Method for one-key calibration of electronic belt scale and belt scale applying method

A technology of electronic belt scales and belt scales, applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of complicated calibration work, electronic belt scales cannot be properly maintained, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

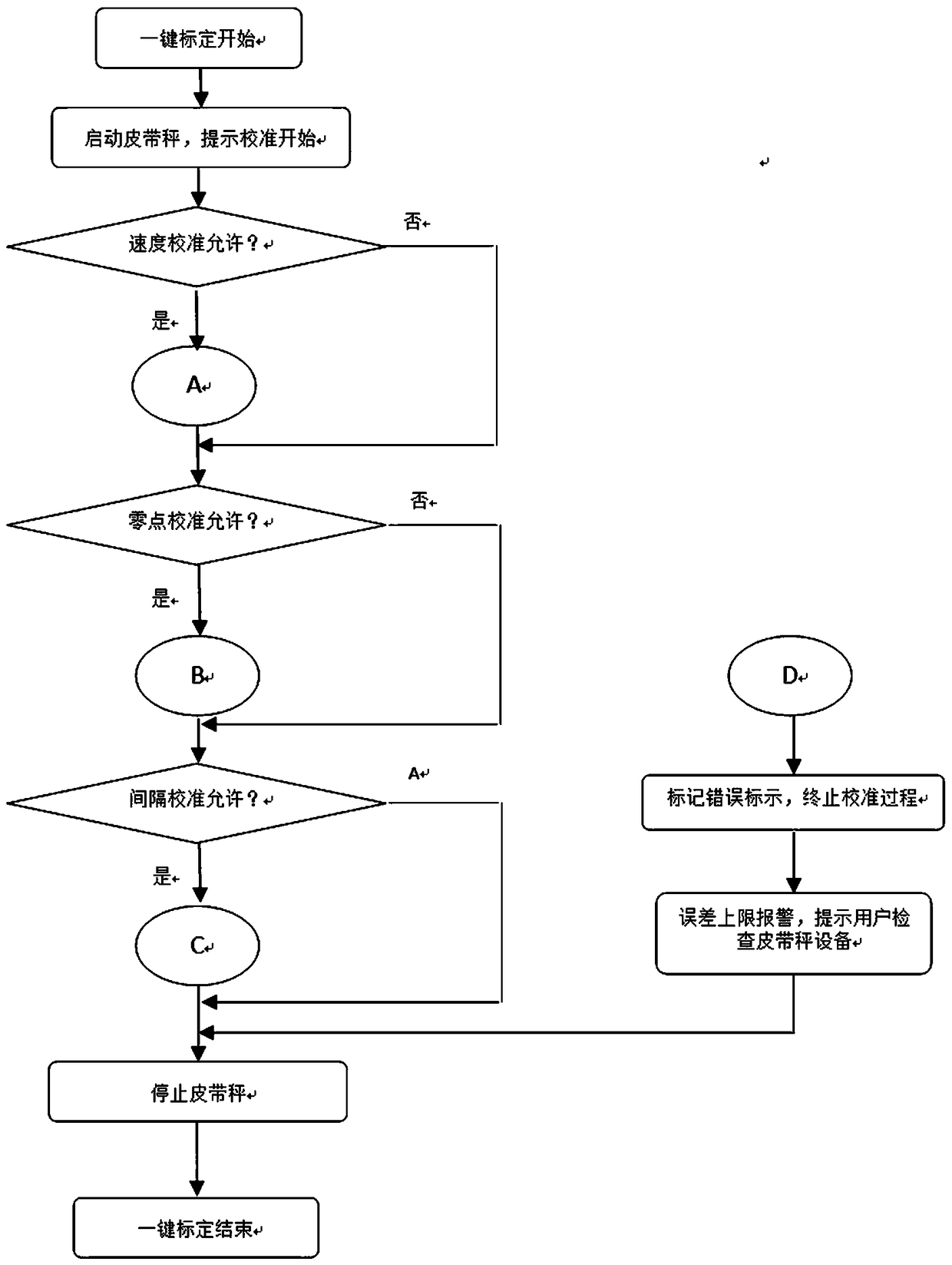

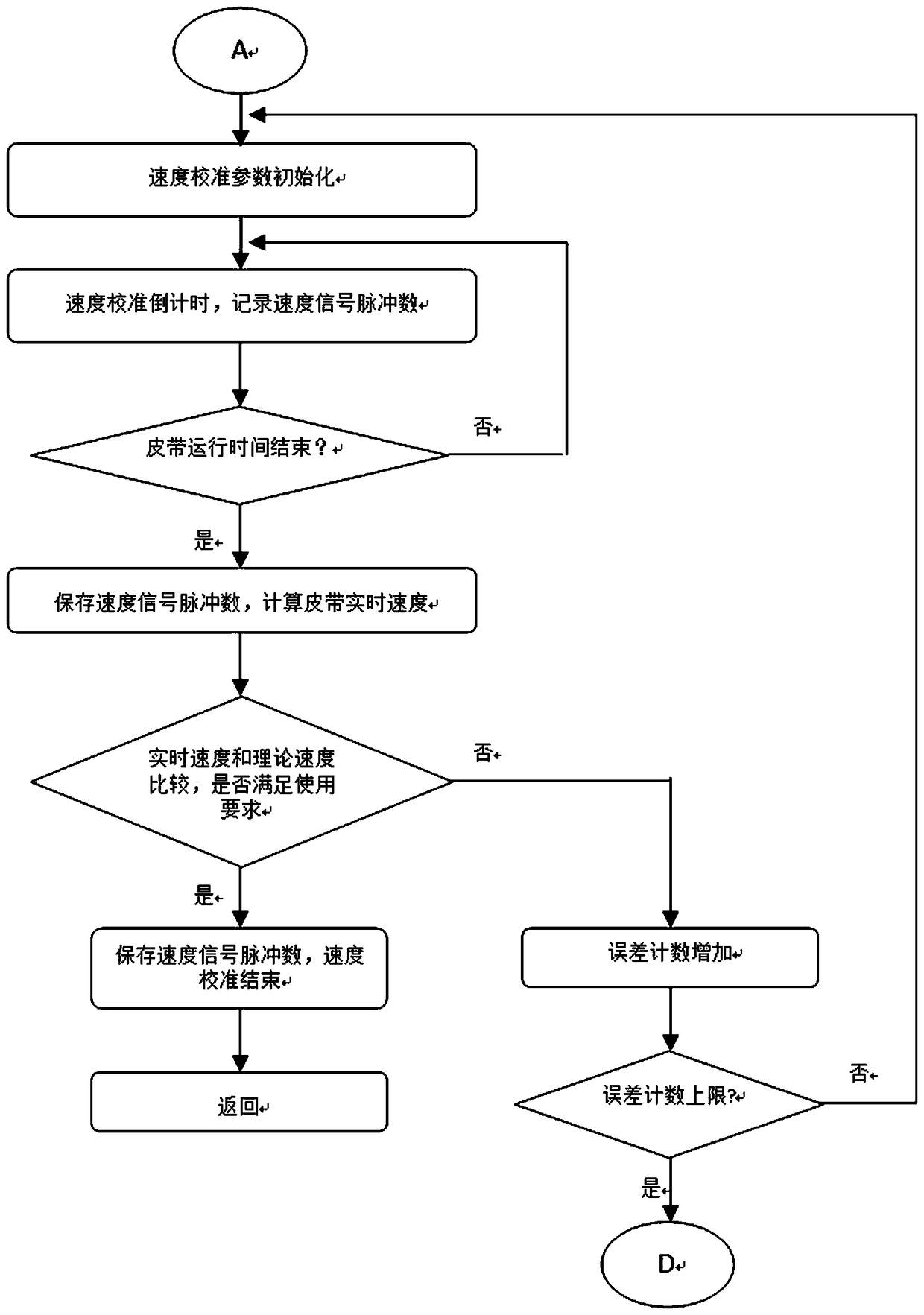

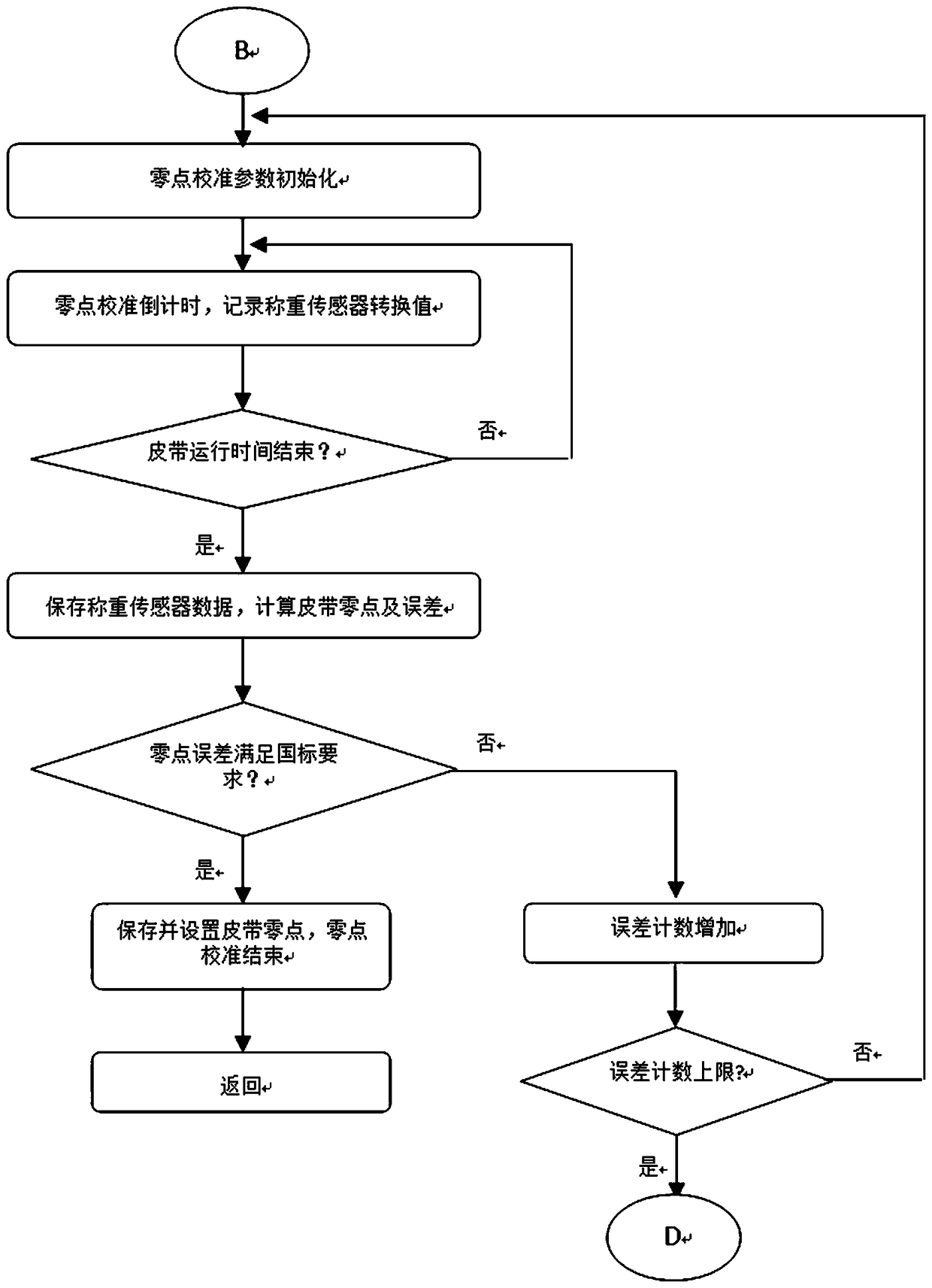

[0028] Such as Figure 1 to Figure 4 A one-key method for calibrating an electronic belt scale is shown, and the specific steps include:

[0029] 1) Start the belt scale and start the one-key calibration;

[0030] 2) Carry out speed calibration, if it meets the requirements, enter step 3, if it does not meet the verification requirements, the error count will increase by one, if the error count does not reach the upper limit, continue to step 2 speed calibration, if the error count upper limit, stop the belt scale and alarm to remind the user to check the belt scale ;

[0031] 3) Carry out zero point calibration. If the requirements are met, enter step 4. If the verification requirements are not met, the error count will increase by one. If the error count does not reach the upper limit, continue to step 3 for zero point calibration. If the error count reaches the upper limit, the belt scale will be stopped and the alarm will prompt the user to check the belt scale. ;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com