Tool for replacing JB type parallel groove clamp on live line

A technology of live replacement and wire clips, which is applied in the direction of cable suspension devices, overhead lines/cable equipment, etc., can solve the problems of small clearance distance, insufficient safety distance, and large safety risk of the drainage line of the tension tower, so as to improve maintenance efficiency and operator safety, high economic benefits, and simplified work procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A tool for replacing JB-type parallel groove clamps with electricity, including an insulating operating rod, a parallel groove clamp body disassembly device 1, a parallel groove clamp pressure plate disassembly device, and a bolt disassembly device.

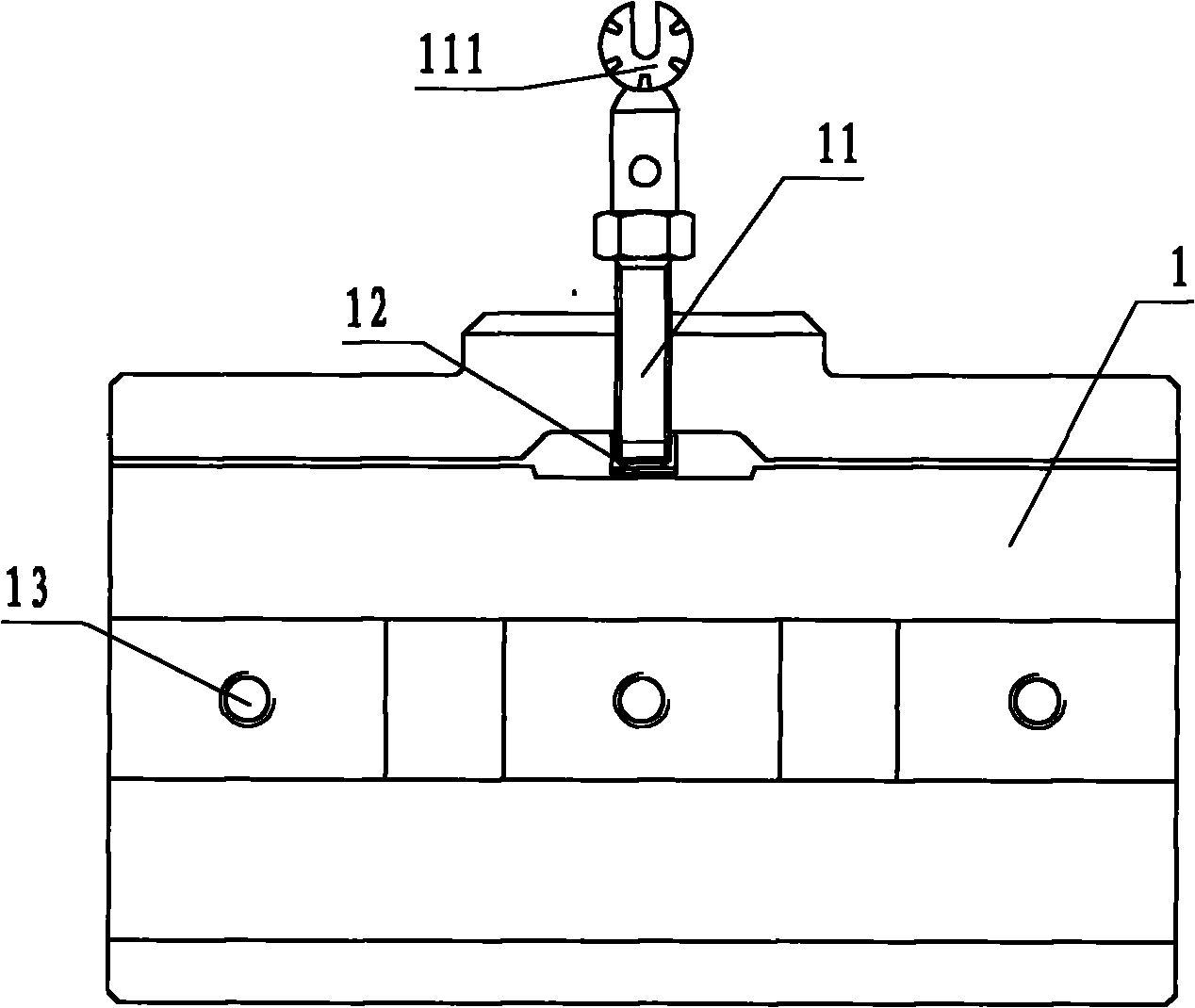

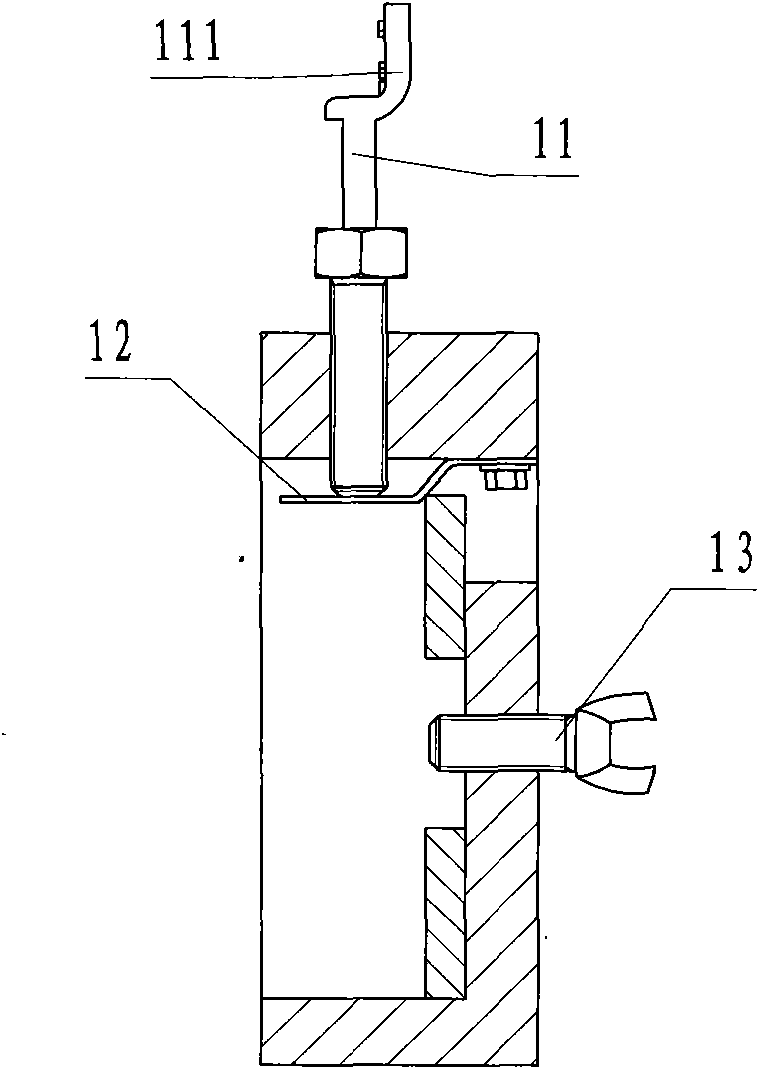

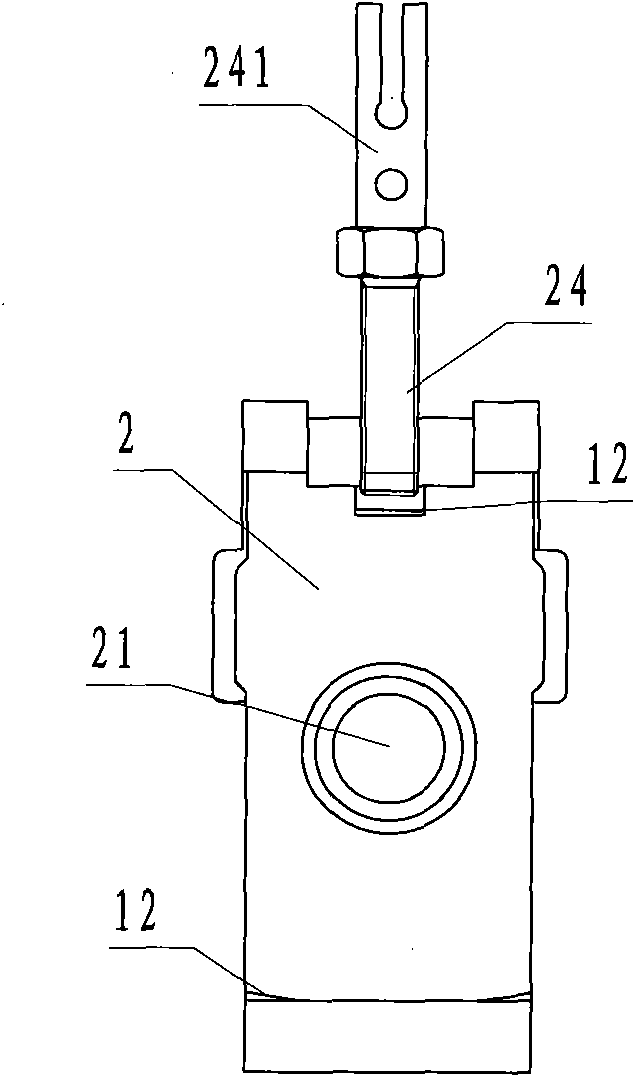

[0039] The dismounting device 1 of the parallel groove clamp body is as follows: figure 1 , 2 As shown, it includes a trough-shaped body whose size matches the main body of the grooved line clamp. A set screw 11 is arranged on one side of the trough-shaped body. The connecting device 111 matched with the connecting device is provided with an elastic compression piece 12 at the screw-in end of the set screw on the side of the trough body, and one or more than one set screw 13 is distributed on the bottom surface of the trough body. The position of the set screw on the bottom surface matches the position of the lock bolt on the body of the parallel groove clamp, and the set screw on the bottom of the groove body is a butter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com