Even material supplying device and even material supplying method thereof

A feeding device and feeding technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of large flow fluctuations in feeding devices, increase costs, waste materials, etc., to ensure stability, The effect of improving control accuracy and ensuring detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

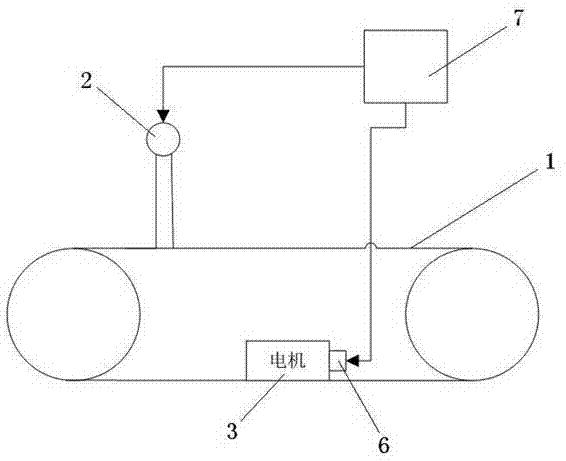

[0035] A kind of uniform feeding device is provided in this embodiment, such as figure 1As shown, it includes a material conveying mechanism, a material height detector, a conveying speed controller and a feeding controller 7 . In this embodiment, the material conveying mechanism is a material conveying belt 1, and the material conveying belt 1 is connected with a belt motor 3, and the belt motor 3 is connected with a belt motor frequency converter 6, and the belt motor frequency converter 6 is used as the material conveying belt 1. The conveying speed controller detects the speed of the material conveying belt 1 and can control it, such as increasing or reducing the speed of the motor through frequency conversion, and then accelerates or decelerates the material conveying belt 1. The material height detector is an ultrasonic height detector.

[0036] An ultrasonic height detection probe 2 is arranged on the material channel of the material conveying belt 1 for detecting the ...

Embodiment 2

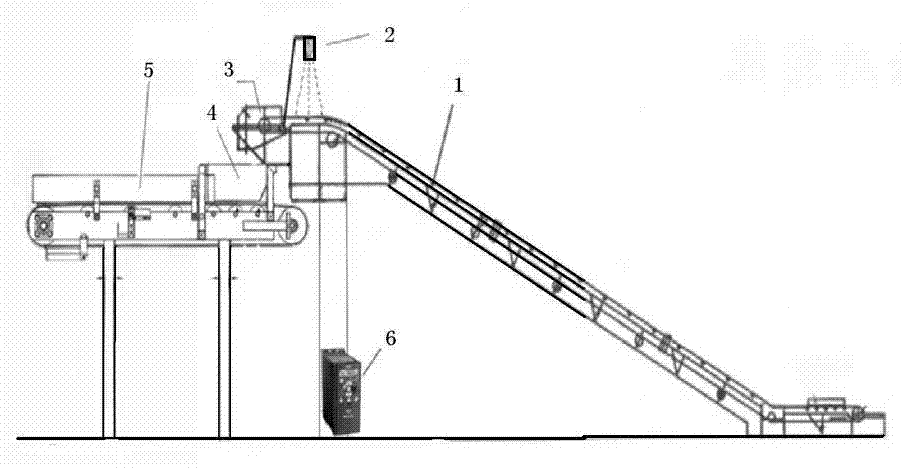

[0042] Provide a kind of uniform feeding device of electronic belt scale in this embodiment, as figure 2 as shown, figure 2 The middle material conveying belt 1 is the material conveying mechanism, and the ultrasonic material height detection probe 2 is set at the material outlet of the material conveying belt 1, specifically at a height of about 60 cm of the material outlet, and the ultrasonic height detecting probe 2 is installed on the material conveying belt 1 to run Channel mounting bracket. The material conveying belt 1 includes a material belt conveyor driven by a belt motor 3, and the signal of the belt motor frequency converter 6 is sent to the belt motor 3, and the belt motor 3 is controlled by the belt motor frequency converter 6 at an operating speed. The electronic scale 5 is arranged below the material outlet of the even feeding device, and the material outlet of the material conveying belt 1 corresponds to the electronic scale inlet 4, and the material enters...

Embodiment 3

[0049] The uniform feeding method of the uniform feeding device in the above embodiment is provided in this embodiment, comprising the following steps:

[0050] First, the material conveying mechanism is running, and the material is conveyed on the material conveying mechanism. The conveying speed controller detects the current speed of the material conveying mechanism, and sends the speed information to the material supply controller.

[0051] At the same time, the material height detector detects the current material height, for example, the current material height can be obtained by detecting the material height at the discharge end of the material channel, and sends the height information to the material supply controller.

[0052] Then, the feed controller receives signals from the conveying speed controller and the material height detector, and obtains the adjusted speed of the material conveying mechanism through calculation according to the current material height and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com