Electric machine fixation structure of linear compressor

A technology of linear compressors and linear motors, applied in electromechanical devices, machines/engines, magnetic circuit shapes/styles/structures, etc., can solve problems such as increasing assembly force limitations, complicated manufacturing processes, and reducing operational reliability, etc., to achieve improved Productivity, simplification of manufacturing process, and improvement of operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, the content of the embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

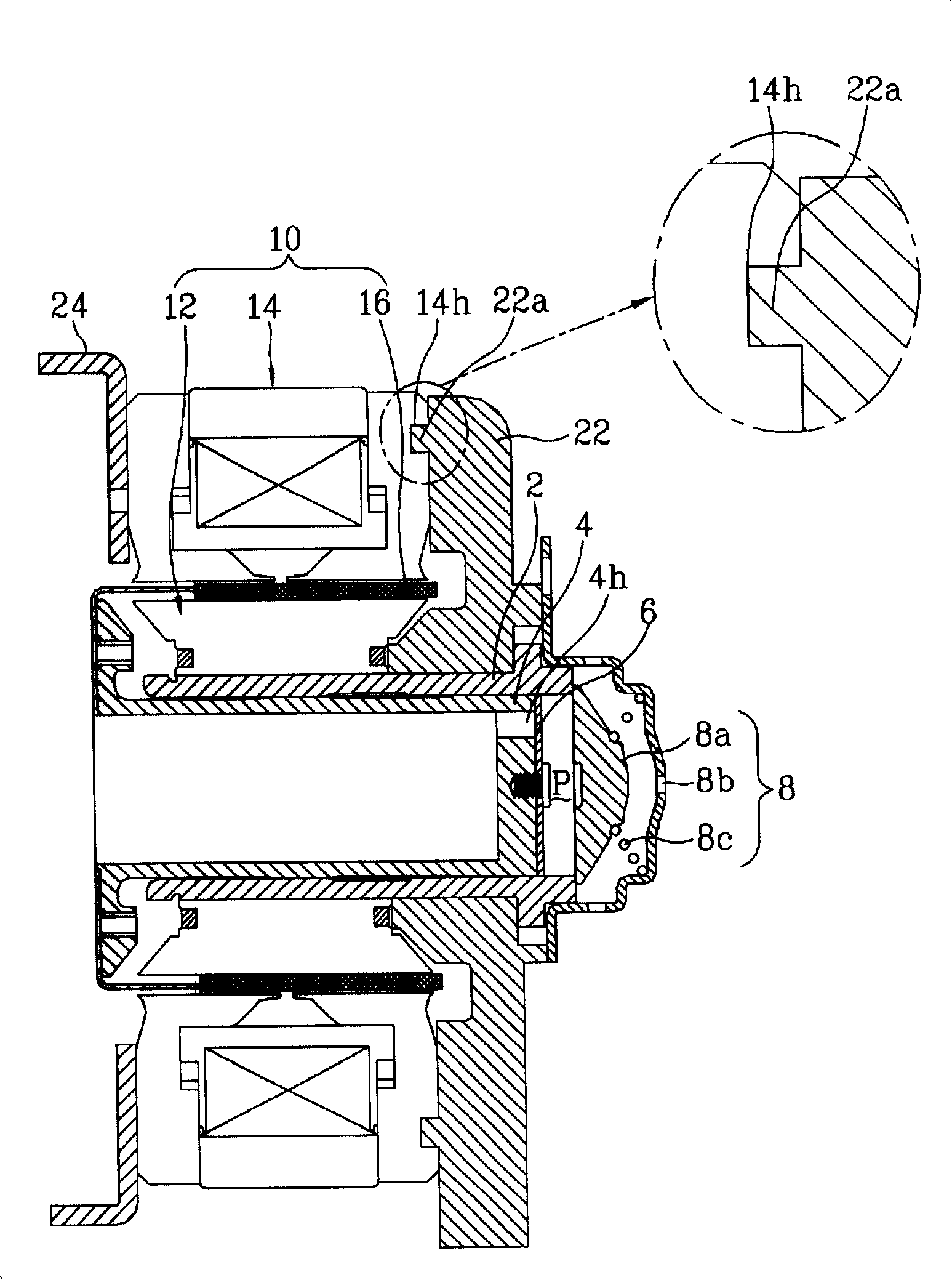

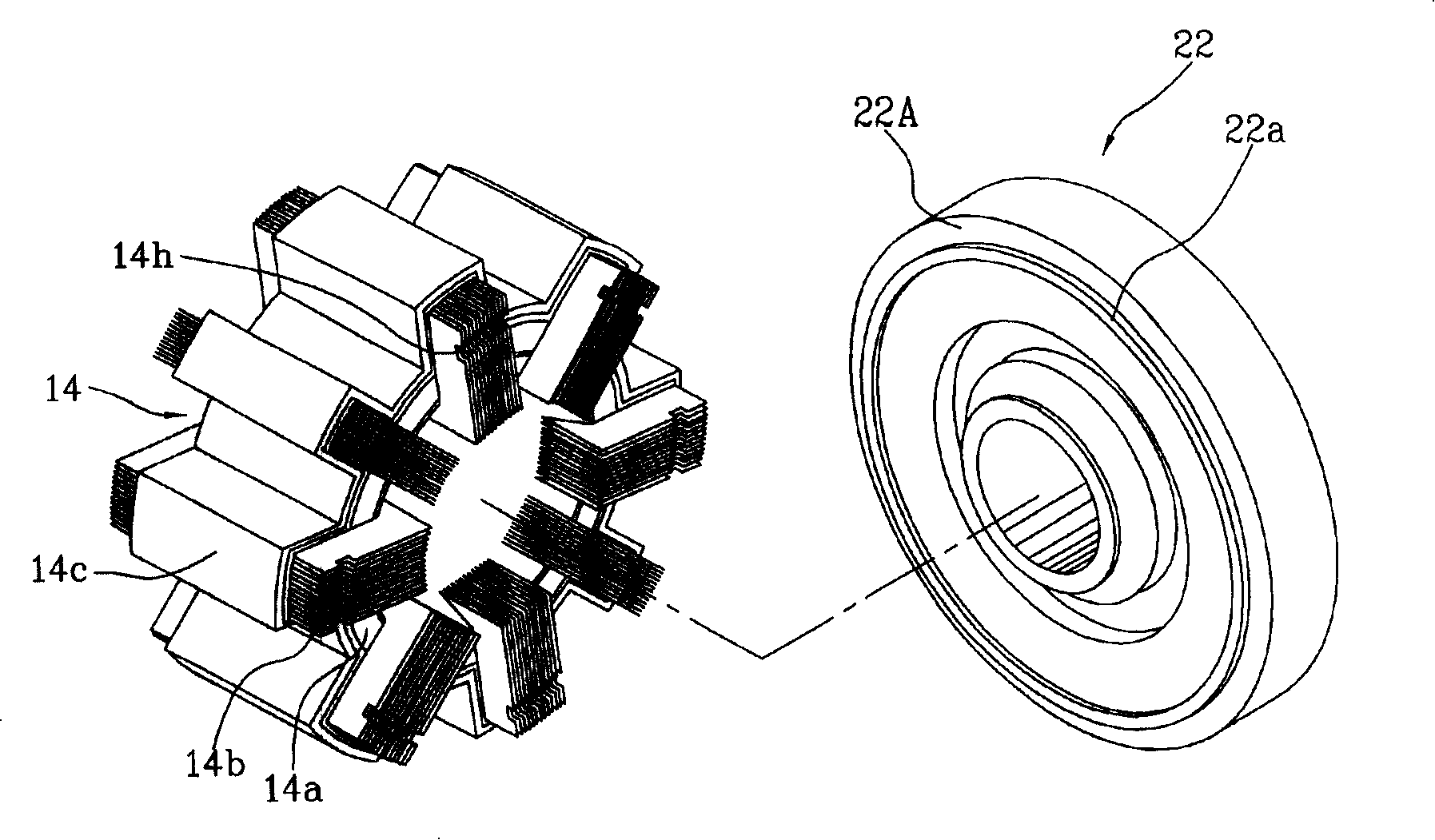

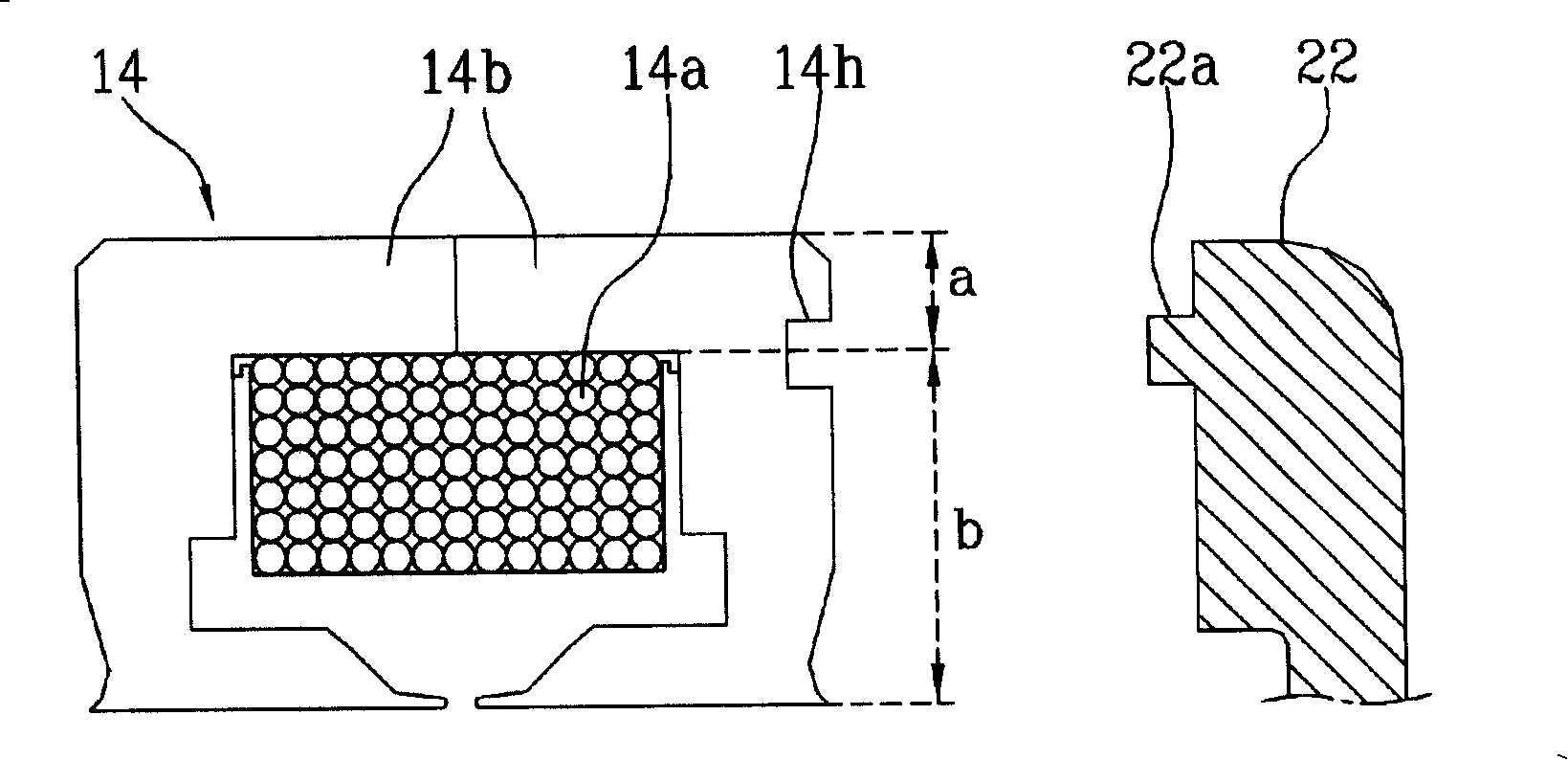

[0031] Figure 4 is a side sectional view of the linear compressor provided by the present invention, Figure 5 as well as Image 6 It is a partial exploded perspective view and an exploded cross-sectional view of the linear motor fixing structure of the linear compressor provided by the present invention.

[0032] The linear compressor provided by the present invention is as Figure 4 As shown, the linear motor 60 structure composed of cylinder 52, piston 54, inner stator 62, outer stator 64 and permanent magnet 66 is supported by a buffer spring (not shown) inside the sealed space of the housing (not shown). , while one end of the cylinder 52 is fixed on the main body frame 72, one end of the piston 54 is inserted into its inner side, thereby forming an internal compression space P, and the inner stator is fixed on the outer pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com