Reflection-permeation array substrate

An array substrate and array technology, applied in the field of anti-transmission array substrates, can solve problems such as difficulty in setting, achieve the effect of improving quality and simplifying manufacturing engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

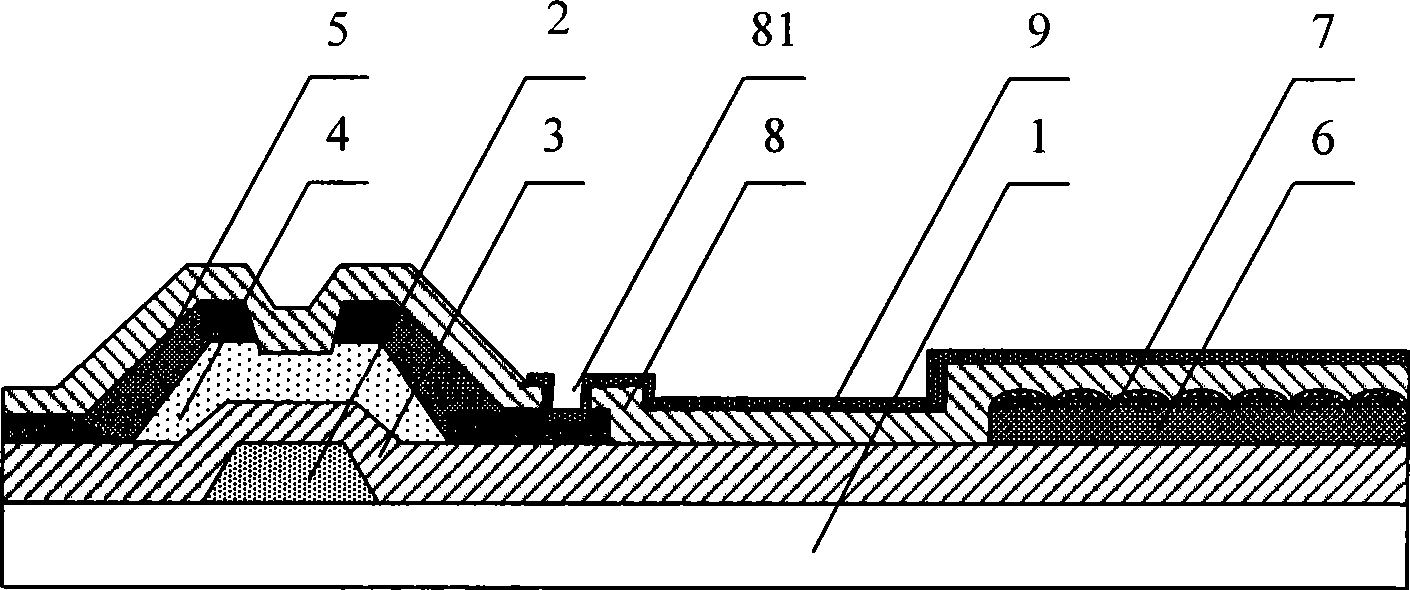

[0028] figure 2 It is a structural schematic diagram of the first embodiment of the present invention. like figure 2 As shown, the anti-transmissive array substrate includes: a glass substrate 1 and an array body, wherein the glass substrate 1 is provided with a transmissive area and a reflective area, and embossing is formed on the first surface of the glass substrate 1 corresponding to the reflective area, and the embossing is The second surface of the glass substrate 1 is recessed, and a reflective plate 7 with uniform thickness is arranged on the embossing of the first surface of the glass substrate 1. The shape of the reflective plate 7 is the same as the embossed shape; An array main body is arranged on the second face of the opposite glass substrate 1, wherein the array main body includes a gate line (not shown in the figure), a gate electrode 2, a gate insulating layer 3, an active layer 4, a source-drain electrode 5, a data line (not shown in the figure), passivat...

no. 2 example

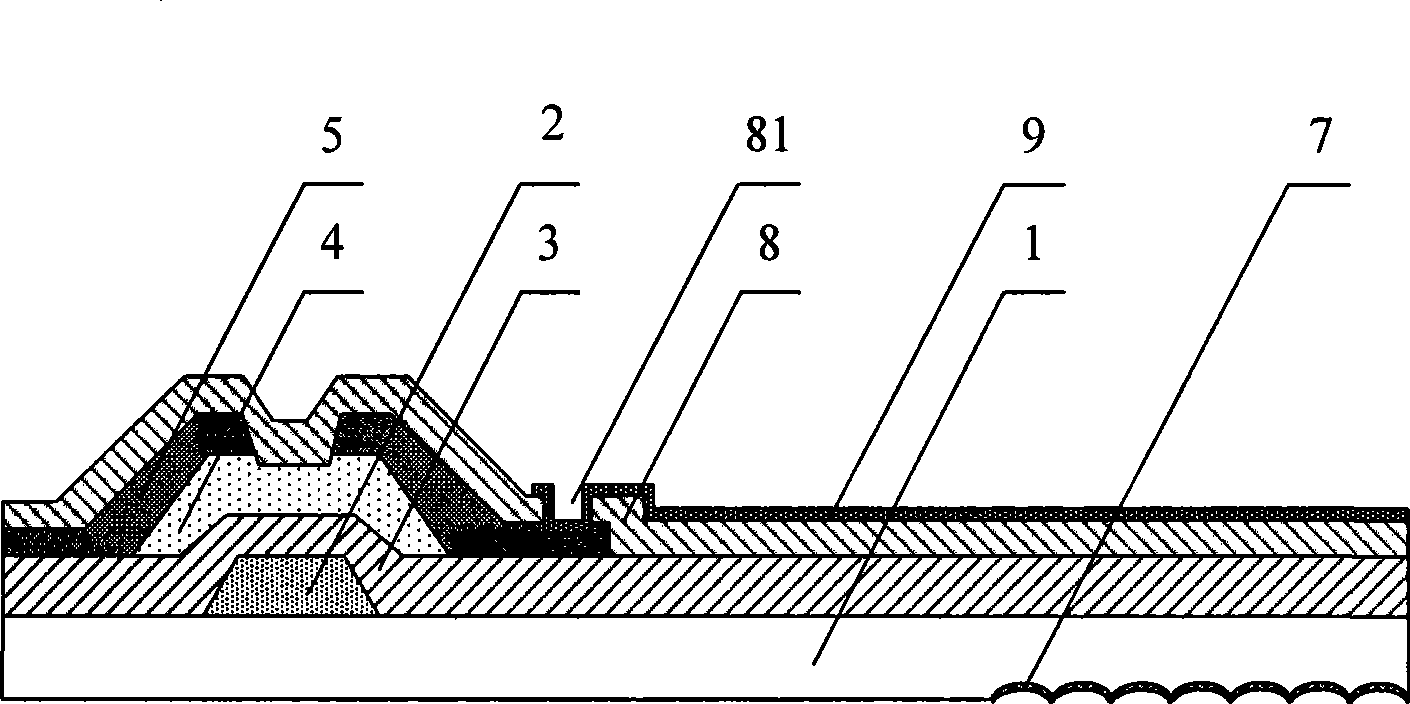

[0035] image 3 It is a structural schematic diagram of the second embodiment of the present invention. like image 3 As shown, the anti-transmissive array substrate includes: a glass substrate 1 and an array body, wherein the glass substrate 1 is provided with a transmissive area and a reflective area, and embossing is formed on the first surface of the glass substrate 1 corresponding to the reflective area, and the embossing is The structure is recessed to the second surface of the glass substrate 1, and a reflective plate 7 with uniform thickness is provided on the embossing of the first surface of the glass substrate 1. The shape of the reflective plate 7 is the same as that of the embossed shape, and a protective plate film 11, and the protective film 11 evenly covers the first surface of the glass substrate 1; the second surface of the glass substrate 1 opposite to the first surface of the glass substrate 1 is provided with an array body, wherein the array body includes...

no. 3 example

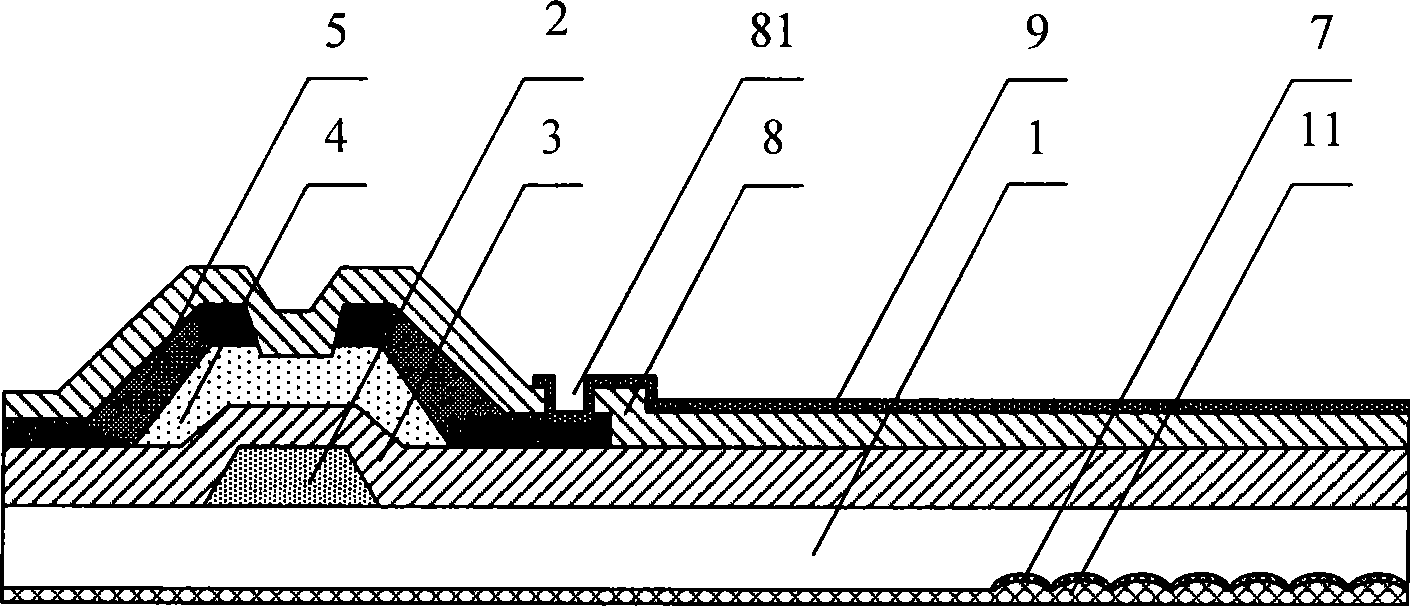

[0039] Figure 4 It is a structural schematic diagram of the third embodiment of the present invention. like Figure 4 As shown, the anti-transmissive array substrate includes: a glass substrate 1 and an array body, wherein the glass substrate 1 is provided with a transmissive area and a reflective area, and embossing is formed on the first surface of the glass substrate 1 corresponding to the reflective area, and the embossing is The second surface of the glass substrate 1 is recessed, and a reflective plate 7 with uniform thickness is arranged on the embossing of the first surface of the glass substrate 1. The shape of the reflective plate 7 is the same as the embossed shape; An array main body is arranged on the second face of the opposite glass substrate 1, wherein the array main body includes a gate line (not shown in the figure), a gate electrode 2, a gate insulating layer 3, an active layer 4, a source-drain electrode 5, a data line (not shown in the figure), passivat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com