Spraying maintenance system for prefabricated segmental box girder

A technology for maintenance systems and box girders, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of difficulty, easy leakage of water resources, waste, etc., and achieve the effects of reducing waste, ensuring maintenance quality, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

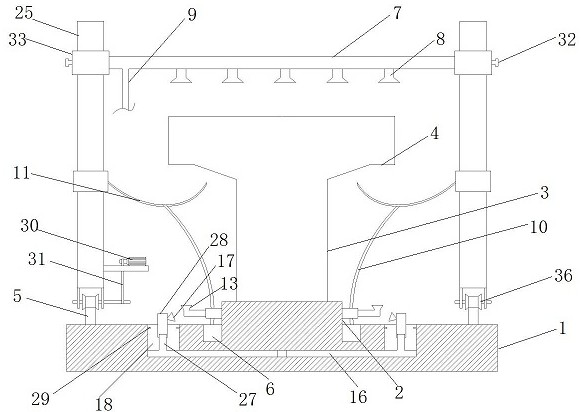

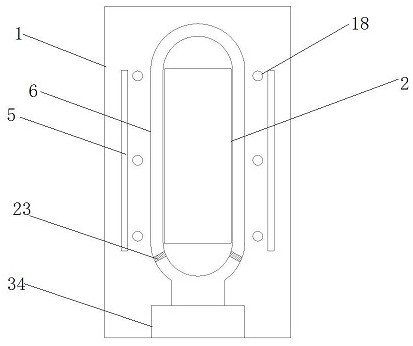

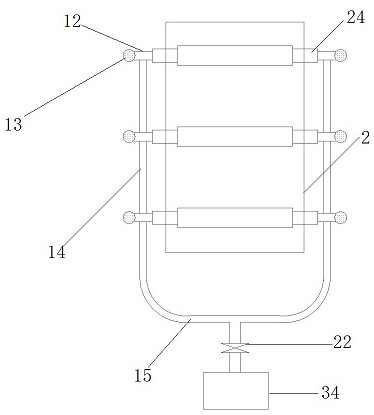

[0036] Such as Figures 1 to 6 As shown, the prefabricated segmental box girder spraying maintenance system includes a support base, a mobile frame, a horizontal section of the box girder, a spraying frame on the side wall of the box girder, and a water supply component.

[0037] Specifically, such as figure 1 with figure 2 As shown, the supporting platform includes a supporting platform 2 for supporting a prefabricated segmental box girder 3 on which a supporting base body 1 is arranged. The length direction of the support base 1 is defined as the front-to-back direction, and the width direction is the left-right direction. The support base 1 is provided with a water tank 6 surrounding the support platform 2 at a position connected to the support platform 2 . The water tank 6 has the same shape as the playground when viewed from above, including a rectangular area and a semicircular area located at two ends of the rectangular area. Such as Figure 5 As shown, in the sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com