Intelligent setting method for on-line target strip shape of cold rolling strip

A technology of cold-rolled strip and setting method, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as plate shape defects, and achieve the effect of clear functions and clear goals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] A method for intelligently setting an online target shape of a cold-rolled strip, comprising the following steps:

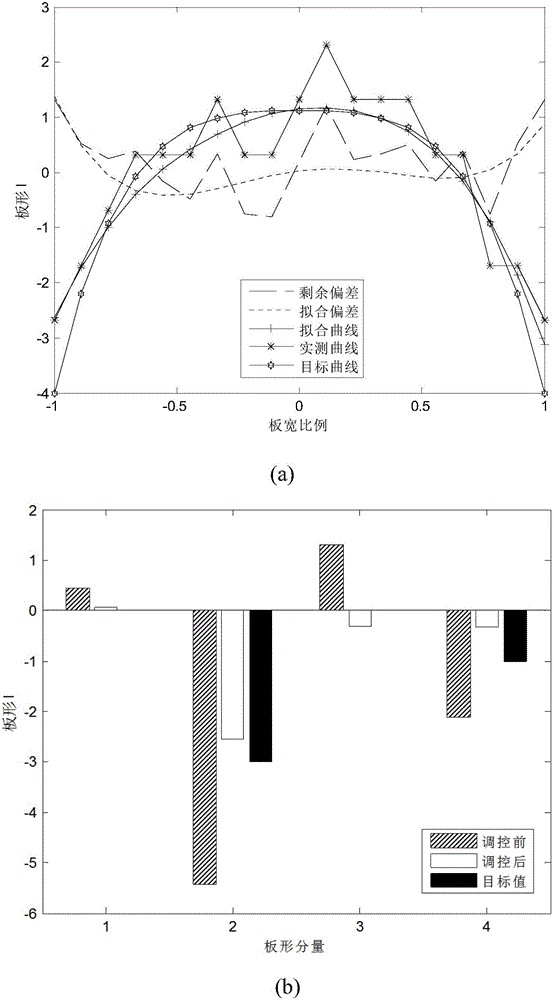

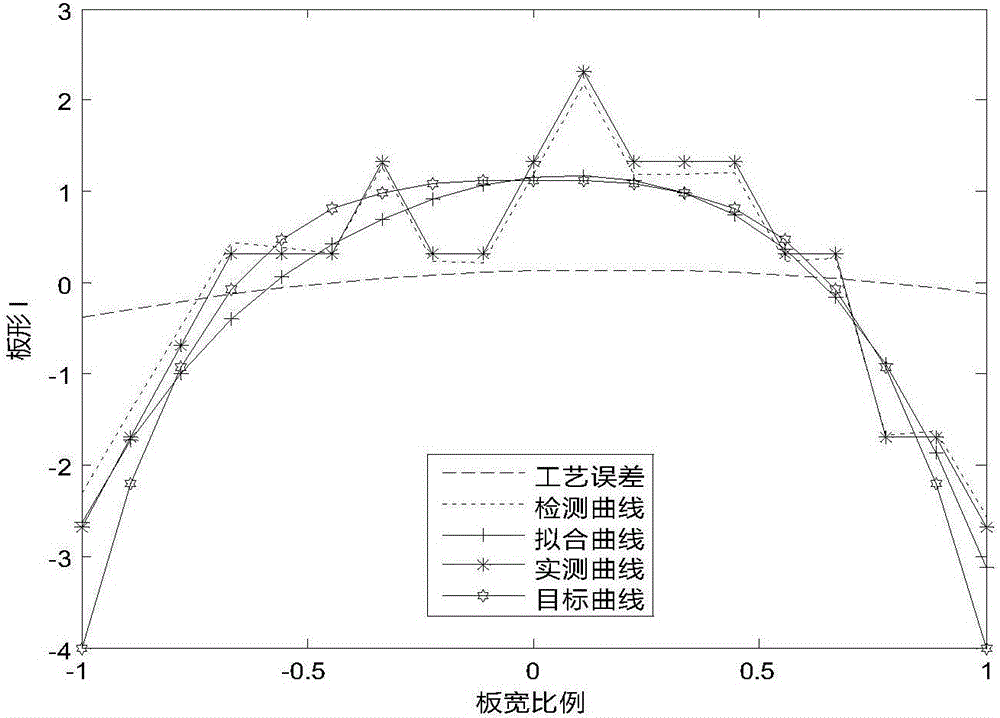

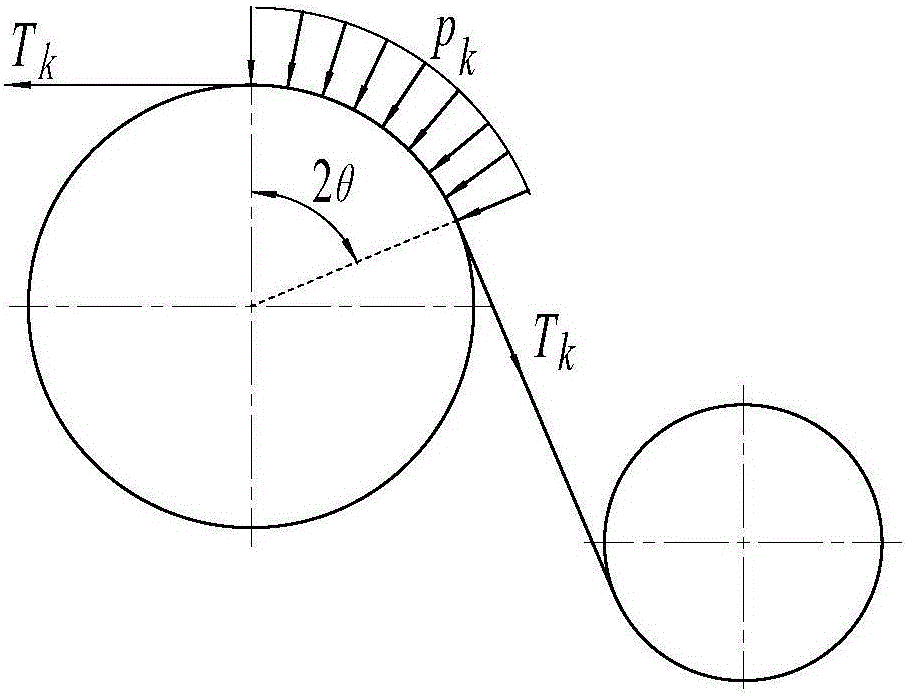

[0021] 1. Split the shape curve into three types: original shape detection curve, process error shape compensation curve and target shape curve; the original shape detection curve and process error shape compensation curve are superimposed to form an effective measured shape curve , referred to as the effective flatness curve, which can truly reflect the actual cold-rolled strip flatness state, and the target flatness curve represents the flatness control target to be achieved considering the requirements of the subsequent process; in the flatness control process, the corresponding flatness The signal error compensation model compensates and corrects the detected online original shape signal to accurately reflect the real sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com