Calibration block, electronic scale and automatic calibration method

A technology for calibrating blocks and electronic scales, which is applied in the direction of weighing equipment testing/calibration, etc., which can solve the problems that the calibration results cannot be monitored efficiently and the electronic scales cannot be automatically calibrated in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The invention discloses a calibration block, an electronic scale and an automatic calibration method of the electronic scale using them.

[0038]

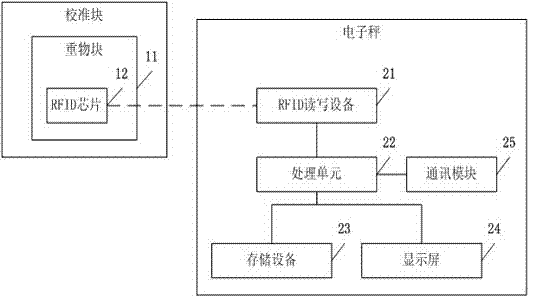

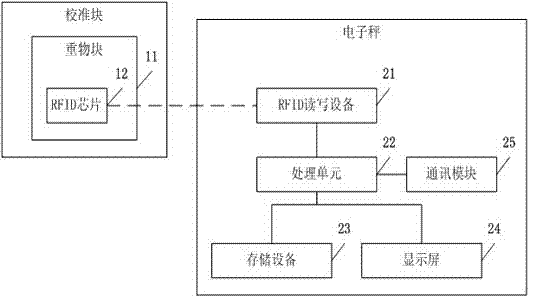

[0039] See attached figure 1 , by attached figure 1 Visible, the calibration block consists of:

[0040] The weight block 11 is a solid with stable shape, at least one plane, and its quality does not change due to ambient temperature and humidity;

[0041] The RFID chip 12 is built into the weight block 11 and records the weight of the calibration block. The weight of the calibration block is the sum of the weight of the weight block 11 and the RFID chip 12 .

[0042] An electronic scale, including a mechanical part and a circuit part, a sensor transmits the change information of the mechanical part caused by the measured object, that is, the weight information of the measured object, to the circuit part, see the attached figure 1 It can be seen that the circuit part includes:

[0043] RFID read-write device 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com