Forming mold for grinding glass optical element blank, manufacturing method of grinding glass optical element blank, and manufacturing method of optical element

A technology for forming molds and optical components, which is applied to the pressing of optical components, glass, and glass forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

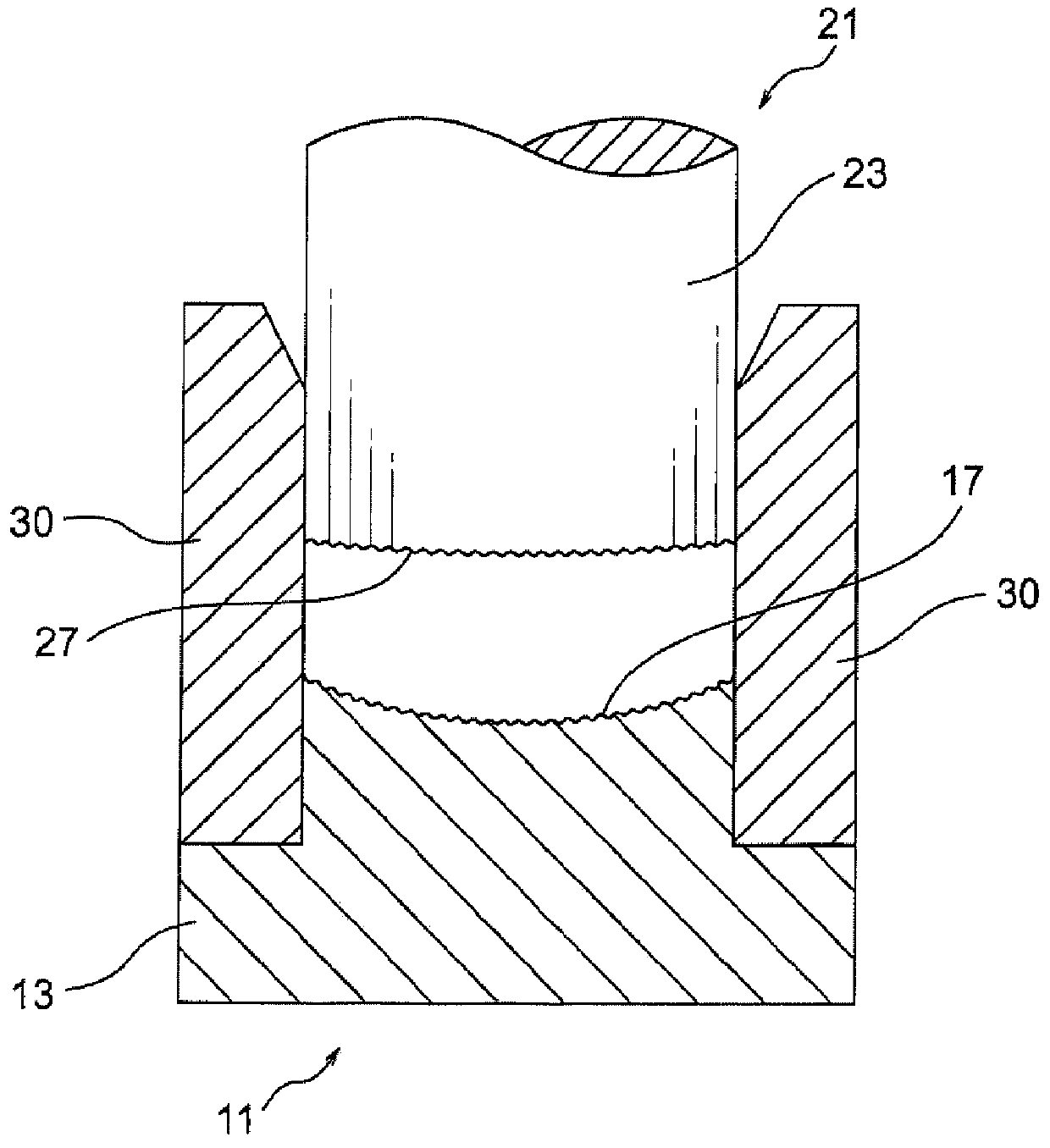

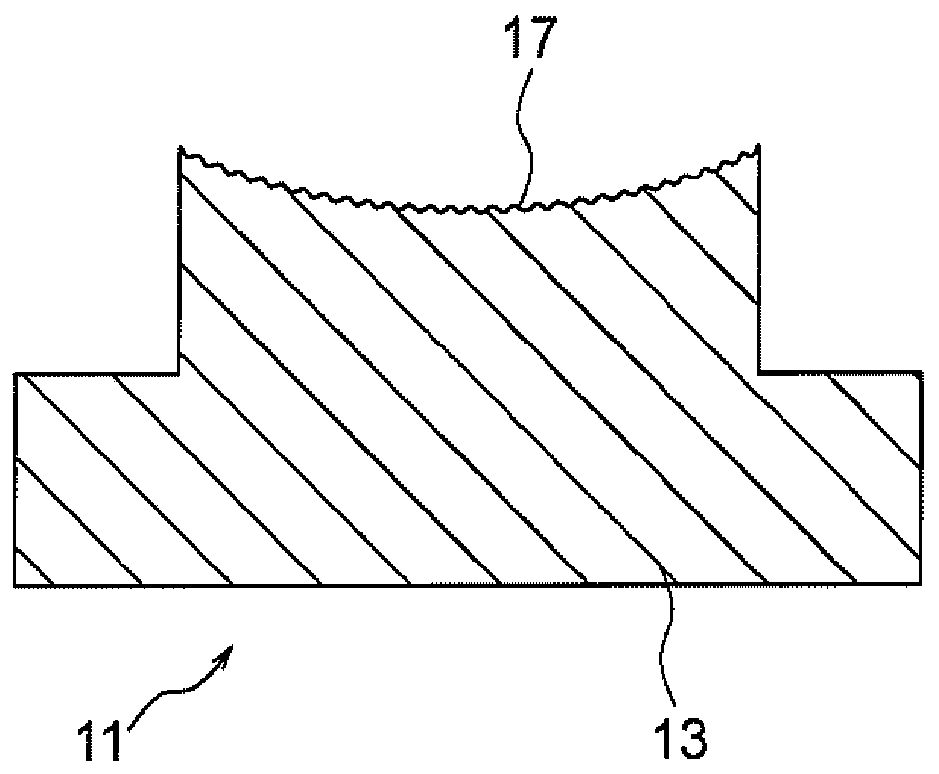

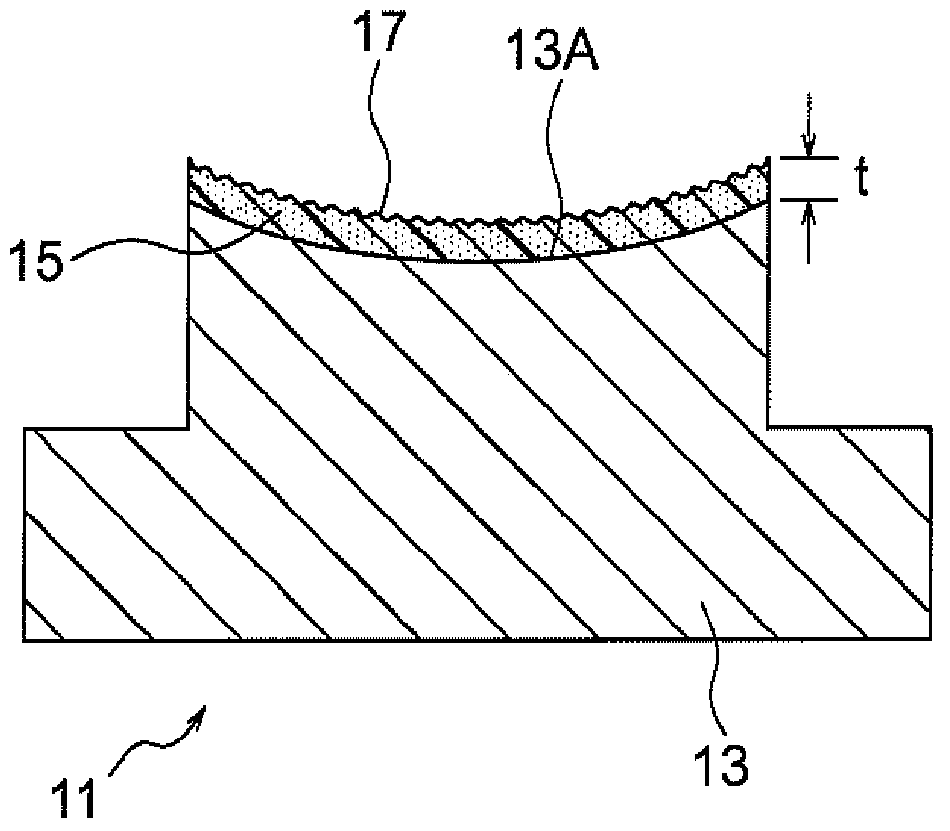

[0036] The molding die of the present invention has at least an upper mold and a lower mold, which are molding molds for manufacturing glass optical element blanks for grinding (hereinafter sometimes simply referred to as "optical element blanks"), wherein the above-mentioned upper mold and lower mold The surface roughness (Rz) of at least one molding surface exceeds 10 μm.

[0037] According to such a molding die of the present invention, when the softened glass raw material is press-molded to manufacture a glass optical element blank for grinding, the occurrence of molding defects (such as cracks / cracks or poor elongation, etc.) or the failure of the molded body can be reduced. High-quality polishing glass optical element blanks can be efficiently produced without shape deviation. Furthermore, the grinding glass optical element blank produced by the molding die of the present invention is excellent in shape accuracy, so in the grinding / grinding process as a subsequent proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com