Online real-time calculation and evaluation method for electronic belt scale

An electronic belt scale and real-time calculation technology, applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of no measurement of the matching between instantaneous flow and cumulative weight, mismatch between instantaneous flow and cumulative weight, and no consideration of electronic belt scales, etc. Achieve the effects of estimating the risk of weighing errors, improving the accuracy and instantaneous accuracy of the feeding process, and enhancing monitoring efforts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An online real-time calculation and evaluation method for an electronic belt scale, comprising:

[0028] Step S1: With the material signal of the electronic belt scale as the trigger condition, collect the weight collection value and speed collection value, instantaneous flow collection value and cumulative weight collection value output by the electronic belt scale, and calculate the instantaneous flow calculation value and cumulative weight calculation value:

[0029] Instantaneous flow calculation value = weight collection value × speed collection value

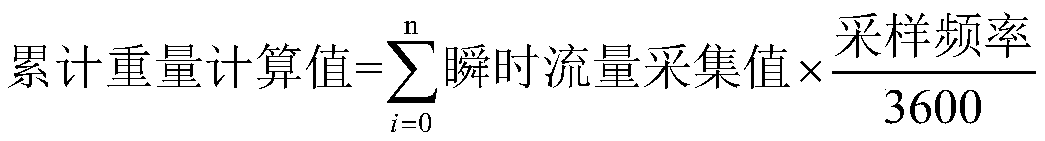

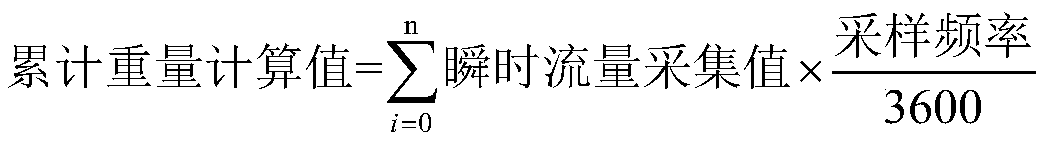

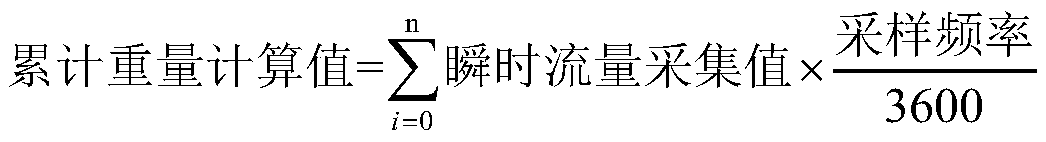

[0030]

[0031] Among them, n is the sampling frequency of each batch of materials, n=production time length / sampling frequency;

[0032] Step S2: Calculate the instantaneous flow rate of pass and the cumulative weight of pass rate during the collection process, specifically:

[0033] During the sampling process, the instantaneous flow collection values satisfying the formula (1) are counted:

[0034] Instant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com