A kind of composite material component mold surface deformation compensation method

A composite material component and mold surface technology, which is applied in the field of composite material component mold surface deformation compensation and repair, can solve the problems of long mold surface correction cycle, poor accuracy, high cost, etc., to shorten the correction cycle and consume Short time, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

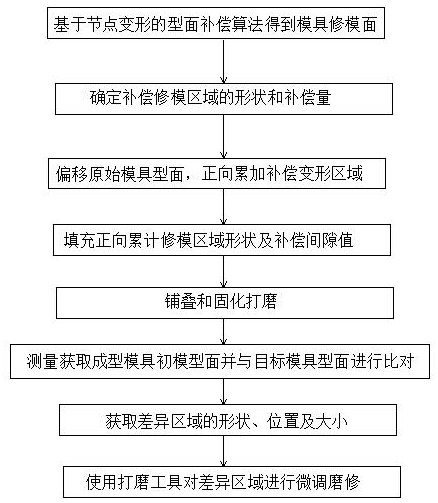

[0024] see figure 1 , a method for compensating and repairing the mold surface deformation of a composite component mold, comprising the following steps:

[0025] a. The surface compensation algorithm based on node deformation obtains the mold repair surface;

[0026] b. Determine the shape and compensation amount of the compensation mold repair area, offset the original mold surface, and positively accumulate the compensation deformation area;

[0027] c. Use glass fiber reinforced plastic materials to fill the shape of the positive cumulative mold repair area and the compensation gap value, and then lay up and solidify and polish to obtain the initial mold of the target molding mold surface;

[0028] d. Then obtain the initial model surface of the forming mold through digital measurement and compare it with the target mold surface to obtain the shape, position and size of the difference area, and use the grinding tool to fine-tune the difference area to complete the qualifi...

Embodiment 2

[0030] see figure 1 , a method for compensating and repairing the mold surface deformation of a composite component mold, comprising the following steps:

[0031] a. The surface compensation algorithm based on node deformation obtains the mold repair surface;

[0032] b. Determine the shape and compensation amount of the compensation mold repair area, offset the original mold surface, and positively accumulate the compensation deformation area;

[0033] c. Use glass fiber reinforced plastic materials to fill the shape of the positive cumulative mold repair area and the compensation gap value, and then lay up and solidify and polish to obtain the initial mold of the target molding mold surface;

[0034] d. Then obtain the initial model surface of the forming mold through digital measurement and compare it with the target mold surface to obtain the shape, position and size of the difference area, and use the grinding tool to fine-tune the difference area to complete the qualifi...

Embodiment 3

[0037] see figure 1 , a method for compensating and repairing the mold surface deformation of a composite component mold, comprising the following steps:

[0038] a. The surface compensation algorithm based on node deformation obtains the mold repair surface;

[0039] b. Determine the shape and compensation amount of the compensation mold repair area, offset the original mold surface, and positively accumulate the compensation deformation area;

[0040] c. Use glass fiber reinforced plastic materials to fill the shape of the positive cumulative mold repair area and the compensation gap value, and then lay up and solidify and polish to obtain the initial mold of the target molding mold surface;

[0041] d. Then obtain the initial model surface of the forming mold through digital measurement and compare it with the target mold surface to obtain the shape, position and size of the difference area, and use the grinding tool to fine-tune the difference area to complete the qualifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com