Controllable electronic belt scale flow control precision self-adaption method and system and computer medium

An electronic belt scale and flow control technology, which is applied in the field of system and computer media, controllable electronic belt scale flow control accuracy self-adaptive method, can solve the problems of not meeting the flow control accuracy requirements, related electrical characteristic variation, output signal error, etc. problems, to achieve the effect of improving convenience, making up for output errors, and making up for linear output errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

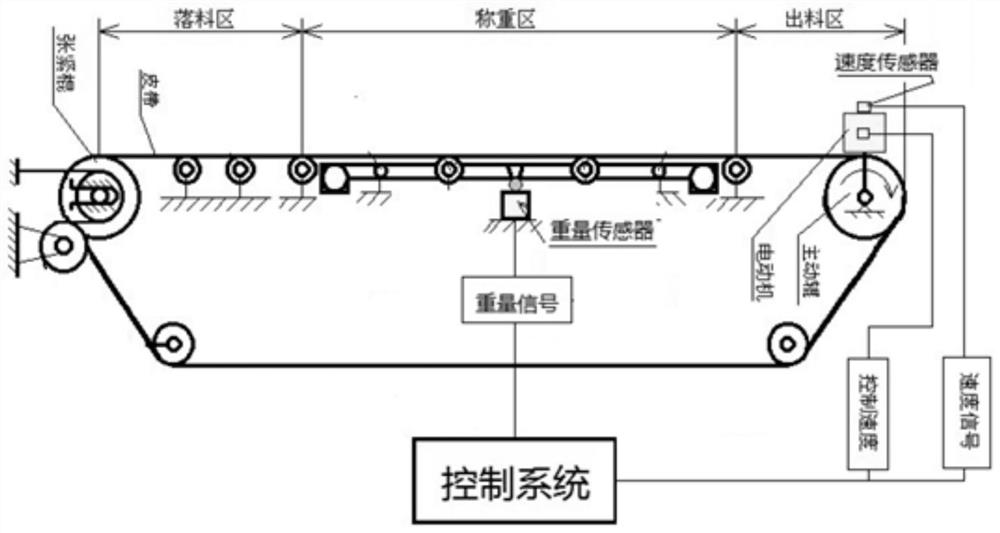

Image

Examples

Embodiment 1

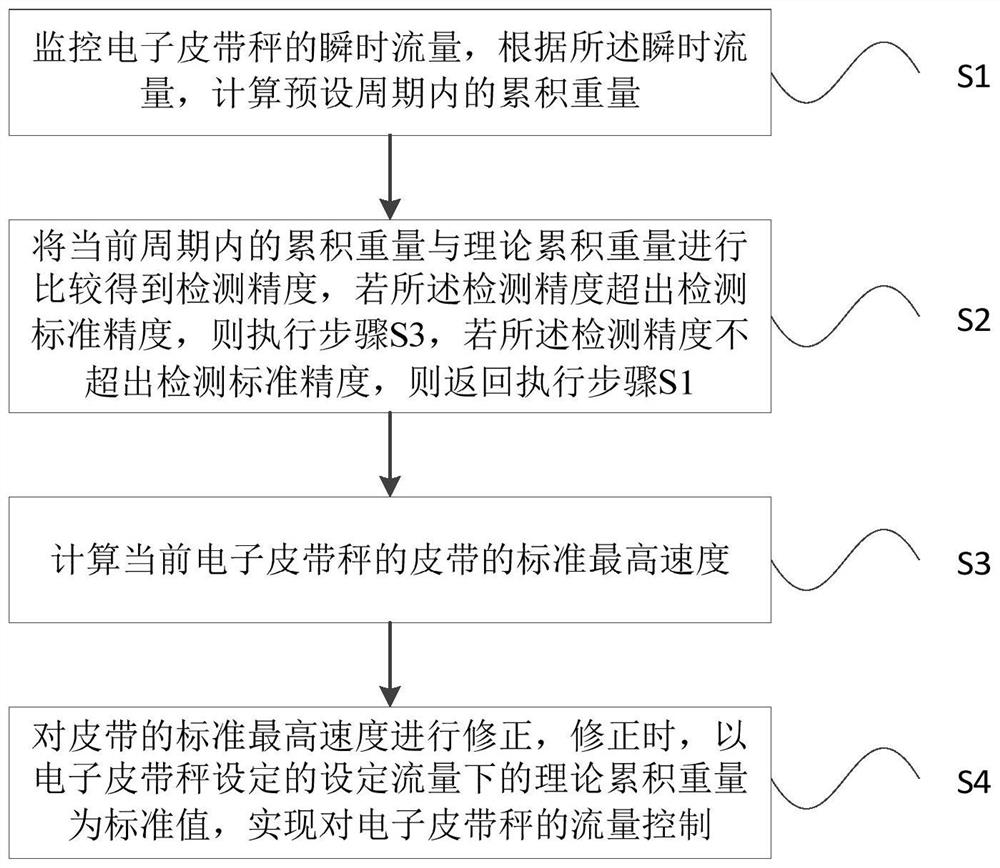

[0049] This embodiment provides an adaptive method for flow control accuracy of a controllable electronic belt scale, such as figure 2 shown, including the following steps:

[0050] S1: Monitor the instantaneous flow rate of the electronic belt scale, and calculate the accumulated weight within a preset period according to the instantaneous flow rate;

[0051] S2: Comparing the accumulated weight in the current cycle with the theoretical accumulated weight to obtain the detection accuracy, if the detection accuracy exceeds the detection standard accuracy, execute step S3, and if the detection accuracy does not exceed the detection standard accuracy, return to execute step S1 ;

[0052] S3: Calculate the standard maximum speed of the belt of the current electronic belt scale;

[0053] S4: Correct the standard maximum speed of the belt. When correcting, take the theoretical accumulated weight under the set flow set by the electronic belt scale as the standard value to realize...

Embodiment 2

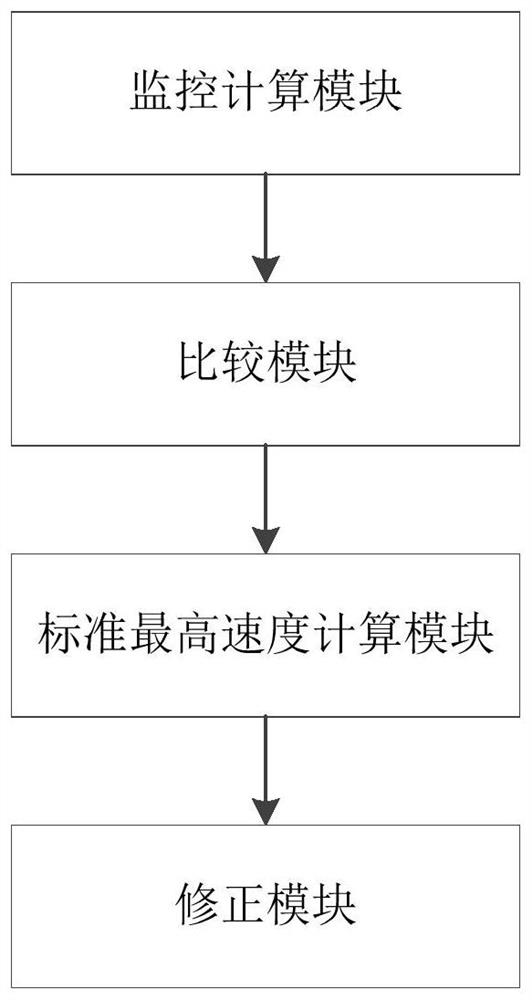

[0094] This embodiment provides a controllable electronic belt scale flow control accuracy adaptive system, such as image 3 shown, including:

[0095] a monitoring calculation module, which is used for monitoring the instantaneous flow of the electronic belt scale, and calculates the accumulated weight in a preset period according to the instantaneous flow;

[0096] The comparison module is used to compare the accumulated weight in the current cycle with the theoretical accumulated weight to obtain the detection accuracy. If the detection accuracy exceeds the detection standard accuracy, it will enter the standard maximum speed calculation module. If the detection accuracy is not If it exceeds the detection standard accuracy, it will return to the monitoring calculation module;

[0097] a standard maximum speed calculation module, the standard maximum speed calculation module is used to calculate the standard maximum speed of the belt of the current electronic belt scale;

...

Embodiment 3

[0102] This embodiment provides a computer medium that, when executed by a processor, implements the method for self-adapting flow control accuracy of a controllable electronic belt scale described in Embodiment 1.

[0103] The same or similar reference numbers correspond to the same or similar parts;

[0104] The terms describing the positional relationship in the accompanying drawings are only used for exemplary illustration, and should not be construed as a limitation on this patent;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com