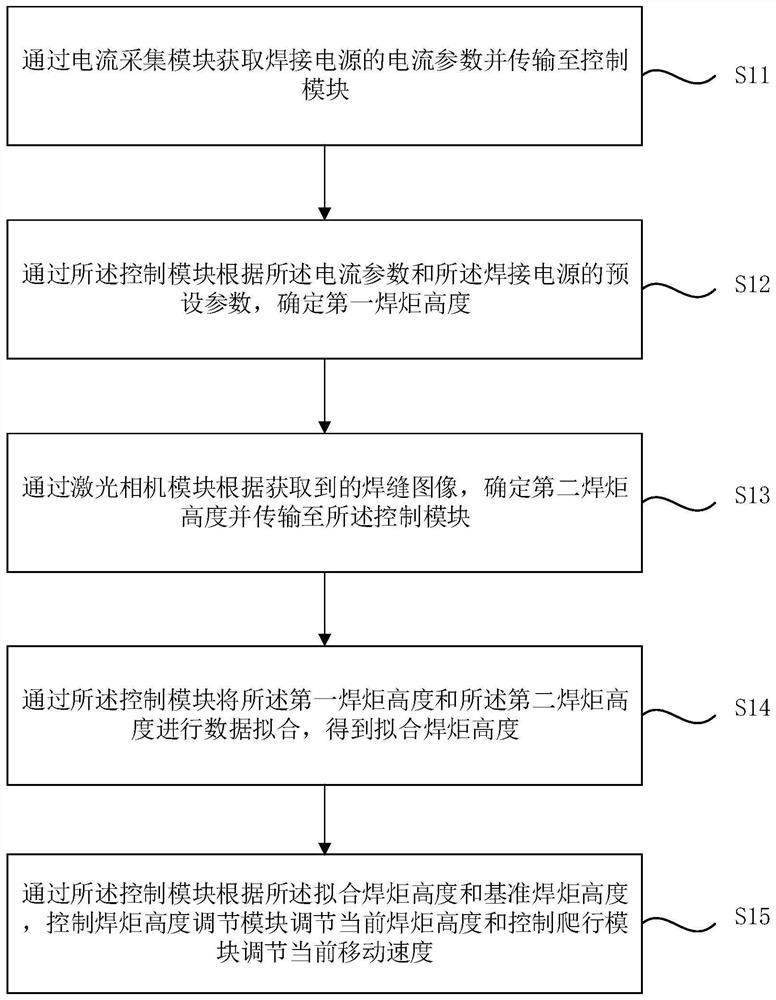

[0024] figure 1 It is a flow chart of the control method of the crawling welding robot provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of using a welding torch for automatic welding. This method can be executed by the control device of the crawling welding robot provided by the embodiment of the present invention. This device can be implemented by hardware and / or software, and generally can be integrated in crawling welding robots. like figure 1 shown, including the following steps:

[0025] S11. Obtain the current parameters of the welding power source through the current acquisition module and transmit them to the control module.

[0026] The current acquisition module can be located in the welding power source. The welding power source provides real-time feedback of current and voltage parameters during welding while providing welding energy. Among them, the current parameters change significantly during the welding proce...

Embodiment 2

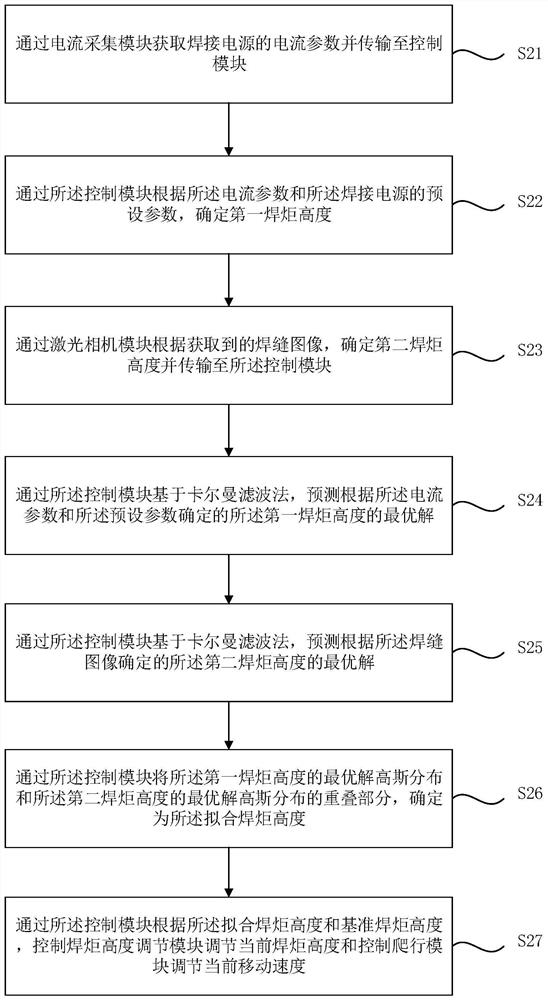

[0045] figure 2 This is a flowchart of the control method of the crawling welding robot provided by the second embodiment of the present invention. The technical solution of this embodiment is further refined on the basis of the above-mentioned technical solution. Optionally, the method used for data fitting of the height of the first welding torch and the height of the second welding torch is the Kalman filtering method, and the most The optimal solution and the characteristics of the Gaussian distribution determine the fitting torch height. correspondingly, as figure 2 shown, including the following steps:

[0046] S21. Acquire the current parameters of the welding power source through the current acquisition module and transmit them to the control module.

[0047] S22. Determine the height of the first welding torch by the control module according to the current parameter and the preset parameter of the welding power source.

[0048] S23. The laser camera module deter...

Embodiment 3

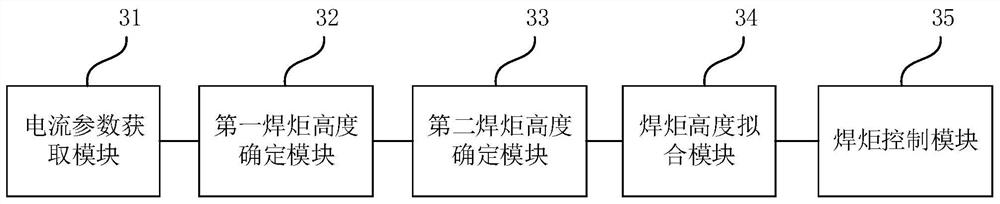

[0059] image 3 This is a schematic structural diagram of the control device of the crawling welding robot provided in the third embodiment of the present invention, the device can be realized by means of hardware and / or software, and can be integrated into the crawling welding robot. like image 3 As shown, the device includes:

[0060] The current parameter acquisition module 31 is used to acquire the current parameters of the welding power source through the current acquisition module and transmit them to the control module;

[0061] The first welding torch height determination module 32 is used for determining the first welding torch height through the control module according to the current parameters and the preset parameters of the welding power source;

[0062] The second welding torch height determination module 33 is used to determine the second welding torch height according to the obtained welding seam image through the laser camera module and transmit it to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com