Ultrasonic wave syringe needle for dental department and medical treatment and manufacture method thereof

A manufacturing method and ultrasonic technology, which are applied in cleaning methods using liquids, chemical instruments and methods, dentistry, etc., can solve the problems of low durability and service life, low medical safety, slow processing speed, etc., and improve durability. and reliability, beneficial to mass production, and the effect of improving machining precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, suitable embodiments of the present invention will be described in detail with reference to the accompanying drawings, but the present invention is not restricted or defined by the described embodiments. In describing the embodiments of the present invention, in order to clarify the key points of the present invention, specific descriptions of known functions or structures will be omitted.

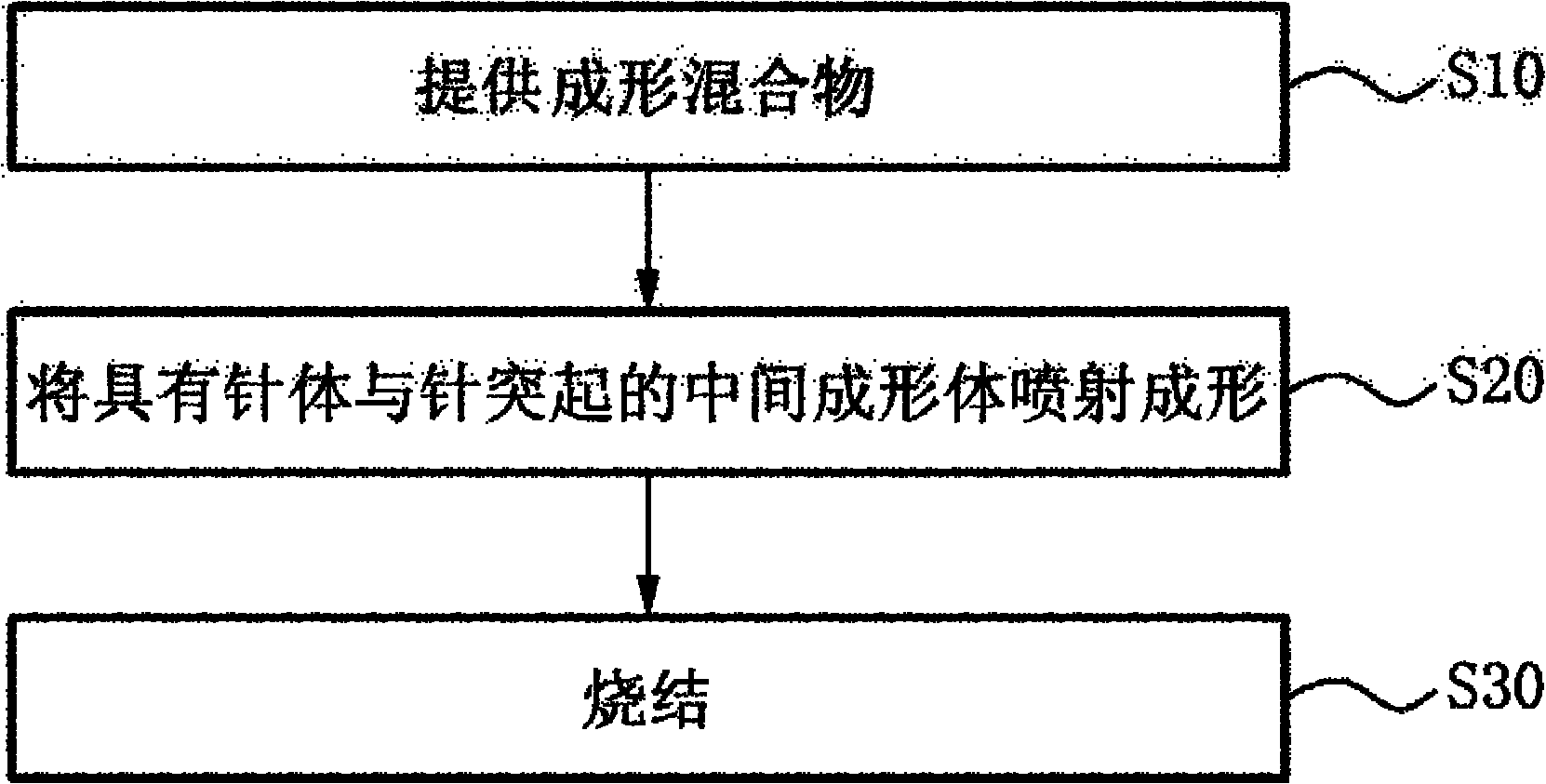

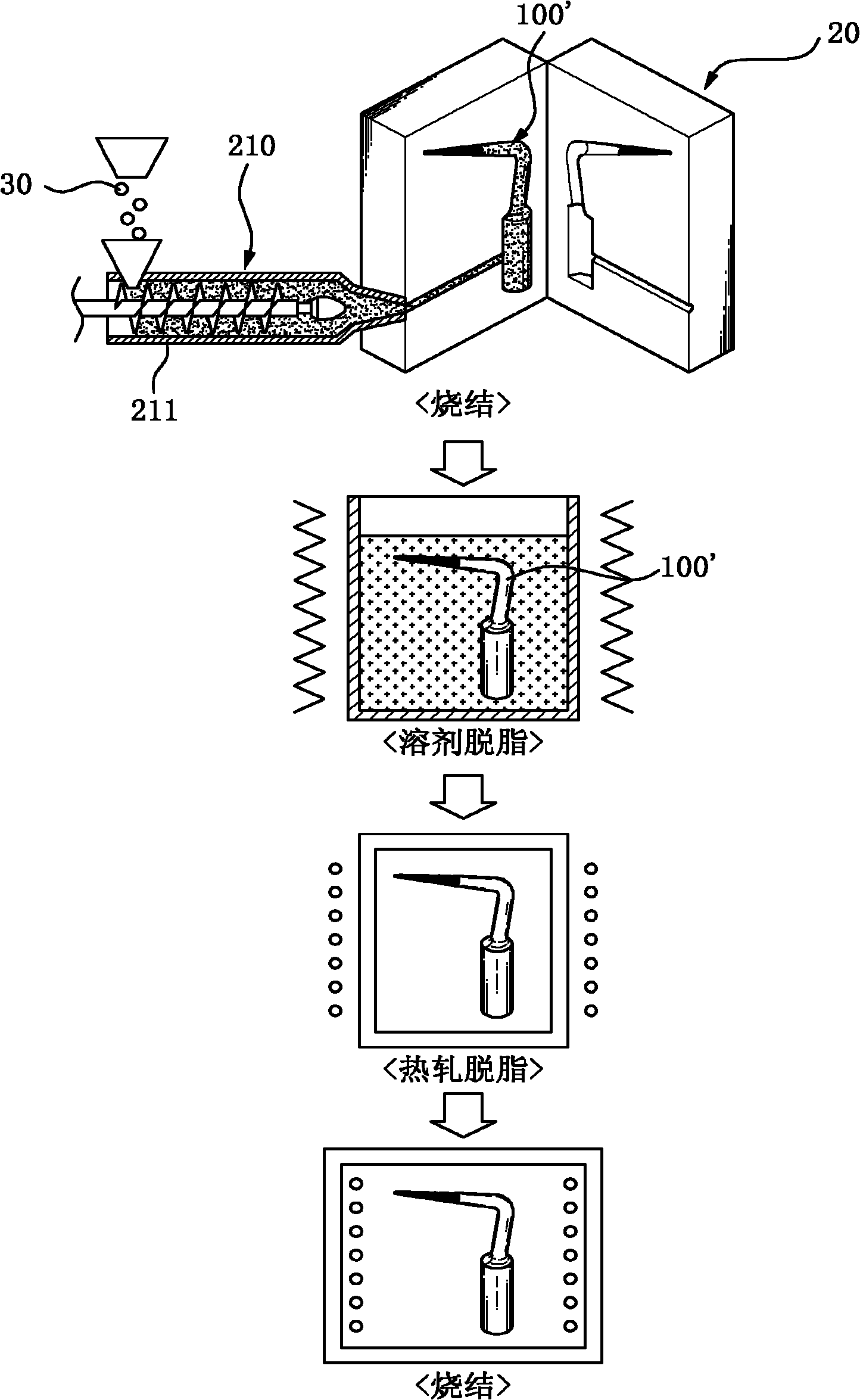

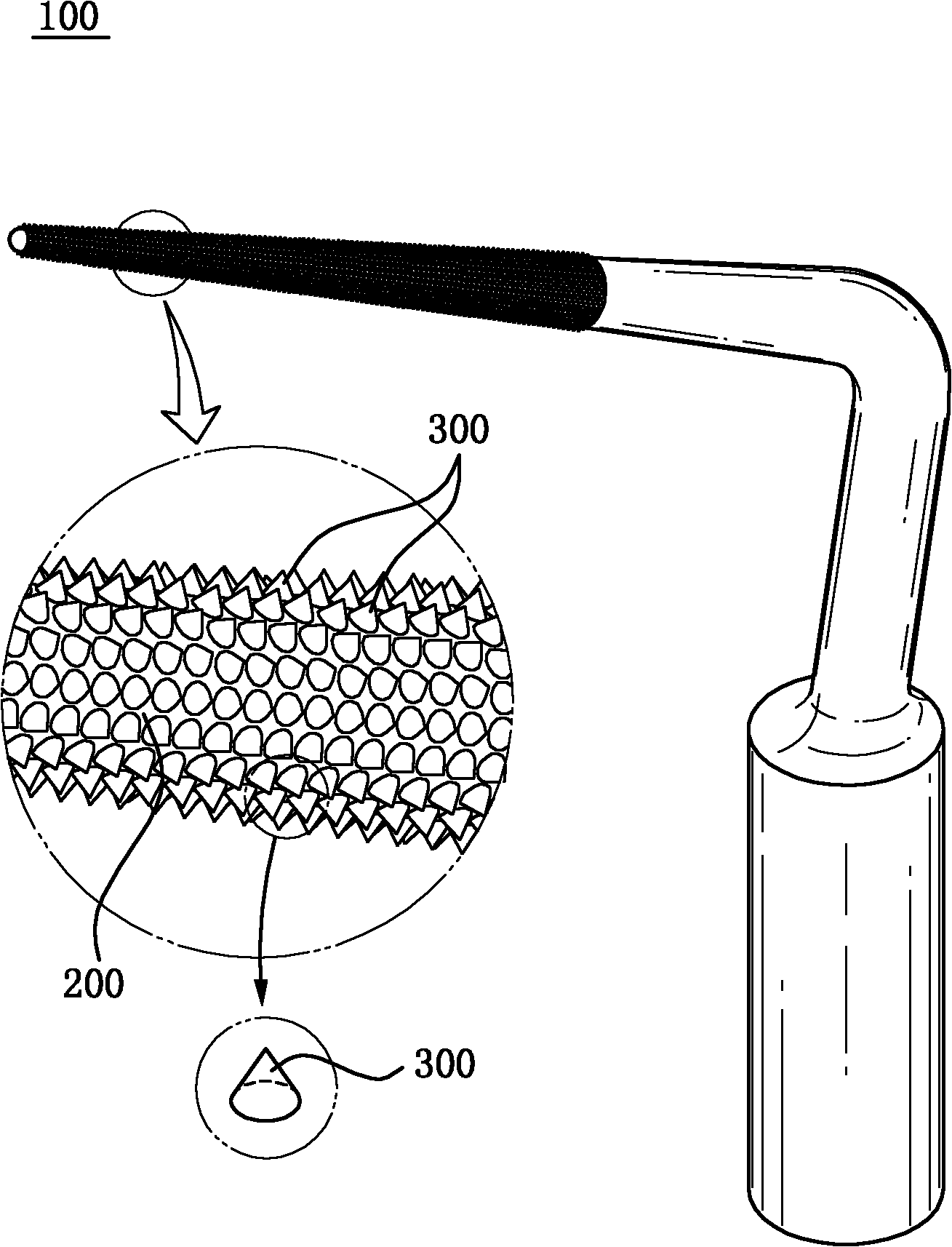

[0038] figure 1 and figure 2 is a block diagram and an engineering diagram for illustrating a manufacturing method of an ultrasonic needle for dental and medical use according to the present invention. also, image 3 is a perspective view showing the construction of an ultrasonic needle for dental and medical use according to the present invention, Figure 4 is a side view showing the construction of an ultrasonic needle for dental and medical use according to the present invention, 5 is Figure 4 I-I line profile.

[0039] As shown in these drawings, the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com